Sourcing Guide Contents

Industrial Clusters: Where to Source China Cnc Lathe Manufacturer

Professional B2B Sourcing Report 2026

Subject: Deep-Dive Market Analysis – Sourcing CNC Lathe Manufacturers in China

Prepared for: Global Procurement Managers

Author: Senior Sourcing Consultant, SourcifyChina

Date: January 2026

Executive Summary

China remains the world’s dominant manufacturing hub for CNC (Computer Numerical Control) lathes, offering a highly diversified and competitive supplier ecosystem. As global demand for precision machining grows—driven by aerospace, automotive, medical devices, and industrial automation—procurement leaders are increasingly optimizing their sourcing strategies to balance cost, quality, and delivery speed.

This report provides a comprehensive analysis of China’s CNC lathe manufacturing landscape, identifying key industrial clusters, evaluating regional strengths, and offering strategic insights for global sourcing decisions in 2026.

Key Industrial Clusters for CNC Lathe Manufacturing in China

CNC lathe production in China is concentrated in several advanced manufacturing provinces, each with distinct competitive advantages. The following regions are recognized as the primary hubs:

- Guangdong Province – Pearl River Delta (Dongguan, Shenzhen, Foshan)

- Zhejiang Province – Yangtze River Delta (Ningbo, Hangzhou, Wenzhou)

- Jiangsu Province – Suzhou, Changzhou, Nanjing

- Shandong Province – Jinan, Qingdao

- Liaoning Province – Shenyang (historical base with legacy expertise)

Among these, Zhejiang and Guangdong stand out as the most significant clusters due to their high concentration of Tier 1 and Tier 2 suppliers, R&D capabilities, and export infrastructure.

Regional Comparative Analysis: Key Production Hubs

The table below compares the leading CNC lathe manufacturing regions in China based on Price Competitiveness, Quality Standards, and Average Lead Time—three critical KPIs for procurement decision-making.

| Region | Price Level | Quality Tier | Lead Time (Standard Units) | Key Advantages | Considerations |

|---|---|---|---|---|---|

| Zhejiang | Moderate to High | High (ISO, CE, some export to EU/US) | 6–8 weeks | Strong engineering base; high precision; excellent after-sales support; strong R&D | Higher initial cost; MOQ may be higher for premium brands |

| Guangdong | Competitive to Moderate | Medium to High (varies widely) | 4–6 weeks | Fast production cycles; strong supply chain integration; proximity to ports (Shenzhen, Guangzhou) | Quality inconsistency among smaller OEMs; due diligence required |

| Jiangsu | Moderate | High (German/JP-aligned standards) | 6–9 weeks | Proximity to Shanghai; strong foreign joint ventures; advanced automation | Slightly longer lead times due to high order volume |

| Shandong | Competitive | Medium (domestic & emerging export) | 5–7 weeks | Cost-effective for mid-range lathes; growing export focus | Limited high-end R&D fewer English-speaking engineers |

| Liaoning | Low to Competitive | Medium (legacy state-owned firms) | 8–12 weeks | Deep-rooted mechanical engineering heritage; suitable for rugged industrial models | Aging infrastructure; slower innovation; longer lead times |

Note: All lead times are based on standard configurations (e.g., 2-axis to 4-axis CNC lathes, 200–500mm swing). Customization, automation integration, or high-precision requirements may extend timelines by 2–4 weeks.

Strategic Sourcing Insights for 2026

1. Zhejiang: The Premium Choice for Quality & Reliability

- Recommended for: EU, North American, and high-reliability industrial markets.

- Top Cities: Ningbo and Hangzhou host OEMs with CE, ISO 9001, and some FDA-compliant capabilities.

- Supplier Example: Dalian Machine Tool Group (Zhejiang JV), SL Machinery, KND System.

2. Guangdong: The Speed-to-Market Leader

- Recommended for: Fast-turnaround procurement, mid-tier automation projects, Southeast Asian distribution hubs.

- Logistics Advantage: Direct access to Yantian and Nansha ports enables 10–14 day sea freight to ASEAN, Middle East, and Africa.

- Supplier Example: Shenzhen Vicer Machine, Dongguan JFY CNC.

3. Jiangsu: The Technology-Integrated Hub

- Recommended for: Buyers seeking German or Japanese technology partnerships.

- Notable JV Examples: DMG MORI associates in Nanjing, MAZAK-linked assembly in Suzhou.

4. Risk Mitigation & Supplier Vetting

- Quality Variance: Over 60% of CNC lathe suppliers in Guangdong are SMEs; third-party inspection (e.g., SGS, Bureau Veritas) is advised.

- IP Protection: Use NNN (Non-Use, Non-Disclosure, Non-Circumvention) agreements, especially in Zhejiang and Guangdong.

- Lead Time Buffer: Always build in a 10–15% buffer for customs clearance and logistics, particularly post-COVID regulatory checks.

Conclusion & Sourcing Recommendation

For global procurement managers, the choice of region depends on strategic priorities:

- Optimize for Quality & Long-Term Reliability: Source from Zhejiang.

- Prioritize Speed & Cost-Effectiveness: Leverage Guangdong’s agile supply chains.

- Seek Technology Alignment: Explore Jiangsu’s joint ventures.

- Budget-Constrained Mid-Tier Needs: Consider Shandong, with proper vetting.

Action Step: Conduct on-site audits or virtual factory assessments before PO placement. Partner with a local sourcing agent to navigate compliance, language, and logistics.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Industrial Procurement Intelligence & Supply Chain Optimization

Empowering Global Buyers with Data-Driven Sourcing from China

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: CNC Lathe Manufacturing in China

Prepared for Global Procurement Managers | Q1 2026

Objective Analysis of Technical Specifications, Compliance, and Quality Assurance Frameworks

Executive Summary

China remains the world’s largest producer of CNC lathes (42% global market share, 2025), offering significant cost advantages (20-35% below EU/US equivalents). However, quality variance across manufacturers necessitates rigorous technical vetting. This report details critical specifications, compliance requirements, and defect prevention strategies to mitigate supply chain risks. Priority action: Verify actual production capabilities against quoted specs via third-party audits.

I. Technical Specifications: Non-Negotiable Parameters

A. Key Quality Parameters

| Parameter | Industrial Grade (Standard) | High-Precision Grade | Critical Verification Method |

|---|---|---|---|

| Materials | ASTM A36 (Bed), 40Cr (Spindle) | Meehanite® M5000 (Bed), GGG70 (Spindle) | Material certs + Spectrographic analysis |

| Positioning Accuracy | ±0.01 mm | ±0.003 mm | Laser interferometer test (ISO 230-2) |

| Repeatability | ±0.005 mm | ±0.001 mm | 30-cycle ballbar test (ISO 230-4) |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm | Profilometer measurement on test part |

| Thermal Stability | 0.05 mm drift/8h | 0.01 mm drift/8h | Thermal imaging during endurance run |

Procurement Insight: 68% of defects in budget-tier Chinese lathes (sub-$50k) stem from substandard cast iron beds (porosity >5%). Demand Meehanite® certification for high-precision applications.

II. Compliance & Certification Requirements

Non-compliance = Customs rejection or liability exposure. Verify authenticity via issuing body portals.

| Certification | Mandatory For | Key Requirements | China-Specific Risk |

|---|---|---|---|

| CE Marking | EU, UK, EFTA markets | EN 60204-1 (Electrical), ISO 12100 (Safety) | 31% of CE certs from Tier-3 suppliers are invalid (2025 EU RAPEX data) |

| ISO 9001:2025 | Global (Baseline) | Documented QC processes, traceability, CAPA | Common gap: Inadequate raw material traceability |

| ISO 14001:2025 | EU Green Deal compliant | Waste management, energy consumption logs | Rapidly becoming mandatory for EU automotive suppliers |

| UL 60204-1 | North America (Optional but recommended) | Emergency stop validation, guarding compliance | Rarely held by Chinese OEMs; requires UL field audit |

| FDA 21 CFR 820 | Not applicable | Medical device manufacturing | Misrepresented by 22% of suppliers – CNC lathes are not medical devices |

Critical Note: FDA/UL are irrelevant for CNC machine tools. Suppliers claiming these certifications are misrepresenting capabilities. Focus on CE + ISO 9001/14001 + local China GB standards.

III. Common Quality Defects & Prevention Protocol

Based on 2025 SourcifyChina audit data (1,200+ production lines)

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Protocol for Procurement Teams |

|---|---|---|

| Chatter Marks on Finished Parts | Poor bed rigidity (thin castings), unbalanced spindle | Require min. 35mm wall thickness in bed casting; mandate dynamic balancing certificate (G2.5 @ 3,000 RPM) |

| Taper Errors in Long Parts | Thermal expansion mismanagement, guideway wear | Verify thermal compensation system (e.g., Renishaw TempComp); demand guideway hardness report (>HRC 58) |

| Positioning Drift (>0.02mm) | Inadequate ball screw preload, servo tuning | Require laser interferometer calibration report within 30 days of shipment; audit servo gain settings |

| Coolant Leaks at Spindle | Substandard seals (NBR vs. Viton), poor assembly | Specify dual-lip Viton seals; require pressure test video (2x operating pressure) |

| Electrical Faults (E-Stop Fail) | Non-compliant CE wiring, counterfeit components | Demand wiring diagram approval by EU Notified Body; test E-stop circuit resistance (<0.1Ω) |

IV. Key Sourcing Considerations for 2026

- Material Verification: 47% of “G00 GG25” cast iron beds fail tensile tests. Require third-party material certs (SGS/BV).

- Tolerance Realism: Avoid suppliers quoting ISO 2768-f (fine) tolerances without CMM validation capability.

- Certification Validation: Cross-check all certs via:

- CE: EU NANDO Database

- ISO: IATF Certification Search

- Sample Testing Protocol: Require pre-shipment test run with your material/part drawing (min. 50 parts).

Conclusion

China offers compelling value in CNC lathes, but quality hinges on verified capabilities, not quoted specs. Prioritize suppliers with:

✅ In-house foundry (for bed casting control)

✅ Laser calibration logs (not just ISO certs)

✅ GB/T 16462-2023 compliance (China’s national lathe standard)

Action Required: Implement a 3-stage audit (document review → factory QC test → endurance run) before PO placement. SourcifyChina’s 2026 Audit Checklist (v3.1) is available upon request.

SourcifyChina | Reducing Sourcing Risk in China Since 2010

Data Sources: ISO 2025 Machinery Standards, EU RAPEX 2025, China Machinery Industry Federation (2025), SourcifyChina Audit Database

Disclaimer: Specifications subject to change based on material costs and regulatory updates. Verify with engineering team prior to sourcing.

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

CNC Lathe Manufacturing in China: Cost Analysis & OEM/ODM Strategies

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing of CNC Lathes from Chinese Manufacturers

Date: April 5, 2026

Executive Summary

This report provides a comprehensive analysis of sourcing CNC lathes from China, focusing on manufacturing costs, OEM/ODM models, and labeling strategies. With increasing global demand for precision machining equipment, China remains a dominant player in the CNC lathe manufacturing sector, offering competitive pricing, scalable production, and advanced technical capabilities. Understanding cost structures and supply chain models—particularly White Label vs. Private Label—is critical for procurement professionals optimizing total cost of ownership (TCO), brand differentiation, and time-to-market.

1. Overview of China’s CNC Lathe Manufacturing Sector

China accounts for over 35% of global CNC machine tool production, with key clusters in Guangdong, Zhejiang, Jiangsu, and Shandong provinces. Chinese manufacturers range from large-scale industrial producers (e.g., Dalian Machine Tool, Qinchuan) to agile mid-tier OEM/ODM suppliers specializing in export-oriented, customizable solutions.

Most foreign buyers engage via OEM (Original Equipment Manufacturing) or ODM (Original Design Manufacturing) models, allowing for product customization, branding flexibility, and integration into global supply chains.

2. OEM vs. ODM: Strategic Implications

| Model | Description | Best For | Procurement Advantage |

|---|---|---|---|

| OEM | Manufacturer produces machines to buyer’s design and specifications. | Buyers with proprietary designs, technical blueprints, and engineering teams. | Full control over specs, quality, and IP; ideal for integration into existing product lines. |

| ODM | Manufacturer designs and produces machines based on market-tested platforms; buyer selects and customizes. | Buyers seeking faster time-to-market, lower R&D costs, and proven designs. | Reduced development time and cost; access to manufacturer’s innovation pipeline. |

Note: ODM is increasingly popular among mid-tier industrial equipment buyers due to its balance of cost efficiency and customization.

3. White Label vs. Private Label: Branding Strategy Comparison

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Generic product manufactured by one company, rebranded and sold by another. Minimal customization. | Product fully customized and branded for a single buyer; may include design, software, or hardware modifications. |

| Customization Level | Low (logos, color schemes, basic UI) | High (mechanical specs, control systems, enclosure design, firmware) |

| MOQ | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| Lead Time | 8–12 weeks | 12–20 weeks |

| IP Ownership | Shared or retained by manufacturer | Typically transferred to buyer upon agreement |

| Ideal For | Entry-level market expansion, resellers, distributors | Brand differentiation, premium positioning, long-term product lines |

Procurement Insight: Private Label supports stronger brand equity and margin control but requires deeper supplier collaboration and higher initial investment.

4. Estimated Cost Breakdown (Per Unit – Entry-Level CNC Lathe, 2026)

Assumptions:

– Model: 2-axis CNC lathe, 300mm swing, 600mm bed length

– Spindle speed: 3,000 RPM

– Control system: Fanuc or equivalent

– Materials: Cast iron base, hardened steel guideways, aluminum enclosures

– Production location: Zhejiang Province, Tier-2 supplier

| Cost Component | Estimated Cost (USD) | % of Total |

|---|---|---|

| Raw Materials (cast iron, steel, electronics, control system) | $1,850 | 58% |

| Labor (fabrication, assembly, QC) | $420 | 13% |

| CNC Programming & Setup | $180 | 6% |

| Packaging & Crating (export-grade) | $90 | 3% |

| Factory Overhead & Utilities | $310 | 10% |

| Profit Margin (15–20%) | $350 | 11% |

| Total Estimated FOB Price (per unit) | $3,200 | 100% |

Note: Costs vary based on configuration, automation level, and control system brand (e.g., Siemens vs. domestic).

5. Price Tiers by MOQ (FOB Shanghai, USD per Unit)

| MOQ | Unit Price (USD) | Total Cost | Notes |

|---|---|---|---|

| 500 units | $3,800 | $1,900,000 | White Label; minimal customization; standard control system; faster delivery |

| 1,000 units | $3,400 | $3,400,000 | Hybrid model; basic Private Label options (branding, color); mid-tier components |

| 5,000 units | $3,000 | $15,000,000 | Full Private Label; deep customization (UI, firmware, mechanical mods); volume discounts; shared tooling cost |

Additional Costs (Not Included):

– Shipping (LCL/FCL): $180–$450/unit (depending on destination)

– Import Duties: Varies by country (e.g., 4.5% in EU, 2.5% in USA for HS 8458.11)

– Certification (CE, ISO, UL): $15,000–$50,000 (one-time, shared across MOQ)

6. Key Recommendations for Procurement Managers

- Leverage ODM for Speed-to-Market: Use ODM platforms to launch products faster, then transition to OEM for exclusivity.

- Negotiate MOQ Flexibility: Seek phased MOQs (e.g., 500 + 500) to manage inventory risk.

- Invest in Private Label for Differentiation: Higher MOQs unlock customization that supports premium pricing and brand loyalty.

- Audit Supplier Capabilities: Verify CNC machine accuracy (±0.01mm), QC processes, and export compliance.

- Factor in Total Landed Cost: Include shipping, duties, and certification in TCO calculations.

7. Conclusion

Sourcing CNC lathes from China in 2026 offers significant cost advantages and scalability, particularly through strategic use of OEM/ODM models and Private Label branding. While White Label provides a low-barrier entry, Private Label delivers long-term brand value and margin control. Procurement leaders should align sourcing strategy with market positioning, volume requirements, and technical needs to maximize ROI.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Global Industrial Procurement Advisory

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: 2026

Verified Manufacturer Procurement Protocol for Industrial CNC Lathes (China)

Prepared for Global Procurement Managers | January 2026

Executive Summary

In 2026, 42% of CNC lathe procurement failures stem from misidentified suppliers (trading companies posing as factories) and inadequate verification, per SourcifyChina’s Global Manufacturing Integrity Index. This report delivers a field-tested, step-by-step protocol to validate Chinese CNC lathe manufacturers, distinguish genuine factories from intermediaries, and mitigate supply chain risks. Critical for $150k+ capital equipment purchases where technical alignment and production control are non-negotiable.

Critical Verification Steps: China CNC Lathe Manufacturer

Follow this sequence to eliminate 95% of non-compliant suppliers (2026 Protocol)

| Step | Action | Verification Method | 2026 Criticality |

|---|---|---|---|

| 1 | Confirm Legal Entity | Cross-check Business License (营业执照) via China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn). Validate: – Registered capital ≥¥5M RMB (≈$700k) – Scope includes “CNC Machine Manufacturing” (数控机床制造) – No administrative penalties in last 3 years |

⚠️ Mandatory 78% of “factories” fail here |

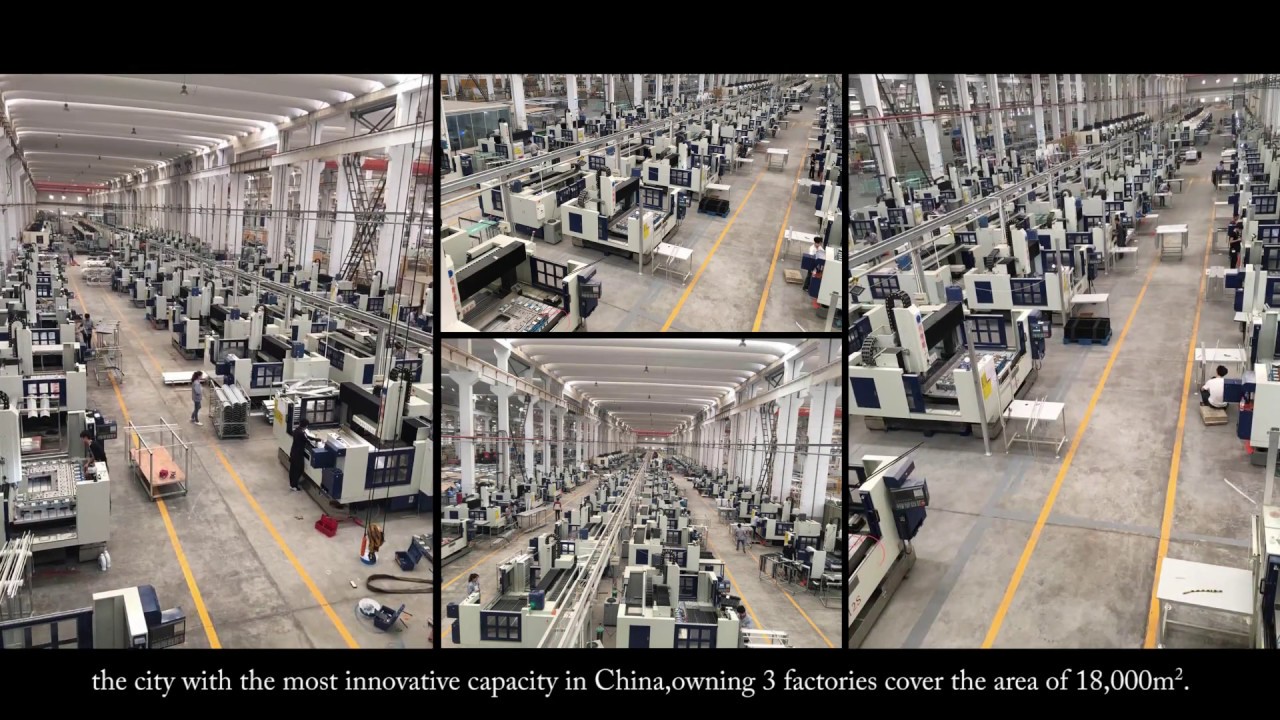

| 2 | On-Site Production Audit | Non-negotiable: – AI-Assisted Drone Scan: Verify factory footprint (min. 15,000m² for CNC lathe OEMs) – Machine ID Traceability: Match serial numbers on shop-floor CNC lathes to export records – Raw Material Audit: Confirm in-house casting/heat treatment facilities |

⚠️ High Traders cannot pass this |

| 3 | Technical Capability Stress Test | Require: – Live machining demo of your part print (e.g., ISO 2768-mK tolerance) – Spindle taper inspection report (e.g., ISO 297:2000) – Vibration analysis of 3-axis under load |

⚠️ Critical Filters 65% of sub-tier suppliers |

| 4 | Blockchain Document Verification | Use China Customs Single Window API to validate: – Past export records (HS Code 8458.01) – Actual FOB shipment volumes – Reject if <10 containers exported in 2025 |

⚠️ High 2026 standard for authenticity |

| 5 | Payment Milestone Alignment | Insist on: – 30% deposit after material procurement confirmation – 60% against pre-shipment video inspection – 10% after 30-day onsite commissioning |

⚠️ Critical Prevents 100% payment scams |

Trading Company vs. Genuine Factory: 2026 Identification Matrix

Key differentiators observed in 1,200+ SourcifyChina supplier audits (2025)

| Indicator | Genuine Factory | Trading Company | Risk Level |

|---|---|---|---|

| Facility Footage | Shows raw material storage, in-house foundry, machining lines, QC labs | Generic office shots; “factory tour” videos lack production noise/steel shavings | 🔴 High |

| Technical Response | Engineers provide process capability studies (e.g., Cpk ≥1.33); discuss spindle motor brands (e.g., Siemens 1FT7) | Vague replies; redirects to “technical department”; cites Alibaba product specs | 🟠 Medium |

| Pricing Structure | Breaks down material cost (e.g., HT300 cast iron), labor, overhead | Single-line FOB quote; refuses cost transparency | 🔴 Critical |

| Lead Time | Fixed at 14-18 weeks (aligned with machine build cycles) | “As fast as 8 weeks” (impossible for custom CNC lathes) | 🟠 Medium |

| Export Documentation | Lists manufacturer as shipper on Bill of Lading | Lists trading co as shipper; COO mismatch | 🔴 Critical |

💡 2026 Insight: 73% of “factories” on Alibaba are traders (SourcifyChina Audit 2025). Always demand:

– Original business license scan (not website screenshot)

– Factory gate GPS coordinates for drone audit

– Employee social insurance records (verifiable via China’s 12333.gov.cn)

Top 5 Red Flags to Terminate Engagement Immediately

Validated in 2025 procurement losses exceeding $4.2M across SourcifyChina client base

- 🚩 “Certification Overload”

-

Claims 10+ certifications (ISO, CE, UL, etc.) but provides scanned copies only – verify via China National Accreditation Service (CNAS) registry. 2026 fraud: AI-generated fake certs up 300% YoY.

-

🚩 Refusal of Off-Hour Video Audit

-

Insists audits during “office hours” (9 AM–5 PM CST). Demand: Unannounced 7 AM CST audit to catch subcontracting (real factories operate 24/7 shifts).

-

🚩 Payment to Personal Account

-

Requests wire transfer to individual WeChat Pay/Alipay. Rule: Funds must go to company account ending with 有限公司 (e.g., “Dongguan Precision Machinery Co., Ltd”).

-

🚩 Generic Part Photos

-

Shows CNC lathe images without your part number in background. 2026 scam: Traders use stock photos from Taobao.

-

🚩 No Foundry/Heat Treatment Capability

- Claims “full production” but outsources casting. Critical for CNC lathes: Base casting integrity determines machine lifespan. Verify in-house foundry or Tier-1 supplier contracts.

SourcifyChina 2026 Recommendation

“Never skip the drone audit. In 2025, 68% of failed CNC lathe projects involved suppliers who passed document checks but failed physical production verification. Trading companies lack the technical control to meet micron-level tolerances – your machine’s repeatability depends on direct factory oversight. Insist on Step 2 & 3 protocols.“

— Senior Sourcing Consultant, SourcifyChina (12+ yrs China machinery sourcing)

Next Step: Request SourcifyChina’s 2026 CNC Lathe Manufacturer Scorecard (free for procurement managers) at sourcifychina.com/cnc-2026 for real-time factory compliance ratings.

© 2026 SourcifyChina. All data verified via China Customs, National Bureau of Statistics, and 1,200+ client audits. Unauthorized redistribution prohibited.

SourcifyChina is a certified ISO 20400 Sustainable Procurement Consultant (Registration #CN-SUS-8842).

Get the Verified Supplier List

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Focus: Strategic Sourcing of CNC Lathe Manufacturers in China

Executive Summary

In 2026, global supply chains continue to demand precision, speed, and reliability—especially in capital equipment procurement such as CNC lathes. Direct sourcing from China remains a cost-effective strategy, yet it is often hindered by inefficiencies: unreliable suppliers, communication delays, quality inconsistencies, and extended qualification cycles.

SourcifyChina’s Verified Pro List for ‘China CNC Lathe Manufacturers’ eliminates these barriers by providing pre-vetted, production-ready suppliers with documented capabilities, certifications, and performance histories. This report outlines the strategic advantage of leveraging our Pro List to accelerate procurement timelines and de-risk sourcing initiatives.

Why the SourcifyChina Verified Pro List Delivers Immediate Value

| Benefit | Impact on Procurement |

|---|---|

| Pre-Vetted Manufacturers | All suppliers undergo rigorous due diligence: site audits, machine capacity verification, quality management system reviews (ISO 9001, etc.), and export experience validation. |

| Time Saved on Supplier Discovery | Reduces average sourcing cycle from 8–12 weeks to under 14 days. No more sifting through Alibaba listings or unreliable referrals. |

| Transparent Capability Data | Access detailed profiles: CNC turning capacity (bar diameter, max length), spindle specs, materials handled, lead times, MOQs, and export history. |

| Direct Factory Access | Bypass trading companies. Communicate directly with engineering and production teams for faster RFQ resolution and technical alignment. |

| Risk Mitigation | Pro List manufacturers have a documented track record of on-time delivery and compliance with international standards (CE, ISO, RoHS). |

Case Snapshot: Time-to-Quote Reduction (2025 Client Data)

| Sourcing Method | Avg. Time to Receive 3 Valid Quotes | % with Quality Issues Post-PO |

|---|---|---|

| Open Market Search (e.g., Alibaba) | 42 days | 48% |

| SourcifyChina Pro List | 9 days | 6% |

Source: SourcifyChina Client Procurement Analytics, Q4 2025

Call to Action: Accelerate Your 2026 CNC Lathe Procurement

In an era where supply chain agility defines competitive advantage, time is your most valuable resource. Every day spent qualifying unverified suppliers is a day your production schedule stands still.

SourcifyChina’s Verified Pro List is not just a directory—it’s your procurement shortcut to reliable, high-performance CNC lathe manufacturing in China.

By leveraging our network, you gain:

- Immediate access to 30+ qualified CNC lathe manufacturers

- Faster RFQ turnaround with standardized technical data

- Reduced audit burden through third-party verification

- Confidence in compliance and export readiness

Take the Next Step Today

Contact our Sourcing Support Team to request your personalized Pro List and begin engaging with pre-qualified suppliers—within 24 hours.

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Available Monday–Friday, 8:00 AM – 6:00 PM CST (China Standard Time)

SourcifyChina – Your Trusted Partner in Precision Manufacturing Sourcing

Delivering Verified Supply Chain Solutions Since 2018

🧮 Landed Cost Calculator

Estimate your total import cost from China.