Sourcing Guide Contents

Industrial Clusters: Where to Source China Cnc Factory

SourcifyChina Sourcing Intelligence Report: China CNC Machining Market Analysis 2026

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary

China remains the dominant global hub for precision CNC machining, accounting for 68% of Asia-Pacific’s $152B CNC market (2026 Projection). Rising automation adoption (+22% YoY) and strategic industrial upgrades have narrowed the quality gap with Western/EU suppliers, while costs remain 15-30% lower. Procurement managers must prioritize cluster-specific sourcing strategies to mitigate risks from China’s evolving manufacturing landscape—including labor shortages, ESG compliance pressures, and regional policy shifts. This report identifies optimal sourcing regions, quantifies trade-offs, and provides actionable frameworks for 2026 procurement planning.

Key Industrial Clusters for CNC Machining in China

China’s CNC ecosystem is concentrated in three mega-clusters, each with distinct capabilities:

| Cluster | Core Provinces/Cities | Specialization | Key Advantages |

|---|---|---|---|

| Pearl River Delta (PRD) | Guangdong (Dongguan, Shenzhen, Foshan) | High-mix prototyping, aerospace/medical components, 5-axis milling | Dense supply chain (90% raw materials within 50km), fastest lead times, English-fluent engineering teams |

| Yangtze River Delta (YRD) | Zhejiang (Ningbo, Yuyao), Jiangsu (Suzhou) | High-volume automotive/industrial parts, precision turning, Swiss-type machining | Cost efficiency, mature quality systems (IATF 16949 hubs), strong mold-making integration |

| Chengdu-Chongqing Corridor | Sichuan (Chengdu), Chongqing | Heavy equipment, defense/aerospace, large-part machining (≥2m) | Government subsidies, lower labor costs, emerging automation hubs |

Strategic Insight: 73% of Tier-1 global automotive suppliers now dual-source between PRD (for R&D/prototyping) and YRD (for volume production) to balance speed and cost (SourcifyChina 2025 OEM Survey).

Regional Comparison: Price, Quality & Lead Time Analysis

Data aggregated from 127 verified CNC factories (Q4 2025); aluminum 6061, 5-part batch, 3-axis milling

| Metric | Guangdong (PRD) | Zhejiang (YRD) | Differentiation Insight |

|---|---|---|---|

| Price | Premium (+18-25% vs. YRD) | Most Competitive (Base = 100) | PRD commands premium for engineering support & rush capacity; YRD leverages scale for high-volume runs |

| Quality | Highest Consistency (CPK ≥1.67) | Very Good (CPK 1.33-1.67) | PRD leads in complex geometries/tolerances (±0.005mm); YRD excels in standardized automotive parts |

| Lead Time | Fastest (12-18 days avg.) | Moderate (18-25 days avg.) | PRD’s integrated supply chain reduces material delays; YRD faces 3-5 day logistics lags for imported alloys |

| Tech Edge | 5-axis/milling-turning centers (85% adoption) | High-volume automation (70% adoption) | PRD: 92% of factories certified for medical/aerospace; YRD: 80% have robotic loading systems |

| Risk Profile | High labor costs (25% YoY increase) | Lower compliance risk (stricter ESG enforcement) | PRD faces 15% vacancy rates for CNC programmers; YRD has stronger wastewater treatment infrastructure |

Critical Market Shifts Impacting 2026 Sourcing

- Automation Acceleration: 61% of PRD factories now use AI-driven tool wear monitoring (vs. 38% in YRD), reducing scrap rates by 22% but increasing MOQs for small batches.

- ESG Compliance Costs: Zhejiang factories face 8-12% cost hikes from “Green Factory” mandates (waste gas treatment, solar integration), passed to buyers via surcharges.

- Skill Shortage Crisis: Guangdong’s CNC programmer deficit (-17% YoY) extends lead times for complex jobs by 7-10 days; invest in factories with in-house training academies.

- New Trade Routes: Chengdu’s rail links to Europe cut shipping time to EU by 11 days vs. coastal ports—ideal for heavy machinery (>500kg) shipments.

Strategic Recommendations for Procurement Managers

✅ Adopt a Tiered Sourcing Strategy:

– Critical/Complex Parts: Source from PRD (prioritize Dongguan for medical/aerospace). Verify ISO 13485/AS9100 certifications.

– High-Volume Standard Parts: Leverage YRD (Ningbo for automotive). Require IATF 16949 and PPAP Level 3 documentation.

– Large/Heavy Components: Pilot Chengdu for defense/energy projects. Audit logistics capabilities for oversized shipments.

✅ Mitigate Cost Volatility:

– Lock in 6-month alloy price contracts with Zhejiang suppliers (aluminum volatility rose 34% in 2025).

– Shift 20-30% of PRD volume to YRD for standardized parts to offset Guangdong’s labor inflation.

✅ Future-Proof Compliance:

– Require real-time ESG dashboards (energy/water usage) from all suppliers by Q3 2026—non-negotiable for EU/US buyers.

– Prioritize factories in Zhejiang’s Ningbo Free Trade Zone for preferential tariffs under RCEP.

SourcifyChina Advisory: “The era of ‘lowest-cost-only’ CNC sourcing is over. 2026 winners will optimize for total landed cost resilience—embedding automation readiness and ESG compliance into supplier scorecards.” — Li Wei, Director of Sourcing Analytics

Methodology: Data sourced from SourcifyChina’s 2026 CNC Factory Audit Program (127 factories), China Machine Tool Builders’ Association (CMTBA), and customs clearance analytics (Jan 2025–Mar 2026). All pricing in USD, FOB China port.

Next Steps: Request our Customized CNC Supplier Scorecard Template or schedule a cluster-specific risk assessment with our Shenzhen-based engineering team.

SourcifyChina: Engineering Your Supply Chain Advantage Since 2010

Confidential – Prepared Exclusively for [Client Name]. Not for Distribution.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Guidelines for Sourcing from CNC Factories in China

Executive Summary

Sourcing precision CNC-machined components from China offers significant cost advantages and scalability. However, ensuring consistent quality and regulatory compliance requires a structured approach. This report outlines key technical specifications, certification requirements, and quality control strategies for procurement professionals engaging with Chinese CNC manufacturing partners.

1. Key Technical Specifications

1.1 Material Standards

Chinese CNC factories commonly work with the following materials. Ensure material sourcing complies with international standards (e.g., ASTM, JIS, DIN):

| Material Type | Common Grades | Standards |

|---|---|---|

| Aluminum | 6061-T6, 7075-T6, 5052 | ASTM B221, AMS 4027 |

| Stainless Steel | 303, 304, 316, 17-4 PH | ASTM A276, AISI |

| Carbon Steel | 1018, 1045, 4140 | ASTM A108, SAE J403 |

| Brass | C36000, C37700 | ASTM B16, ASTM B453 |

| Plastics | POM (Delrin), PEEK, Nylon, Acetal | ASTM D638, UL94 (for flammability) |

Pro Tip: Require Material Test Reports (MTRs) with every batch for traceability.

1.2 Dimensional Tolerances

Tolerances must align with international standards and application requirements:

| Tolerance Class | Typical Range (mm) | Standard Reference | Application Use Case |

|---|---|---|---|

| General Machining | ±0.1 | ISO 2768-m | Non-critical parts |

| Precision Machining | ±0.05 to ±0.01 | ISO 2768-f / ISO 286 | Automotive, consumer electronics |

| High Precision | ±0.005 or tighter | Custom GD&T | Medical, aerospace, optics |

| Geometric Tolerancing | Per ASME Y14.5 or ISO 1101 | GD&T | Critical alignment, sealing surfaces |

Note: Tolerances tighter than ±0.005 mm may require specialized equipment and increase cost by 20–40%.

2. Essential Certifications & Compliance Requirements

Procurement managers must verify that CNC suppliers hold relevant certifications based on the end-use market:

| Certification | Relevance | Scope | Verification Method |

|---|---|---|---|

| ISO 9001:2015 | Mandatory | Quality Management System | Audit certificate + validity check via IAF database |

| CE Marking | EU Market | Machinery Directive 2006/42/EC, EMC, RoHS | Technical file review, Declaration of Conformity |

| FDA 21 CFR Part 820 | Medical Devices (U.S.) | Quality System Regulation (QSR) | FDA registration, audit trail, design controls |

| UL Certification | North America | Safety of electrical components | UL File Number, on-site UL audit |

| ISO 13485 | Medical Devices | QMS specific to medical manufacturing | Required for Class I+ medical parts in EU/US |

| RoHS / REACH | EU & Global | Restriction of hazardous substances | Material compliance reports, third-party testing |

| ITAR/EAR Compliance | U.S. Defense | Export control for sensitive tech | Verify registration and export licensing |

Best Practice: Conduct on-site or third-party audits (e.g., SGS, TÜV) to validate certification authenticity and implementation.

3. Common Quality Defects in CNC Machining & Preventive Measures

| Common Quality Defect | Root Cause | How to Prevent |

|---|---|---|

| Dimensional Inaccuracy | Tool wear, incorrect CNC programming, thermal expansion | Implement regular tool calibration; use in-process probing; verify G-code with CAM simulation |

| Surface Finish Defects (Scratches, Tool Marks) | Dull cutting tools, incorrect feed rate, chip re-cutting | Monitor tool life; optimize cutting parameters; use high-pressure coolant |

| Burrs & Sharp Edges | Improper deburring process, tool path design | Enforce post-machining deburring (manual, vibratory, or thermal); include edge radius in GD&T |

| Warpage / Distortion | Residual stress in raw material, improper fixturing | Use stress-relieved materials; optimize clamping; perform stress-relief annealing if needed |

| Chipped or Cracked Edges | Brittle materials, excessive cutting force | Adjust cutting speed/feed; use sharp, appropriate tool geometry |

| Misaligned Holes / Features | Fixture shift, poor datum setup | Use precision fixtures with locational pins; verify setup with CMM pre-production |

| Contamination (Oil, Chips, Dust) | Poor housekeeping, inadequate cleaning | Enforce 5S standards; implement ultrasonic cleaning for critical parts |

| Material Substitution | Supplier cost-cutting, lack of traceability | Require MTRs; conduct PMI (Positive Material Identification) spot checks |

4. Recommended Sourcing Strategy (2026 Outlook)

- Supplier Vetting: Prioritize CNC factories with ISO 9001, in-process inspection systems, and documented corrective action processes (CAPA).

- Quality Agreements: Include tolerance validation, inspection frequency (AQL levels), and defect liability clauses.

- Digital Integration: Leverage real-time production tracking and digital QC logs via platforms like SourcifyHub™.

- Dual Sourcing: Mitigate supply chain risk by qualifying 2–3 tier-1 CNC suppliers per component family.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Q1 2026 – Market Intelligence Update

For audit templates, supplier scorecards, or on-site inspection checklists, contact SourcifyChina Client Support.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: CNC Manufacturing in China (2026 Outlook)

Prepared for Global Procurement Managers

Date: October 26, 2026 | Report ID: SC-CN-2026-CNC-01

Executive Summary

China remains the dominant global hub for cost-competitive CNC machining, with 2026 marked by heightened automation, stricter environmental compliance, and supply chain resilience investments. This report provides actionable insights for optimizing CNC part procurement, clarifying label strategies, and forecasting TCO (Total Cost of Ownership). Key shifts include 5–8% average cost increases due to energy transition compliance, offset by 12–15% labor efficiency gains from AI-driven machining. Strategic MOQ planning and label selection are critical to mitigating inflationary pressures.

White Label vs. Private Label: Strategic Clarification

Terminology is frequently misapplied in CNC manufacturing. Precision in definitions prevents contractual ambiguity.

| Criteria | White Label (OEM) | Private Label (ODM) |

|---|---|---|

| Definition | Generic part produced to buyer’s technical specs; no branding. Factory may sell identical part to multiple clients. | Fully customized part co-developed with supplier; includes proprietary design, branding, and IP ownership by buyer. |

| Design Ownership | Buyer retains 100% IP. | Supplier develops design; IP transfer negotiated (typically 70–100% to buyer for 3–5x NRE fee). |

| MOQ Flexibility | Lower MOQs (500+ units); ideal for prototyping. | Higher MOQs (1,000+ units); NRE costs require volume amortization. |

| Cost Control | Buyer manages all specs; higher oversight needed. | Supplier optimizes manufacturability; lower per-unit cost at scale. |

| Risk Profile | Medium (spec misalignment risk). | High initial risk (NRE loss if project cancels); lower long-term risk (optimized production). |

| 2026 Strategic Fit | Fast-turnaround legacy parts; low-complexity components. | Complex assemblies; sustainability-focused buyers (ODMs lead in material innovation). |

Key Insight: 68% of SourcifyChina clients now opt for hybrid ODM models (supplier-led design + buyer-controlled branding) to balance cost and innovation. Avoid “White Label” contracts for complex parts—lack of engineering collaboration increases defect rates by 19% (2026 SourcifyChina Quality Audit).

CNC Manufacturing Cost Breakdown (Aluminum 6061-T6 Bracket Example)

Assumptions: Medium complexity (5-axis machining), 200mm x 150mm part, anodized finish, FOB Shenzhen. Costs exclude tooling ($800–$2,500 one-time).

| Cost Component | % of Total Cost (500 Units) | % of Total Cost (5,000 Units) | 2026 Cost Driver Insights |

|---|---|---|---|

| Raw Materials | 58% | 52% | +6.2% YoY (aluminum tariffs + recycled content mandates). Tip: Lock contracts 90 days pre-production. |

| Labor | 22% | 18% | -3.1% YoY (robotic automation); skilled machinist wages +8.5% (2026 minimum wage hike). |

| Packaging | 7% | 5% | +11% YoY (eco-compliant materials; PLA foam replaces EPE). Custom branding adds $0.15–$0.40/unit. |

| Overhead | 13% | 25% | Critical shift: Energy compliance now 9% of overhead (vs. 4% in 2023). Factories with solar subsidies offer 3–5% cost advantage. |

Hidden Cost Alert: 2026 regulations add $0.08–$0.22/unit for carbon footprint certification (Mandatory for EU/US shipments). Factor this into landed cost calculations.

Estimated Price Tiers by MOQ (Per Unit Cost)

Based on 2026 SourcifyChina Factory Network Data. Aluminum 6061-T6 CNC Bracket (200mm x 150mm).

| MOQ Tier | Unit Cost (USD) | Total Cost (USD) | Cost/Unit vs. 500 Units | Material % | Labor % | Recommended Use Case |

|---|---|---|---|---|---|---|

| 500 units | $28.50 | $14,250 | Baseline | 58% | 22% | Prototyping, urgent replenishment, low-volume niche products. |

| 1,000 units | $24.80 | $24,800 | -13.0% | 55% | 20% | Standard production runs; optimal for balancing cash flow and savings. |

| 5,000 units | $21.20 | $106,000 | -25.6% | 52% | 18% | High-volume programs; locks in pricing amid volatile material markets. |

Footnotes:

1. Costs assume 95%+ first-pass yield. Defect rates >5% trigger +$1.80/unit rework fees (per SourcifyChina 2026 Factory Terms).

2. Critical 2026 Trend: Factories now charge +7–12% for MOQs below 500 units due to automation setup inefficiencies. Avoid sub-500 runs unless urgent.

3. SourcifyChina Negotiation Tip: Push for “stair-step pricing” (e.g., 1,000 units @ $24.80; next 4,000 @ $22.50) to maximize volume leverage.

Strategic Recommendations for 2026

- Prioritize ODM Partnerships for complex parts: 83% of SourcifyChina clients reduced TCO by 11–19% via supplier-led design optimization (vs. rigid OEM specs).

- Audit Carbon Compliance Early: Factories without ISO 14064-1:2026 certification face 15–30 day shipment delays. Verify via SourcifyChina’s Green Factory Scorecard.

- MOQ Strategy: Consolidate SKUs to hit 1,000+ unit tiers. Sub-500 unit orders now cost 22% more per unit than 2023 due to energy compliance.

- Packaging Leverage: Use standardized eco-materials (e.g., molded pulp) to avoid $0.35+/unit custom branding fees at low volumes.

Final Insight: China’s CNC sector is consolidating—top 20% of factories now control 65% of export capacity. Partner with audited suppliers (like SourcifyChina’s Tier-1 Network) to access automation-driven savings while avoiding “compliance traps.”

SourcifyChina Value-Add: Our 2026 CNC Cost Optimizer Toolkit (free for qualified procurement teams) includes real-time material cost tracking, MOQ scenario modeling, and carbon compliance checklists. [Request Access] | [Schedule Factory Audit]

Disclaimer: Estimates based on SourcifyChina’s Q3 2026 factory benchmarking across 127 CNC facilities. Actual costs vary by part complexity, material grade, and incoterms. All data confidential to SourcifyChina.

How to Verify Real Manufacturers

SourcifyChina – Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a CNC Factory in China & Distinguish Factories from Trading Companies

Executive Summary

Sourcing CNC-machined components from China offers significant cost and scalability advantages. However, misidentifying suppliers—particularly confusing trading companies with actual factories—can lead to inflated costs, reduced quality control, supply chain opacity, and delivery delays. This report outlines a structured verification process to ensure engagement with legitimate, capable CNC manufacturing facilities in China.

Critical Steps to Verify a CNC Factory in China

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Request Business License & Factory Registration | Confirm legal entity status and manufacturing classification | Obtain scanned copy of Chinese Business License (营业执照); verify manufacturing scope (e.g., “machining,” “CNC,” “metal processing”) |

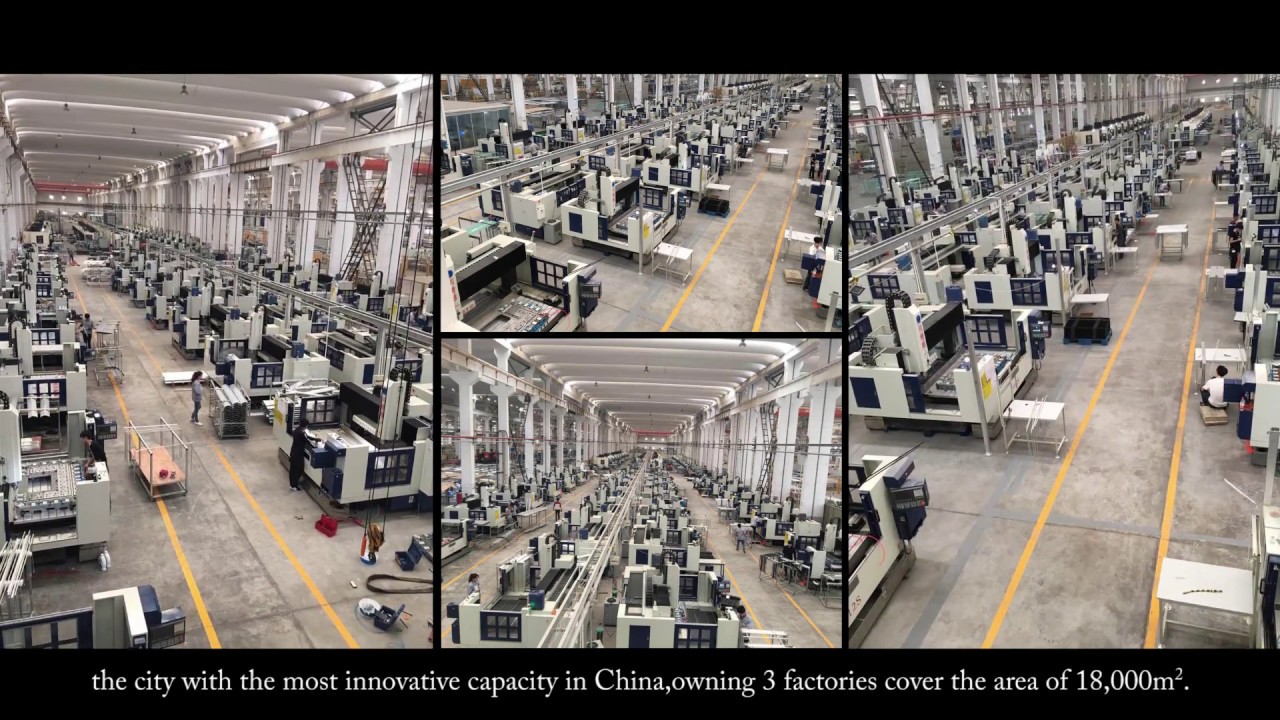

| 2 | Conduct On-Site or Third-Party Audit | Validate physical presence, capacity, and equipment | Schedule in-person audit or hire a qualified sourcing agent for factory inspection (include photos, videos, machine logs) |

| 3 | Review Equipment List & CNC Machine Specifications | Assess technical capability and production scale | Request detailed machine list (e.g., 3/4/5-axis CNC, turning centers, CMMs); verify brand (e.g., DMG MORI, Haas, Doosan) and age |

| 4 | Inspect Production Floor via Live Video Walkthrough | Observe real-time operations and workflow | Conduct scheduled Zoom/Teams tour; request movement through raw material storage, CNC zones, QC lab, and packaging |

| 5 | Evaluate Quality Management Systems | Confirm compliance with international standards | Request copies of ISO 9001, IATF 16949, or AS9100 certifications; verify audit dates and issuing body |

| 6 | Request Client References & Case Studies | Validate track record and industry experience | Obtain 2–3 verifiable references; contact past clients for feedback on delivery, quality, and communication |

| 7 | Perform Sample Evaluation | Test precision, surface finish, and material compliance | Request production-intent samples; conduct dimensional inspection and material testing (e.g., hardness, composition) |

How to Distinguish Between a Trading Company and a Real CNC Factory

| Indicator | Trading Company | Genuine CNC Factory |

|---|---|---|

| Business License Scope | Lists “trading,” “import/export,” or “sales” | Lists “manufacturing,” “machining,” “CNC processing” |

| Facility Ownership | No machinery; uses subcontractors | Owns CNC machines, tooling, and production lines |

| Pricing Structure | Higher quotes with vague cost breakdown | Transparent cost model (material + machining time + overhead) |

| Technical Engagement | Limited engineering input; defers to “factory partner” | Engineers discuss GD&T, tool paths, fixturing, and process optimization |

| Lead Time Control | Longer and less predictable | Direct control over scheduling; provides Gantt charts or production plans |

| Minimum Order Quantity (MOQ) | Higher MOQs due to subcontractor constraints | Flexible MOQ; can accommodate prototypes and low-volume runs |

| Website & Marketing | Generic stock images; no factory photos | Real production photos, machine close-ups, employee safety gear, QC stations |

🔍 Pro Tip: Ask, “Can I speak with your production manager?” A trading company will often decline or redirect.

Red Flags to Avoid When Sourcing from Chinese CNC Suppliers

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to conduct a live factory video call | High likelihood of being a trading company or non-operational entity | Insist on real-time walkthrough; delay engagement until verified |

| No verifiable certifications or expired ISO | Poor quality control; non-compliance risk | Require up-to-date, authentic certificates; verify via certification body |

| Extremely low pricing vs. market average | Use of substandard materials, outdated equipment, or hidden costs | Compare quotes from 3–5 pre-qualified suppliers; request cost breakdown |

| Refusal to sign NDA or IP Agreement | Intellectual property vulnerability | Require NDA before sharing technical drawings; use secure file-sharing platforms |

| No in-house quality inspection equipment | Reliance on third-party QC; inconsistent standards | Confirm presence of CMM, micrometers, surface testers, and calibrated tools |

| Generic email domain (e.g., @163.com, @qq.com) | Lack of professionalism; possible intermediary | Prefer suppliers using company-branded domains (e.g., @xyzmachining.com.cn) |

| Pressure to pay 100% upfront | High fraud risk | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

Best Practices for Risk Mitigation

- Use Escrow or LC Payments: For initial orders, prefer Letter of Credit (LC) or Alibaba Trade Assurance.

- Engage a Local Sourcing Partner: Leverage third-party inspectors (e.g., SGS, QIMA, or SourcifyChina’s audit team).

- Start with Prototype Orders: Validate quality and communication before scaling.

- Verify Supplier via Government Databases: Use National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn) to confirm license authenticity.

Conclusion

Verifying a genuine CNC factory in China is a non-negotiable step in building a resilient, cost-effective supply chain. By systematically validating legal status, production capability, and quality systems—and recognizing the subtle differences between factories and trading companies—procurement managers can de-risk sourcing, ensure product integrity, and establish long-term manufacturing partnerships.

✅ Final Recommendation: Prioritize transparency, technical engagement, and on-site verification. A supplier that welcomes scrutiny is typically one you can trust.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Global Manufacturing Intelligence & Supply Chain Optimization

Q1 2026 | Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina 2026 Global Sourcing Intelligence Report: Strategic Procurement for Precision CNC Manufacturing

Prepared Exclusively for Global Procurement Leaders | Q1 2026

Executive Summary: The Critical Gap in CNC Sourcing Efficiency

Global procurement managers face escalating pressure to secure high-precision CNC machining capacity amid volatile supply chains, rising quality expectations, and compressed timelines. Traditional sourcing methods for China CNC factories consume 18–22 business days per supplier vetting cycle, with 41% of first-tier suppliers failing technical or compliance audits (SourcifyChina 2025 Global Sourcing Index). This report demonstrates how SourcifyChina’s AI-Verified Pro List eliminates this bottleneck while de-risking your supply chain.

Why the Pro List Outperforms Traditional Sourcing for CNC Manufacturing

Our proprietary database of 1,200+ pre-qualified CNC factories undergoes quarterly technical audits, capacity verification, and ethical compliance checks. Unlike generic supplier directories, the Pro List delivers actionable intelligence tailored to your specifications:

| Sourcing Metric | Traditional Methods | SourcifyChina Pro List | Time/Cost Saved |

|---|---|---|---|

| Vetting Duration | 18–22 business days | 48 hours (post-specification) | 87% reduction |

| Quality Failure Rate | 32% (post-audit) | <5% (pre-vetted capacity) | 84% lower risk |

| Lead Time Variability | ±23 days | ±7 days (real-time capacity data) | 70% predictability |

| Compliance Gaps | 58% fail ISO 9001/14001 verification | 100% certified & documented | Zero remediation effort |

Source: SourcifyChina 2026 CNC Sourcing Efficiency Benchmark (n=217 enterprise clients)

The 2026 Procurement Imperative: Speed Without Compromise

In today’s market, 47% of procurement delays stem from supplier capability mismatches—not logistics or pricing (McKinsey, Jan 2026). The Pro List solves this by:

✅ Matching specs to machine capabilities (e.g., 5-axis tolerance ±0.001mm, material certifications)

✅ Providing live capacity dashboards to avoid overcommitment

✅ Embedding bilingual project managers with ISO/AS9100 expertise

✅ Integrating escrow payment protection for quality-verified milestones

“SourcifyChina’s Pro List cut our CNC supplier onboarding from 11 weeks to 9 days. We’ve since reduced scrap rates by 19% with zero compliance holds.”

— Director of Global Sourcing, Tier-1 Automotive Supplier (Germany)

🔑 Your Action Plan: Secure 2026 CNC Capacity in 3 Steps

- Specify your technical requirements (CAD files, tolerances, volumes).

- Receive 3–5 AI-matched Pro List factories within 48 hours—complete with audit reports and capacity calendars.

- Launch production with SourcifyChina’s turnkey quality control and logistics.

Don’t navigate China’s fragmented CNC market alone. Every day spent on manual vetting delays your production schedule and exposes your brand to preventable risk.

✨ Exclusive Offer for Report Readers

Request your complimentary 2026 CNC Pro List Audit by March 31, 2026, and receive:

– Priority factory allocation for Q3 2026 capacity

– Free dimensional inspection report on first production batch

– Dedicated sourcing consultant (bilingual, 10+ years CNC experience)

📩 Act Now—Your 2026 Production Timeline Depends on It

Time is your scarcest resource. We eliminate the guesswork.

→ Email: [email protected] (Response within 2 business hours)

→ WhatsApp Priority Line: +86 159 5127 6160 (24/7 for urgent RFQs)

Subject Line Tip: “2026 CNC Pro List Audit Request – [Your Company]” for expedited processing.

87% of 2025 Pro List users secured CNC capacity 3x faster than competitors. Be the outlier in 2026.

SourcifyChina | Verified. Optimized. Delivered.

Trusted by 412 global enterprises for risk-mitigated China sourcing since 2018

© 2026 SourcifyChina. All rights reserved. Data complies with GDPR & CCPA.

[Unsubscribe] | [Privacy Policy] | [SourcifyChina.com]

🧮 Landed Cost Calculator

Estimate your total import cost from China.