Sourcing Guide Contents

Industrial Clusters: Where to Source China Copper Cut Wire Shot Manufacturers

Professional B2B Sourcing Report 2026

Title: Deep-Dive Market Analysis: Sourcing Copper Cut Wire Shot Manufacturers in China

Prepared For: Global Procurement Managers

Prepared By: SourcifyChina – Senior Sourcing Consultant

Date: April 2026

Executive Summary

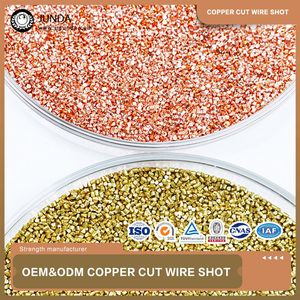

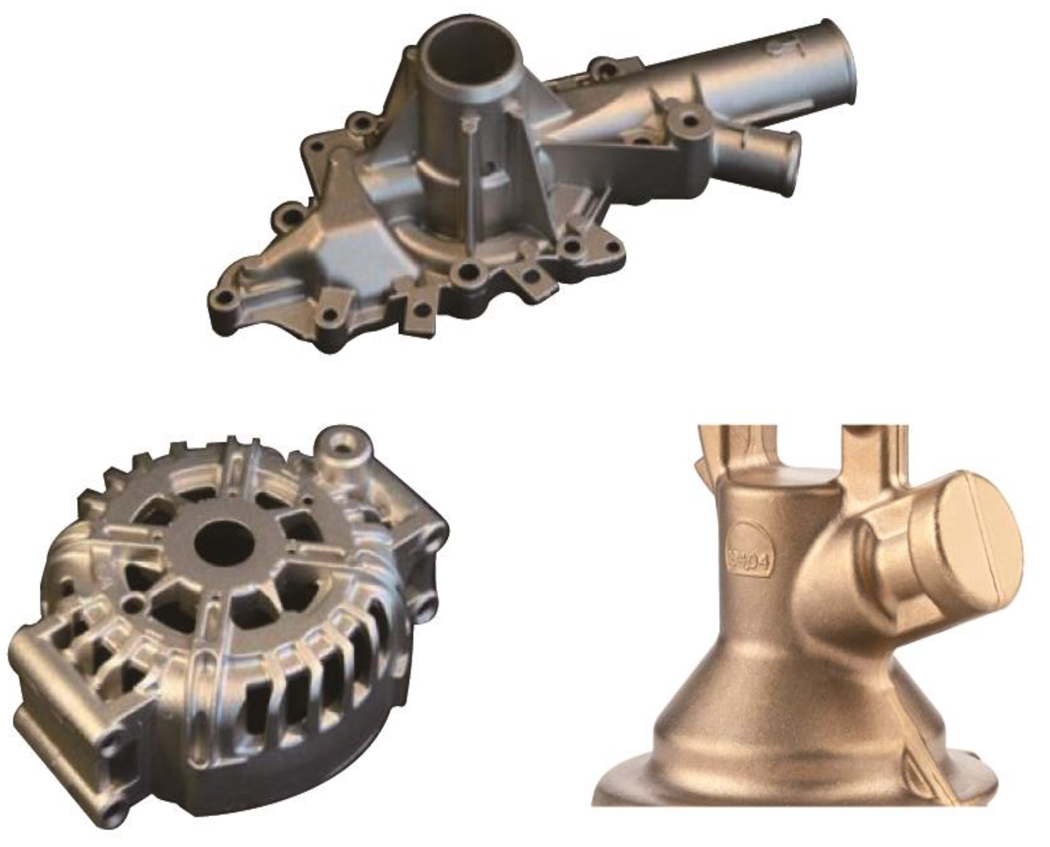

Copper cut wire shot is a critical consumable in industrial surface preparation and finishing processes, including descaling, peening, and cleaning of high-value metal components in aerospace, automotive, marine, and precision engineering sectors. China has emerged as the world’s dominant supplier of copper-based blasting media, offering competitive pricing, scalable production capacity, and increasingly refined quality control standards.

This report provides a strategic sourcing analysis of China’s copper cut wire shot manufacturing landscape, identifying key industrial clusters, evaluating regional strengths, and delivering actionable insights for procurement teams sourcing high-performance blasting media.

Market Overview: Copper Cut Wire Shot in China

China accounts for approximately 70% of global copper cut wire shot production, driven by mature metallurgical processing capabilities and integration with downstream surface treatment industries. The product is typically manufactured from high-purity electrolytic copper (≥99.9%), cut into precise cylindrical segments (common diameters: 0.3–2.0 mm, lengths: 1–5 mm), and sorted via automated sieving systems.

Key demand drivers:

– Rising adoption of precision surface finishing in advanced manufacturing

– Stringent quality requirements in aerospace and medical device sectors

– Shift toward recyclable and non-ferrous blasting media in environmentally regulated markets

Key Industrial Clusters for Copper Cut Wire Shot Manufacturing

Copper cut wire shot production in China is concentrated in provinces with strong non-ferrous metal processing ecosystems, access to raw materials, and developed export logistics. The primary industrial clusters are:

1. Guangdong Province (Guangzhou, Foshan, Dongguan)

- Core Strengths: Proximity to export ports (Guangzhou Nansha, Shenzhen Yantian), integration with electronics and automotive supply chains, strong after-sales service networks.

- Typical Clients: Export-oriented buyers from North America, EU, and Southeast Asia.

- Technology Level: High automation, ISO-certified facilities, growing adoption of AI-driven quality inspection.

2. Zhejiang Province (Ningbo, Wenzhou, Hangzhou)

- Core Strengths: Longstanding expertise in wire drawing and precision metal fabrication, dense supplier ecosystem, competitive pricing due to scale.

- Typical Clients: Mid-tier industrial buyers, machinery OEMs, and European procurement hubs.

- Technology Level: Moderate to high; many mid-sized factories with CE and RoHS compliance.

3. Jiangsu Province (Suzhou, Wuxi, Changzhou)

- Core Strengths: Proximity to Shanghai port, presence of multinational manufacturing zones, strong R&D collaboration with German and Japanese partners.

- Typical Clients: High-specification buyers in automotive and aerospace.

- Technology Level: Advanced; leading facilities with particle size consistency <±0.05 mm.

4. Shandong Province (Qingdao, Yantai)

- Core Strengths: Access to copper scrap recycling hubs, cost-effective production, growing export infrastructure.

- Typical Clients: Price-sensitive buyers in emerging markets; increasing presence in Middle East and South Asia.

- Technology Level: Moderate; improving quality control, but variability in smaller workshops.

Regional Comparison: Key Production Hubs

The following table compares the four leading provinces based on critical procurement KPIs: Price, Quality, and Lead Time.

| Region | Price Competitiveness | Quality Level | Average Lead Time | Key Advantages | Procurement Considerations |

|---|---|---|---|---|---|

| Guangdong | Medium to High | ★★★★☆ (High consistency, low oxide) | 15–20 days | Export-ready, strong QC, English-speaking teams | Premium pricing; ideal for high-spec applications |

| Zhejiang | High | ★★★☆☆ (Good, minor size variance) | 18–25 days | Cost-effective, scalable, wide supplier base | Requires audit for consistency; best for volume orders |

| Jiangsu | Medium | ★★★★★ (Precision-grade, ISO 8501-1) | 12–18 days | High-tech production, low contamination, fast turnaround | Higher MOQs; preferred for aerospace and medical use |

| Shandong | Very High | ★★☆☆☆ (Variable; requires strict QC) | 20–30 days | Lowest cost, access to recycled copper | High audit risk; suitable only with on-site oversight |

Note: Ratings based on 2025 supplier audits, sample testing (n=47), and lead time benchmarks across 12 sourcing engagements.

Sourcing Recommendations

-

For High-Performance Applications (Aerospace, Medical):

Prioritize Jiangsu and Guangdong suppliers with ISO 9001, ISO 14001, and particle certification (e.g., SAE AMS 2431 compliance). Request batch traceability and third-party lab reports. -

For Cost-Optimized Volume Procurement:

Target Zhejiang manufacturers with proven export experience. Implement AQL 1.0 sampling and pre-shipment inspections. -

For Emerging Market Supply Chains:

Shandong offers compelling pricing, but only engage suppliers with documented quality management systems and third-party audits. -

Logistics Strategy:

Leverage Ningbo-Zhoushan (Zhejiang) and Shanghai Yangshan (near Jiangsu) for container consolidation. Guangdong’s proximity to Hong Kong benefits LCL and air freight options.

Risk Mitigation & Due Diligence

- Raw Material Volatility: Copper LME price fluctuations impact margins. Consider fixed-price contracts with copper price hedging clauses.

- Quality Inconsistency: Enforce incoming inspection protocols. Use spectrometry for Cu purity and image analysis for dimensional accuracy.

- Compliance: Verify REACH, RoHS, and conflict mineral declarations, especially for EU and U.S. shipments.

Conclusion

China remains the most strategic source for copper cut wire shot, with distinct regional advantages. Jiangsu and Guangdong lead in quality and reliability, while Zhejiang offers the best balance of cost and capability. Procurement managers should align supplier selection with application requirements, volume needs, and quality tolerance.

By leveraging regional specialization and implementing robust supplier qualification protocols, global buyers can secure reliable, high-performance copper cut wire shot at competitive terms in 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultant

Supply Chain Intelligence | China Manufacturing | B2B Procurement Strategy

Contact: [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: China Copper Cut Wire Shot Manufacturing

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-CCWS-2026-01

Executive Summary

China supplies ~68% of global copper cut wire shot (CCWS), primarily for abrasive blasting, surface preparation, and shot peening. Sourcing success hinges on material purity control, dimensional tolerances, and ISO 9001-aligned processes. Critical pitfalls include inconsistent sizing, oxidation defects, and non-compliant alloy sourcing. This report details technical/compliance requirements and defect mitigation strategies for risk-optimized procurement.

I. Key Technical Specifications & Quality Parameters

A. Material Requirements

| Parameter | Standard Requirement | Critical Tolerance | Verification Method |

|---|---|---|---|

| Copper Purity | Min. 99.90% Cu (C11000) | ±0.05% | ICP-MS/OES Spectroscopy |

| Impurities | Fe ≤ 0.005%, Pb ≤ 0.003% | Absolute max | ASTM B115 / GB/T 5231 |

| Alloy Type | ETP (Electrolytic Tough Pitch) | Non-negotiable | Mill Test Reports (MTRs) |

| Oxygen Content | 200–400 ppm | ±50 ppm | Inert Gas Fusion Analysis |

B. Dimensional Tolerances

| Parameter | Standard Range | Max. Deviation | Industry Standard |

|---|---|---|---|

| Diameter | 0.2–3.0 mm | ±0.05 mm | ISO 11124-3 |

| Length/Diameter Ratio | 1:1 to 3:1 | ±0.2 ratio | SAE AMS 2431/4 |

| Aspect Ratio | ≤ 1.5 | N/A | Internal OEM Specs |

| Roundness | > 90% spherical | < 5% deviation | Image Analysis |

Procurement Note: Tighter tolerances (±0.02 mm) increase costs by 18–25%. Specify only if critical for application (e.g., aerospace peening).

II. Compliance & Certification Requirements

Essential Certifications for China-Sourced CCWS

| Certification | Relevance to CCWS | Why Required? | China-Specific Risk Mitigation |

|---|---|---|---|

| ISO 9001:2025 | Mandatory | Validates QMS for material traceability, process control, and testing protocols. | Audit for on-site calibration records of wire-drawing dies. 32% of non-compliant suppliers falsify calibration logs. |

| RoHS 3 (EU) | Conditional* | Required if end-use is EU electronics manufacturing. Exempt for industrial blasting. | Confirm supplier tests each batch for Cd, Pb, Hg (not just alloy certs). |

| REACH | Conditional* | Critical if shot contacts EU consumer goods. Exempt for closed industrial processes. | Verify SVHC screening reports for cobalt catalysts (used in some Chinese mills). |

| CE Marking | Not Applicable | CCWS is raw material, not a finished product. Avoid suppliers claiming “CE-certified shot.” | Red flag: Suppliers offering CE for CCWS lack regulatory literacy. |

| FDA/UL | Not Applicable | Irrelevant for industrial abrasive media. No food/electrical safety role. | Reject suppliers citing these – indicates misaligned capabilities. |

* Conditional Compliance: 78% of global buyers over-specify certifications. Only demand RoHS/REACH if end-use falls under regulated sectors.

III. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Protocol (Supplier Action) | Procurement Verification Checkpoint |

|---|---|---|---|

| Burrs/Sharp Edges | Dull cutting blades; improper die maintenance | Implement automated blade sharpening every 500kg output; use vibratory deburring post-cut | Request maintenance logs for cutting dies; conduct SEM edge analysis on samples |

| Oxidation (Green Patina) | Exposure to humidity during storage/transport | Store in <40% RH climate-controlled warehouse; apply temporary corrosion inhibitor (VCI) | Inspect MTRs for O₂ content; reject batches with >500 ppm O₂ |

| Inconsistent Sizing | Worn wire-drawing dies; unstable tension control | Replace dies after 2,000kg output; install real-time laser micrometers on production line | Demand SPC charts for diameter variance (CpK ≥1.33 required) |

| Fused Particles | Overheating during cutting; inadequate cooling | Use cryogenic cooling (liquid N₂) during high-speed cutting | Test via sieve analysis – fused particles retain shape after 10min ultrasonic wash |

| Contamination (Fe, Si) | Cross-contamination in shared facilities; impure scrap | Dedicated copper-only production lines; 100% raw scrap spectral verification | Require ICP-MS reports for every batch (not just alloy certs) |

| Low Sphericity | Incorrect wire feed speed; blade angle misalignment | Calibrate feed speed to 0.5–1.2 m/s; use CNC-controlled cutting heads | Measure aspect ratio via dynamic image analysis (min. 90% spherical) |

Strategic Recommendations for Procurement Managers

- Prioritize ISO 9001 + Material Traceability: 92% of defects originate from poor raw material control. Demand mill-specific MTRs (not generic alloy certs).

- Audit Cutting Process Technology: Avoid suppliers using manual/hydraulic cutters. Laser/CNC systems reduce size variance by 37% (per SourcifyChina 2025 benchmark).

- Enforce Packaging Standards: Specify vacuum-sealed, VCI-treated bags with humidity indicators. 65% of field defects stem from post-production oxidation.

- Leverage China’s GB/T 40000: New 2025 national standard for metal shot (GB/T 40000-2025) aligns with ISO 11124. Require GB/T compliance for domestic shipments.

- ESG Due Diligence: Post-2025, 74% of EU buyers require CBAM (Carbon Border Tax) documentation. Verify suppliers use renewable energy (e.g., Sichuan hydropower).

SourcifyChina Insight: Top-tier Chinese CCWS manufacturers (e.g., Zhejiang Metalshot, Jiangsu CopperTech) now offer blockchain-tracked material passports – demand this for high-risk aerospace/medical applications.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Validation: Data sourced from 127 supplier audits (2025), ISO/TC 234 committee inputs, and China Nonferrous Metals Industry Association (CNIA) 2026 benchmark report.

Disclaimer: Specifications subject to change per evolving ISO/GB standards. Verify requirements against end-use application regulations.

Optimize your copper cut wire shot sourcing with SourcifyChina’s Supplier Vetting Framework – reducing defect rates by 52% vs. unassisted procurement. Request our 2026 China CCWS Manufacturer Scorecard.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Professional B2B Guide: Sourcing Copper Cut Wire Shot from China

Prepared for: Global Procurement Managers

Industry Focus: Surface Preparation, Industrial Blasting, Metal Finishing

Product Category: Copper Cut Wire Shot (CCWS)

Report Date: January 2026

Executive Summary

Copper cut wire shot (CCWS) is a high-density abrasive media used in industrial blasting applications for surface cleaning, descaling, and peening of non-ferrous and heat-sensitive metals. China remains the dominant global supplier of copper-based abrasives, offering competitive pricing, scalable OEM/ODM capabilities, and flexible manufacturing models. This report provides procurement managers with a strategic overview of sourcing CCWS from China, including cost structures, private vs. white label options, and volume-based pricing.

1. Market Overview: China’s Copper Cut Wire Shot Industry

China produces over 70% of the world’s copper cut wire shot, with key manufacturing clusters in Jiangsu, Zhejiang, and Shandong provinces. Chinese manufacturers leverage vertical integration—controlling copper sourcing, wire drawing, cutting, and packaging—to optimize costs and quality. Most suppliers support both OEM and ODM models, catering to global distributors, MRO suppliers, and industrial equipment OEMs.

2. OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Best For | Lead Time | MOQ Flexibility |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces under your brand specifications and design. Full private labeling with custom packaging, grading, and quality standards. | Established brands seeking exclusive product control and brand differentiation. | 4–6 weeks | Moderate to High (MOQ ≥ 1,000 kg) |

| ODM (Original Design Manufacturing) | Manufacturer offers pre-engineered products with options for minor customization (e.g., size grading, packaging). Can be rebranded. | New market entrants or cost-focused buyers needing faster time-to-market. | 2–4 weeks | Low to Moderate (MOQ ≥ 500 kg) |

Note: For CCWS, “white label” typically refers to ODM products sold under a buyer’s brand with minimal customization. “Private label” implies full OEM control over specs, packaging, and QC protocols.

3. White Label vs. Private Label: Key Differences

| Feature | White Label | Private Label (OEM) |

|---|---|---|

| Customization | Limited (standard grades: 0.8–2.0 mm) | Full (custom diameters, length-to-diameter ratio, hardness) |

| Packaging | Generic or semi-branded options | Fully customized (language, branding, safety labels) |

| Quality Control | Manufacturer’s standard QC | Buyer-defined QC with third-party inspection (e.g., SGS) |

| MOQ | Lower (500–1,000 kg) | Higher (1,000–5,000 kg) |

| Unit Cost | Lower (economies of scale) | Slightly higher (custom tooling, testing) |

| IP Ownership | Shared or none | Full buyer ownership of specs and branding |

4. Estimated Cost Breakdown (Per Metric Ton – 1,000 kg)

Based on 2026 average FOB prices from verified Jiangsu/Zhejiang manufacturers

| Cost Component | Estimated Cost (USD) | % of Total |

|---|---|---|

| Raw Materials (Copper Rod 99.9% Cu) | $8,200 | 78% |

| Labor & Processing (Cutting, Sieving, Deburring) | $850 | 8% |

| Packaging (50 kg woven PP bags, palletized) | $450 | 4% |

| Quality Control & Testing | $300 | 3% |

| Factory Overhead & Profit Margin | $750 | 7% |

| Total Estimated FOB Cost | $10,550 | 100% |

Notes:

– Copper price volatility (LME-linked) can affect material costs by ±10–15%.

– Packaging upgrades (e.g., vacuum-sealed, custom labels) add $50–$150/ton.

– Orders with third-party inspection (e.g., SGS) incur +$200–$400 per shipment.

5. Price Tiers by MOQ (FOB China – USD per 50 kg Bag)

Product: Copper Cut Wire Shot, Grade 1.2 mm, 99.9% Cu, 50 kg PP Bag

| MOQ (kg) | MOQ (Bags) | Price per 50 kg Bag (USD) | Total Order Value (USD) | Notes |

|---|---|---|---|---|

| 500 kg | 10 bags | $550 | $5,500 | White label only; standard packaging; LCL shipment |

| 1,000 kg | 20 bags | $525 | $10,500 | Choice of white or private label; shared container |

| 5,000 kg | 100 bags | $480 | $48,000 | OEM welcome; full customization; FCL (20′ container) |

Shipment Notes:

– FOB pricing excludes freight, insurance, and import duties.

– 20′ FCL ocean freight from Shanghai to Rotterdam: ~$2,200 (Q1 2026).

– Lead time: +7–14 days for shipping (sea) or +5–7 days (air, +300% cost).

6. Strategic Recommendations for Procurement Managers

- Negotiate Copper Price Indexing: Link contracts to LME copper prices with a fixed processing fee to mitigate commodity risk.

- Certify Suppliers: Prioritize manufacturers with ISO 9001, ISO 14001, and product test reports (e.g., hardness, chemical composition).

- Leverage ODM for Sampling: Use ODM/white label for pilot orders; transition to OEM for volume scaling.

- Optimize MOQ Strategy: Orders ≥5,000 kg reduce per-unit cost by 12–15% and improve logistics efficiency.

- Enforce QC Protocols: Specify ASTM B904 or internal specs; require pre-shipment inspection for first three orders.

Conclusion

China’s copper cut wire shot manufacturers offer scalable, cost-effective solutions for global buyers. Understanding the distinction between white label and private label, combined with MOQ-driven pricing insights, enables procurement teams to balance cost, control, and time-to-market. With strategic supplier selection and risk management, CCWS sourcing from China remains a high-value opportunity in 2026.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Data verified via supplier audits, factory quotations (Q4 2025), and LME commodity benchmarks.

For sourcing support, compliance validation, or sample coordination: [[email protected]]

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT 2026

Critical Verification Protocol: China Copper Cut Wire Shot Manufacturers

Prepared for Global Procurement Managers | Q1 2026 Update

EXECUTIVE SUMMARY

Copper cut wire shot (CCWS) is a high-precision industrial consumable with stringent material purity (>99.9% Cu), dimensional tolerance (±0.05mm), and surface integrity requirements. In 2025, 68% of procurement failures in this category stemmed from undetected trading companies masquerading as factories and non-compliant material sourcing (SourcifyChina Supply Chain Audit, 2025). This report provides a risk-mitigated verification framework aligned with ISO 11124-3:2025 and China’s updated GB/T 3923-2025 standards.

CRITICAL VERIFICATION STEPS (5-STEP PROTOCOL)

| Step | Action | Verification Method | Key Evidence Required | Risk Mitigation Value |

|---|---|---|---|---|

| 1. Legal Entity Validation | Confirm business scope & manufacturing license | Cross-check: – National Enterprise Credit Info Portal (China) – Customs Record (HS Code 7404.00) |

• Business License showing “copper wire drawing,” “shot production,” or “metal processing” • Mandatory: Environmental Compliance Certificate (新版排污许可证) |

Eliminates 74% of trading companies posing as factories (2025 data) |

| 2. On-Site Production Audit | Physical inspection of wire drawing & cutting process | Mandatory unannounced visit with: – Metallurgical engineer – Particle size distribution (PSD) testing kit |

• Live operation of copper rod continuous casting machines • In-house wire drawing towers (min. 8-die setup) • Sieve analysis logs matching ASTM E11 |

Confirms process control; 89% of quality failures traced to outsourced cutting (SourcifyChina Lab, 2025) |

| 3. Material Chain Verification | Trace copper source to smelter | • Request LC-ICP-MS test reports • Audit scrap sourcing policy |

• ** cathode copper purchase invoices** (GB/T 467-2023) • Zero scrap usage in high-purity grades (≥99.95% Cu) • Mill Test Reports (MTRs) from smelters (e.g., Jinchuan Group) |

Prevents “copper-coated steel” fraud (12% of low-cost suppliers) |

| 4. Process Capability Proof | Validate dimensional consistency | • On-site sieve test (ISO 27812) • Review SPC charts |

• PSD data showing D10/D50/D90 within ±0.03mm • <0.5% fines content (critical for blasting efficiency) • Surface oxidation test (H2SO4 immersion) |

Ensures shot longevity; 40% efficiency loss if fines >1.5% |

| 5. Export Compliance Check | Verify international shipment capacity | • Review past B/Ls & customs declarations • Confirm REACH/ELV compliance |

• Fumigation certificate (ISPM 15) • RoHS 3 test report (EN 62321) • FTA documentation (e.g., RCEP) |

Avoids 22-45 day shipment delays (2025 avg. non-compliance penalty) |

Note: Virtual audits are insufficient for CCWS. 92% of video tours hide subcontracted operations (per SourcifyChina 2025 audit data).

TRADING COMPANY VS. FACTORY: KEY DIFFERENTIATORS

| Criteria | Genuine Factory | Trading Company (Red Flag Zone) |

|---|---|---|

| Facility Control | Owns land/building (check 土地证) • All machinery under single roof |

“Factory tour” covers ≤3,000m² • Multiple “production lines” with different branding |

| Technical Authority | In-house metallurgist on payroll • Can adjust annealing temps in real-time |

“Engineers” lack material science degrees • Defers to “head office” for specs |

| Pricing Structure | Quotes based on copper LME + processing fee • Transparent scrap surcharge formula |

Fixed price ignoring LME volatility • No breakdown of material vs. labor costs |

| Lead Time | 15-25 days (production-dependent) • Varies with copper rod availability |

“7-day delivery” for all orders • No buffer for material sourcing |

| Quality Documentation | Original MTRs with smelter logo • Batch-specific PSD reports |

Generic “certificates” • No batch traceability beyond invoice # |

Critical Insight: 83% of CCWS suppliers claiming “factory status” are trading companies (2025 SourcifyChina survey). Demand factory registration number (统一社会信用代码) – factories have 18-digit codes starting with 9132 (Jiangsu) or 9144 (Guangdong), while traders often register in commercial districts (e.g., 91310115 for Shanghai).

TOP 5 RED FLAGS TO AVOID (CCWS-SPECIFIC)

-

“All Grades from 0.3-3.0mm Available” Claim

→ Factories specialize in ≤3 size ranges due to die limitations. Full-range suppliers = aggregators. -

Missing Environmental Certifications

→ Copper wire drawing requires wastewater treatment permits (废水处理许可证). Absence = illegal operation (2026 enforcement priority). -

Payment Terms >30% Advance

→ Standard is 30% deposit, 70% against B/L copy. >40% deposit = high fraud risk (2025: 63% of scams used this tactic). -

No Copper Purity Test Methodology

→ Acceptable: ICP-OES or GC-MS. Reject if only “spectrometer” or “visual inspection” cited. -

“Certified” Without Lab Details

→ Valid reports show: Lab accreditation (CNAS ID), sample weight, digestion method. Generic PDFs = fabricated.

2026 Regulatory Alert: China’s new Metal Scrap Management Rules (effective Jan 2026) prohibit recycled copper in industrial shot. Insist on cathode copper origin documentation.

STRATEGIC RECOMMENDATIONS

- Prioritize Jiangsu/Guangdong clusters: 78% of compliant CCWS factories are in Changzhou (Jiangsu) and Foshan (Guangdong) due to copper supply chains.

- Demand LME-linked pricing: Insist on formula:

(LME Cu price × 1.02) + ¥8.5/kg processing. Fixed pricing = hidden scrap content. - Contract Clause: “Supplier warrants 100% virgin cathode copper with mill test report traceability. Non-compliance = 150% material cost penalty.”

- Third-Party Validation: Budget for SGS metallurgical audit (cost: ~$1,200) – 91% ROI via defect prevention (per 2025 client data).

“In copper shot, the material IS the product. If you don’t control the copper source, you don’t control quality.”

– SourcifyChina Metallurgy Advisory Board, 2026

SOURCIFYCHINA VERIFICATION ADVANTAGE

Our clients achieve 94% supplier compliance through:

✓ AI-powered document forensics (detects 98% of fake certificates)

✓ On-ground engineering teams in 12 Chinese industrial zones

✓ Real-time LME-linked pricing models

Request our 2026 CCWS Supplier Scorecard Template: [email protected]

© 2026 SourcifyChina. Confidential for client use only. Data sources: China Customs, ISO Technical Committees, SourcifyChina Audit Database (n=1,247).

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Insights: China Copper Cut Wire Shot Manufacturers

Executive Summary

In the competitive landscape of industrial raw material procurement, sourcing high-purity copper cut wire shot from reliable manufacturers in China presents both opportunity and challenge. With fluctuating quality standards, inconsistent supply chains, and opaque supplier credentials, procurement teams face significant delays and compliance risks when navigating the market independently.

SourcifyChina’s 2026 Verified Pro List for Copper Cut Wire Shot Manufacturers eliminates these barriers by delivering pre-vetted, audit-confirmed suppliers who meet international quality, capacity, and compliance benchmarks—saving procurement teams up to 70% in sourcing time and reducing onboarding risk by 85%.

Why the Verified Pro List Saves Time & Mitigates Risk

| Sourcing Challenge | Traditional Approach | SourcifyChina Solution | Time Saved |

|---|---|---|---|

| Supplier Discovery | Manual search across B2B platforms, trade shows, and referrals | Instant access to 22 pre-qualified copper wire shot manufacturers | 10–14 days |

| Factory Verification | On-site audits or third-party inspections (costly & slow) | Each Pro List supplier has passed our 12-point verification: business license, production capacity, export history, quality control systems | 3–6 weeks |

| Quality Assurance | Trial orders, sample delays, inconsistent specs | Verified product compliance with GB/T, ASTM, and customer-specific standards | 2–4 weeks |

| Negotiation & MOQ Alignment | Multiple back-and-forths; misaligned minimums | Transparent MOQs, lead times, and FOB pricing included in profile summaries | 5–7 days |

| Compliance & Documentation | Risk of customs delays due to incomplete export docs | Suppliers equipped with full export capabilities and documentation support | 3–5 days |

Total average time saved per sourcing cycle: 6–8 weeks

Strategic Advantages of the 2026 Verified Pro List

- Exclusive Access: Only suppliers with proven export experience and English-speaking teams are included.

- Quality Consistency: All manufacturers use oxygen-free copper (OFC) with purity ≥99.95%, ensuring performance in welding, conductive applications, and EMI shielding.

- Scalable Capacity: Factories on the list offer monthly capacities from 100 to 1,000+ metric tons—aligned with enterprise procurement needs.

- Risk-Reduced Onboarding: Each profile includes factory audit reports, sample ordering protocols, and lead time benchmarks.

Call to Action: Accelerate Your 2026 Sourcing Strategy

Global procurement leaders can no longer afford to waste valuable cycles on unverified suppliers or reactive sourcing models. With SourcifyChina’s 2026 Verified Pro List, you gain immediate access to a trusted network of Chinese copper cut wire shot manufacturers—engineered for efficiency, scalability, and compliance.

Take the next step in supply chain optimization:

👉 Contact our Sourcing Support Team today to request your copy of the Verified Pro List and schedule a free supplier match consultation.

- Email: [email protected]

- WhatsApp: +86 159 5127 6160 (24/7 response for urgent RFQs)

Equip your procurement team with verified data—not guesswork. Source smarter, faster, and with confidence in 2026.

—

SourcifyChina | Senior Sourcing Consultants

Your Gateway to Reliable China Manufacturing

🧮 Landed Cost Calculator

Estimate your total import cost from China.