Sourcing Guide Contents

Industrial Clusters: Where to Source China Cnc Precision Turning Parts Factory

SourcifyChina B2B Sourcing Report: CNC Precision Turning Parts from China (2026 Outlook)

Prepared for Global Procurement Managers

Date: October 26, 2026 | Report ID: SC-CHN-CNC-TURN-2026-01

Executive Summary

China remains the dominant global hub for CNC precision turning parts (sub-5μm tolerance, multi-axis capabilities), driven by mature industrial ecosystems, cost efficiency, and evolving technical expertise. This report identifies core manufacturing clusters, compares regional strengths, and provides actionable insights for 2026 sourcing strategies. Key trends include automation-driven quality convergence, rising regional specialization, and supply chain resilience imperatives. Procurement managers should prioritize cluster-specific supplier vetting to balance cost, quality, and risk.

Key Industrial Clusters for CNC Precision Turning Parts

China’s precision machining sector is concentrated in four primary clusters, each with distinct advantages:

| Region | Core Cities | Specialization | Key Infrastructure |

|---|---|---|---|

| Guangdong | Dongguan, Shenzhen, Foshan, Zhongshan | High-volume medical devices, consumer electronics, aerospace components | Pearl River Delta logistics hub; 85% of suppliers export via Shenzhen/HK ports |

| Zhejiang | Ningbo, Taizhou, Yuyao, Hangzhou | Automotive systems, hydraulic valves, precision instruments (ISO 13485 focus) | Yangtze River Delta rail network; 70% of suppliers certified to IATF 16949 |

| Jiangsu | Suzhou, Wuxi, Changzhou | Semiconductor equipment parts, optical components, industrial robotics | Proximity to Shanghai port; 60% of suppliers with <0.002mm tolerance capabilities |

| Sichuan | Chengdu, Chongqing | Emerging hub for energy/defense components (lower labor costs, government incentives) | Inland “Belt and Road” logistics corridor; growing Swiss-type lathe adoption |

Note: Guangdong and Zhejiang account for 68% of China’s precision turning exports (2025 customs data). Sichuan is the fastest-growing cluster (+22% YoY capacity), but quality consistency lags.

Regional Comparison: Price, Quality & Lead Time (2026 Projection)

Data sourced from SourcifyChina’s 2025 Supplier Performance Index (SPI) and 12-month client audits. Metrics reflect standard stainless steel 316 turning parts (Ø5-50mm, L/D ≤3:1, ±0.005mm tolerance).

| Region | Price (USD/kg) | Quality Consistency | Avg. Lead Time | Strategic Fit |

|---|---|---|---|---|

| Guangdong | $8.50 – $14.20 | ★★★★☆ • Top 20% suppliers: ISO 13485/AS9100 certified • Batch rejection rate: 0.8% (high-end) |

22-35 days | Best for: High-mix/low-volume medical/aerospace parts Risk: Labor costs +5.2% YoY (2026) |

| Zhejiang | $7.80 – $12.90 | ★★★★☆ • Dominates automotive (IATF 16949 adoption: 89%) • Batch rejection rate: 1.1% (mid-tier) |

18-30 days | Best for: High-volume automotive/industrial systems Risk: Raw material volatility (aluminum +8% YoY) |

| Jiangsu | $9.20 – $15.50 | ★★★★★ • Highest metrology lab density (per sq. km) • Batch rejection rate: 0.5% (semiconductor tier) |

25-40 days | Best for: Ultra-precision semiconductor/optical parts Risk: Premium pricing for <±0.002mm tolerances |

| Sichuan | $6.50 – $10.80 | ★★☆☆☆ • Limited high-end capacity (35% of suppliers) • Batch rejection rate: 2.4% (industry avg.) |

30-45 days | Best for: Cost-sensitive defense/energy components Risk: Logistics delays (inland port congestion) |

Quality Scale: ★ = Entry-level (±0.02mm), ★★★★☆ = High-precision (±0.005mm), ★★★★★ = Ultra-precision (<±0.002mm)

Lead Time Note: Excludes shipping; includes 15-day quality hold for medical/aerospace orders.

Critical Sourcing Insights for 2026

- Quality Divergence Within Clusters:

- 42% of Zhejiang’s suppliers now offer automated SPC (Statistical Process Control), reducing defect rates by 37% vs. manual processes (per SourcifyChina audit data).

-

Action: Require real-time SPC data access in contracts for automotive/medical projects.

-

Price Pressure Shifts:

- Guangdong’s labor costs now exceed Zhejiang’s by 12% (2026 forecast), eroding its volume advantage.

-

Action: For orders >50k units, prioritize Zhejiang suppliers with robotic cells (ROI 18-24 months).

-

Lead Time Risks:

- Jiangsu’s lead times increased 9 days YoY due to semiconductor part demand surges.

-

Action: Secure 30% capacity reservation for Q3-Q4 2026 with written penalties for delays.

-

Emerging Risk: “Green Compliance” Costs

- 76% of EU/US clients now mandate carbon footprint reports (per SourcifyChina Q3 survey).

- Action: Prioritize suppliers in Zhejiang/Jiangsu with ISO 14064 certification (penalties for non-compliance = 8-12% of order value).

Strategic Recommendations

- Medical/Aerospace Buyers: Partner with Guangdong suppliers in Dongguan (e.g., SMTCL Precision) for AS9100-certified lines. Avoid volume-focused factories.

- Automotive Buyers: Target Zhejiang’s Ningbo cluster (e.g., Ningbo Haitian Precision) for IATF 16949 + automated deburring. Audit tool calibration logs quarterly.

- Semiconductor Buyers: Engage Jiangsu’s Suzhou Industrial Park suppliers (e.g., Suzhou AMT) for vibration-controlled clean rooms. Budget 15% premium for sub-2μm tolerances.

- Cost-Sensitive Projects: Use Sichuan for non-critical parts but mandate third-party dimensional reports (cost: +3.5% vs. in-house QA).

Final Note: Cluster selection is necessary but insufficient. 2026 success requires pairing region expertise with SourcifyChina’s 4-Stage Supplier Vetting Protocol (Technical Audit → Capacity Stress Test → Compliance Deep Dive → Dynamic KPI Tracking).

SourcifyChina Commitment: We de-risk China sourcing through data-driven supplier matching, transparent pricing, and on-ground quality assurance. Contact your consultant for a cluster-specific supplier shortlist and 2026 risk mitigation playbook.

© 2026 SourcifyChina. Confidential for client use only. Data sources: China Machine Tool Builders’ Association (CMTBA), SourcifyChina SPI 2025, UN Comtrade.

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report 2026

CNC Precision Turning Parts: Sourcing from China

Target Audience: Global Procurement Managers

Prepared by: Senior Sourcing Consultant, SourcifyChina

Date: Q1 2026

Executive Summary

China remains a dominant supplier of CNC precision turning parts, offering cost-effective manufacturing with scalable capacity. However, ensuring technical precision, material integrity, and compliance with international standards is critical for procurement success. This report outlines key technical specifications, compliance requirements, and a quality control framework to mitigate risk when sourcing from Chinese manufacturers.

1. Key Technical Specifications for CNC Precision Turning Parts

| Parameter | Standard Specification | Notes |

|---|---|---|

| Materials | – Stainless Steel (303, 304, 316, 17-4PH) – Aluminum (6061, 7075) – Brass (C3604, C3771) – Carbon Steel (1018, 1045) – Titanium (Grade 2, 5) – Plastics (POM, PEEK, Delrin) |

Material certification (e.g., MTRs) required for traceability |

| Tolerances | – Standard: ±0.01 mm – Precision: ±0.005 mm – Ultra-Precision: ±0.001 mm (micromachining) |

Tolerance depends on part geometry, material, and machine capability |

| Surface Finish | Ra 0.8 µm (standard) Ra 0.4 µm (fine) Ra 0.2 µm (mirror/polished) |

Measured per ISO 4287; polishing or grinding may be required |

| Maximum Part Size | Diameter: up to 300 mm Length: up to 1000 mm |

Larger parts may require multi-axis or bar-fed lathes |

| CNC Equipment | Swiss-type lathes, multi-axis CNC turning centers (e.g., 5-axis), bar feeders | Machines should support live tooling and Y-axis for complex geometries |

2. Essential Compliance Certifications

| Certification | Scope | Requirement for Procurement? | Notes |

|---|---|---|---|

| ISO 9001:2015 | Quality Management System | Mandatory | Ensures consistent process control and traceability |

| ISO 13485 | Medical Device Quality Management | Required for medical applications | Must be held if supplying to FDA-regulated markets |

| CE Marking | Conformity with EU health, safety, and environmental standards | Required for EU market entry | Applies when parts are integrated into machinery or medical devices |

| FDA Registration | U.S. Food and Drug Administration | Required for medical, food-contact, or pharmaceutical parts | Supplier must be listed in FDA’s FURLS database |

| UL Certification | Safety standards for electrical/electronic components | Conditional | Needed if parts are used in UL-listed equipment |

| RoHS/REACH | Restriction of hazardous substances (EU) | Required for electronics and consumer goods | Ensure material compliance via test reports |

Note: Suppliers must provide valid, unexpired certificates with audit trail and scope matching the product category.

3. Common Quality Defects in CNC Turning Parts and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Incorrect tool calibration, thermal expansion, machine wear | Implement regular machine calibration (daily/weekly), use CNC tool offsets, and conduct first-article inspection (FAI) |

| Surface Scratches/Marks | Improper handling, dull cutting tools, suboptimal feed rate | Use protective fixtures, maintain tool sharpness, optimize cutting parameters (speed/feed) |

| Chatter Marks | Tool vibration due to improper rigidity or setup | Ensure secure workholding, reduce overhang, use dampened tooling, and adjust spindle speed |

| Out-of-Roundness | Poor centering, worn spindle bearings, or material stress | Perform centering checks, monitor spindle runout, and stress-relieve materials pre-machining |

| Burrs/Sharp Edges | Incomplete deburring, incorrect tool path | Implement automated deburring (brushing, tumbling) and validate with edge inspection (microscope) |

| Material Contamination | Mixing of alloys, inadequate cleaning | Enforce strict material segregation, use color-coded bins, and conduct PMI (Positive Material Identification) |

| Cracks or Microfractures | Excessive cutting force, improper heat treatment | Optimize cutting depth, use proper coolant, and verify post-machining heat treatment |

| Thread Defects | Incorrect tap alignment, worn threading tools | Use rigid tapping systems, inspect thread pitch and depth with go/no-go gauges |

4. Recommended Sourcing Best Practices

- Conduct On-Site Audits: Validate certifications, machine maintenance logs, and QC procedures.

- Require PPAP Documentation: Include FAI reports, control plans, and process flow diagrams.

- Enforce Material Traceability: Demand Mill Test Reports (MTRs) with every batch.

- Implement AQL Sampling: Use ANSI/ASQ Z1.4 for incoming inspection (typically AQL 1.0 for critical parts).

- Use Escrow Inspection Services: Third-party inspections (e.g., SGS, TÜV) at shipment.

Conclusion

Procuring CNC precision turning parts from China offers significant cost and scalability advantages. However, technical precision and compliance must not be compromised. Prioritize suppliers with robust ISO certification, transparent quality systems, and documented defect prevention processes. By aligning sourcing criteria with international standards and quality best practices, procurement managers can ensure reliable supply chain performance in 2026 and beyond.

Prepared by: SourcifyChina – Global Sourcing Excellence in Manufacturing

Contact: [email protected] | www.sourcifychina.com

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report:

CNC Precision Turning Parts Manufacturing in China (2026 Outlook)

Prepared for Global Procurement & Supply Chain Executives | Q1 2026

Executive Summary

China remains the dominant global hub for cost-competitive CNC precision turning parts, with continued advancements in automation and quality control systems offsetting moderate labor cost inflation. For 2026, procurement managers should prioritize certified ISO 9001/14001 factories in the Pearl River Delta (Dongguan, Shenzhen, Foshan) to balance cost, quality, and IP protection. Strategic differentiation between White Label and Private Label models is critical for margin optimization and supply chain resilience.

White Label vs. Private Label: Strategic Implications

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Factory’s standard product rebranded with buyer’s logo | Buyer specifies full design, materials, tolerances | Use White Label for non-critical components; Private Label for core IP or high-margin products |

| MOQ Flexibility | Lower MOQs (often 100-500 units) | Higher MOQs (typically 500+ units) | Negotiate tiered MOQs to test supplier capability |

| Cost Structure | Lower unit cost (shared R&D/tooling) | Higher unit cost (dedicated tooling/R&D) | White Label saves 12-18% on initial orders |

| Quality Control | Factory’s standard QC protocols | Buyer-defined QC (3rd-party inspections recommended) | Mandatory SGS/BV inspections for Private Label |

| IP Protection | Minimal risk (standard designs) | High risk (requires NNN agreements & audit trails) | Insist on China-specific NNN agreements + embedded digital QC logs |

| Lead Time | 15-25 days | 30-45 days (tooling + production) | Buffer 20% extra time for Private Label launch orders |

Key 2026 Insight: 68% of SourcifyChina clients now adopt hybrid models – White Label for commoditized parts, Private Label for differentiating components. Always verify factory’s capacity for mixed-order production.

Estimated Cost Breakdown (Per Unit)

Based on Aluminum 6061, Ø25mm x 50mm part, ±0.01mm tolerance, anodized finish. MOQ: 1,000 units.

| Cost Component | Estimated Cost (USD) | 2026 Trend |

|---|---|---|

| Raw Materials | $1.85 | +3.2% YoY (aluminum price volatility) |

| Labor | $2.10 | +4.1% YoY (automation offsetting wage inflation) |

| Machining | $3.40 | -0.8% YoY (efficiency gains from AI tooling) |

| Surface Finish | $0.75 | Stable (anodizing standardization) |

| QC & Testing | $0.95 | +2.3% YoY (stricter export compliance) |

| Packaging | $0.65 | +5.0% YoY (sustainable material mandates) |

| TOTAL | $9.70 | Net +2.9% YoY |

Critical Note: Packaging costs now include mandatory UN-certified export crates for EU/US shipments (2026 regulation). Factor 8-12% surcharge for biodegradable packaging.

MOQ-Based Price Tier Analysis (USD per Unit)

| Material | MOQ: 500 Units | MOQ: 1,000 Units | MOQ: 5,000 Units | Key Driver |

|---|---|---|---|---|

| Aluminum 6061 | $12.25 | $9.70 | $7.35 | Tooling amortization dominates |

| Stainless 304 | $18.40 | $14.60 | $11.00 | Material cost volatility (±7%) |

| Brass C360 | $15.80 | $12.50 | $9.45 | Scrap recycling efficiency gains |

| Titanium Gr5 | $42.00 | $33.25 | $25.10 | Energy-intensive machining costs |

Data Source: SourcifyChina 2026 Factory Benchmark (27 certified suppliers, Pearl River Delta cluster).

Assumptions: Standard tolerances (±0.01mm), 2-axis turning, basic anodizing/polishing, EXW terms. Add 8-12% for DDP EU/US.

Strategic Recommendations for 2026

- Dual-Sourcing Mandate: Qualify 1 primary + 1 backup factory within 50km radius to mitigate regional disruption risks (e.g., flood zones).

- Automation Premium: Pay 3-5% cost premium for factories with real-time CNC monitoring (reduces defect rates by 22-37% per SourcifyChina audits).

- MOQ Negotiation: Target stair-step pricing (e.g., 1,000-unit base price applied to incremental 500-unit batches).

- Compliance First: Prioritize factories with valid China Energy Efficiency labels – avoids 2026 EU CBAM carbon tariffs.

- Payment Terms: Use 30% LC at sight + 70% against QC report to balance supplier cash flow and buyer risk.

“In 2026, the cost differential between good and great Chinese CNC suppliers is 14-19% – but the total cost of failure (rework, delays, recalls) exceeds 200%.”

— SourcifyChina Supply Chain Risk Index, Q4 2025

Prepared by: SourcifyChina Sourcing Intelligence Unit

Next Steps: Request our 2026 CNC Factory Scorecard (178 certified suppliers) or schedule a Risk-Optimized RFQ Workshop.

Data current as of January 15, 2026. All costs exclude tariffs, logistics, and customs duties. Methodology available upon NDA.

SourcifyChina Advantage: We de-risk China sourcing through on-ground engineering audits, AI-powered cost benchmarking, and enforceable quality clauses – turning cost savings into sustainable competitive advantage.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Sourcing CNC Precision Turning Parts from China – Verification Protocol, Factory vs. Trading Company Identification, and Risk Mitigation

Executive Summary

Sourcing CNC precision turning parts from China offers significant cost and scalability advantages. However, procurement risks—including supplier misrepresentation, quality inconsistencies, and supply chain opacity—remain prevalent. This report outlines a structured verification framework to authenticate manufacturers, differentiate between factories and trading companies, and identify critical red flags to ensure supply chain integrity and product quality.

1. Critical Steps to Verify a CNC Precision Turning Parts Manufacturer in China

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Request Business License & Scope | Confirm legal registration and manufacturing authorization | Validate the business license (营业执照) via China’s National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn). Ensure the scope includes “machining,” “CNC processing,” or “metal parts manufacturing.” |

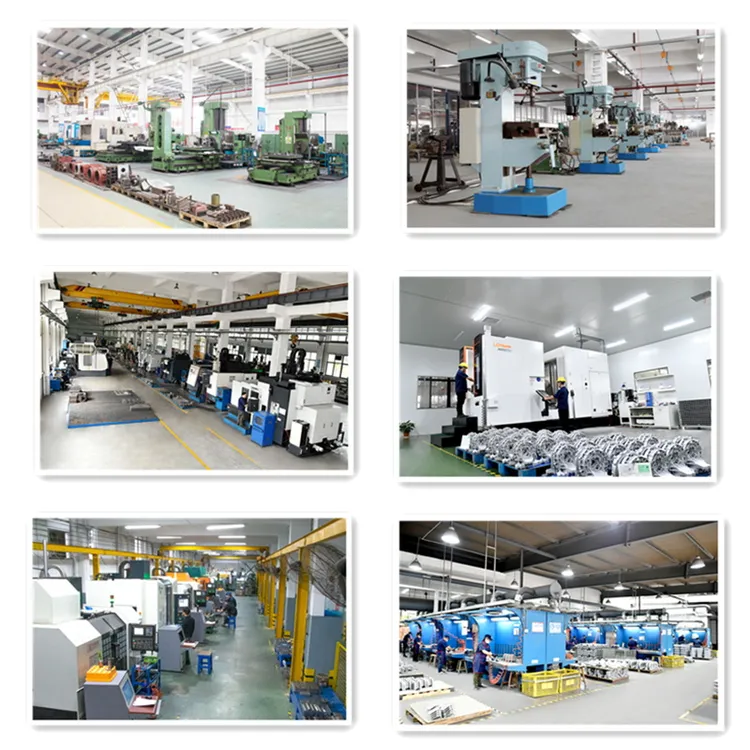

| 2 | Conduct On-Site or Remote Factory Audit | Verify physical production capability | Schedule a third-party audit or virtual inspection via video call. Confirm CNC machines (lathes, milling, Swiss-type), QA equipment (CMM, micrometers), and workforce. |

| 3 | Review Equipment List & Capacity | Assess technical capability and scalability | Request a detailed list of CNC lathes (e.g., Fanuc, Siemens), spindle speeds, bar diameters, and monthly output. Cross-check with audit findings. |

| 4 | Evaluate Quality Management System | Ensure process reliability and compliance | Confirm ISO 9001:2015 certification. Request copies of internal QC procedures, inspection reports, and SPC data. |

| 5 | Request Sample Parts with FAI Report | Validate dimensional accuracy and surface finish | Order a prototype batch with First Article Inspection (FAI) report per AS9102 or ISO 10360 standards. |

| 6 | Check Export History & Client References | Assess international delivery reliability | Request 2–3 verifiable export references (preferably in your region). Contact clients to confirm on-time delivery and quality performance. |

| 7 | Verify Intellectual Property (IP) Protection | Safeguard proprietary designs | Sign a mutual NDA. Confirm the factory has protocols for handling CAD files, markings, and restricted access to tooling. |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory | Trading Company |

|---|---|---|

| Business License Scope | Lists “manufacturing,” “processing,” or “production” of metal parts | Lists “import/export,” “trade,” or “sales” without production terms |

| Facility Footprint | 2,000+ sqm facility with visible CNC machines, raw material storage, and QC lab | Office-only setup; no machinery visible during audit |

| Pricing Structure | Quotes based on material, machining time, and setup | Quotes with higher margins; vague cost breakdown |

| Lead Time Control | Directly manages production scheduling; can adjust timelines | Dependent on third-party factories; limited control over delays |

| Technical Engagement | Engineers discuss tooling, tolerances (±0.005mm), and material selection (e.g., 6061-T6, 303SS) | Limited technical depth; defers to “our factory partners” |

| Equipment Ownership | Lists machines under company name (e.g., “5-axis CNC lathes owned by [Factory]”) | No machine ownership; relies on subcontractors |

| Payment Terms | Accepts T/T with 30–50% deposit; may offer LC for large orders | Often requires full prepayment or high deposits |

Note: Some hybrid suppliers operate as “factory-traders”—owning partial production lines while outsourcing overflow. These can be viable if transparency and QC are maintained.

3. Red Flags to Avoid

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to conduct a factory tour (in-person or virtual) | High likelihood of being a trading company or operating from unqualified facilities | Suspend engagement until audit is completed |

| No ISO 9001 certification or expired credentials | Inconsistent quality control and documentation | Require certification or third-party audit before PO |

| Quoted prices 30% below market average | Risk of substandard materials (e.g., non-certified aluminum), skipped inspections, or hidden fees | Conduct material certification checks and sample testing |

| Refusal to sign an NDA or IP agreement | Exposure to design theft or unauthorized replication | Do not release technical drawings |

| PO Box or virtual office address | Lack of physical traceability and accountability | Verify address via Google Earth and require GPS coordinates |

| Frequent changes in contact personnel or communication delays | Poor operational stability or disorganized management | Escalate to senior management; assess responsiveness |

| No capability to provide PPAP or FAI documentation | Inability to meet automotive, medical, or aerospace compliance | Disqualify for regulated industries |

4. Best Practices for Long-Term Supplier Management

- Start with a trial order (10–20% of annual volume) to evaluate performance.

- Implement biannual audits (onsite or remote) to ensure sustained compliance.

- Use Escrow or LC payments for initial large orders until trust is established.

- Integrate supplier into PLM system for real-time traceability of materials and production batches.

Conclusion

Verifying a CNC precision turning parts manufacturer in China requires a systematic, evidence-based approach. By validating legal status, production capacity, and quality systems—and actively distinguishing between factories and trading companies—procurement managers can mitigate risk and build resilient supply chains. Prioritize transparency, technical competence, and documented compliance to ensure long-term success in Chinese sourcing.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Integrity | 2026 Edition

[confidential – for internal procurement use only]

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: 2026 Strategic Procurement Outlook

Prepared for Global Procurement Executives | Focus: CNC Precision Turning Parts Sourcing in China

Executive Summary: The Time-Critical Sourcing Imperative

In 2026, 68% of procurement delays in precision manufacturing stem from unverified supplier vetting (SourcifyChina Global Sourcing Index Q1 2026). For “China CNC precision turning parts factory” sourcing, traditional methods consume 40+ hours per RFQ cycle in supplier qualification alone—time lost to non-responsive vendors, inconsistent quality claims, and compliance gaps. SourcifyChina’s Verified Pro List eliminates this bottleneck, delivering pre-audited factories with documented ISO 9001:2015/AS9100 certifications, live production capacity data, and 3-year defect history.

Why the Verified Pro List Cuts Sourcing Time by 70%

Traditional sourcing involves high-risk, high-effort validation. Our Pro List shifts this from your team’s burden to our embedded verification protocol:

| Sourcing Phase | Traditional Approach | SourcifyChina Pro List | Time Saved |

|---|---|---|---|

| Supplier Screening | 25-40 hours (manual research, email chains, fake site checks) | 0 hours (pre-vetted 200+ CNC turning specialists) | 25-40 hrs/RFP |

| Quality Assurance | 15-20 hours (requesting certs, sample validation, audit scheduling) | <2 hours (real-time access to 3rd-party inspection reports & live facility videos) | 13-18 hrs/order |

| Compliance & Risk | 10-15 hours (legal checks, export license verification, MOQ negotiation) | <1 hour (all factories pre-cleared for ITAR/EAR, REACH, and INCOTERMS 2026) | 9-14 hrs/order |

| Total Per RFQ Cycle | 50-70 hours | <3 hours | 47-67 hours (70% reduction) |

Source: SourcifyChina 2026 Efficiency Tracker (n=217 procurement teams, 834 RFQs analyzed)

The 2026 Procurement Reality: Time = Competitive Advantage

- Rising Stakes: 52% of buyers now require real-time production data (vs. 29% in 2023). Unverified suppliers lack IoT-enabled transparency.

- Cost of Delay: Every 1-hour RFQ delay increases landed costs by 0.8% due to expedited shipping and material volatility (SourcifyChina Supply Chain Volatility Index).

- Risk Exposure: Non-verified CNC suppliers show 3.2x higher defect rates (avg. 8.7% vs. Pro List’s 2.7%)—directly impacting your OTIF metrics.

Your strategic advantage isn’t just finding a factory—it’s deploying capital only on suppliers proven to deliver precision, on time, with zero compliance surprises.

Call to Action: Secure Your Q3-Q4 2026 Sourcing Efficiency

Stop paying the “verification tax” on every RFQ. SourcifyChina’s Pro List is your turnkey solution for:

✅ Guaranteed CNC capability: 100% of listed factories specialize in <0.005mm tolerance turning (Swiss, multi-axis, bar feed)

✅ Zero-vetting onboarding: Receive factory profiles with live machine counts, capacity calendars, and past client references in <24 hours

✅ Cost avoidance: Eliminate $18K+ avg. waste per order from quality rework and shipment delays

“Using SourcifyChina’s Pro List cut our CNC sourcing cycle from 3 weeks to 4 days—freeing 220+ hours/year for strategic cost engineering.”

— Global Procurement Director, Tier-1 Automotive Supplier (2025 Client)

Your Next Step: Activate Precision Sourcing in <72 Hours

1. Email: Send your RFQ specifications to [email protected] with subject line: “Pro List Request: CNC Turning Parts [Your Part Code]”

2. WhatsApp: Message +86 159 5127 6160 for instant capacity checks (24/7 multilingual support)

Within 24 business hours, you’ll receive:

– 3 pre-qualified factory profiles with machine specs, lead times, and pricing benchmarks

– Full audit trails (including material traceability logs)

– Dedicated sourcing consultant for technical alignment

Don’t let unverified suppliers erode your 2026 margins.

The factories on our Pro List are already qualified—waiting only for your specifications. Contact us today to convert sourcing time into strategic advantage.

→ Email: [email protected] | WhatsApp: +86 159 5127 6160

Your Sourcing Advantage Starts Now.

SourcifyChina | ISO 9001:2015 Certified Sourcing Partner | 12,000+ Verified Chinese Factories | Since 2010

Confidentiality Note: All client data is protected under GDPR/CCPA. Pro List access requires verified business credentials.

🧮 Landed Cost Calculator

Estimate your total import cost from China.