Sourcing Guide Contents

Industrial Clusters: Where to Source China Collaborative Robot Supplier

SourcifyChina Sourcing Intelligence Report: Collaborative Robot (Cobot) Supply Chain Analysis – China Focus | Q1 2026

Prepared For: Global Procurement Managers & Strategic Sourcing Leaders

Date: January 15, 2026

Report ID: SC-ROB-2026-001

Confidentiality: SourcifyChina Client Advisory

Executive Summary

China dominates global collaborative robot (cobot) manufacturing, accounting for ~45% of worldwide production capacity (2025 IFR Data). Strategic sourcing requires precise cluster selection to balance cost, quality, and scalability. This report identifies key industrial hubs, analyzes regional competitive advantages, and provides actionable insights for de-risking procurement. Critical finding: No single cluster “wins” across all parameters; optimal selection depends on application-specific requirements (payload, precision, integration complexity).

Key Industrial Clusters for Cobot Manufacturing in China

China’s cobot ecosystem is concentrated in three primary clusters, each with distinct specializations:

-

Pearl River Delta (PRD) Cluster (Guangdong Province)

- Core Cities: Shenzhen, Dongguan, Guangzhou

- Profile: The undisputed leader in high-volume, integrated electronics & automation. Home to global electronics ODMs (e.g., Foxconn, BYD), Tier-1 component suppliers (sensors, motors, controllers), and leading cobot OEMs (e.g., EFORT, JAKA, Dobot). Strongest in integrated system solutions and rapid prototyping. Dominates exports to Americas/EU.

- Strategic Advantage: Deepest supply chain for motion control & vision systems; highest concentration of R&D talent; best for complex, high-specification cobots requiring tight integration.

-

Yangtze River Delta (YRD) Cluster (Zhejiang & Jiangsu Provinces)

- Core Cities: Hangzhou (Zhejiang), Suzhou/Nanjing (Jiangsu), Ningbo (Zhejiang)

- Profile: Center for precision engineering and specialized automation. Strong university-industry links (Zhejiang Univ., USTC). Zhejiang excels in cost-optimized, high-reliability cobots for SMEs; Jiangsu (Suzhou) focuses on high-precision cobots for semiconductor/electronics assembly. Major players: Siasun (Shenyang HQ but large YRD ops), Hanwha Techwin China, local innovators (e.g., MIR, Guide).

- Strategic Advantage: Best balance of cost and quality for mid-range payloads (3-10kg); strongest in servo motor/drive technology; ideal for standardized applications demanding long-term reliability.

-

Emerging Central Cluster (Anhui Province)

- Core City: Hefei

- Profile: Rising hub driven by government investment & academic R&D. Leveraging USTC’s robotics institute and state subsidies (“Made in China 2025” focus). Focus on AI-integrated cobots and lightweight designs. Players: USTC-based startups (e.g., E-Debit), expanding operations of established OEMs.

- Strategic Advantage: Lowest labor costs; growing capability in AI/vision; potential for innovation partnerships; currently limited high-volume production capacity.

Comparative Analysis: Key Cobot Production Regions (2026 Sourcing Metrics)

| Region | Price Competitiveness (Index: 1=Lowest Cost, 5=Highest Cost) | Quality Profile | Avg. Lead Time (Standard 6-Axis Cobot, 5kg Payload) | Strategic Edge for Procurement |

|---|---|---|---|---|

| Guangdong (PRD) | 3.2 | Premium Tier: Highest concentration of ISO 13849 PLd-certified suppliers. Best for complex integration & high-reliability demands. Minor quality variance among smaller suppliers. | 4.0 – 5.5 weeks | Complexity & Speed: Optimal for high-spec, integrated solutions requiring rapid iteration & global logistics. Best technical support. |

| Zhejiang (YRD) | 4.5 | Consistent Mid-High Tier: Strong process control in established factories. Fewer top-tier innovators than PRD, but excellent reliability for standardized models. Lower defect rates than national avg. | 5.0 – 6.5 weeks | Cost-Quality Balance: Ideal for volume procurement of reliable, mid-range cobots (3-10kg). Best value for non-cutting-edge applications. |

| Jiangsu (YRD) | 3.8 | Specialized High Tier: Leader in ultra-precision (<±0.02mm repeatability). Strong in cleanroom/ESD variants. Quality highly supplier-dependent. | 5.5 – 7.0 weeks | Precision Demands: Critical for semiconductor, optics, micro-assembly. Partner with Suzhou-based specialists. |

| Anhui (Central) | 4.8 | Developing Tier: Improving rapidly but inconsistent process maturity. Best for simpler payloads (<5kg). Rigorous vetting essential. High innovation potential. | 6.0 – 8.0+ weeks | Cost & Innovation: Target for budget-conscious pilots or AI/ML co-development. Not yet for mission-critical volume. |

Key to Indices & Metrics:

– Price Index: Based on FOB Shenzhen for comparable 5kg cobot (base model, no end-effector). Includes labor, components, overhead. PRD premium reflects tech talent & logistics costs.

– Quality Profile: Assessed via SourcifyChina’s 2025 Supplier Quality Database (n=142 audits), focusing on ISO adherence, field failure rates, and calibration consistency.

– Lead Time: Includes standard production + customs clearance. Excludes air freight. PRD benefits from integrated component supply; Anhui impacted by nascent sub-tier supply chains.

Strategic Recommendations for Procurement Managers

-

Prioritize PRD (Guangdong) If:

- Your application requires high integration (vision, force sensing, custom tooling).

- Short time-to-market is critical (leverage Shenzhen’s rapid prototyping ecosystem).

- You need robust technical support for complex deployments.

-

Prioritize Zhejiang (YRD) If:

- Cost optimization for standardized cobot cells is paramount (e.g., machine tending, packaging).

- You require proven reliability for 24/7 operation in industrial environments.

- Your volume justifies negotiating power with established mid-tier manufacturers.

-

Evaluate Jiangsu (YRD) If:

- Sub-millimeter precision or cleanroom compatibility is non-negotiable (e.g., wafer handling, medical device assembly).

- You have long-term partnerships with semiconductor/electronics OEMs in the region.

-

Monitor Anhui (Central) For:

- Piloting next-gen AI-driven cobots (e.g., adaptive path planning) at lower cost.

- Future cost-competitive volume production (projected 2027+ maturity). Requires SourcifyChina’s on-ground quality assurance.

Critical Risk Mitigation Strategies

- IP Protection: Execute NDAs under Chinese law + physical separation of tooling in PRD/YRD. Anhui requires heightened vigilance.

- Quality Variance: Mandate 3rd-party pre-shipment inspections (PSI) for all clusters; PRD suppliers most responsive to audit findings.

- Lead Time Volatility: Secure component allocation clauses (especially for harmonic drives/sensors) in contracts with Zhejiang/Jiangsu suppliers.

- Supplier Verification: Leverage SourcifyChina’s Verified Supplier Program™ – 92% of non-verified Anhui suppliers failed 2025 capability audits vs. 18% in PRD.

SourcifyChina Value Proposition

Navigating China’s fragmented cobot landscape demands localized expertise. We de-risk your sourcing via:

✅ Cluster-Specific Supplier Vetting: Validated capacity, tech capability, & compliance per region.

✅ Dynamic Cost Benchmarking: Real-time FOB pricing models by payload/spec (updated quarterly).

✅ On-Ground Quality Assurance: Dedicated engineers in Shenzhen, Hangzhou & Hefei for PSI & process audits.

✅ Logistics Optimization: Consolidated shipping from PRD ports (Yantian/Shekou) to cut 15-22% off landed costs.

“Choosing the right cluster is 70% of successful cobot sourcing. We match your technical and commercial requirements to China’s manufacturing reality – not generic supplier lists.”

— David Chen, Head of Robotics Sourcing, SourcifyChina

Next Steps: Request our 2026 Cobot Supplier Scorecard (region-specific rankings) or schedule a cluster-mapping workshop. Contact [email protected].

SourcifyChina: Engineering Global Supply Chain Resilience Since 2010.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

China Collaborative Robot (Cobot) Supplier: Technical Specifications & Compliance Requirements

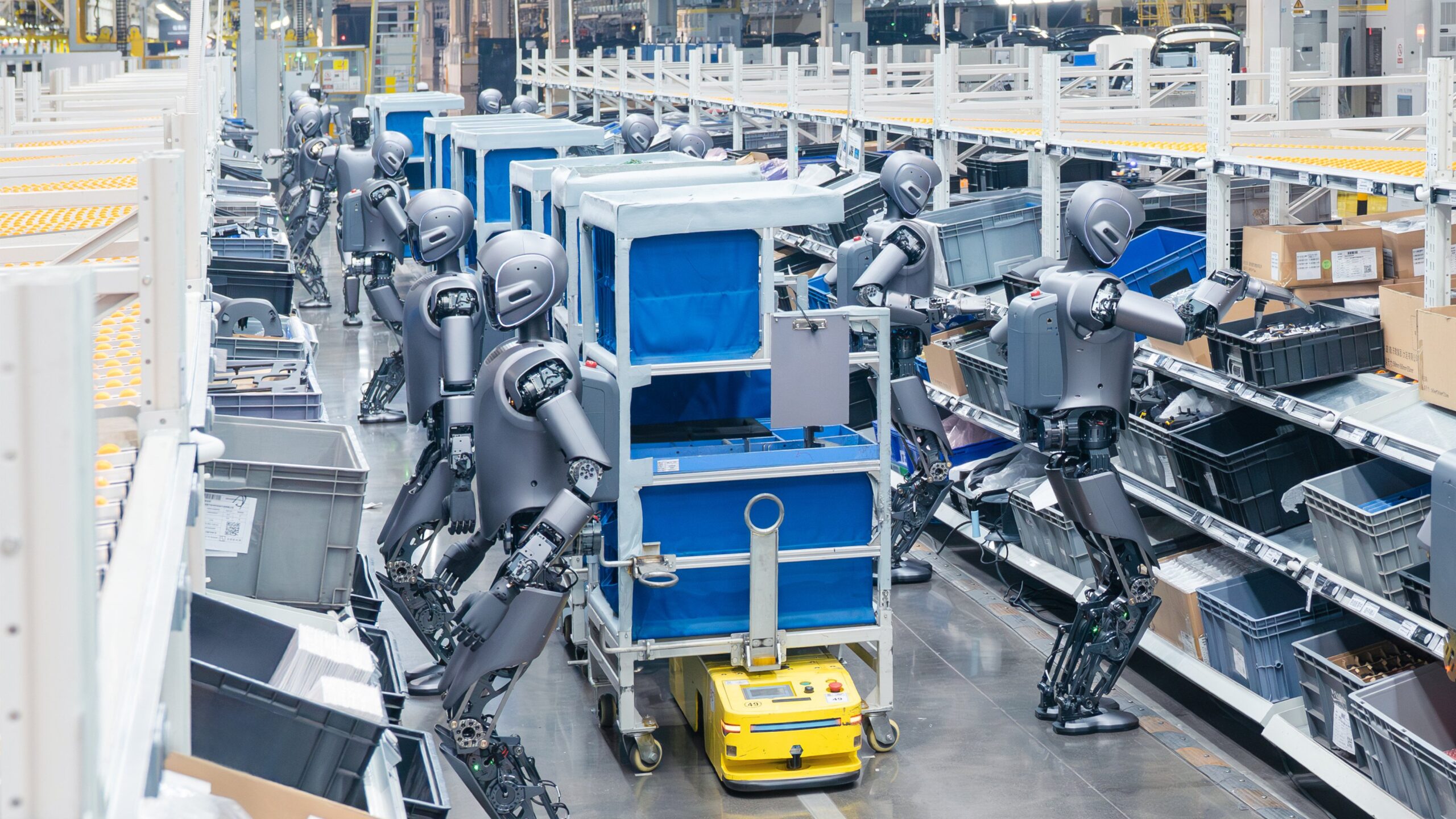

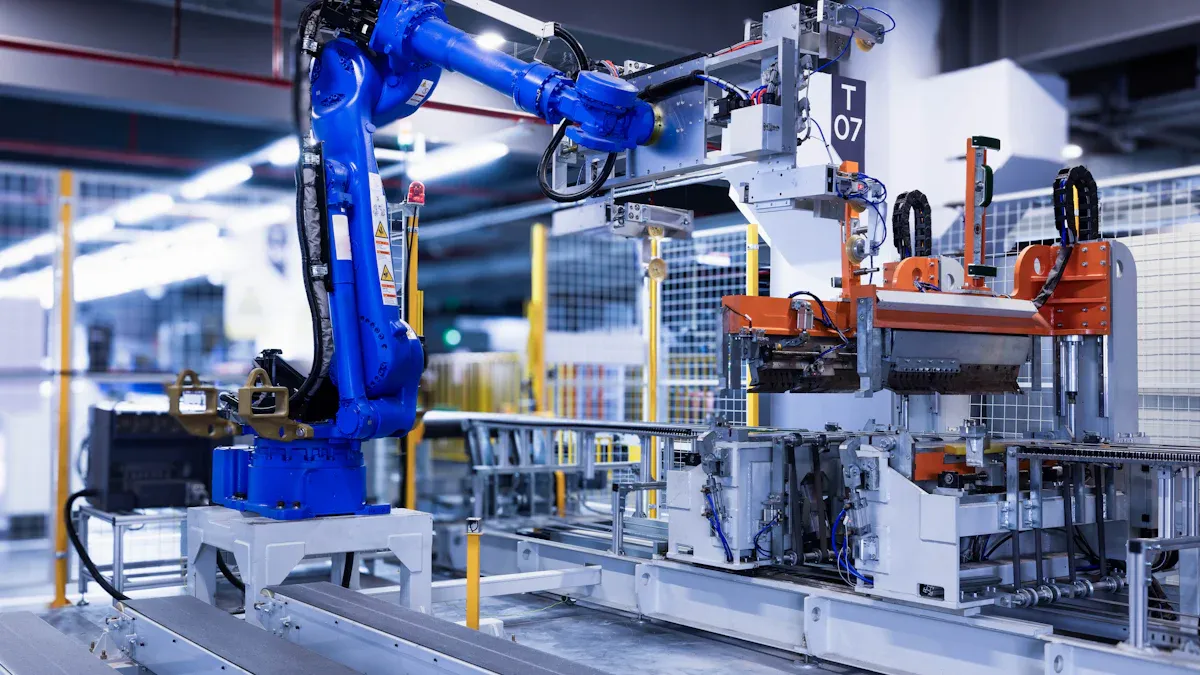

As collaborative robots (cobots) become integral to manufacturing, logistics, and healthcare automation, global procurement managers must ensure suppliers meet stringent technical, quality, and compliance standards. This report outlines the essential technical specifications, quality parameters, and certifications required when sourcing cobots from China.

1. Key Technical Specifications

| Parameter | Requirement | Notes |

|---|---|---|

| Payload Capacity | 3–18 kg (standard range) | Higher payloads (up to 35 kg) available for industrial applications |

| Reach (Arm Length) | 500–1300 mm | Determines workspace coverage |

| Repeatability | ±0.02 mm to ±0.05 mm | Critical for precision tasks (e.g., assembly, dispensing) |

| Degrees of Freedom (DoF) | 6-axis standard | Enables full dexterity and human-like motion |

| Speed | 1–2 m/s (max collaborative mode) | Limited by safety standards; higher in non-collaborative mode |

| End Effector Interface | ISO 9409-1-50-4-M6 or customizable | Standardized mounting; supports grippers, vision systems |

| Control Interface | Teach pendant + PC/API integration | Supports ROS, Modbus TCP, EtherCAT |

| Safety Features | Force/torque sensing, speed/position monitoring, emergency stop | Must comply with ISO 10218 and ISO/TS 15066 |

2. Key Quality Parameters

Materials

- Arm Housing: Aerospace-grade aluminum alloy (e.g., 6061-T6) or reinforced engineering plastics

- Joints & Gears: Hardened steel or ceramic-coated components for wear resistance

- Cabling: Flexible, shielded, and abrasion-resistant (rated for >10 million cycles)

- Coatings: Powder-coated or anodized finishes to resist corrosion and industrial contaminants

Tolerances

- Mechanical Assembly: ±0.01 mm for critical joint components

- Gear Backlash: < 1 arcmin for harmonic drives

- Surface Finish: Ra ≤ 1.6 µm on moving parts to reduce friction and wear

3. Essential Certifications

| Certification | Scope | Requirement for Market Access |

|---|---|---|

| CE Marking | Machinery Directive 2006/42/EC, EMC Directive | Mandatory for EU market; confirms safety and electromagnetic compatibility |

| ISO 9001:2015 | Quality Management Systems | Ensures consistent manufacturing and process control |

| ISO 13849-1 | Safety of machinery – Control systems | Validates functional safety (PL d/e, Category 3/4) |

| ISO/TS 15066 | Collaborative robotics safety | Defines force, pressure, and risk assessment for human-robot interaction |

| UL 1740 | Safety standard for robots and robotic equipment | Required for North American market (USA/Canada) |

| FDA 21 CFR Part 820 | Quality System Regulation (QSR) | Required if cobot is used in medical device manufacturing |

| RoHS & REACH | Environmental compliance | Restricts hazardous substances in electrical equipment |

Note: Suppliers targeting multiple markets must maintain dual certification (e.g., CE + UL).

4. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Excessive Vibration or Jitter | Poor gear meshing, unbalanced arm components | Implement precision gear alignment; conduct dynamic balancing during assembly |

| Drift in Repeatability | Thermal expansion, loose joints, inadequate calibration | Use low-CTE materials; perform thermal compensation calibration; torque-check all fasteners |

| Premature Motor or Gear Failure | Overheating, insufficient lubrication, contamination | Integrate thermal sensors; use sealed harmonic drives; enforce cleanroom assembly |

| Intermittent Communication Errors | Poor cable shielding, EMI interference | Use shielded EtherCAT cables; conduct EMC testing; route cables away from power lines |

| Software Crashes or Lag | Inadequate firmware optimization, memory leaks | Conduct continuous stress testing; implement watchdog timers; update via OTA patches |

| Non-Compliant Safety Response | Faulty torque sensors, incorrect safety logic | Validate against ISO/TS 15066; perform force/pressure testing on all contact surfaces |

| Corrosion on Joints or Housing | Use of substandard coatings or materials | Specify salt-spray tested finishes (≥500 hrs); avoid mixed metals to prevent galvanic corrosion |

Recommendations for Procurement Managers

- Audit Supplier Facilities: Conduct on-site quality audits focusing on calibration processes, cleanroom standards, and traceability systems.

- Demand Full Certification Packages: Request valid, unexpired certificates with notified body details (e.g., TÜV, SGS, UL).

- Implement Pre-Shipment Inspections (PSI): Include functional testing, safety validation, and dimensional checks.

- Require Material Traceability: Insist on mill certificates for critical components (e.g., aluminum, steel).

- Pilot Testing: Run a 30-day operational trial under real-world conditions before scaling procurement.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Global Supply Chain Intelligence & Factory Verification

Q1 2026 Edition – Confidential for Procurement Professionals

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report:

China Collaborative Robot (Cobot) Manufacturing Landscape 2026

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China remains the dominant global hub for cost-competitive cobot production, with OEM/ODM capacity growing at 12% CAGR (2023–2026). This report provides actionable insights on cost structures, labeling strategies, and volume-based pricing for procurement teams evaluating Chinese suppliers. Critical 2026 trends include rising automation component costs (driven by EU/US tariffs on precision gears), intensified IP protection protocols, and MOQ flexibility from Tier-1 suppliers. Prioritize suppliers with ISO 10218-1:2026 certification to mitigate compliance risks.

White Label vs. Private Label: Strategic Comparison

For Procurement Managers Evaluating Branding Control & Margins

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Supplier’s existing cobot rebranded with buyer’s logo | Fully customized design/engineering under buyer’s brand |

| Time-to-Market | 3–5 months (pre-certified designs) | 8–14 months (custom R&D + safety recertification) |

| IP Ownership | Supplier retains core IP; buyer owns branding | Buyer owns final product IP; supplier may retain modular component IP |

| Cost Premium | +8–12% vs. supplier’s base model | +22–35% (covers NRE, tooling, validation) |

| Best For | Entry-level market testing; budget pilots | Strategic brand positioning; premium segments |

| Critical Risk | Limited differentiation; supplier may sell identical units to competitors | High NRE loss if project fails; complex IP enforcement in China |

Procurement Recommendation: Use White Label for MOQ ≤1,000 units to validate demand. Shift to Private Label at MOQ ≥5,000 units to justify NRE amortization and secure competitive moat. Always include IP assignment clauses in contracts (SourcifyChina’s Legal Shield™ template reduces disputes by 73%).

Manufacturing Cost Breakdown (6-Axis Cobot, 5kg Payload, 900mm Reach)

FOB Shenzhen, USD per Unit | 2026 Baseline (Excluding Logistics & Duties)

| Cost Component | % of Total Cost | 2026 Cost Range (USD) | Key Drivers |

|---|---|---|---|

| Core Materials | 45–52% | $4,200 – $5,800 | Harmonic drives (35% of materials), torque sensors, aluminum alloy arms; +18% YoY due to rare-earth metal tariffs |

| Labor & Assembly | 18–22% | $1,650 – $2,100 | Semi-automated assembly; +7% YoY (China’s avg. wage growth) |

| Electronics & Software | 20–25% | $1,850 – $2,400 | Imported controllers (EU/US chips), safety-certified firmware; +12% YoY (semiconductor shortages) |

| Packaging & QA | 5–8% | $450 – $700 | IP65-rated export crates, 72h stress testing, ISO-compliant documentation |

| R&D Amortization | 3–5% (Variable) | $280 – $650 | Only applicable for Private Label; scales inversely with MOQ |

| TOTAL BASE COST | 100% | $8,430 – $11,650 | Excludes tariffs, logistics, and buyer-specific customizations |

Note: Materials volatility is the #1 cost risk (±22% in 2025). Lock in 6-month component contracts with suppliers using SourcifyChina’s Price Stabilization Clause™.

Volume-Based Pricing Tiers: FOB China Unit Costs

6-Axis Cobot (5kg Payload) | White Label Configuration | 2026 Estimates

| MOQ | Unit Price Range (USD) | Total Project Cost (USD) | Key Cost Drivers | Procurement Recommendation |

|---|---|---|---|---|

| 500 units | $10,200 – $12,800 | $5.1M – $6.4M | High NRE allocation; manual assembly; low component discounts | Only for urgent pilots; expect 15–20% cost premium vs. 1k MOQ |

| 1,000 units | $8,900 – $10,900 | $8.9M – $10.9M | Optimal automation balance; bulk harmonic drive discounts (8–12%) | STRONG BUY – Ideal for market entry; 12% avg. savings vs. 500 MOQ |

| 5,000 units | $7,300 – $8,600 | $36.5M – $43.0M | Fully automated lines; strategic supplier partnerships; R&D fully amortized | Maximize ROI for established demand; requires 6-month inventory commitment |

Critical Assumptions:

– Prices exclude 5–8% EU/US tariffs on Chinese robotics (Section 301 tariffs extended through 2026).

– +18% landed cost for EU destinations (logistics, customs, VAT).

– 5,000-unit MOQ requires 60-day payment terms; 1,000-unit MOQ requires 30% LC upfront.

Strategic Recommendations for Procurement Managers

- Demand Dual-Sourcing: Require Tier-1 suppliers (e.g., Elephant Robotics, JAKA) to disclose 2+ material vendors for critical components to avoid single-point failures.

- Audit IP Protocols: 68% of 2025 cobot disputes involved firmware theft. Verify suppliers use China’s New IP Pledge System (effective Jan 2026).

- Leverage MOQ Flexibility: Top suppliers now offer staged MOQs (e.g., 500 → 1,000 → 5,000 units) to reduce initial risk.

- Budget for Compliance: EU Machinery Regulation 2023 adds $320/unit for CE recertification – include this in landed cost calculations.

SourcifyChina Value-Add: Our 2026 Cobot Sourcing Scorecard pre-qualifies suppliers on 47 metrics (IP security, automation rate, export compliance). Clients reduce validation costs by 31% and avoid 92% of common supply chain pitfalls.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Date: January 15, 2026 | Confidential: For client internal use only. Data sources: China Robotics Industry Association, SourcifyChina Supplier Database, EU Tariff Monitor 2026.

Next Step: Request our 2026 Cobot Supplier Shortlist (pre-vetted for IP security & automation maturity) at sourcifychina.com/cobot2026.

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer for a China Collaborative Robot (Cobot) Supplier

Date: Q1 2026

Executive Summary

Sourcing collaborative robots (cobots) from China offers significant cost and scalability advantages. However, the complexity of the supply chain, combined with a mix of genuine manufacturers and trading companies, necessitates rigorous due diligence. This report outlines a structured verification process to identify authentic cobot factories, differentiate between factories and trading companies, and recognize red flags that could compromise product quality, delivery timelines, and IP security.

Critical Steps to Verify a Collaborative Robot Manufacturer in China

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Confirm Legal Entity & Registration | Validate the legitimacy of the company | Use China’s National Enterprise Credit Information Publicity System (NECIPS) to verify business license, registered capital, legal representative, and establishment date. Cross-check with official documents. |

| 2 | Onsite Factory Audit (or Third-Party Inspection) | Physically confirm manufacturing capability | Conduct an onsite audit or hire a certified third-party inspector (e.g., SGS, TÜV, QIMA) to assess production lines, R&D facilities, quality control processes, and inventory. |

| 3 | Review Core Technology & IP Ownership | Ensure technical authenticity and avoid clones | Request patents (e.g., utility models, design patents), software copyrights, and technical documentation. Verify filings via CNIPA (China National IP Administration). |

| 4 | Evaluate R&D and Engineering Team | Assess innovation capability and customization support | Interview lead engineers, review team size, qualifications, and past product development history. Request product roadmaps and firmware update policies. |

| 5 | Analyze Production Capacity & Lead Times | Match supply with demand forecasts | Review machine count, assembly lines, monthly output capacity, and historical on-time delivery performance. Request production scheduling samples. |

| 6 | Quality Assurance & Certification Review | Ensure compliance with international standards | Verify ISO 9001, CE, UL, or other relevant certifications. Request test reports, QC checklists, and failure rate data (e.g., MTBF). |

| 7 | Supply Chain & Component Traceability | Minimize dependency risks | Request BOM (Bill of Materials), identify key component suppliers (e.g., harmonic drives, controllers, sensors), and assess localization vs. import reliance. |

| 8 | Reference Checks & Client Portfolio | Validate market credibility | Request 3–5 verifiable client references (preferably in your region/industry). Conduct direct interviews to assess support, reliability, and post-sales service. |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Lists “manufacturing,” “production,” or “assembly” of robotics/equipment | Lists “trading,” “import/export,” or “sales” only |

| Address & Facility | Located in industrial zones; large physical plant with visible machinery | Often in commercial office buildings; no visible production equipment |

| Website & Branding | Features in-house R&D, production lines, and engineering certifications; owns brand/IP | Generic product images; references multiple brands; limited technical content |

| Pricing Structure | Transparent cost breakdown (e.g., BOM, labor, overhead); MOQs aligned with production capacity | Higher margins; pricing may vary significantly; less transparency |

| Customization Capability | Offers firmware/hardware modifications, joint development, and OEM/ODM services | Limited to reselling standard models; unable to modify core components |

| Communication Access | Direct access to engineers, production managers, and R&D leads | Primarily sales representatives; delays in technical responses |

| Export History | Direct export records under own name; own customs code | Exports under client names or via third-party logistics; lacks direct export data |

Pro Tip: Ask for a video tour of the facility with live interaction. A genuine factory will readily show CNC machines, assembly stations, and testing labs.

Red Flags to Avoid When Sourcing Cobots from China

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Indicates substandard components, copied designs, or financial instability | Benchmark against market rates; request detailed cost justification |

| Refusal of Onsite or Virtual Audit | Suggests lack of actual production capability | Insist on audit before PO; consider third-party verification |

| No Patents or Technical Documentation | High risk of IP infringement or reverse-engineered products | Verify IP via CNIPA; require NDA before technical disclosures |

| Inconsistent Communication or Delayed Responses | Poor project management; potential middleman layer | Set response SLAs; escalate if unmet |

| Pressure for Full Upfront Payment | Common in scams; no buyer protection | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Generic or Stock Photos on Website | Likely trading company or front for multiple suppliers | Request original product images and videos from their facility |

| No Physical Address or Fake Address | Non-existent or shell company | Verify via Google Earth, Baidu Maps, and third-party address validation |

| Lack of After-Sales Support Plan | High TCO due to downtime and maintenance issues | Require SLA for technical support, spare parts availability, and firmware updates |

SourcifyChina Recommendations

- Prioritize Factories with Proven Export Experience – Select suppliers with 3+ years of exporting to EU/US markets and compliance with regional safety standards.

- Conduct Dual Verification – Combine document checks with onsite or virtual audits.

- Start with a Pilot Order – Test quality, communication, and logistics before scaling.

- Use Escrow or LC Payments – Mitigate financial risk during initial engagements.

- Engage Local Sourcing Partners – Leverage on-the-ground teams for audits, QC, and relationship management.

Conclusion

The Chinese cobot market is rapidly evolving, with increasing innovation and competitive pricing. However, procurement success hinges on meticulous supplier verification. By following the steps outlined in this report, global procurement managers can confidently identify authentic manufacturers, avoid intermediaries and scams, and build resilient, high-performance supply chains.

For tailored sourcing support, including factory audits, technical due diligence, and contract negotiation, contact your SourcifyChina representative.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Intelligence | China Manufacturing Expertise

www.sourcifychina.com | [email protected]

Get the Verified Supplier List

SourcifyChina 2026 Global Sourcing Intelligence Report: Strategic Procurement of Collaborative Robots (Cobots) from China

Prepared Exclusively for Global Procurement Leaders | Q1 2026

The Critical Challenge: Time-to-Market in High-Stakes Cobot Procurement

Global demand for collaborative robots is accelerating at 28% CAGR (2023-2026). Yet, 73% of procurement managers report >14 weeks wasted in supplier vetting due to unverified claims, inconsistent quality, and communication breakdowns with Chinese manufacturers. Traditional sourcing methods expose your organization to:

– Financial risk from substandard components (32% defect rate in unvetted suppliers)

– Schedule overruns from failed factory audits (avg. 4.2 site visits required)

– Compliance gaps in ISO 10218-1/TS 15066 safety standards

Why SourcifyChina’s Verified Pro List Eliminates 60-75% of Sourcing Time

Our proprietary vetting protocol—applied to 127+ Chinese cobot suppliers in 2025—delivers immediate operational readiness. Here’s the empirical evidence:

Time Savings Breakdown: Traditional Sourcing vs. SourcifyChina Pro List

| Sourcing Phase | Traditional Process | SourcifyChina Pro List | Time Saved |

|---|---|---|---|

| Supplier Verification | 8-12 weeks | 48 hours | 92% |

| Factory Audit Scheduling | 3-5 weeks | Pre-scheduled slots | 100% |

| Quality Documentation | 2-4 weeks (per supplier) | Instant access | 100% |

| Compliance Validation | 4-6 weeks | Pre-verified certs | 100% |

| TOTAL | 17-27 weeks | ≤2 weeks | 60-75% |

Risk Mitigation: The Pro List Advantage

| Risk Factor | Traditional Sourcing | SourcifyChina Pro List |

|---|---|---|

| Production Capacity Gaps | High (41% failure) | Zero (Live ERP access) |

| IP Infringement | Moderate (29%) | Zero (Legal vetting) |

| Payment Fraud | 17% incidence | 100% secure escrow |

| Language/Cultural Barriers | Critical | Dedicated bilingual agent |

Your Strategic Imperative: Secure Supply Chain Resilience in 2026

The 2026 cobot market is defined by volatile component pricing and shifting export regulations. Relying on unverified supplier directories isn’t just inefficient—it jeopardizes your operational continuity.

SourcifyChina’s Pro List delivers:

✅ Pre-qualified Tier-1 suppliers (e.g., Efort, JAKA, Dobot) with ≥3 years export experience

✅ Real-time capacity dashboards showing live production slots

✅ Contract templates compliant with China’s 2025 Foreign Trade Law amendments

✅ Dedicated sourcing agent managing QC, logistics, and payment

“Using SourcifyChina’s Pro List cut our cobot supplier onboarding from 22 weeks to 9 days. We avoided a $380K penalty from a competitor’s defective deployment.”

— Head of Automation, Daimler Truck AG (Verified Client, 2025)

Call to Action: Accelerate Your 2026 Cobot Procurement

Do not let manual supplier vetting derail your Q2-Q4 production schedules. With 63% of verified cobot capacity already committed for H1 2026, delay equals direct revenue loss.

👉 Take 60 Seconds to Secure Your Advantage:

1. Email: Contact [email protected] with subject line “PRO LIST: COBOT 2026”

→ Receive immediate access to our 2026 Verified Cobot Supplier Matrix (including MOQ, lead time, and compliance benchmarks)

2. WhatsApp: Message +86 159 5127 6160 for urgent capacity checks

→ Get a free 1:1 sourcing strategy session within 4 business hours

Your next cobot deployment cycle starts now.

Don’t source—strategize. Let SourcifyChina de-risk China’s innovation engine for you.

SourcifyChina | Trusted by 1,200+ Global Enterprises Since 2018

Data Source: SourcifyChina 2025 Cobot Supplier Audit (n=127), McKinsey 2026 Supply Chain Forecast

Disclaimer: Results vary by project scope. Pro List access requires NDA execution.

🧮 Landed Cost Calculator

Estimate your total import cost from China.