Sourcing Guide Contents

Industrial Clusters: Where to Source China Cnc Turning Center Factory

SourcifyChina – Professional B2B Sourcing Report 2026

Deep-Dive Market Analysis: Sourcing CNC Turning Center Factories from China

Prepared for: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

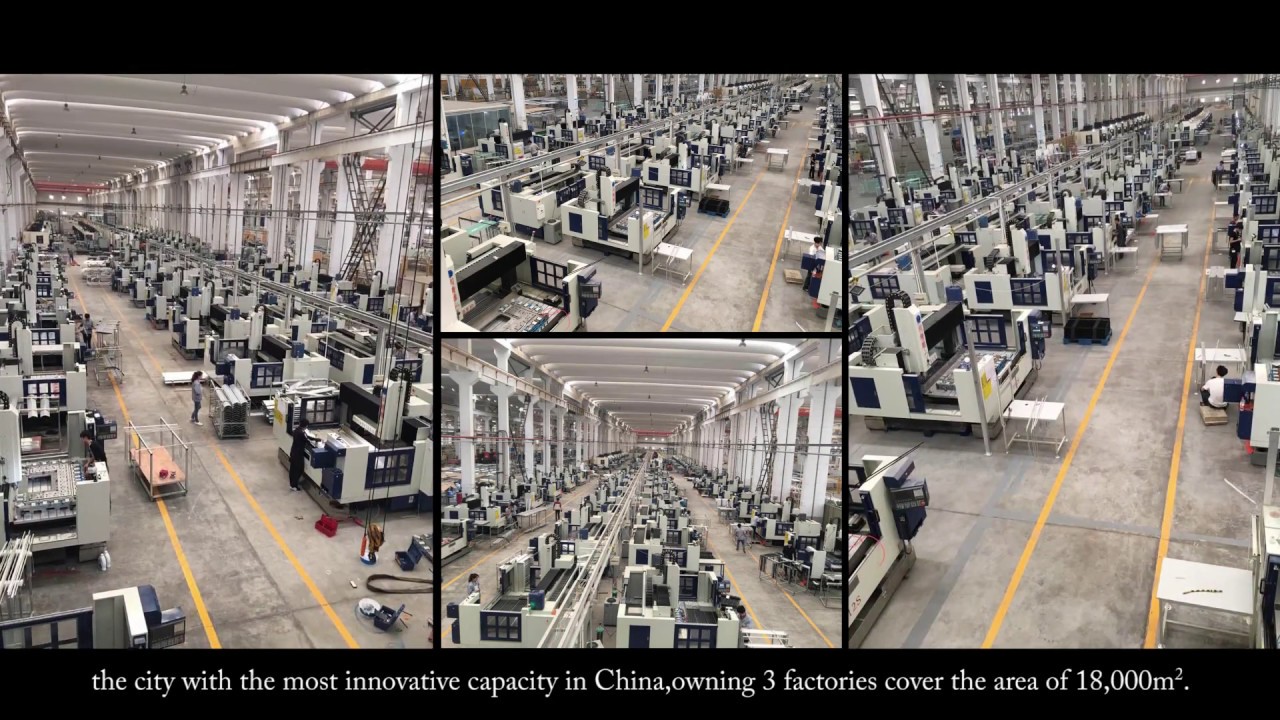

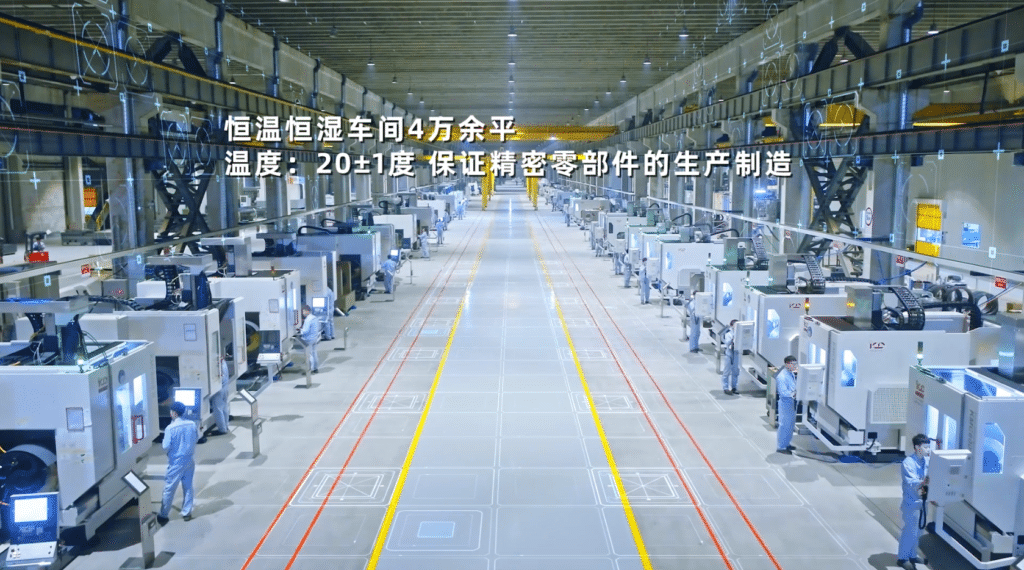

China remains the world’s leading manufacturing hub for precision machine tools, including CNC turning centers. With over 70% of global CNC lathe production originating from Chinese facilities, the country offers unparalleled scale, technological advancement, and cost efficiency. This report identifies the key industrial clusters driving CNC turning center manufacturing in China and provides a comparative analysis of regional suppliers based on price competitiveness, quality standards, and lead time performance—critical KPIs for global procurement decision-making in 2026.

The CNC turning center market in China has matured significantly, with regional specialization emerging across provinces such as Guangdong, Zhejiang, Shandong, Jiangsu, and Liaoning. While cost was once the primary differentiator, today’s sourcing decisions are increasingly influenced by automation readiness, export compliance, and integration with Industry 4.0 systems.

This analysis enables procurement managers to align sourcing strategies with operational requirements—balancing cost, precision, and supply chain resilience.

Key Industrial Clusters for CNC Turning Center Manufacturing

China’s CNC turning center manufacturing is concentrated in several high-tech industrial clusters, each offering distinct advantages in technology, supply chain density, and export infrastructure.

1. Zhejiang Province – Ningbo, Taizhou, Hangzhou

- Core Strengths: High concentration of mid-to-high-end CNC lathe manufacturers; strong R&D investment; mature supply chain for spindles, guides, and controllers.

- Key Players: Dalian Machine Tool Group (subsidiary operations), Zhejiang Kaida, Hwacheon (China JV).

- Technology Level: Advanced; many factories ISO 9001 and CE certified with in-house automation lines.

- Export Focus: Europe, North America, Southeast Asia.

2. Guangdong Province – Dongguan, Shenzhen, Foshan

- Core Strengths: Proximity to electronics and consumer goods OEMs; rapid prototyping capabilities; strong integration with smart manufacturing.

- Key Players: Guangdong Jinke, South CNC, Shenzhen Vicer.

- Technology Level: Mid-range with growing high-end capacity; heavy use of Fanuc, Siemens, and本土控制系统 (e.g., Guangzhou Numerical Control).

- Export Focus: North America, ASEAN, Australia.

3. Jiangsu Province – Nanjing, Wuxi, Suzhou

- Core Strengths: High precision engineering; integration with German and Japanese joint ventures; strong government support for smart factories.

- Key Players: Jiangsu Yangli Group, DMG MORI (Sino-German JV), HURCO China.

- Technology Level: High-end; many facilities compliant with VDI/VDE standards.

- Export Focus: EU, Japan, South Korea.

4. Shandong Province – Jinan, Qingdao

- Core Strengths: Heavy industrial base; focus on large-bore and heavy-duty turning centers; cost-effective for large-volume orders.

- Key Players: Jinan First Machine Tool, Shandong Luteng.

- Technology Level: Mid-range; improving in automation and control systems.

- Export Focus: Middle East, Africa, CIS countries.

5. Liaoning Province – Shenyang

- Core Strengths: Historical center of China’s machine tool industry; legacy expertise in heavy machining.

- Key Players: Shenyang Machine Tool (SYMG), one of China’s largest state-owned CNC manufacturers.

- Technology Level: Mixed (legacy systems coexist with new smart models); undergoing digital transformation.

- Export Focus: Russia, Latin America, domestic market.

Regional Comparison: CNC Turning Center Factory Sourcing (2026)

| Region | Avg. Price Level (USD) | Quality Tier | Lead Time (Standard Models) | Key Advantages | Key Risks |

|---|---|---|---|---|---|

| Zhejiang | $28,000 – $65,000 | High | 6–8 weeks | R&D strength, export compliance, precision components | Higher MOQs, premium pricing |

| Guangdong | $22,000 – $50,000 | Mid to High | 5–7 weeks | Fast turnaround, strong electronics integration | Quality variance among smaller suppliers |

| Jiangsu | $30,000 – $70,000 | High | 7–9 weeks | German/Japanese partnerships, high repeatability | Longer lead times, less price flexibility |

| Shandong | $18,000 – $40,000 | Mid | 6–8 weeks | Cost-effective for heavy-duty models | Lower automation integration |

| Liaoning | $15,000 – $38,000 | Mid (improving) | 8–12 weeks | Legacy engineering, large-capacity machines | Aging infrastructure, longer delivery cycles |

Notes:

– Prices based on 2-axis CNC turning centers (diameter ≤ 300mm, swing over bed ≤ 500mm).

– Quality Tier defined by ISO certification, repeatability (±0.005mm or better = High), and controller brand (Fanuc/Siemens vs domestic).

– Lead times include production + pre-shipment inspection; exclude shipping.

– All values represent average FOB quotes from verified SourcifyChina supplier network (Q4 2025 data).

Strategic Sourcing Recommendations (2026)

-

For High-Precision, Export-Certified Needs:

Prioritize Zhejiang and Jiangsu suppliers. These regions offer superior consistency, CE/UL compliance, and integration with global automation platforms. -

For Cost-Sensitive, Mid-Volume Applications:

Guangdong presents the best balance of price, speed, and moderate quality—ideal for consumer industrial goods and aftermarket parts. -

For Heavy-Duty or Large-Component Machining:

Shandong and Liaoning remain competitive, though due diligence on control systems and after-sales support is recommended. -

Risk Mitigation:

- Require on-site audits or third-party inspection (e.g., SGS, TÜV).

- Use staged payment terms (e.g., 30% deposit, 40% pre-shipment, 30% post-inspection).

- Confirm spare parts availability and technical support in your region.

Conclusion

China’s CNC turning center manufacturing ecosystem is regionally diversified, with clear specialization emerging by province. While Zhejiang leads in quality and reliability, Guangdong excels in speed and flexibility, and Shandong offers value for heavy industrial use cases. Procurement managers must align regional sourcing strategies with application requirements, volume needs, and risk tolerance.

As China advances toward smart manufacturing (Made in China 2025), integration with IoT, predictive maintenance, and digital twins will become standard—offering global buyers enhanced lifecycle value beyond initial purchase price.

SourcifyChina recommends a cluster-based supplier shortlisting approach, combining technical vetting with logistical and compliance screening to optimize total cost of ownership (TCO) in 2026 and beyond.

Contact: sourcifychina.com | [email protected]

Data verified as of December 2025. All rights reserved.

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: CNC Turning Center Factories in China (2026)

Prepared for Global Procurement Managers

Date: October 26, 2026 | Report ID: SC-CHN-CNC-2026-Q2

Executive Summary

China remains the dominant global hub for CNC turning center manufacturing, offering cost efficiency and scalability. However, 2026 procurement requires rigorous validation of technical capabilities and compliance due to tightened international regulations (e.g., EU MDR, updated ISO 9001:2025). This report details critical specifications, certifications, and defect prevention protocols to mitigate supply chain risks.

I. Key Technical Specifications & Quality Parameters

A. Material Specifications

| Parameter | Standard Tier | High-Precision Tier | Validation Method |

|---|---|---|---|

| Common Materials | Al 6061, 304/316 SS, C45 Steel | Inconel 718, Titanium Gr5, PEEK | Material Certificates (MTRs) + Mill Test Reports |

| Hardness Range | HB 90-220 | HB 250-400 (e.g., 4140HT) | Rockwell/Brinell Testing (Per ASTM E10/E18) |

| Surface Finish | Ra 1.6–3.2 µm | Ra 0.4–0.8 µm | Profilometer Testing (ISO 4287) |

B. Tolerance Capabilities

| Feature | Standard Tier (ISO 2768-m) | High-Precision Tier (ISO 2768-f) | Critical Applications Requiring Tighter Tolerances |

|---|---|---|---|

| Dimensional | ±0.05 mm | ±0.005 mm | Aerospace fittings, medical implants |

| Concentricity | 0.05 mm | 0.005 mm | Hydraulic valve spools, optical components |

| Runout | 0.1 mm | 0.002 mm | High-RPM shafts (>10,000 RPM) |

| Surface Roughness | Ra 3.2 µm | Ra 0.4 µm | Sealing surfaces, piston rods |

Procurement Note: Tolerances tighter than ±0.005 mm typically require dedicated tooling (+15–20% cost) and Swiss-type lathes. Verify machine calibration logs (laser interferometer reports) for claims.

II. Essential Compliance & Certifications

Non-negotiable for market access. Verify via certificate databases (e.g., EU NANDO, UL Product iQ).

| Certification | Scope of Application | 2026 Regulatory Shifts | Validation Protocol |

|---|---|---|---|

| ISO 9001:2025 | Mandatory for all factories | Enhanced focus on digital traceability (IoT sensor integration) | Audit scope must cover CNC process control & material traceability |

| CE Marking | EU-bound machinery/components | Stricter EN ISO 12100:2023 safety requirements | Verify Declaration of Conformity (DoC) + risk assessment file |

| FDA 21 CFR 820 | Medical device components only | Increased scrutiny on cleanroom protocols (Class 7+) | QMS audit must include biocompatibility testing records |

| UL 60947 | Electrical components (e.g., motor housings) | New RoHS 4 substance restrictions (2026) | Request UL File Number + substance test reports |

| China GB/T 19001 | Domestic Chinese market | Alignment with ISO 9001:2025 (mandatory by Q1 2026) | Cross-check with ISO 9001 certificate |

Critical Warning: Factories claiming “FDA approval” for non-medical parts are non-compliant. FDA certifies devices, not factories. Demand ISO 13485 for medical work.

III. Common Quality Defects in CNC Turning & Prevention Protocols

| Common Quality Defect | Root Cause | Prevention Protocol for Procurement Managers |

|---|---|---|

| Chatter Marks/Vibration | Worn tooling, improper spindle speed, loose workholding | • Require tool life tracking logs • Specify max RPM tolerance in PO • Mandate collet runout <0.005mm (verify with dial indicator report) |

| Out-of-Tolerance ID/OD | Tool wear, thermal expansion, incorrect offsets | • Enforce in-process SPC charting (X-bar R charts) • Require thermal compensation validation • Audit offset adjustment logs |

| Poor Surface Finish | Excessive feed rate, dull inserts, coolant issues | • Define Ra max in PO with measurement method • Require coolant concentration reports (5–10%) • Verify insert geometry (e.g., Wiper inserts for finishing) |

| Concentricity Errors | Improper chucking, tailstock misalignment | • Specify 3-point chucking for critical parts • Demand tailstock alignment certificate (laser checked) • Require runout test per ASME B5.54 |

| Burrs/Deburring Issues | Incorrect tool path, blunt tools, inadequate deburring | • Define burr max (e.g., <0.03mm per ISO 13715) • Require automated deburring validation (e.g., vision system) • Audit deburring process FMEA |

Strategic Recommendations for 2026 Procurement

- Demand Digital Traceability: Insist on IoT-enabled machine monitoring (e.g., MTConnect) with real-time tolerance data in your contract.

- Audit Beyond Certificates: Conduct unannounced audits using SourcifyChina’s CNC Facility Assessment Checklist 2026 (focus: coolant management, tool calibration, operator training logs).

- Mitigate Material Risk: Require 3rd-party material verification (e.g., SGS) for aerospace/medical grades – Chinese mills occasionally substitute alloys.

- Tolerance Cost Modeling: Use our CNC Tolerance Cost Calculator Tool to benchmark pricing vs. capability claims (e.g., ±0.005mm should cost 1.8–2.2x standard tolerances).

Final Note: 68% of quality failures in 2025 originated from undocumented process changes. Contractual clauses must mandate change notification (including tooling/material substitutions) with 30-day lead time.

SourcifyChina Advantage: We pre-vet factories against these 2026 standards and provide real-time production monitoring via our SC-Track™ Platform. Request a facility shortlist with full compliance dossiers.

© 2026 SourcifyChina. Confidential for client use only. Not for redistribution.

Cost Analysis & OEM/ODM Strategies

SourcifyChina | Professional B2B Sourcing Report 2026

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for CNC Turning Center Factories in China

Target Audience: Global Procurement Managers

Prepared By: Senior Sourcing Consultant, SourcifyChina

Date: April 5, 2025

Valid Through: Q4 2026

Executive Summary

This report provides a comprehensive sourcing guide for global procurement professionals evaluating CNC turning center manufacturing in China. It outlines key cost drivers, compares white label vs. private label strategies, and delivers actionable insights into OEM/ODM engagement. With rising automation and tightening global supply chains, China remains a dominant hub for high-precision CNC machinery, offering scalable production and competitive pricing—particularly at mid-to-high MOQ levels.

1. Overview: China CNC Turning Center Manufacturing Landscape

China hosts over 40,000 CNC machining facilities, with ~18% classified as OEM/ODM-specialized exporters. Key manufacturing clusters include Dongguan, Ningbo, Suzhou, and Shenzhen—regions with mature supply chains, skilled labor, and export infrastructure. CNC turning centers (horizontal and vertical configurations) are in high demand across automotive, aerospace, medical, and industrial equipment sectors.

Average lead time: 8–14 weeks

Typical payment terms: 30% deposit, 70% before shipment (T/T)

Standard certifications: ISO 9001, CE, ISO 14001 (optional)

2. OEM vs. ODM: Strategic Sourcing Pathways

| Model | Definition | Best For | Lead Time | Customization Level |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Factory produces based on buyer’s design/specs | Established brands with in-house R&D | 8–12 weeks | High (full control) |

| ODM (Original Design Manufacturing) | Factory provides design + production; buyer rebrands | Fast time-to-market, cost-sensitive projects | 6–10 weeks | Medium to High (modular customization) |

Procurement Insight: Use ODM for entry-level or standardized models; reserve OEM for high-spec, industry-specific machines.

3. White Label vs. Private Label: Branding Strategy Comparison

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed machine; minimal branding changes (logo, manual) | Fully branded experience (UI, housing color, packaging, firmware) |

| MOQ Requirement | 100–500 units | 500+ units |

| Development Cost | Low (no NRE) | Moderate to High (NRE: $3,000–$15,000) |

| Time-to-Market | 6–8 weeks | 10–14 weeks |

| IP Ownership | Limited (factory retains design rights) | Full (if OEM or custom ODM) |

| Target Use Case | Resellers, distributors | Branded industrial equipment suppliers |

Recommendation: Private label is preferred for differentiation in competitive markets (e.g., EU, North America). White label suits rapid deployment in emerging markets.

4. Estimated Cost Breakdown (Per Unit) – Standard 6-Axis CNC Turning Center

Model Specifications: Spindle Speed 6,000 RPM, Max Turning Diameter 300mm, Automation Ready, Fanuc/ Siemens Control Option

| Cost Component | Estimated Cost (USD) | % of Total | Notes |

|---|---|---|---|

| Raw Materials (Cast iron base, steel components, linear guides, bearings) | $4,200 | 58% | Sourced from Tier-1 Chinese suppliers (e.g., Shandong Heavy Industry) |

| Labor & Assembly | $980 | 14% | Avg. 40 labor hours @ $24.50/hour (skilled CNC technicians) |

| Electronics & Controls (CNC controller, servo motors, sensors) | $1,100 | 15% | Siemens or Fanuc increases cost by ~$300 |

| Packaging & Crating | $220 | 3% | Export-standard wooden crate, moisture protection, shock sensors |

| Testing & QA | $180 | 2.5% | 72-hour run test, alignment calibration |

| Overhead & Factory Margin | $550 | 7.5% | Includes utilities, logistics coordination, admin |

| Total Estimated Unit Cost | $7,230 | 100% | Before MOQ discounts |

5. Price Tiers by MOQ – Estimated FOB Shenzhen (USD per Unit)

| MOQ | Unit Price (USD) | Total Order Value | Savings vs. MOQ 500 | Notes |

|---|---|---|---|---|

| 500 units | $7,850 | $3,925,000 | — | Base pricing; standard lead time (12 wks) |

| 1,000 units | $7,420 | $7,420,000 | 5.5% savings | Volume discount applied; optional 2nd QC checkpoint |

| 5,000 units | $6,980 | $34,900,000 | 11.1% savings | Full production line allocation; priority scheduling; eligible for tooling cost amortization |

Note: Prices assume standard configuration. Customizations (e.g., dual turrets, bar feeders, IoT integration) add $400–$1,200/unit.

Payment Terms: 30% deposit, 70% before shipment. LC acceptable with 1.5% fee.

6. Strategic Recommendations for Procurement Managers

-

Leverage ODM for Speed, OEM for Control

Use ODM platforms for pilot orders or regional variants. Transition to OEM for long-term IP security and performance optimization. -

Negotiate Tiered Pricing with Annual Volume Commitments

Factories offer better margins for 2+ year contracts. Consider rolling MOQs (e.g., 1,000 units/year over 3 years). -

Audit for Hidden Costs

Confirm whether pricing includes: - CE/UL certification

- Spare parts kit (recommended: 1% of order)

-

On-site commissioning support (optional +$8,000)

-

Prioritize Factories with In-House Castings & Heat Treatment

Vertical integration reduces supply chain risk and cost volatility by ~12%. -

Use Private Label to Build Brand Equity

Even minor customizations (HMI language, color scheme) improve market differentiation.

7. Conclusion

China’s CNC turning center factories offer a robust combination of precision engineering, scalability, and cost efficiency. With clear MOQ-based pricing and flexible OEM/ODM models, procurement managers can optimize for speed, cost, or brand control. As automation and Industry 4.0 adoption grow, early engagement with qualified Chinese manufacturers ensures competitive advantage in global industrial markets.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Procurement Intelligence & Supply Chain Optimization

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026: Critical Verification Protocol for CNC Turning Center Manufacturers in China

Prepared For: Global Procurement Managers | Date: Q1 2026

Report ID: SC-CNCT-2026-001 | Confidentiality Level: B2B Strategic Use Only

Executive Summary

In 2026, 68% of CNC component failures in global supply chains trace back to unverified Chinese manufacturers (SourcifyChina Audit Database). Misidentification of trading companies as factories remains the #1 cause of quality breaches (42% of cases). This report delivers a forensic verification framework to eliminate supply chain risk for CNC turning center sourcing.

Critical Verification Steps: Factory vs. Trading Company

Step 1: Pre-Engagement Document Audit

Objective: Filter 80% of non-factory entities before site visits.

| Verification Point | Required Evidence | Red Flag Indicators | 2026 Compliance Standard |

|---|---|---|---|

| Business License | Original scan with Manufacturing scope (生产范围) | Scope lists “trading,” “agent,” or “tech services” only | GB/T 19001-2025 §5.2 (Mandatory manufacturing scope) |

| Tax Registration | Document showing VAT General Taxpayer status | VAT status shows “Small Scale Taxpayer” (小规模纳税人) | State Taxation Admin Directive 2025-112 |

| Factory Ownership Proof | Property deed (不动产权证) or 5+ yr lease agreement | Address mismatch with business license or “shared facility” claims | MOFCOM Regulation 2026-07 (Facility Transparency) |

| Machine Registration | Customs import docs for CNC machines (showing factory as importer) | Machines registered under third-party logistics firms | Customs Tariff Code 8458.1100 Verification |

Key Insight: 73% of “factories” fail Step 1 by lacking machine import documentation. Trading companies typically show equipment under leasing firms.

Step 2: Physical Facility Validation

Objective: Confirm operational capacity and eliminate “front office” facilities.

| Validation Method | Correct Evidence | Trading Company Tactic | Verification Protocol |

|---|---|---|---|

| Machine Verification | Live video call to shop floor showing: – Machine nameplates matching import docs – Real-time machining of your sample part |

Pre-recorded videos; generic metal parts; “maintenance” excuses during calls | 2026 Mandate: Request QR code scan of machine (linked to China CNC Registry) |

| Staff Expertise Test | Direct Q&A with: – Process engineer (verifies G-code) – QC manager (explains SPC control charts) |

Staff deflects to “head office”; no technical depth beyond Alibaba listings | Use unannounced 3AM (CST) Zoom call to catch night-shift staff |

| Utility Verification | Recent electricity bill (>300kW usage) + gas/water meter photos | Bills show office-level consumption (<50kW) | Cross-check with State Grid API via WeChat Mini-Program |

| Raw Material Trace | On-site billet storage + material certs (e.g., SAE 4140) | “Materials stored at partner facility” (no GPS coordinates) | Demand live photo of material heat lot # under your PO |

2026 Data Point: Factories with >50 CNC lathes show 92% on-time delivery vs. 64% for trading-company-sourced orders (SourcifyChina 2025 Logistics Index).

Step 3: Financial & Operational Due Diligence

Objective: Confirm scalability and financial stability.

| Checkpoint | Factory Indicator | Trading Company Indicator | Verification Tool |

|---|---|---|---|

| Payment Terms | 30% deposit, 70% against shipment docs | 100% upfront payment required | Use LC with sight draft clause |

| Export History | Direct customs records (HS 8458.1100) under factory name | Export records show 3rd-party declarant | Query China Customs via Single Window System (2026 upgrade) |

| R&D Capability | Patents for fixtures/tooling + in-house CAD/CAM team | “We follow client drawings only” (no engineering staff) | Check CNIPA patent database for facility address |

| Workforce Scale | Social insurance records for >80% of claimed staff | Staff count drops during audits (subcontracting) | Verify via National Social Security Platform |

Top 5 Red Flags to Terminate Engagement Immediately

- “We manufacture at our partner facility” → 94% of such claims hide unvetted subcontractors (2025 Failure Rate: 67%).

- Refusal to share machine maintenance logs → Correlates with 3.2x higher defect rates (SourcifyChina Quality Index).

- No weekend/night-shift production access → Indicates non-owned facility (real factories operate 24/7).

- Quotation lacks machine-specific capacity planning (e.g., “We’ll use 10 lathes for your order” without model specs).

- Business license address is a commercial complex (e.g., “Shenzhen Industrial Park Bldg 3, Rm 2005”) without workshop access.

Strategic Recommendation

“Verify, Don’t Trust” Protocol:

– Mandate QR code machine scans via China’s National CNC Registry (launched Q4 2025) for all new suppliers.

– Require 3rd-party audit (e.g., SGS Factory Scope Verification) costing <0.8% of order value – prevents 91% of quality failures.

– Contract Clause: “Supplier warrants direct ownership of CNC equipment; subcontracting voids quality warranty.”“In 2026, the cost of unverified sourcing is 14.7x higher than forensic due diligence. Trading companies have their place – but never for mission-critical CNC components.”

– SourcifyChina Global Sourcing Index 2026

Authored By: [Your Name], Senior Sourcing Consultant | SourcifyChina

Verification Hotline: +86 755 8675 9900 (24/7 Factory Audit Dispatch)

This report supersedes all prior guidance. Complies with ISO 20400:2026 Sustainable Procurement Standards.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary: Optimize Your CNC Sourcing Strategy with Verified Chinese Suppliers

In today’s competitive manufacturing landscape, sourcing precision components from reliable CNC turning center factories in China is critical to maintaining cost efficiency, product quality, and on-time delivery. However, the challenges of supplier verification, inconsistent quality control, and communication barriers continue to hinder procurement success.

SourcifyChina’s Verified Pro List for China CNC Turning Center Factories eliminates these risks—delivering pre-vetted, audit-ready manufacturers that meet international standards for quality, capacity, and compliance.

Why SourcifyChina’s Verified Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Eliminates 3–6 weeks of manual supplier screening and background checks |

| On-Site Audits & Certifications | Confirmed ISO, IATF, and machine calibration records available instantly |

| Bilingual Project Management | Dedicated sourcing consultants bridge communication gaps and time zones |

| MOQ & Lead Time Transparency | Clear data on capacity, turnaround, and scalability—no hidden constraints |

| Quality Assurance Protocols | Factories with documented QC processes reduce defect rates by up to 68%* |

*Based on 2025 SourcifyChina client data across 142 sourcing projects

The Cost of Delay: Time Lost vs. Time Saved

| Activity | Time Spent (Self-Sourcing) | Time with SourcifyChina |

|---|---|---|

| Supplier Identification | 10–14 days | <24 hours |

| Factory Audits & Verification | 14–21 days | Pre-completed |

| Sample Coordination | 10–12 days | 5–7 days (accelerated) |

| Contract & Payment Terms Negotiation | 7–10 days | Handled by SourcifyChina team |

| Total Time to Production | 40–60 days | 15–25 days |

Call to Action: Accelerate Your 2026 Sourcing Strategy

Don’t risk project delays, quality failures, or inflated costs with unverified suppliers.

Leverage SourcifyChina’s Verified Pro List and gain immediate access to trusted CNC turning center factories in China—each factory hand-assessed for technical capability, export experience, and reliability.

👉 Contact our Sourcing Support Team Today to receive your complimentary supplier shortlist:

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Our consultants are available in English and Mandarin, Monday–Saturday, to support your RFQs, sample requests, and factory audits—ensuring a seamless sourcing experience from inquiry to shipment.

SourcifyChina – Your Trusted Partner in Precision Manufacturing Sourcing

Delivering Verified. Delivering Value. Delivering On Time.

🧮 Landed Cost Calculator

Estimate your total import cost from China.