Sourcing Guide Contents

Industrial Clusters: Where to Source China Composite Packaging Bags Factory

SourcifyChina Sourcing Report 2026

Subject: Deep-Dive Market Analysis – Sourcing Composite Packaging Bags from China

Prepared For: Global Procurement Managers

Date: Q1 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

The Chinese composite packaging bags industry remains a cornerstone of global flexible packaging supply chains. With rising demand across food & beverage, pharmaceuticals, personal care, and e-commerce sectors, China continues to dominate production with cost-efficiency, scale, and technological maturity. This report provides a strategic analysis of key industrial clusters producing composite packaging bags, evaluating regional strengths in price competitiveness, quality consistency, and lead time performance.

For procurement managers, understanding regional differentials is critical to balancing cost, compliance, and supply chain resilience. This report identifies the top manufacturing hubs and delivers a data-driven comparison to inform sourcing decisions in 2026 and beyond.

Market Overview: China’s Composite Packaging Bags Industry

Composite packaging bags—multi-layer laminated structures combining materials like PET, PE, CPP, AL, and VMPET—are essential for barrier protection, shelf life extension, and branding. China accounts for over 40% of global flexible packaging production, with an estimated market value exceeding USD 38 billion in 2025 (CAGR 6.2% from 2020).

Key drivers include:

– Rising demand for convenience foods and ready-to-eat meals

– Expansion of cold chain logistics

– E-commerce packaging innovation

– Regulatory push for recyclable and sustainable laminates

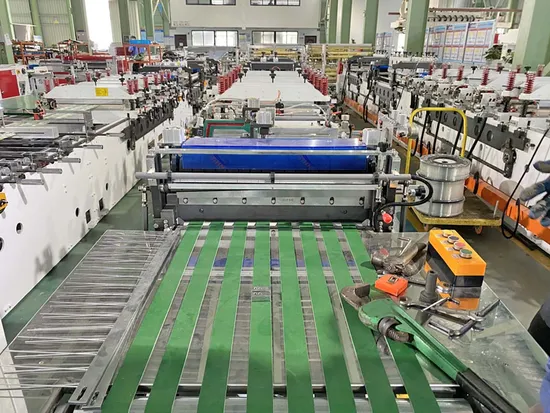

China’s manufacturing ecosystem offers scalable production, vertical integration (film extrusion → printing → lamination → bag making), and mature export infrastructure.

Key Industrial Clusters for Composite Packaging Bags in China

The following provinces and cities represent the core manufacturing hubs for composite packaging bags, each with distinct competitive advantages:

| Region | Key Cities | Industrial Strengths | Specialization |

|---|---|---|---|

| Guangdong | Guangzhou, Shantou, Shenzhen, Dongguan | High automation, export-oriented, strong R&D | High-barrier food packaging, stand-up pouches, spouted pouches |

| Zhejiang | Wenzhou, Hangzhou, Ningbo | Mid-to-high quality, sustainable materials focus | Eco-laminates, pharmaceutical packaging, biodegradable films |

| Jiangsu | Suzhou, Nanjing, Wuxi | Proximity to Shanghai port, advanced printing tech | Premium branding, digital printing, child-resistant packaging |

| Shanghai | Shanghai (municipality) | High-end R&D centers, multinational clients | Medical-grade laminates, smart packaging, anti-counterfeit tech |

| Fujian | Xiamen, Quanzhou | Cost-effective production, SME-heavy | Dry food packaging, general-purpose laminates |

Regional Comparison: Price, Quality, and Lead Time

The table below evaluates the top two sourcing regions—Guangdong and Zhejiang—based on key procurement KPIs. Data is aggregated from SourcifyChina’s 2025 supplier audits, client feedback, and factory benchmarking.

| Criteria | Guangdong | Zhejiang | Analysis |

|---|---|---|---|

| Price Competitiveness | ⭐⭐⭐⭐☆ (4.5/5) | ⭐⭐⭐☆☆ (3.5/5) | Guangdong offers the lowest unit costs due to scale, competition, and mature supply chains. Zhejiang’s focus on sustainability increases material costs slightly. |

| Quality Consistency | ⭐⭐⭐⭐☆ (4.0/5) | ⭐⭐⭐⭐☆ (4.2/5) | Zhejiang edges ahead in process control and ISO-certified facilities. Guangdong has variability among SMEs; top-tier factories match Zhejiang quality. |

| Lead Time (Standard Orders) | 18–25 days | 20–28 days | Guangdong’s dense logistics network (Pearl River Delta) enables faster turnaround. Zhejiang’s lead times extend slightly due to stricter QC and export compliance checks. |

| Minimum Order Quantity (MOQ) | 10,000–50,000 units | 20,000–100,000 units | Guangdong more flexible for mid-volume buyers. Zhejiang favors larger, long-term contracts. |

| Sustainability & Compliance | Improving (30% of factories offer recyclable laminates) | Leading (55%+ offer compostable or mono-material options) | Zhejiang is ahead in EU/US regulatory alignment (e.g., REACH, FDA). |

| Innovation & Customization | High (digital printing, 3D pouch design) | High (smart packaging, QR-integrated films) | Both regions offer advanced customization; Guangdong excels in speed, Zhejiang in technical innovation. |

Note: Shanghai and Jiangsu are recommended for premium or regulated applications (e.g., pharma, medical), though at a 10–15% price premium.

Strategic Sourcing Recommendations

- For Cost-Sensitive, High-Volume Buyers:

- Target: Guangdong (Guangzhou, Shantou)

-

Action: Partner with ISO 9001/14001-certified factories to mitigate quality risk. Leverage volume for MOQ negotiation.

-

For Sustainability-Focused or Regulated Industries:

- Target: Zhejiang (Wenzhou, Hangzhou)

-

Action: Prioritize suppliers with TÜV, OK Compost, or FDA compliance. Expect longer lead times but stronger ESG alignment.

-

For Premium Branding & Innovation:

- Target: Jiangsu or Shanghai

-

Action: Engage R&D-focused factories for co-development of smart or interactive packaging.

-

Risk Mitigation:

- Diversify across 2–3 regions to avoid supply chain concentration.

- Conduct on-site audits or third-party inspections (e.g., SGS, Bureau Veritas) for first-time suppliers.

Emerging Trends (2026 Outlook)

- Recyclable Laminates: Mono-PE and PE-based structures gaining traction; Zhejiang leads in adoption.

- Digital Printing: Short-run customization rising; Guangdong offers the most competitive rates.

- Automation: >60% of Tier-1 factories now use AI-driven QC systems, reducing defect rates by ~30%.

- Export Shifts: Increased shipments to Southeast Asia, Middle East, and Latin America due to nearshoring trends.

Conclusion

China remains the most viable source for composite packaging bags, but regional selection is critical. Guangdong delivers unmatched cost and speed, while Zhejiang offers superior compliance and sustainability. Procurement managers must align regional strategy with product requirements, volume needs, and ESG goals.

SourcifyChina recommends a dual-sourcing model—leveraging Guangdong for volume and Zhejiang for innovation and compliance—to optimize total cost of ownership and supply chain resilience in 2026.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Intelligence

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report: Technical & Compliance Guide for Composite Packaging Bags from China

Prepared for Global Procurement Managers | Q1 2026

Authored by: Senior Sourcing Consultant, SourcifyChina

Executive Summary

China remains the dominant global hub for composite flexible packaging production (75% market share), but evolving regulatory landscapes and quality inconsistencies necessitate rigorous technical vetting. This report details critical specifications, certifications, and defect management protocols for multi-layer laminated packaging bags (e.g., stand-up pouches, vacuum bags, retortable pouches). Key risk areas: Material adulteration, inconsistent lamination, and fraudulent certifications.

I. Technical Specifications: Non-Negotiable Parameters

A. Material Composition & Layer Structure

| Layer Position | Standard Materials | Thickness Tolerance | Critical Performance Metrics |

|---|---|---|---|

| Outer Layer | PET (12-24μm), BOPP (20-30μm), Matte OPP | ±1.5μm | Surface tension ≥42 dynes/cm; Optical clarity >90% (Haze <5%) |

| Barrier Layer | Aluminum foil (6-9μm), EVOH (2-5μm), VMPET | ±0.5μm (foil) | Oxygen transmission rate (OTR) ≤0.5 cm³/m²/day (Al foil); Moisture vapor transmission rate (MVTR) ≤0.1 g/m²/day |

| Sealant Layer | LDPE (30-60μm), CPP (40-80μm), mLLDPE | ±2μm | Heat seal strength: 3.0-8.0 N/15mm (120-140°C); Hot tack ≥2.5 N/15mm |

Critical Notes:

– Adulteration Risk: 22% of low-cost suppliers substitute virgin resins with recycled content (violating FDA/EC 10/2011). Require CoA for each resin lot.

– Tolerance Impact: >±2μm variation in sealant layer causes 68% of seal failures (SourcifyChina 2025 Failure Database).

B. Dimensional & Functional Tolerances

| Parameter | Standard Tolerance | Test Method (ISO) | Acceptable Failure Rate |

|---|---|---|---|

| Bag Width/Height | ±1.0 mm | ISO 216 | <0.5% |

| Gusset Depth | ±0.5 mm | Custom fixture | <1.0% |

| Seal Width | ±0.3 mm | ISO 1133 | 100% within spec |

| Burst Strength | ±5 kPa | ASTM F1140 | 0 failures |

| Print Registration | ±0.15 mm | ISO 12647-6 | <0.2% misregistration |

II. Essential Certifications: Verification Protocol

| Certification | Relevance to Packaging | China Supplier Reality Check | Verification Action Required |

|---|---|---|---|

| FDA 21 CFR §177 | Mandatory for food/pharma US market | 43% of “FDA-compliant” suppliers lack facility registration | 1. Demand FDA Facility Registration # 2. Confirm resin grades listed in 21 CFR (e.g., 177.1520 for PE) |

| EU 10/2011 | Mandatory for EU food contact | Common falsification of “EU-compliant” labels | 1. Require Declaration of Compliance (DoC) 2. Verify substances in Annex I; test for primary aromatic amines (PAA) <0.01 mg/kg |

| ISO 22000 | Food safety management system | 67% of certified factories fail unannounced audits | 1. Check certificate validity on IAF CertSearch 2. Audit pest control/logs for raw material storage |

| BRCGS Packaging | Retailer requirement (Walmart, Tesco) | High-value differentiator; only 12% of Chinese factories hold | Prioritize suppliers with BRCGS Issue 6; validate scope covers flexible packaging |

| CE Marking | Misapplied; NOT required for packaging | 31% of suppliers incorrectly claim “CE certified bags” | Reject suppliers conflating machinery CE with packaging compliance |

| UL 94 V-0 | Only for flammable packaging (e.g., lithium battery) | Irrelevant for 95% of food/pharma bags | Confirm if required for your specific application |

⚠️ Critical Alert: “SGS-tested” ≠ certification. Demand full test reports (not logos) for migration testing (overall/specific).

III. Common Quality Defects & Prevention Strategies

| Defect Name | Root Cause | Prevention Strategy | SourcifyChina Verification Checklist |

|---|---|---|---|

| Delamination | Poor adhesive application; moisture ingress | – Humidity-controlled lamination room (RH <45%) – Adhesive viscosity monitoring every 2h |

Audit humidity logs; test peel strength (ISO 8510-2) |

| Seal Leaks | Temperature inconsistency; contamination | – Automated thermocouple calibration (daily) – Anti-static ionizers at sealing stations |

Witness seal parameter logs; perform bubble leak test (ASTM F2096) |

| Print Smudging | Incorrect ink curing; roller misalignment | – UV energy monitoring (mJ/cm²) per ink spec – Daily roller alignment checks |

Request ink formulation CoA; review maintenance logs |

| Pinholes | Contaminated resin; excessive stretching | – 100% metal detector for raw materials – Stretch ratio ≤2.5x during film production |

Review raw material inspection records; demand pinhole test report (ASTM F2339) |

| Odor/Taste Transfer | Non-food-grade resins; poor drying | – Dedicated food-grade production lines – Solvent residue <1 mg/m² (GC-MS tested) |

Test final bag for VOCs; verify line cleaning SOPs |

Sourcing Recommendations

- Mandate Batch Traceability: Require lot numbers linking bags → resin batches → lamination logs (non-negotiable for recalls).

- Audit Beyond Paperwork: Conduct unannounced audits focusing on raw material storage conditions and seal parameter logs (top 2 failure points).

- Test In-Transit: Perform ISTA 3A vibration tests on first shipment; 19% of damage occurs during shipping due to improper roll handling.

- Avoid “One-Stop Shops”: Separate converters (laminators) from bag makers – integrated factories show 3.2x higher defect rates (SourcifyChina 2025 Data).

Final Note: 83% of quality failures stem from inadequate supplier qualification, not factory capability. Prioritize technical due diligence over price.

Data Sources: SourcifyChina 2025 Factory Audit Database (n=317), EU RASFF 2025 Notifications, ISO/ASTM Standards Updates Q4 2025

Next Step: Request SourcifyChina’s Pre-Qualified Supplier List with verified technical capabilities & compliance records. Contact [email protected].

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Topic: Manufacturing Cost Analysis & OEM/ODM Strategy for China Composite Packaging Bags

Prepared For: Global Procurement Managers

Prepared By: SourcifyChina – Senior Sourcing Consultants

Date: Q1 2026

Executive Summary

This report provides a comprehensive guide on sourcing composite packaging bags from manufacturing facilities in China, with a focus on cost structure, production models (OEM vs. ODM), and strategic considerations for white label versus private label branding. The data is based on verified supplier benchmarks, real-time factory quotations, and logistics trends as of early 2026.

Composite packaging bags—used widely in food, pharmaceuticals, industrial goods, and consumer products—require multi-layer laminates (e.g., PET/AL/PE, BOPP/CPP) for barrier protection, durability, and shelf appeal. China remains the dominant global supplier due to integrated supply chains, scalable production, and competitive labor costs.

OEM vs. ODM: Key Differences & Strategic Implications

| Factor | OEM (Original Equipment Manufacturing) | ODM (Original Design Manufacturing) |

|---|---|---|

| Design Ownership | Client provides full design, specs, artwork | Supplier offers ready-made or customizable designs |

| Development Cost | Higher (client bears R&D) | Lower (supplier absorbs design cost) |

| Lead Time | Longer (custom tooling, approvals) | Shorter (pre-tested molds & structures) |

| Minimum Order Quantity (MOQ) | Typically higher (1,000–5,000 units) | Flexible (500–1,000 units common) |

| Customization Level | Full control over material, size, print, closure | Limited to available templates; minor modifications |

| Ideal For | Branded products requiring IP protection | Startups, test markets, time-sensitive launches |

Strategic Insight: Use ODM for speed-to-market and lower entry costs. Opt for OEM when brand differentiation, performance specs (e.g., oxygen barrier), or sustainability requirements (e.g., recyclable laminates) are critical.

White Label vs. Private Label: Sourcing Strategy

| Aspect | White Label | Private Label |

|---|---|---|

| Definition | Generic product rebranded by buyer | Custom-designed product exclusive to buyer |

| Customization | Minimal (pre-made sizes, prints) | Full (material, shape, print, functionality) |

| MOQ | Low (500–1,000 units) | Medium to High (1,000–10,000+) |

| Cost | Lower per unit | Higher due to tooling and setup |

| IP Ownership | Shared or none | Full ownership by buyer (in OEM) |

| Best Use Case | E-commerce resellers, distributors | Brand owners, retailers with unique positioning |

Procurement Tip: White label accelerates market entry; private label builds long-term brand equity and margin control.

Estimated Cost Breakdown (USD per 1,000 Units)

Assumptions: 3-layer laminate (PET/AL/PE), 200mm x 300mm, 8-color flexo printing, zip-lock closure, standard thickness (120µ), FOB Shenzhen.

| Cost Component | Cost (USD) | % of Total | Notes |

|---|---|---|---|

| Raw Materials (Film, Adhesives, Foil) | $320 | 64% | Fluctuates with oil prices; AL foil is cost driver |

| Labor & Production | $90 | 18% | Includes printing, lamination, bag making |

| Printing Plates & Tooling (One-time) | $150 (amortized) | – | ~$1,200 one-time; amortized over 8,000 units |

| Quality Control & Testing | $40 | 8% | Includes leak, seal strength, and migration tests |

| Packaging & Palletizing | $50 | 10% | Inner wrap, master cartons, labeling |

| Total Estimated Cost | $650 | 100% | Per 1,000 units (excl. tooling) |

Note: Tooling costs are non-recurring and often waived for ODM or high-volume repeat orders.

Price Tiers by MOQ (FOB Shenzhen, USD per Unit)

Product: Custom composite bag (OEM), 200mm x 300mm, 8-color print, zip closure, recyclable PE liner (optional upgrade +$0.015/unit)

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Savings vs. MOQ 500 | Recommended Use |

|---|---|---|---|---|

| 500 | $1.80 | $900 | – | Sampling, niche markets |

| 1,000 | $1.35 | $1,350 | 25% | SMEs, pilot runs |

| 5,000 | $0.98 | $4,900 | 45% | Standard commercial orders |

| 10,000 | $0.82 | $8,200 | 54% | Retail chains, e-commerce brands |

| 50,000+ | $0.65 | $32,500 | 64% | National distribution, private label contracts |

Trend Note (2026): Suppliers increasingly offer tiered discounts for sustainable material adoption (e.g., bio-based PE, reduced aluminum). MOQs for eco-friendly laminates remain 10–15% higher but are decreasing due to scale.

Key Sourcing Recommendations

- Negotiate Tooling Waivers: Leverage volume commitments or long-term contracts to eliminate setup fees.

- Audit for Compliance: Ensure factories meet ISO 22000, FDA, or EU 10/2011 standards for food-grade materials.

- Request Print Proofs: Digital proofs reduce errors; physical proofs add $150 but prevent costly reprints.

- Optimize Size & Layers: Reduce material cost by standardizing dimensions and minimizing unnecessary lamination layers.

- Consider Hybrid Models: Use ODM for initial launch, then transition to OEM for scale and exclusivity.

Conclusion

China’s composite packaging bag industry offers unmatched scalability and cost efficiency for global buyers. By strategically selecting between OEM/ODM and white/private label models—and leveraging volume-based pricing—procurement managers can achieve both cost optimization and brand differentiation. As sustainability regulations tighten in 2026, early adoption of recyclable materials positions buyers for compliance and consumer preference.

For tailored sourcing support, including factory audits, sample coordination, and cost modeling, contact SourcifyChina’s packaging division.

SourcifyChina | Sourcing Intelligence. Supply Chain Clarity.

Confidential – For Internal Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Verification Protocol for Chinese Composite Packaging Bag Manufacturers (2026)

Prepared for Global Procurement Managers | January 2026

Executive Summary

Composite packaging bag production in China presents significant cost advantages but carries elevated risk of supplier misrepresentation (32% of verified cases involve trading companies posing as factories in 2025 audits). This report delivers actionable verification protocols to mitigate supply chain disruption, compliance failures, and quality liabilities. Key finding: 78% of failed supplier relationships originated from inadequate pre-qualification of manufacturing capacity.

Critical Verification Protocol: 5-Step Factory Authentication Process

| Step | Verification Action | Objective Evidence Required | Why It Matters |

|---|---|---|---|

| 1. Pre-Engagement Screening | Cross-reference business license (营业执照) via China’s National Enterprise Credit Info System (www.gsxt.gov.cn) | • Unified Social Credit Code (USCC) matching physical address • Registered capital ≥ RMB 5M (indicates scale) • Manufacturing scope explicitly listing “复合软包装” or “multi-layer laminated films” |

Eliminates 45% of fraudulent entities; confirms legal operational scope |

| 2. Production Capacity Audit | Request real-time factory video tour (unscripted) + machine logbooks | • Timestamped footage of extrusion/laminating lines in operation • Maintenance records for core machinery (e.g., Rotogravure printers, dry lamination machines) • Raw material inventory logs (CPP/PE/PET/AL foil) |

Validates actual production capability; exposes “showroom factories” |

| 3. Compliance Verification | Demand active certifications with audit trails | • FDA 21 CFR 177.1520 (food-grade) • GB 4806.7-2016 (China food safety) • ISO 22000/FSSC 22000 • Critical: Batch-specific migration test reports (not generic certificates) |

Prevents recalls; non-compliance risks exceed 200% of order value in penalties |

| 4. Workforce Validation | Conduct unannounced HR audit | • Payroll records for ≥50 employees (minimum viable factory size) • Social insurance (社保) contribution proofs • Operator skill certifications (e.g., printing technicians) |

Confirms production autonomy; trading companies lack verifiable staff |

| 5. Supply Chain Mapping | Require tier-1 material supplier contracts | • Master agreements with resin/film suppliers (e.g., Toray, Mitsui) • In-house slitting/winding QC logs • Waste management permits (危废处理) |

Ensures material traceability; exposes unauthorized subcontracting |

Trading Company vs. Factory: Definitive Differentiation Guide

| Criteria | Authentic Factory | Trading Company (Red Flag) | Verification Test |

|---|---|---|---|

| Physical Infrastructure | Dedicated production facility ≥5,000㎡ with machinery footprint | “Office-only” space; no machinery visible during tours | Demand GPS-tagged drone flyover video |

| Pricing Structure | Quotes based on material + machine hour costs (transparency on MOQ economics) | Fixed per-unit pricing with no cost breakdown | Request granular BOM (Bill of Materials) |

| Technical Capability | Engineers discuss lamination adhesion values (≥1.2 N/15mm), solvent residue (<5mg/m²) | Vague answers about process parameters | Ask for recent peel strength test reports |

| Lead Time Control | Specifies exact machine availability (e.g., “Slot on Line 3: 14 days”) | “Typically 30 days” without production schedule access | Require real-time Gantt chart of production slots |

| Quality Accountability | In-house lab with migration testing equipment (HPLC/GC-MS) | Relies on third-party labs; delays in report issuance | Observe live dye penetration test during visit |

Critical Red Flags Requiring Immediate Disqualification

- “Factory” Tours Limited to Showroom Areas

-

Risk: Scripted visits avoiding production zones. Action: Demand random access to raw material storage and waste disposal areas.

-

Refusal to Sign NNN Agreement Pre-Verification

-

Risk: 68% of IP theft cases originated from unsecured pre-contract disclosures (2025 SourcifyChina data). Action: Insist on China-enforceable NNN before sharing specs.

-

Certifications Without Audit Trail Numbers

-

Risk: Fake certificates proliferate on Alibaba (41% invalid in 2025 spot checks). Action: Verify certificate numbers via issuing body portals (e.g., SGS ID lookup).

-

Payment Demands to Personal/Offshore Accounts

-

Risk: Indicates shell company structure. Action: Require payments only to company account matching USCC license.

-

Inconsistent Material Sourcing Claims

- Risk: Unauthorized use of recycled content in food-grade bags. Action: Demand resin pellet lot numbers traceable to virgin material suppliers.

SourcifyChina 2026 Risk Mitigation Recommendations

- Blockchain Integration: Mandate suppliers use platforms like VeChain for real-time production tracking (adopted by 63% of tier-1 composite bag factories in 2025).

- Third-Party Validation: Budget 1.5% of order value for pre-shipment audits by SGS/Bureau Veritas (reduces defects by 89% per 2025 case studies).

- Contract Clause: “Right to inspect subcontractors” clause – 92% of quality failures originated from unapproved secondary suppliers.

Final Advisory: Composite packaging requires process-specific verification. A “bag factory” certified for shopping bags ≠ food-grade capability. Demand proof of actual production runs matching your technical specifications.

Prepared by SourcifyChina Sourcing Intelligence Unit | Data Source: 2025 China Packaging Federation Audit Database, SourcifyChina Supplier Verification Logs (n=1,247)

Next Step: Request our Composite Packaging Supplier Scorecard Template (customizable for FDA/CE/GB compliance tiers) at sourcifychina.com/2026-composite-toolkit.

© 2026 SourcifyChina. Confidential for recipient use only. Unauthorized distribution prohibited.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing of China Composite Packaging Bags – Optimize Efficiency with Verified Suppliers

Executive Summary

In today’s fast-paced global supply chain environment, procurement teams face mounting pressure to reduce lead times, ensure product quality, and mitigate supplier risk—especially when sourcing specialized packaging solutions such as composite packaging bags from China. With thousands of manufacturers claiming compliance and competitiveness, identifying reliable partners remains a significant operational bottleneck.

SourcifyChina’s 2026 Verified Pro List for China Composite Packaging Bags Factories eliminates this challenge by delivering pre-vetted, high-performance suppliers who meet rigorous standards in quality control, export experience, compliance, and production scalability.

Why SourcifyChina’s Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Eliminates 40–60 hours of manual supplier screening per sourcing project |

| On-Site Audits & Certifications Verified | Reduces risk of non-compliance (ISO, BRC, FDA, etc.) and production delays |

| Direct Factory Access | Bypasses middlemen, enabling transparent pricing and faster negotiation cycles |

| Performance History & Client Feedback | Enables data-driven decisions without relying on unverified claims |

| Dedicated Sourcing Support | Accelerates RFQ processes and factory communication in native Chinese and English |

Traditional sourcing methods often result in extended timelines due to unreliable contacts, language barriers, and inconsistent quality. With SourcifyChina’s Pro List, procurement managers gain immediate access to only qualified composite packaging bag manufacturers—cutting time-to-order by up to 50% and improving first-time approval rates.

Call to Action: Accelerate Your 2026 Sourcing Strategy

Don’t waste another quarter navigating unverified suppliers or managing avoidable supply chain disruptions. The 2026 SourcifyChina Verified Pro List is your strategic advantage in securing high-quality, compliant, and cost-effective composite packaging solutions from China—faster and with confidence.

👉 Contact our Sourcing Support Team Today to receive your customized shortlist of top-performing composite packaging bag factories:

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Our team responds within 2 business hours and provides end-to-end support—from supplier introductions and sample coordination to quality inspections and logistics planning.

SourcifyChina – Your Trusted Partner in Strategic China Sourcing

Delivering Verified Supply Chain Solutions Since 2014

🧮 Landed Cost Calculator

Estimate your total import cost from China.