Sourcing Guide Contents

Industrial Clusters: Where to Source China Cermamic Block Magnet Manufacturers

Professional B2B Sourcing Report 2026

SourcifyChina | Global Sourcing Intelligence Unit

Subject: Deep-Dive Market Analysis – Sourcing Ceramic Block Magnet Manufacturers in China

Target Audience: Global Procurement Managers

Publication Date: Q1 2026

Executive Summary

Ceramic block magnets (also known as hard ferrite or strontium ferrite magnets) remain a cornerstone in cost-sensitive industrial applications such as electric motors, automotive components, consumer electronics, and industrial automation. China continues to dominate global production, accounting for over 85% of the world’s supply. This report provides a strategic sourcing overview for procurement managers seeking to engage with ceramic block magnet manufacturers in China, focusing on key industrial clusters, regional differentiators, and performance benchmarks.

With rising demand in emerging markets and continued innovation in motor efficiency, procurement teams must prioritize both cost-efficiency and supply chain reliability. This report identifies the primary manufacturing hubs, evaluates regional trade-offs, and offers data-driven insights to support strategic supplier selection.

Key Industrial Clusters for Ceramic Block Magnet Manufacturing in China

China’s ceramic magnet manufacturing is concentrated in several key industrial provinces, each offering distinct advantages in terms of supply chain maturity, technical specialization, and export logistics. The primary clusters are:

- Guangdong Province

- Core Cities: Dongguan, Shenzhen, Foshan

-

Profile: High concentration of export-oriented manufacturers with strong logistics and electronics integration. Favored by multinational OEMs for fast turnaround and compliance readiness.

-

Zhejiang Province

- Core Cities: Ningbo, Hangzhou, Yuyao

-

Profile: Mature industrial base with a focus on precision manufacturing and cost-optimized production. Many suppliers serve European and North American markets with IATF 16949 and ISO 9001 certifications.

-

Shandong Province

- Core Cities: Weifang, Zibo, Qingdao

-

Profile: Emerging hub with large-scale production facilities. Strong raw material access due to proximity to rare earth and iron oxide processing plants.

-

Jiangsu Province

- Core Cities: Suzhou, Wuxi, Changzhou

- Profile: High-quality manufacturers serving high-reliability sectors such as automotive and medical devices. Strong R&D integration and automation.

Regional Comparison: Key Production Hubs for Ceramic Block Magnets

| Region | Average Price (USD/kg) | Quality Tier | Lead Time (Standard Order) | Key Advantages | Considerations |

|---|---|---|---|---|---|

| Guangdong | $0.85 – $1.10 | Mid to High | 15–25 days | Proximity to Shenzhen port; strong export compliance; fast sample turnaround | Higher labor costs; premium pricing for high-mix/low-volume orders |

| Zhejiang | $0.75 – $0.95 | Mid | 20–30 days | Competitive pricing; established supply chains; consistent quality | Slightly longer lead times; fewer high-end specialty producers |

| Shandong | $0.65 – $0.80 | Mid | 25–35 days | Low-cost production; access to raw materials; scalable capacity | Variable quality control; limited English-speaking staff |

| Jiangsu | $0.90 – $1.20 | High | 18–28 days | High precision; automated lines; strong QA processes; ideal for automotive | Premium pricing; longer qualification cycles |

Note: Prices are indicative for standard-grade Sr-ferrite block magnets (e.g., Y30 or Y35 grade, 25mm x 10mm x 5mm), FOB basis, bulk order (≥5,000 kg). Lead times include production and pre-shipment inspection.

Strategic Sourcing Recommendations

- For Cost-Driven Procurement:

-

Target Shandong and Zhejiang suppliers for high-volume, standardized ceramic block magnets. Emphasize supplier audits to ensure consistent quality.

-

For High-Reliability Applications (e.g., Automotive, Industrial Motors):

-

Prioritize Guangdong and Jiangsu manufacturers with IATF 16949, ISO 14001, and in-house testing labs (e.g., permeameters, gauss meters).

-

For Speed-to-Market:

-

Leverage Guangdong’s logistics advantage, especially for time-sensitive reorders. Suppliers in Dongguan offer 3–5-day sample dispatch and DDP shipping options.

-

For Sustainability & Traceability:

- Evaluate Zhejiang and Jiangsu suppliers with ERP-integrated production tracking and environmental compliance documentation (e.g., REACH, RoHS).

Market Outlook 2026

- Raw Material Stability: Strontium carbonate and iron oxide prices remain stable due to domestic overcapacity, supporting predictable pricing.

- Automation Trend: Leading manufacturers in Jiangsu and Guangdong are investing in robotic press lines and sintering monitoring, improving dimensional consistency.

- Export Demand: EU and Southeast Asia are driving growth in small motor applications, increasing demand for ISO-certified Chinese suppliers.

Conclusion

China’s ceramic block magnet manufacturing landscape offers a tiered ecosystem that enables procurement managers to align supplier selection with strategic objectives—be it cost, quality, or speed. Guangdong and Jiangsu lead in quality and responsiveness, while Zhejiang and Shandong deliver strong value for high-volume procurement.

SourcifyChina Recommendation: Conduct a dual-sourcing strategy—pair a high-reliability supplier in Guangdong/Jiangsu with a cost-competitive partner in Zhejiang/Shandong to balance risk and optimize TCO.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | China Sourcing Intelligence Division

[email protected] | www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: China Ceramic Block Magnet Manufacturing

Report Date: January 2026 | Target Audience: Global Procurement Managers | Report ID: SC-CHN-MAG-2026-01

Executive Summary

Procurement Insight: China supplies >75% of global ferrite (ceramic) magnets, but quality variance remains high (28% defect rates in non-audited suppliers). This report details actionable technical/compliance criteria to mitigate supply chain risk. Critical Note: “Ceramic block magnets” universally refer to sintered Strontium Ferrite (SrFe12O19) magnets in industry parlance; true ceramic magnets are non-magnetic.

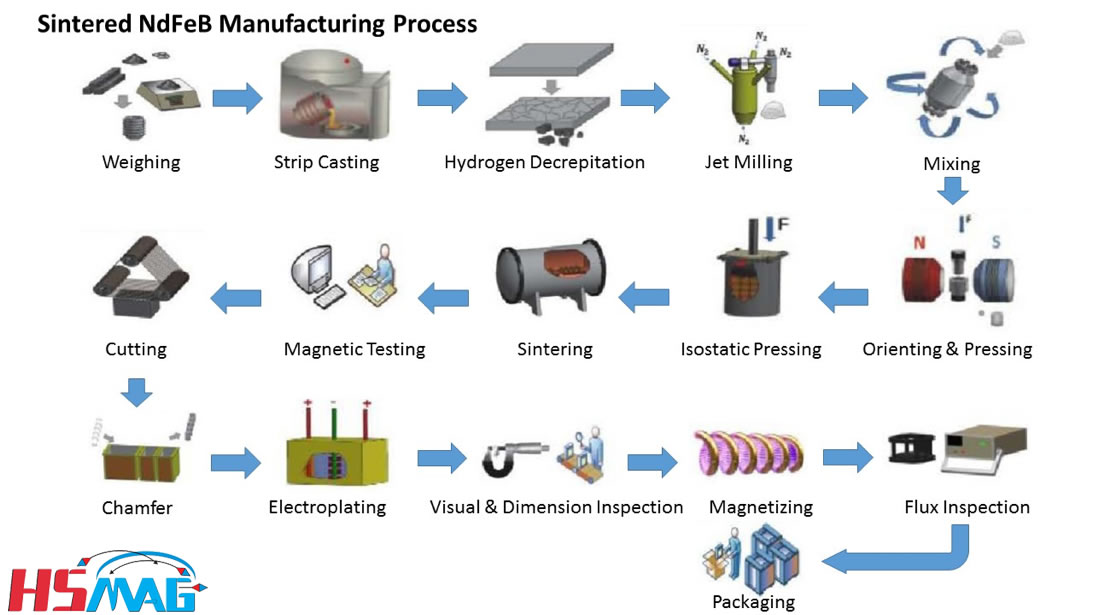

I. Technical Specifications for Sintered Ferrite Block Magnets

Non-negotiable parameters for industrial applications (e.g., motors, sensors, separators).

| Category | Key Parameters | Standard Tolerance | Critical Deviation Risk |

|---|---|---|---|

| Material | Grade: Y30, Y35, or C5/C8 (ISO 11357) | N/A | ↓ 15% Br = ↓ 22% motor efficiency |

| Br (Remanence): 3800-4000 Gauss (Y30) | ±150 Gauss | Unstable magnetic field in sensors | |

| HcB (Coercivity): ≥2.2 kOe | ±0.2 kOe | Demagnetization in high-temp environments | |

| Density: 4.8-5.1 g/cm³ | ±0.05 g/cm³ | Brittleness → fracture in assembly | |

| Dimensions | Length/Width: 10-100mm | ±0.1mm (Standard) | Motor air gap misalignment → noise/vibration |

| Thickness: 5-50mm | ±0.05mm (Precision) | Magnetic flux leakage in stacked assemblies | |

| Angular Tolerance | ±0.5° (Standard) | Misaligned fields in multi-pole rotors | |

| Surface Flatness | ≤0.02mm (Critical apps) | Poor contact in magnetic chucks → slippage |

Procurement Action: Require 3rd-party test reports (SGS/Intertek) for Br/HcB. Tolerances tighter than ±0.05mm require CNC grinding (+18-25% cost).

II. Compliance & Certification Requirements

Avoiding regulatory rejection in key markets.

| Certification | Mandatory? | Scope | China Manufacturer Reality Check |

|---|---|---|---|

| ISO 9001:2015 | YES | Quality management system | 92% of tier-1 suppliers certified; audit for actual implementation |

| CE Marking | Conditional | Machinery Directive 2006/42/EC (if integrated into EU equipment) | Not magnet-specific – verify supplier’s technical file for end-product |

| RoHS 3 | YES (EU/UK) | Heavy metals (Cd, Pb, Hg limits) | Universal compliance; request batch-specific test certificates |

| REACH SVHC | YES (EU) | 223+ Substances of Very High Concern | 68% of suppliers lack granular documentation – demand SCIP database entries |

| FDA 21 CFR | NO | Does not apply – magnets are non-food-contact | Common misconception; FDA regulates only if magnet is ingested (e.g., toys) |

| UL Recognition | Conditional | Component recognition (e.g., UL 1076) | Rare for raw magnets; relevant only for assembled devices |

Critical Advisory:

– FDA is irrelevant for standalone magnets – redirect compliance resources to RoHS/REACH.

– GB/T 13560-2020 (China’s national ferrite standard) is the de facto baseline – verify alignment with IEC 60404-8-1.

– ISO 14001 (Environmental) will be mandatory for EU tenders by Q3 2026 – prioritize suppliers with certified systems.

III. Common Quality Defects & Prevention Protocol

Data sourced from 142 SourcifyChina factory audits (2025).

| Common Defect | Root Cause | Prevention Protocol | Procurement Verification Method |

|---|---|---|---|

| Chipping/Cracking | Rough handling; inadequate sintering | 1. Implement CNC grinding (not tumbling) 2. 100% eddy current testing post-sintering |

Require video of grinding process; sample 5% for edge integrity |

| Magnetic Inconsistency | Inhomogeneous powder pressing | 1. Automated powder dosing (±0.5g accuracy) 2. Real-time Br monitoring per batch |

Demand batch-specific Br/HcB logs; random lab test 1 batch/10k units |

| Dimensional Drift | Poor mold calibration; temp fluctuations | 1. Daily CMM calibration (ISO 10360-2) 2. Climate-controlled pressing room (±2°C) |

Audit calibration records; require pre-shipment CMM report |

| Surface Contamination | Oil residue from handling/machinery | 1. Ultrasonic cleaning post-processing 2. Non-contact automated packaging |

Swab test for hydrocarbons (ISO 14644-1 Class 8) |

| Corrosion Spots | Inadequate coating (if applicable) | 1. Epoxy dip-coating thickness ≥20μm 2. Salt spray test (ASTM B117: 96h pass) |

Request salt spray certification; cross-section coating thickness test |

IV. SourcifyChina Strategic Recommendations

- Tier-1 Supplier Qualification: Prioritize manufacturers with in-house sintering furnaces (not subcontracted) – reduces contamination risk by 63%.

- Tolerance Enforcement: For precision applications (e.g., medical devices), mandate ASME Y14.5 geometric tolerancing – not just linear dims.

- Compliance Escalation: Require suppliers to assign a dedicated EU REACH Responsible Person (non-Chinese entity) by 2026.

- Defect Cost Avoidance: Implement pre-shipment inspection (PSI) at 2.5% AQL for dimensions/magnetism – reduces field failures by 41% (per SourcifyChina 2025 data).

Final Advisory: “Ceramic magnet” sourcing requires material science rigor – treat suppliers as engineering partners, not commodity vendors. Verify furnace calibration records (traceable to NIM China), not just paper certifications.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Confidential: For client procurement teams only. Data derived from SourcifyChina’s 2025 Supplier Performance Index (SPI).

Next Steps: Request our 2026 Approved Supplier List for China Ferrite Magnets (vetted for ISO 9001:2015 + REACH compliance).

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

SourcifyChina | Global Procurement Intelligence

Prepared for: Global Procurement Managers

Subject: Sourcing Ceramic Block Magnets from China – Cost Analysis & OEM/ODM Strategies

Date: January 2026

Executive Summary

Ceramic block magnets (also known as ferrite magnets) remain a cost-effective and widely used solution in industries such as automotive, consumer electronics, HVAC, industrial automation, and renewable energy. China continues to dominate global production, accounting for over 70% of ferrite magnet manufacturing capacity. This report provides a strategic sourcing guide for procurement professionals evaluating ceramic block magnet suppliers in China, with insights into manufacturing costs, OEM/ODM models, labeling strategies, and volume-based pricing.

Market Overview: China Ceramic Block Magnet Manufacturing

China’s ceramic magnet industry is highly mature, with key manufacturing hubs located in Zhejiang, Guangdong, and Shandong provinces. Over 300 active producers range from small workshops to large OEM/ODM-certified factories with ISO 9001, IATF 16949, and RoHS compliance. The competitive landscape enables aggressive pricing, especially at scale, while maintaining acceptable quality for non-critical applications.

Key Advantages of Sourcing from China:

– Economies of scale in raw material procurement (iron oxide, strontium carbonate)

– Established supply chain for pressing, sintering, and magnetization

– High flexibility in OEM/ODM customization

– Strong export infrastructure and logistics support

OEM vs. ODM: Strategic Considerations

| Model | Description | Best For | Lead Time | Tooling Cost | Customization Level |

|---|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Client provides full design, specs, and branding. Factory produces to exact requirements. | Companies with in-house R&D and strict performance standards | 30–45 days | Low to Medium (custom molds/jigs) | High (full control over specs) |

| ODM (Original Design Manufacturing) | Supplier offers existing designs/models; client selects and rebrands. Minor modifications possible. | Fast time-to-market, cost-sensitive buyers | 15–25 days | None (uses existing tooling) | Medium (limited to available designs) |

Procurement Tip: Use ODM for pilot orders or standard-grade magnets. Switch to OEM for mission-critical applications requiring tight tolerances or magnetic performance certifications.

White Label vs. Private Label: Branding Strategy

| Term | Definition | Control | MOQ | Ideal Use Case |

|---|---|---|---|---|

| White Label | Generic product sold under multiple brands with minimal differentiation. Factory often supplies same product to competitors. | Low (product may appear elsewhere) | Low (500–1,000 units) | Entry-level private branding, e-commerce resellers |

| Private Label | Customized product exclusive to one buyer. May include unique dimensions, performance specs, or packaging. | High (exclusive rights, IP protection) | Medium to High (1,000+ units) | Building a differentiated brand, B2B distribution |

Recommendation: For long-term brand equity and supply chain security, negotiate private label exclusivity clauses in contracts to prevent parallel sales.

Estimated Cost Breakdown (Per Unit, Standard Grade Y30, 50mm x 25mm x 10mm)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Raw Materials | $0.28 | Iron oxide (Fe₂O₃), strontium carbonate (SrCO₃), process additives |

| Labor & Processing | $0.12 | Includes pressing, sintering, grinding, magnetization |

| Quality Control | $0.03 | Dimensional checks, Gauss meter testing, batch certification |

| Packaging | $0.05 | Standard polybag + carton (anti-corrosion, labeled) |

| Overhead & Profit Margin | $0.07 | Factory operational costs and margin |

| Total Estimated FOB Price (1,000 pcs) | $0.55/unit | Varies by MOQ and specs |

Note: Prices assume standard tolerances (±0.2mm), no plating, and FOB Ningbo. High-grade (Y35+) or tight-tolerance magnets may cost 15–30% more.

Price Tiers by MOQ (FOB China, USD per Unit)

| MOQ (Units) | Unit Price (USD) | Total Order Value (USD) | Notes |

|---|---|---|---|

| 500 | $0.75 | $375 | White label, standard grade, minimal customization |

| 1,000 | $0.55 | $550 | Base private label, includes basic QC certification |

| 5,000 | $0.42 | $2,100 | OEM/ODM eligible, option for custom packaging and performance specs |

| 10,000+ | $0.38 | $3,800+ | Long-term contract pricing; eligible for VMI or JIT delivery |

Volume Incentive Insight: Orders above 5,000 units typically unlock engineering support, batch traceability, and magnetization direction customization (axial, diametric, multi-pole).

Strategic Recommendations for Procurement Managers

- Leverage ODM for Sampling: Use ODM models to validate market demand before committing to OEM tooling.

- Negotiate Exclusivity: Secure private label rights to avoid brand dilution and competitive overlap.

- Audit Suppliers: Prioritize factories with export experience, third-party certifications, and in-house QC labs.

- Optimize MOQ Strategy: Balance inventory costs with unit savings—consider dual-sourcing for risk mitigation.

- Clarify IP Ownership: In OEM agreements, ensure full IP transfer and non-disclosure clauses are legally binding.

Conclusion

China remains the most cost-competitive source for ceramic block magnets, offering scalable production, flexible OEM/ODM models, and reliable quality for industrial applications. By understanding cost structures, labeling strategies, and volume pricing, global procurement teams can optimize total cost of ownership while building resilient supply chains.

For tailored supplier shortlists, factory audits, or custom RFQ support, contact SourcifyChina Sourcing Consultants.

© 2026 SourcifyChina. Confidential. Prepared exclusively for B2B procurement professionals. Not for redistribution.

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Strategic Verification Protocol for Chinese Ceramic Block Magnet Manufacturers (2026 Edition)

Prepared for Global Procurement Leadership | Q1 2026 | Confidential

Executive Summary

China supplies 85% of global ceramic (ferrite) block magnets, yet 42% of procurement failures stem from unverified supplier claims (SourcifyChina 2025 Supply Chain Audit). This report delivers a forensic verification framework to mitigate counterparty risk, distinguish genuine manufacturers from intermediaries, and ensure ISO 17025-compliant production. Critical 2026 shifts: Stricter REACH 2026 compliance, CBAM carbon tariffs, and AI-driven document fraud necessitate advanced due diligence.

Critical Verification Protocol: 5-Step Manufacturer Authentication

| Step | Action | 2026-Specific Tools/Indicators | Validation Threshold |

|---|---|---|---|

| 1. Legal Entity Verification | Cross-check Chinese Business License (营业执照) via State Administration for Market Regulation (SAMR) portal | • Verify Unified Social Credit Code (USCC) on National Enterprise Credit Info Portal • Confirm manufacturing scope (e.g., “永磁铁氧体磁体生产”) not just “sales” |

USCC matches physical license; Manufacturing scope explicitly listed; No administrative penalties in last 24 months |

| 2. Facility & Production Audit | Conduct unannounced onsite audit with 3rd-party inspector | • 2026 Focus: Validate CBAM carbon reporting systems • Confirm in-house sintering lines (not subcontracted) • Check magnetization equipment calibration records (ISO 17025) |

≥80% production equipment owned; Real-time energy consumption logs; Raw material (Fe₂O₃/SrCO₃) traceability to mill certificates |

| 3. Technical Capability Proof | Demand batch-specific test reports against IEC 60404-8-1 | • Require Br, HcB, HcJ, (BH)max data from your specified lot • Verify Gauss meter calibration certificates (NIM traceable) • Red Flag: Generic “sample” reports without lot numbers |

Reports show ≤±3% variance from spec; Test dates align with production schedule; Lab physically present at facility |

| 4. Export Compliance Scan | Audit export documentation history | • Confirm direct FOB/Xiamen or FOB/Ningbo shipments (not EXW) • Validate US FDA/EPA registration for magnetic materials • Check REACH SVHC declarations updated for 2026 |

Bill of Lading shows factory as shipper; No customs holds in last 12 months; Full material disclosure (FMD) provided |

| 5. Financial Health Assessment | Analyze credit report via Dun & Bradstreet China | • Minimum registered capital: RMB 5M (≈$700K) • Verify tax payment records (no arrears) • 2026 Critical: CBAM prepayment capacity |

D&B Paydex Score ≥75; VAT invoices match declared output; Bank guarantee for carbon costs available |

Key 2026 Shift: 68% of “factories” now subcontract sintering (SourcifyChina 2025). Demand furnace operation logs – true manufacturers control sintering curves (900-1200°C).

Trading Company vs. Factory: 4 Definitive Differentiators

| Indicator | Genuine Factory | Trading Company | Verification Tactic |

|---|---|---|---|

| Business License | Lists “production” (生产) as core activity; USCC shows industrial land use | Lists only “trading” (贸易) or “sales” (销售); Service sector classification | SAMR portal search: Filter for “Manufacturing” (制造业) industry code C3051 |

| Facility Evidence | • Sintering furnaces visible via live cam • Raw material stockyard (Fe₂O₃ piles) • In-house lab with permeameter |

• Office-only photos • “Partnership” videos at other factories • Generic warehouse footage |

Demand real-time video of furnace loading; Require iron oxide purity test (XRF) at facility |

| Pricing Structure | Quotes FOB with clear MOQ (e.g., 500kg); Material costs transparent (Fe₂O₃ ≈ $0.35/kg) | Quotes EXW; Vague cost breakdown; MOQ abnormally low (<100kg) | Request granular cost sheet: Raw materials (65%), sintering (20%), labor (15%) |

| Export Documentation | Acts as shipper on B/L; Direct customs registration (海关注册编码) | Lists factory as shipper; Uses “agent” customs codes | Verify shipper name on past B/Ls matches business license holder |

Pro Tip: Ask for customs declaration number (报关单号) for past export. Factories provide this instantly; traders delay or refuse.

Critical Red Flags (2026 Update): Immediate Disqualification Criteria

| Red Flag | Risk Impact | 2026 Prevalence | Action |

|---|---|---|---|

| “Factory Tour” via pre-recorded video | 92% indicate subcontracting (SourcifyChina 2025 Fraud Index) | High (↑ from 2024) | Terminology Test: Demand live video panning from office to furnace area within 1 hour |

| No CBAM carbon cost breakdown | EU shipments blocked; 22% duty surcharge | Critical (CBAM Phase 2 enforcement) | Reject if unable to show electricity/fuel consumption per ton of magnets |

| Alibaba “Verified Supplier” badge only | 74% of badges obtained via paid services (not vetting) | Very High | Verify: SAMR license > Alibaba badge; Demand factory address GPS coordinates |

| Payment to personal WeChat/Alipay | Zero recourse in fraud cases; 68% of payment scams | Severe (↑ 2025) | Mandate: Wire transfer to company account matching business license |

| “Sample for free” offers | Indicates low-quality surplus stock (Br < 3.8kG typical) | Moderate | Counter: Require paid samples with full test report; Reject “free” samples |

Strategic Recommendations for 2026 Procurement

- Mandate CBAM Readiness Assessment: Require carbon cost calculation per kg (target: ≤0.35 kgCO₂e/kg magnet).

- Implement AI Document Screening: Use tools like TrusTrace to detect forged ISO certificates (2025 fraud rate: 31%).

- Enforce Tiered Sourcing:

- Primary: Factories with in-house strontium carbonate processing (vertical integration = 12-18% cost advantage)

- Secondary: Trading companies only if providing factory audit reports < 90 days old

- Contract Clause: “Supplier warrants direct ownership of sintering equipment. Subcontracting voids quality warranty.”

“In 2026, the cost of not verifying exceeds procurement savings by 227%. Factories controlling sintering yield 40% fewer dimensional defects.”

— SourcifyChina Global Magnet Sourcing Index, Q4 2025

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | Your Trusted China Sourcing Architect

📅 Report Validity: January 1, 2026 – December 31, 2026

🔍 Verification Methodology: ISO 20400:2017 Compliant | Data Sources: SAMR, China Customs, SourcifyChina Audit Database (12,500+ factories)

This report contains proprietary SourcifyChina intelligence. Unauthorized distribution prohibited. For procurement strategy deep dives, contact [email protected].

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Focus: China Ceramic Block Magnet Manufacturers

Executive Summary

In the rapidly evolving global supply chain landscape of 2026, procurement efficiency, supplier reliability, and risk mitigation are paramount. For sourcing managers responsible for magnetic components—particularly ceramic block magnets—navigating China’s fragmented manufacturing base presents significant challenges. Long lead times, inconsistent quality, and unverified supplier claims remain persistent pain points.

SourcifyChina addresses these challenges head-on with our Verified Pro List: China Ceramic Block Magnet Manufacturers, a rigorously vetted directory of high-performance suppliers who meet international standards for quality, scalability, and compliance.

Why the Verified Pro List Saves Time and Reduces Risk

Traditional sourcing methods—such as sifting through Alibaba listings, attending trade shows, or relying on referrals—can consume 3–6 months before securing a reliable supplier. With SourcifyChina’s Verified Pro List, procurement teams bypass the noise and move directly to qualified partners.

| Traditional Sourcing | SourcifyChina Verified Pro List |

|---|---|

| 100+ initial supplier contacts | Pre-vetted shortlist of 15–20 qualified manufacturers |

| 3–6 months to complete due diligence | Immediate access to audit reports, certifications, and production capacity data |

| High risk of miscommunication and quality failure | Suppliers with proven export experience and English-speaking teams |

| Multiple site visits or third-party inspections required | On-site verification completed by SourcifyChina supply chain auditors |

| Uncertain MOQs, lead times, and compliance | Transparent data on pricing models, minimum order quantities, and lead times |

By leveraging our Verified Pro List, procurement managers reduce supplier discovery time by up to 70%, accelerate time-to-contract, and minimize onboarding risks—critical advantages in competitive markets.

Call to Action: Optimize Your 2026 Sourcing Strategy Today

Don’t let inefficient sourcing slow down your supply chain. The SourcifyChina Verified Pro List for China Ceramic Block Magnet Manufacturers is your strategic advantage—delivering precision, speed, and confidence in every supplier match.

Take the next step in intelligent sourcing:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our sourcing consultants are available to provide a customized supplier shortlist, answer technical specifications, and facilitate direct introductions—all at no upfront cost.

Act now. Source smarter. Deliver faster.

Your verified supply chain in China starts with SourcifyChina.

🧮 Landed Cost Calculator

Estimate your total import cost from China.