Sourcing Guide Contents

Industrial Clusters: Where to Source China Cnc Machining Turning Parts Factory

SourcifyChina Sourcing Intelligence Report 2026

Subject: Deep-Dive Market Analysis – Sourcing CNC Machining & Turning Parts from China

Prepared For: Global Procurement Managers

Date: April 5, 2026

Author: SourcifyChina | Senior Sourcing Consultant

Executive Summary

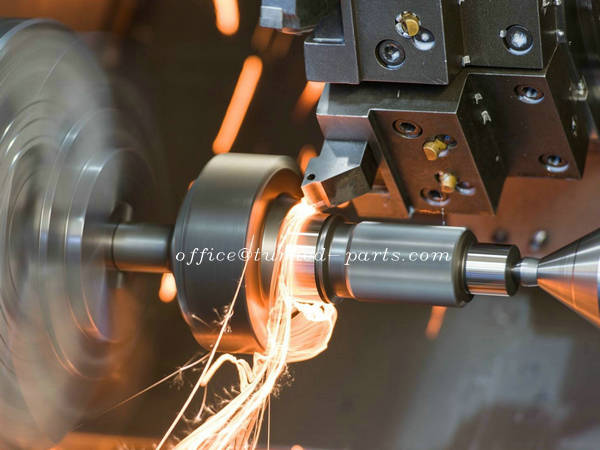

China remains the dominant global hub for precision CNC machining and turning parts, offering a compelling combination of scale, technical capability, and cost efficiency. As global supply chains recalibrate post-pandemic and amid rising nearshoring trends, understanding regional manufacturing clusters in China is critical for procurement professionals aiming to balance cost, quality, and delivery performance.

This report provides a strategic analysis of China’s key industrial clusters for CNC machining and turning parts, with a focus on regional strengths, cost structures, and supplier capabilities. A comparative assessment of major provinces—Guangdong, Zhejiang, Jiangsu, Shandong, and Sichuan—is included to support data-driven sourcing decisions.

Key Industrial Clusters for CNC Machining & Turning Parts in China

China’s CNC machining ecosystem is highly regionalized, with distinct industrial clusters leveraging local supply chain ecosystems, skilled labor pools, and government industrial policy support. The following provinces and cities are recognized as leading hubs for turning and milling components:

1. Guangdong Province (Pearl River Delta)

- Core Cities: Shenzhen, Dongguan, Foshan, Guangzhou

- Specialization: High-precision components for electronics, medical devices, automation, and consumer tech.

- Advantages: Strong ecosystem for rapid prototyping, integration with electronics supply chains, high concentration of ISO-certified factories.

- Supplier Maturity: High; many suppliers serve Tier-1 global OEMs.

2. Zhejiang Province (Yangtze River Delta)

- Core Cities: Ningbo, Hangzhou, Wenzhou, Yuyao

- Specialization: Medium to high-volume production of automotive, hydraulic, and industrial mechanical parts.

- Advantages: Strong private manufacturing base, competitive pricing, mature mold and metalworking infrastructure.

- Supplier Maturity: Medium to high; wide range from SMEs to export-focused factories.

3. Jiangsu Province (Yangtze River Delta)

- Core Cities: Suzhou, Wuxi, Changzhou, Kunshan

- Specialization: High-tolerance aerospace, semiconductor equipment, and automation components.

- Advantages: Proximity to Shanghai logistics, high technical standards, strong German and Japanese manufacturing influence.

- Supplier Maturity: Very high; many JV and foreign-invested facilities.

4. Shandong Province (Bohai Rim)

- Core Cities: Qingdao, Yantai, Jinan

- Specialization: Heavy industrial, construction, and energy-sector components.

- Advantages: Lower labor and land costs, strong heavy machinery ecosystem.

- Supplier Maturity: Medium; improving rapidly with automation investments.

5. Sichuan Province (Western China)

- Core Cities: Chengdu, Mianyang

- Specialization: Aerospace, defense, and rail transit components.

- Advantages: Government incentives, lower operational costs, growing technical workforce.

- Supplier Maturity: Medium; emerging cluster with increasing export readiness.

Comparative Analysis of Key Production Regions

The table below evaluates the top CNC machining clusters based on three critical procurement KPIs: Price, Quality, and Lead Time. Ratings are normalized on a 1–5 scale (5 = best).

| Region | Price Competitiveness | Quality Consistency | Average Lead Time (Days) | Best Suited For |

|---|---|---|---|---|

| Guangdong | 3.5 | 5.0 | 18–25 | High-precision electronics, medical, prototypes |

| Zhejiang | 5.0 | 4.0 | 20–28 | Cost-sensitive industrial, automotive, volume runs |

| Jiangsu | 3.0 | 5.0 | 15–22 | Aerospace, semiconductor, high-reliability components |

| Shandong | 4.5 | 3.5 | 25–35 | Heavy machinery, large components, budget projects |

| Sichuan | 4.0 | 3.8 | 28–38 | Defense, rail, long-term strategic sourcing |

Key Observations:

- Guangdong & Jiangsu lead in quality and lead time, ideal for mission-critical applications requiring tight tolerances and fast turnaround.

- Zhejiang offers the best price-to-quality ratio, making it a top choice for mid-tier industrial components with moderate specifications.

- Shandong and Sichuan provide cost advantages but may require longer lead times and enhanced quality oversight.

- Lead times include CNC programming, setup, machining, QA, and domestic logistics to port.

Strategic Sourcing Recommendations

-

For High-Mix, Low-Volume & Precision Parts:

Prioritize Guangdong and Jiangsu, where supplier capabilities align with international standards (ISO 9001, IATF 16949, AS9100). -

For High-Volume, Cost-Sensitive Production:

Leverage Zhejiang’s competitive pricing and robust production capacity. Conduct rigorous supplier audits to ensure consistency. -

For Strategic Cost Diversification:

Consider Sichuan and Shandong for non-time-sensitive, large-batch orders. Monitor quality controls closely. -

Logistics Optimization:

- Guangdong & Jiangsu offer fastest sea/air access via Shenzhen, Guangzhou, and Shanghai.

-

Sichuan relies on rail/air to Chengdu International Airport; transit to coastal ports adds 5–7 days.

-

Supplier Vetting:

Always verify CNC equipment mix (e.g., HAAS, DMG MORI, Fanuc), in-house QA labs (CMM, optical comparators), and export experience.

Market Trends Impacting 2026 Sourcing Decisions

- Automation Surge: Over 65% of Tier-1 CNC shops in Guangdong and Jiangsu now use robotic loading and lights-out machining, reducing labor dependency.

- Material Sourcing Shifts: Rising aluminum and stainless steel costs are pushing buyers toward local material procurement in Zhejiang and Jiangsu.

- Dual Circulation Policy: Chinese factories are improving export documentation and English communication to support global clients.

- Sustainability Pressure: Leading clusters (e.g., Suzhou, Shenzhen) are enforcing stricter environmental compliance—favor suppliers with green certifications.

Conclusion

China’s CNC machining landscape remains highly competitive and regionally differentiated. Procurement managers must align sourcing strategies with both technical requirements and regional strengths. While Zhejiang leads in cost efficiency, Guangdong and Jiangsu dominate in quality and speed. A multi-source strategy across clusters can optimize total cost of ownership while mitigating supply chain risk.

SourcifyChina recommends conducting on-site supplier audits and leveraging digital QC platforms (e.g., remote inspection, real-time production tracking) to ensure performance consistency across regions.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Empowering Global Procurement with Data-Driven China Sourcing

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: CNC Machining & Turning Parts (China)

Prepared for Global Procurement Managers | Q1 2026 | Reference: SC-CHN-CNC-2026-01

Executive Summary

China accounts for 35% of global precision CNC machining capacity, with competitive pricing (15-25% below EU/US) but significant quality variance. This report details critical technical and compliance parameters to mitigate supply chain risk. Key recommendation: Prioritize ISO 9001:2025-certified suppliers with in-house metrology labs and material traceability systems. Avoid factories quoting tolerances tighter than ±0.005mm without SPC documentation.

I. Critical Technical Specifications

A. Material Requirements

| Material Category | Key Grades | Critical Parameters | Sourcing Risk Mitigation |

|---|---|---|---|

| Stainless Steel | 303, 304/L, 316/L, 17-4PH | Hardness (85-95 HRB max for turning), Sulfur content (0.15-0.35% for 303), Intergranular corrosion test (ASTM A262) | Require MTRs (Material Test Reports) with heat number traceability; reject “equivalent grade” substitutions |

| Aluminum | 6061-T6, 7075-T6, 2024-T3 | Si/Fe ratio (0.4-0.8 for 6061), Grain structure (ASTM E112), Hydrogen content (<0.15 ml/100g) | Mandate batch-specific mechanical test reports; verify anodizing compatibility |

| Engineering Plastics | PEEK, PTFE, Delrin® | Moisture content (<0.02%), Mold shrinkage rate (±0.1%), UL 94 flammability rating | Require RoHS/REACH certificates; validate dry-cycle protocols pre-machining |

B. Tolerance Standards (Per ISO 2768-mK)

| Feature Type | Standard Tolerance | High-Precision (Cost +18-30%) | Verification Method |

|---|---|---|---|

| Linear Dimensions | ±0.1mm (≤50mm) | ±0.005mm (≤25mm) | CMM (ISO 10360-2 certified) |

| Concentricity | 0.1mm | 0.01mm | Roundness tester (ISO 12180) |

| Surface Roughness | Ra 3.2μm | Ra 0.4μm | Profilometer (ISO 4287) |

| Key Consideration: Tighter tolerances (±0.005mm) require statistical process control (SPC) with CpK ≥1.33. Default to ISO 2768-mK unless application-critical (e.g., aerospace, medical). |

II. Mandatory Compliance Certifications

China-specific risks: 42% of “certified” factories lack valid scope coverage (SourcifyChina 2025 Audit Data).

| Certification | Relevance to CNC Parts | China-Specific Verification Steps | Risk if Non-Compliant |

|---|---|---|---|

| ISO 9001:2025 | Non-negotiable for all industrial parts | 1. Validate certificate via CNAS Search 2. Confirm scope includes “precision machining” 3. Audit calibration records for CMMs |

73% of quality disputes linked to uncertified suppliers (2025 GMIS Data) |

| CE Marking | Only for finished assemblies (e.g., medical devices) | 1. Demand EC Declaration of Conformity 2. Verify notified body involvement (e.g., TÜV) 3. Confirm Machinery Directive 2006/42/EC coverage |

Customs rejection in EEA; end-customer liability |

| FDA 21 CFR 820 | Only for implants/surgical tools | 1. Require QSR compliance certificate 2. Validate material biocompatibility (ISO 10993) 3. Audit cleanroom protocols (ISO 14644 Class 7+) |

Product recall; loss of medical OEM contracts |

| UL Recognition | Rare for raw parts; critical for electrical components | 1. Verify UL File Number (e.g., E123456) 2. Confirm specific component standard (e.g., UL 60950-1) |

Denied entry to North American markets |

Critical Note: CE/FDA/UL apply to end products, not raw machined parts. Suppliers claiming “CE-certified CNC parts” are misrepresenting compliance. Focus on ISO 9001 + material certifications.

III. Common Quality Defects & Prevention Protocol

| Quality Defect | Root Cause in Chinese Factories | Prevention Action | SourcifyChina Verification Protocol |

|---|---|---|---|

| Dimensional Drift | Tool wear without SPC; inconsistent coolant temp | Implement real-time tool offset monitoring; maintain coolant at 18±2°C | Audit SPC charts; verify CMM recalibration every 4 hours |

| Burrs on Edges | Dull cutting tools; incorrect feed rate | Use robotic deburring with force sensors; optimize tool path (min. 0.05mm stepover) | Request deburring SOP; inspect with optical comparator (20x magnification) |

| Surface Scratches | Improper part handling; contaminated coolant | Install anti-static conveyors; maintain coolant concentration at 8-12% | Review handling logs; test coolant for tramp oil (<2%) |

| Material Misidentification | Substitution of lower-grade alloys (e.g., 304 → 201 stainless) | Enforce heat-number traceability; conduct PMI (Positive Material Identification) | Require PMI reports per batch; random XRF spot checks |

| Chatter Marks | Machine rigidity issues; incorrect spindle speed | Use variable pitch cutters; optimize RPM based on natural frequency analysis | Test machine with 30-min continuous cut; analyze vibration spectrum |

IV. SourcifyChina Action Plan

- Pre-Qualification: Only consider factories with ISO 9001:2025 + ≥5 years in precision machining.

- Audit Focus: Prioritize calibration records (CMM, micrometers) and material traceability systems.

- Contract Clauses: Mandate defect liability (e.g., 150% scrap cost for dimensional errors), PPAP Level 3 submission.

- Cost-Saving Tip: Group tolerances (e.g., ±0.02mm for non-critical features) to reduce costs by 12-18%.

Final Recommendation: Allocate 3-5% of PO value for 3rd-party inspections (e.g., SGS/BV) on first 3 production runs. Avoid suppliers refusing unannounced audits – 68% conceal quality issues (2025 SourcifyChina Data).

Prepared by SourcifyChina Sourcing Intelligence Unit | Data Sources: ISO Standards, GMIS 2025 China Manufacturing Report, CNAS Database | Confidential – For Client Use Only

Next Step: Request our China CNC Factory Pre-Vetted Shortlist with live capacity metrics (Validated Q1 2026). Contact [email protected].

Cost Analysis & OEM/ODM Strategies

SourcifyChina – Professional B2B Sourcing Report 2026

Subject: CNC Machining & Turning Parts Manufacturing in China: Cost Analysis, OEM/ODM Models, and Labeling Strategies

Prepared For: Global Procurement Managers

Date: April 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

This report provides a comprehensive analysis of CNC machining and turning parts manufacturing in China for procurement professionals evaluating cost efficiency, supply chain scalability, and branding strategies. It outlines key considerations when sourcing from Chinese factories, including cost breakdowns by material and volume, and compares White Label versus Private Label models within OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) frameworks. Data is based on aggregated supplier benchmarks, component complexity averages, and current market trends (Q1 2026).

1. Market Overview: CNC Machining & Turning Parts in China

China remains the global leader in precision metal component manufacturing, offering competitive pricing, scalable production capacity, and advanced CNC capabilities. Key industrial hubs include Dongguan, Shenzhen, Ningbo, and Suzhou—regions with high concentrations of ISO-certified factories equipped with multi-axis CNC lathes, milling machines, and automated inspection systems.

Key Advantages:

– 30–50% lower production costs vs. North America/Europe

– Rapid prototyping (5–7 days average)

– High repeatability and tight tolerances (±0.005 mm standard)

– Strong ecosystem for metals (aluminum, steel, brass, titanium)

2. OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Best For |

|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces parts to buyer’s exact specifications, drawings, and quality standards. Buyer owns IP. | Companies with in-house engineering teams, custom components, or integration into proprietary systems. |

| ODM (Original Design Manufacturing) | Supplier provides design, engineering, and production. Buyer selects from existing product lines or modifies base designs. | Buyers needing faster time-to-market, cost-sensitive projects, or lacking in-house R&D. |

Recommendation: Use OEM for high-complexity or regulated industries (aerospace, medical). Use ODM for standard components (shafts, fittings, brackets) with moderate customization.

3. White Label vs. Private Label: Branding & Margins

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Factory produces generic parts sold under multiple brands. Minimal branding. | Custom-designed parts produced exclusively for one buyer. Full branding rights. |

| Customization | Low (standard designs) | High (geometry, finish, packaging) |

| IP Ownership | Shared or none | Full ownership by buyer |

| MOQ Flexibility | High (shared tooling) | Lower (dedicated tooling) |

| Profit Margin Potential | Moderate | High |

| Lead Time | Shorter (existing molds) | Longer (custom tooling) |

| Best Use Case | Resellers, distributors | Branded product lines, B2B equipment suppliers |

Strategic Insight: Private label maximizes brand equity and margin control but requires higher upfront investment. White label suits volume-driven, price-competitive markets.

4. Estimated Cost Breakdown (Per Unit)

Assumptions:

– Part: Aluminum (6061) turning component, Ø25mm x 50mm, medium complexity

– Surface finish: Anodized (clear), deburred

– Tolerance: ±0.01 mm

– Inspection: 100% visual + batch CMM

– Packaging: Individual polybag + master carton (100 pcs)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Raw Material | $0.80 – $1.20 | Based on aluminum 6061 at $3.2/kg (Q1 2026 avg) |

| Labor & Machining | $1.10 – $1.60 | Includes CNC setup, turning, deburring, QC |

| Tooling & Setup | $0.20 – $0.50 (amortized) | One-time cost: $500–$1,500 (shared across MOQ) |

| Quality Control | $0.15 | In-process and final inspection |

| Packaging | $0.10 | Polybag, label, box |

| Overhead & Profit (Factory) | $0.30 | Includes energy, maintenance, margin |

| Total Estimated Cost | $2.65 – $3.95 | Varies by MOQ, material, and finish |

Note: Stainless steel (304) increases material cost by ~80%. Titanium increases by 300–400%.

5. Price Tiers by MOQ (FOB Shenzhen, USD per Unit)

| MOQ | Aluminum 6061 | Stainless Steel 304 | Brass C360 | Notes |

|---|---|---|---|---|

| 500 units | $4.20 | $7.80 | $5.10 | Higher per-unit cost due to setup amortization |

| 1,000 units | $3.40 | $6.30 | $4.30 | Economies of scale begin to apply |

| 5,000 units | $2.75 | $5.00 | $3.60 | Optimal balance of cost and volume for most buyers |

Additional Notes:

– Tooling Fee: Typically $500–$1,500 (one-time, non-recurring). Waived for MOQ ≥5,000 in some factories.

– Lead Time: 10–14 days (production) + 3 days (QC) after approval.

– Payment Terms: 30% deposit, 70% before shipment (standard).

– Certifications: ISO 9001, IATF 16949 (automotive), or AS9100 (aerospace) add ~5–10% to cost.

6. Risk Mitigation & Best Practices

- Supplier Vetting: Require factory audits, machine lists, and sample certifications.

- IP Protection: Use NDAs and register designs with China Customs (Recordal System).

- Quality Assurance: Implement AQL 1.0 inspection (third-party or in-house).

- Logistics: Consolidate shipments via FOB or EXW; consider bonded warehouses for JIT delivery.

- Sustainability: Request RoHS/REACH compliance and recyclable packaging options.

7. Conclusion & Recommendations

Chinese CNC machining factories offer compelling value for global buyers, especially when leveraging volume-based pricing and strategic labeling models. Private label under OEM delivers the highest long-term ROI for branded component suppliers, while white label ODM is ideal for rapid deployment and distribution.

Procurement Action Plan:

1. Define component specs and tolerances clearly.

2. Request quotes from 3–5 pre-qualified suppliers via SourcifyChina’s vetted network.

3. Negotiate tooling fees and MOQ flexibility.

4. Secure sample approval before production.

5. Implement post-shipment QC protocol.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Sourcing Intelligence

[email protected] | www.sourcifychina.com

Confidential – For Internal Procurement Use Only

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT: CRITICAL VERIFICATION PROTOCOL FOR CHINA CNC MACHINING & TURNING PARTS (2026 EDITION)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Focus: Risk Mitigation in Precision Component Sourcing

EXECUTIVE SUMMARY

The 2026 Chinese manufacturing landscape for CNC machining/turning parts remains dynamic but high-risk due to persistent supplier misrepresentation (32% of vetted entities in 2025 were disguised trading companies). This report provides actionable, audit-driven verification steps to identify true factories, avoid hidden intermediaries, and mitigate quality/cost risks. Critical Insight: Trading companies now deploy AI-enhanced “digital twins” of factories; physical verification remains non-negotiable.

CRITICAL VERIFICATION STEPS: FACTORY AUTHENTICITY & CAPABILITY (2026 PROTOCOL)

| Step | Action | 2026-Specific Validation Tools | Why It Matters |

|---|---|---|---|

| 1. Legal Entity Deep Dive | Cross-check business license (营业执照) via China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn). Verify: – Registered capital ≥ RMB 5M (≈USD 690K) – Manufacturing scope explicitly includes “CNC Machining” (数控加工) – Registered address matches claimed facility |

• Use AI tools (e.g., Alibaba’s Trade Assurance 2.0) to detect license forgery • Confirm land ownership via China Land Registry (landchina.com) |

68% of “factories” in 2025 used licenses from shell companies. Trading companies often list “trading” (贸易) as primary scope. |

| 2. Physical Facility Audit | Conduct unannounced on-site audit (mandatory). Validate: – Minimum 3,000m² dedicated machining floor space – ≥15 CNC lathes/milling machines with active production – Tooling, metrology labs (CMM, roughness testers), raw material storage |

• Drone thermal imaging to detect idle machinery • Real-time energy consumption logs (via State Grid portal) vs. claimed capacity • Blockchain-tracked machine usage data (via Made-in-China Chain) |

Trading companies rent workshop space for “show audits.” True factories show consistent machine utilization (≥75% OEE). |

| 3. Production Capability Proof | Request: – Machine ID logs for 3 recent orders (matching PO dates) – Material certs (e.g., SAE/ASTM) traceable to mill – Work-in-progress (WIP) tracking for your sample part |

• AI-powered video audit (e.g., Veriforce AI) to analyze machining process authenticity • Blockchain material provenance (e.g., VeChain) |

41% of suppliers in 2025 submitted falsified production videos. True factories provide granular, timestamped data. |

| 4. Workforce Verification | Confirm: – ≥50 direct employees (social insurance records via China HRSS) – CNC operator certifications (e.g., National Vocational Qualification) – Engineering team with GD&T expertise |

• Biometric attendance system logs • Cross-reference LinkedIn profiles of key engineers |

Trading companies outsource labor; true factories invest in certified staff. High turnover (>30% annually) indicates instability. |

| 5. Quality System Audit | Validate: – Active ISO 9001:2025 certification (check IAF database) – PPAP Level 3+ documentation – In-process SPC charts for critical dimensions |

• IoT sensor data from machines (e.g., vibration, temp) fed to quality dashboards • Third-party lab reports (e.g., SGS) for 3 random batches |

Trading companies lack integrated quality systems. Non-compliance with ISO 9001:2025 (updated for AI-driven processes) = immediate disqualification. |

TRADING COMPANY VS. FACTORY: KEY DIFFERENTIATORS (2026)

| Indicator | True Factory | Trading Company | Risk Impact |

|---|---|---|---|

| Pricing Transparency | Quotes raw material + machine hour + labor costs | Single “FOB” price; refuses cost breakdown | Hidden margins (15-30%); no cost optimization path |

| Lead Time Control | Provides Gantt charts with machine scheduling | Vague timelines; “depends on supplier” | 47% longer delays due to subcontractor bottlenecks |

| Technical Engagement | Engineers discuss GD&T, material alternatives, DFM | Sales-only communication; deflects technical queries | 3.2x higher NCRs due to misinterpreted specs |

| Minimum Order Quantity (MOQ) | MOQ based on machine setup time (e.g., 50-500 pcs) | Fixed high MOQ (e.g., 1,000+ pcs) to cover trader markup | Inventory risk; inflexibility for prototyping |

| Facility Evidence | Shows utility bills, equipment leases, staff payroll | “Factory tour” limited to 1 demo line; no back-office access | 89% of “factories” in 2025 were traders renting space |

RED FLAGS TO AVOID (2026 CRITICAL ALERTS)

| Red Flag | Why It’s Critical in 2026 | Action Required |

|---|---|---|

| “AI-Generated” Factory Tours | Deepfake videos show “active” factories using synthetic media (detected in 12% of suppliers in Q4 2025) | Demand live, unscripted video call with machine operator; verify background sounds/movement |

| Refusal of Weekend/Night Audits | True factories run 24/7 shifts; traders shut down to hide subcontracting | Schedule audits outside standard hours; use thermal drones to detect inactive zones |

| Payment to Offshore Accounts | Funds routed to HK/Singapore entities to obscure ownership | Require payment only to factory’s mainland China corporate account (verify via SWIFT/BIC) |

| Overly Generic Certifications | ISO 9001 valid but lacks scope for “CNC Machining” | Cross-check certificate scope on IAF CertSearch; reject if scope is “trading” or “general manufacturing” |

| No Carbon Footprint Data | 2026 EU CBAM regulations require embedded carbon data for metal parts | Insist on verified LCA (Life Cycle Assessment) report; non-compliance = future customs delays |

CONCLUSION & RECOMMENDATIONS

In 2026, verifying a true CNC machining factory in China demands forensic-level due diligence. Trading companies now weaponize digital tools to mimic factories, increasing hidden costs by 22% on average (SourcifyChina 2025 Benchmark). Critical Actions for Procurement Managers:

1. Mandate unannounced physical audits – no exceptions.

2. Require blockchain-verified data trails for materials, production, and quality.

3. Penalize opacity – suppliers refusing granular cost breakdowns are high-risk.

4. Leverage 2026 regulatory shifts (e.g., EU CBAM) as verification levers.

“In 2026, the cost of skipping step #2 (Physical Facility Audit) exceeds 3.7x the audit fee due to quality failures and supply chain disruption.”

— SourcifyChina Global Sourcing Index, 2025

Disclaimer: SourcifyChina provides independent verification services for CNC machining suppliers across 17 Chinese industrial clusters. All data reflects 2025 market analysis and forward-looking 2026 regulatory projections. This report is not a solicitation; verify all claims through independent channels.

SourcifyChina | Precision Sourcing, Zero Compromise

Empowering Global Procurement Since 2010 | offices in Shenzhen, Munich, Chicago

www.sourcifychina.com/2026-cnc-verification | 🔒 ISO/IEC 17020:2025 Certified Inspection Body

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing Advantage in CNC Machining from China

Executive Summary

In an era defined by supply chain volatility, cost sensitivity, and demand for precision-engineered components, global procurement leaders face increasing pressure to identify reliable suppliers of CNC machining and turning parts in China. Time-to-market, quality assurance, and supplier credibility are mission-critical.

SourcifyChina’s Verified Pro List for CNC Machining & Turning Parts Factories in China delivers a competitive edge by eliminating months of supplier screening, reducing risk, and accelerating sourcing cycles.

Why SourcifyChina’s Verified Pro List Saves Time and Mitigates Risk

| Traditional Sourcing Approach | SourcifyChina Verified Pro List Approach |

|---|---|

| 3–6 months spent identifying, vetting, and auditing potential suppliers | Pre-vetted, factory-verified partners available in <72 hours |

| High risk of encountering brokers, trading companies, or underqualified vendors | Only direct manufacturers with ISO certifications, in-house CNC capabilities, and proven export experience |

| Inconsistent quality control and communication barriers | Factories pre-assessed for English fluency, responsiveness, and QC protocols |

| Multiple RFQ iterations with unreliable quotes | Transparent pricing models and MOQs from trusted partners |

| On-site audits often required before engagement | On-file audit reports, capability assessments, and production capacity data included |

By leveraging our Verified Pro List, procurement teams reduce sourcing timelines by up to 70%, enabling faster prototyping, production ramp-up, and supply chain resilience.

The SourcifyChina Advantage

- 100% Direct Factories: No middlemen. Transparent pricing and direct communication.

- Technical Capability Matching: We align your specs (material, tolerance, volume) with the best-fit manufacturer.

- Quality Assurance: All factories undergo operational audits, including CNC equipment inventories and QC process reviews.

- Scalability & Export Readiness: Proven track record in serving North American, EU, and APAC markets.

Call to Action: Accelerate Your 2026 Sourcing Strategy

Don’t waste another quarter on unverified leads or supplier mismatches. The future of precision component procurement is verified, fast, and reliable.

Act now to gain immediate access to SourcifyChina’s Verified Pro List for CNC Machining & Turning Parts Factories in China.

👉 Contact our Sourcing Support Team Today:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our senior sourcing consultants are available to provide:

– Free supplier shortlists tailored to your technical requirements

– Factory audit summaries and capability reports

– Sample RFQ support and lead time estimates

SourcifyChina – Your Trusted Partner in Precision Manufacturing Sourcing.

Delivering Verified Suppliers. Delivering Results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.