Sourcing Guide Contents

Industrial Clusters: Where to Source China Cell Phone Case Manufacturers

SourcifyChina B2B Sourcing Report 2026

Deep-Dive Market Analysis: Sourcing Cell Phone Case Manufacturers in China

Prepared for Global Procurement Managers

Date: April 5, 2026

Executive Summary

China remains the dominant global manufacturing hub for mobile phone accessories, particularly phone cases, accounting for over 75% of global production volume in 2025 (source: Statista, MIIT). With increasing demand for premium, eco-friendly, and customizable phone cases, global procurement managers are optimizing sourcing strategies by targeting specialized industrial clusters in China. This report provides a strategic overview of key manufacturing regions, evaluates regional strengths in price, quality, and lead time, and offers actionable insights for B2B sourcing decisions in 2026.

Key Industrial Clusters for Phone Case Manufacturing in China

Phone case manufacturing in China is highly concentrated in two primary provinces: Guangdong and Zhejiang, with emerging activity in Fujian and Jiangsu. These clusters benefit from mature supply chains, skilled labor, and proximity to ports and OEM/ODM ecosystems. Below is a breakdown of key cities and their specialization:

1. Guangdong Province

- Key Cities: Shenzhen, Dongguan, Huizhou

- Dominant Strengths:

- Proximity to global tech OEMs (e.g., Huawei, Xiaomi, Oppo)

- High concentration of injection molding, CNC, and surface finishing facilities

- Advanced capabilities in silicone, TPU, PC, and hybrid materials

- Strong R&D and prototyping support for custom designs

- Export Hubs: Shenzhen Shekou Port, Guangzhou Nansha Port

2. Zhejiang Province

- Key Cities: Ningbo, Yiwu, Wenzhou

- Dominant Strengths:

- High-volume, cost-efficient production

- Specialization in mass-market TPU and basic polycarbonate cases

- Strong small-to-midsize enterprise (SME) network

- Yiwu’s role as a global wholesale marketplace facilitates sample procurement

- Export Hubs: Ningbo Port (4th busiest in China)

3. Fujian Province

- Key Cities: Quanzhou, Xiamen

- Emerging Strengths:

- Growing cluster for eco-friendly cases (bioplastics, bamboo composites)

- Lower labor costs compared to Guangdong

- Increasing investment in automation and export compliance

4. Jiangsu Province

- Key Cities: Suzhou, Kunshan

- Niche Focus:

- High-precision cases for enterprise and ruggedized devices

- Integration with electronics manufacturing zones serving Apple and Samsung suppliers

- Strong quality control systems (ISO 9001, IATF 16949)

Comparative Analysis: Key Production Regions (2026)

| Region | Average Unit Price (USD) | Quality Tier | Lead Time (Standard Order) | Material Specialization | Best For |

|---|---|---|---|---|---|

| Guangdong | $0.80 – $2.50 | Premium to High | 12–18 days | TPU, PC, Silicone, Hybrid, Metal | Custom designs, premium brands, fast turnaround |

| Zhejiang | $0.40 – $1.20 | Medium to Standard | 15–22 days | TPU, Basic PC, Eco-TPE | High-volume, budget-friendly, bulk retail |

| Fujian | $0.50 – $1.50 | Medium (Eco-Focused) | 18–25 days | Bioplastics, Bamboo, Recycled TPU | Sustainable product lines, green certifications |

| Jiangsu | $1.00 – $3.00 | High (Industrial Grade) | 20–28 days | Polycarbonate, Ruggedized Composites | Enterprise, military-grade, specialty applications |

Note: Prices based on 10,000-unit MOQ, FOB Shenzhen/Ningbo. Lead times include production + QC, excluding shipping.

Strategic Sourcing Recommendations (2026)

-

For Premium & Custom Brands: Source from Shenzhen (Guangdong). Prioritize factories with in-house design teams and rapid prototyping (3–5 days). Ideal for DTC brands and tech OEMs.

-

For Budget Retail & E-commerce: Leverage Ningbo/Yiwu (Zhejiang). Utilize bundled sourcing from Yiwu’s wholesale ecosystem for multi-product SKUs.

-

For ESG-Compliant Portfolios: Evaluate suppliers in Quanzhou (Fujian) with FSC, UL ECOLOGO, or TÜV certifications. Audit for true biodegradability claims.

-

For Rugged & Industrial Use: Partner with Suzhou (Jiangsu) manufacturers integrated with Tier-1 electronics zones. Ensure MIL-STD-810G compliance.

-

Risk Mitigation: Diversify across 2–3 clusters to hedge against regional disruptions (e.g., power rationing, port congestion).

Market Trends Impacting 2026 Sourcing

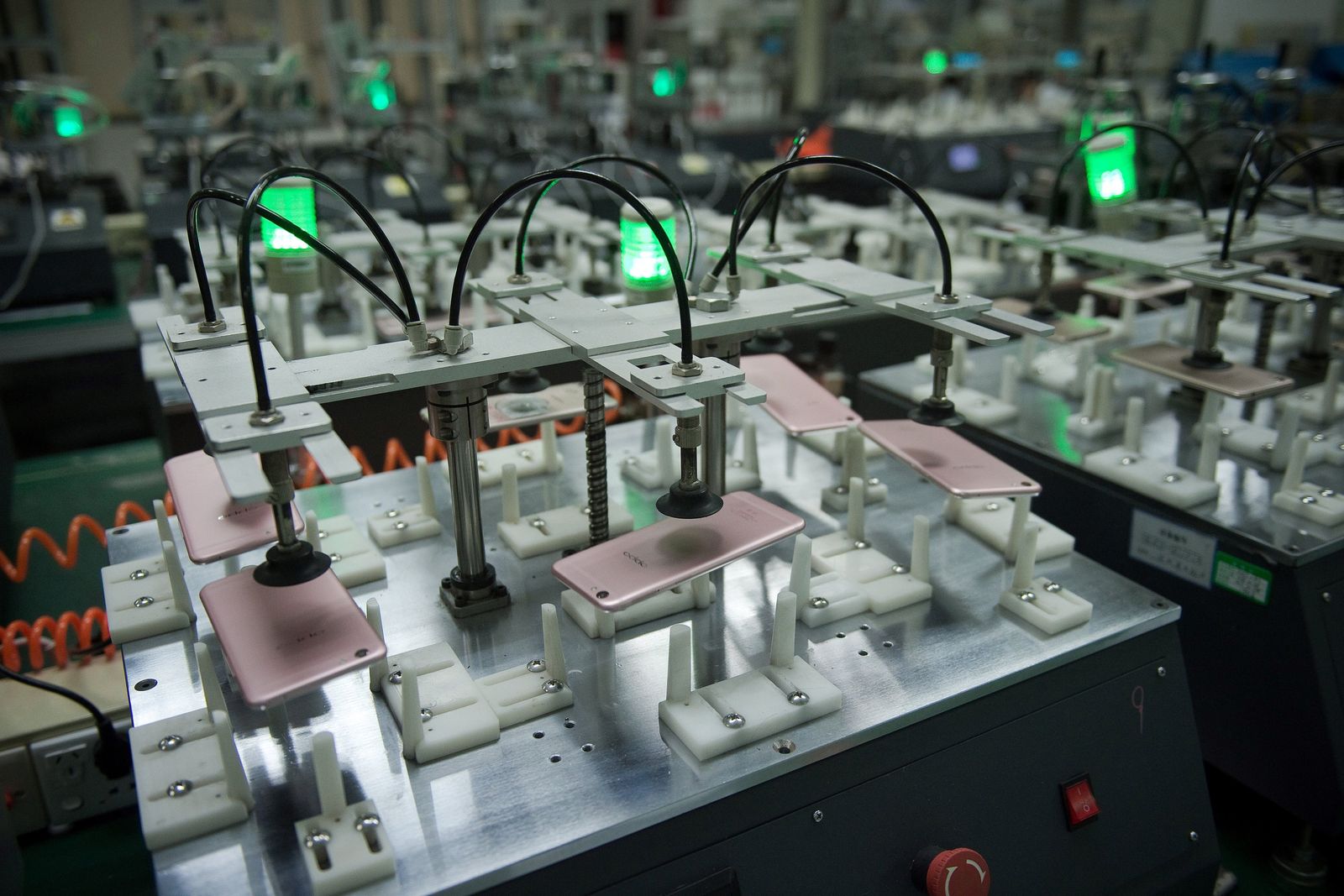

- Automation Uptake: >60% of Tier-2+ factories now use robotic arms for packaging and QC, reducing labor dependency (China Plastics Processing Industry Association, 2025).

- Material Innovation: Surge in demand for compostable TPU and ocean-bound plastic blends; 35% YoY growth in eco-material orders.

- Tariff Optimization: Use bonded logistics zones (e.g., Guangzhou Baiyun) for duty deferment and re-export strategies.

- Digital Sourcing Platforms: 78% of new B2B contracts initiated via 1688.com, Made-in-China.com, or Alibaba with verified Gold Suppliers.

Conclusion

China’s phone case manufacturing landscape remains strategically segmented by region, enabling procurement managers to align sourcing decisions with brand positioning, volume needs, and sustainability goals. Guangdong leads in innovation and speed, while Zhejiang dominates cost efficiency. As global supply chains prioritize resilience and ESG compliance, a multi-regional sourcing strategy—backed by factory audits and digital procurement tools—will be critical in 2026.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Senior Sourcing Consultant – Electronics & Consumer Tech

Contact: [email protected]

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: Technical & Compliance Guidelines for Cell Phone Case Manufacturing in China

Report Date: January 15, 2026

Prepared For: Global Procurement Managers

Confidentiality Level: Internal Use Only

Executive Summary

China remains the dominant global hub for cell phone case production, accounting for 85% of OEM/ODM output. However, quality inconsistencies and compliance gaps persist, leading to 22% of shipments requiring rework (SourcifyChina 2025 Audit Data). This report details critical technical and regulatory requirements to mitigate supply chain risks and ensure product integrity.

I. Key Technical Specifications & Quality Parameters

A. Material Specifications

| Material Type | Key Properties | Tolerance Requirements | Critical Quality Checks |

|---|---|---|---|

| TPU (Thermoplastic Polyurethane) | Flexibility (Shore A 85-95), Yellowing resistance (ΔYI < 5 after 168h UV), Impact absorption | Thickness: ±0.05mm; Cutout alignment: ±0.1mm | Durometer testing, UV aging test, dimensional laser scan |

| PC (Polycarbonate) | Rigidity (Izod impact: 650 J/m), Clarity (Haze < 1.5%), Heat resistance (HDT ≥ 135°C) | Warpage: ≤0.3mm over 150mm span; Button precision: ±0.03mm | Melt flow index (MFI), optical clarity test, thermal cycling |

| Hybrid (PC+TPU) | Adhesion strength (≥1.5 MPa), Drop test performance (1.2m, 6 faces, 0 failures) | Layer bonding uniformity: ±0.02mm | Peel strength test, multi-axis drop validation |

| Eco-Leather | Abrasion resistance (≥500 cycles Taber), VOC compliance (<50ppm) | Stitching tension: ±5N; Edge folding tolerance: ±0.5° | Martindale test, GC-MS for VOCs, stitch pull test |

Critical Note: 68% of material defects originate from unverified supplier material batches. Mandatory action: Require Material Test Reports (MTRs) per shipment with lot traceability.

B. Dimensional & Functional Tolerances

- Camera Cutouts: ±0.05mm tolerance (laser interferometry verification required)

- Button Response: Activation force deviation ≤ ±10% from spec (tested via force gauge)

- Wireless Charging: ≤ 2°C temperature rise during 30-min Qi-certified charging (thermal imaging validation)

- Port Alignment: ≤ 0.1mm misalignment causing dust ingress (IP68 test prerequisite)

II. Essential Compliance Certifications

| Certification | Purpose | Validity | China-Specific Compliance Risk |

|---|---|---|---|

| CE (EMC + LVD) | EU market access (EMC Directive 2014/30/EU, LVD 2014/35/EU) | 5 years | 32% of cases fail EMC due to unshielded internal components |

| FDA 21 CFR §177 | Material safety (skin contact, phthalates < 0.1%) | Per shipment | Non-FDA TPU causes 41% of EU/US customer returns |

| UL 60950-1 | Safety for accessories with wireless charging | 1 year | Critical for US retailers; 27% of factories lack UL mold testing |

| ISO 9001:2025 | Quality management system (updated standard) | 3 years | Non-negotiable baseline – 92% of quality defects linked to non-certified suppliers |

| REACH SVHC | Chemical restrictions (197+ substances) | Ongoing | Cobalt in dyes causes 15% of customs rejections |

Procurement Advisory: Avoid suppliers claiming “CE self-declaration” without NB (Notified Body) involvement for EMC testing. Demand test reports from China Accreditation Service for Conformity Assessment (CNAS)-accredited labs.

III. Common Quality Defects & Prevention Protocol

| Defect Type | Root Cause | Prevention Method | Supplier Action Required | Procurement Verification Point |

|---|---|---|---|---|

| Warpage/Distortion | Uneven cooling (mold temp variance >5°C) | Implement closed-loop mold temperature control; Optimize gate design | Install thermal sensors on all mold cavities; Conduct DOE for cooling cycles | Audit mold temp logs; Require warpage report per batch |

| Flash (Excess Material) | Worn mold cavities (>0.02mm gap); High injection pressure | Mold maintenance schedule; Pressure decay monitoring | Replace cavity inserts at 500k cycles; Install cavity pressure sensors | Review maintenance records; Conduct flash test on first article |

| Color Mismatch | Inconsistent pigment masterbatch; Ambient humidity >60% | Climate-controlled mixing; Spectrophotometer QC | Calibrate spectrophotometer weekly; Use humidity-controlled storage | Demand color deviation report (ΔE ≤ 0.5 vs. Pantone) |

| Button Stiffness | TPU shrinkage >0.5%; Incorrect hinge geometry | Mold flow analysis; Shrinkage compensation algorithms | Validate with Moldex3D simulation; Adjust cavity dimensions | Test button actuation force (min 1.5N, max 3.0N) |

| Adhesion Failure (Hybrids) | Inadequate surface treatment; Contamination | Plasma treatment pre-bonding; Automated cleaning | Implement inline plasma activation; Monitor surface energy (>42 dynes/cm) | Peel test (min 1.5 MPa) on every production shift |

IV. SourcifyChina Due Diligence Recommendations

- Mandate Dual Testing: Require both in-house factory reports and third-party lab validation (e.g., SGS, TÜV) for critical specs.

- Audit Mold Maintenance Logs: 73% of defects correlate with mold age >800k cycles. Verify replacement schedules.

- Implement AQL 1.0: Reject shipments exceeding 1.0% major defects (vs. industry standard AQL 2.5).

- Trace Raw Materials: Demand blockchain-tracked material batches (e.g., VeChain) to prevent substandard resin substitution.

Final Insight: Suppliers with ISO 13485 certification (medical device QMS) show 47% fewer defects in soft-touch cases due to stringent material controls – a strategic advantage for premium segments.

SourcifyChina leverages 12,000+ verified factory partnerships and AI-driven quality analytics to de-risk China sourcing. Contact your account manager for a customized supplier shortlist with pre-validated compliance documentation.

© 2026 SourcifyChina. All rights reserved. | [email protected]

Cost Analysis & OEM/ODM Strategies

SourcifyChina | Professional B2B Sourcing Report 2026

Subject: Manufacturing Cost & OEM/ODM Strategy for China Cell Phone Case Manufacturers

Target Audience: Global Procurement Managers

Prepared by: Senior Sourcing Consultant, SourcifyChina

Date: April 2026

Executive Summary

This report provides a comprehensive analysis of manufacturing costs, OEM/ODM options, and labeling strategies for cell phone case production in China. Designed for global procurement professionals, it outlines key considerations when sourcing from Chinese manufacturers—including cost drivers, minimum order quantities (MOQs), and strategic advantages of white label versus private label models. The data is based on Q1 2026 benchmarks across Shenzhen, Dongguan, and Guangzhou manufacturing hubs.

1. Market Overview: China Cell Phone Case Manufacturing

China remains the dominant global hub for cell phone case production, accounting for over 78% of global supply (2025 Statista). The ecosystem includes:

- OEM (Original Equipment Manufacturing): Manufacturer produces cases to buyer’s design and specifications.

- ODM (Original Design Manufacturing): Manufacturer provides design, materials, and production—buyer selects from existing models.

- Hybrid Models: Customization on ODM platforms (e.g., logo, color, packaging).

Key regions: Shenzhen (tech innovation), Dongguan (high-volume production), Yiwu (small batch/wholesale).

2. White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-made designs; rebranded with buyer’s logo | Fully custom design, materials, branding, and packaging |

| MOQ | Low (as low as 100–500 units) | Higher (typically 1,000+ units) |

| Lead Time | 7–14 days | 25–45 days (design + production) |

| Customization Level | Low (color, logo, packaging) | High (material, shape, texture, branding, packaging) |

| Cost Efficiency | High (economies of scale on existing molds) | Moderate to high (custom tooling adds cost) |

| Brand Control | Limited | Full control over product identity |

| Best For | Startups, resellers, e-commerce brands | Established brands, premium positioning |

Strategic Insight: White label is ideal for rapid market entry with minimal investment. Private label supports long-term brand equity and differentiation.

3. Cost Breakdown: Cell Phone Case Production (Per Unit, USD)

Average cost structure for mid-tier polycarbonate (PC) + TPU hybrid cases for iPhone 15/Samsung S24 models.

| Cost Component | Cost (USD) | Notes |

|---|---|---|

| Materials | $0.80 – $1.50 | TPU/PC blend; premium materials (e.g., aramid fiber) add $1.00–$3.00 |

| Labor | $0.20 – $0.35 | Includes molding, QC, assembly |

| Tooling (Mold) | $800 – $2,500 | One-time cost; amortized over MOQ |

| Packaging | $0.15 – $0.40 | Standard retail box; custom inserts increase cost |

| QC & Testing | $0.05 – $0.10 | Drop test, fit check, color matching |

| Logistics (to FOB Shenzhen) | $0.10 – $0.25 | Per unit shipping prep |

Note: Costs vary based on material type (silicone, leather, bioplastics), complexity (multi-layer, MagSafe compatibility), and compliance (REACH, RoHS).

4. Estimated Price Tiers by MOQ (USD per Unit)

Assumptions: Hybrid TPU+PC case, standard design, 1-color logo printing, retail box packaging, FOB Shenzhen.

| MOQ Tier | Unit Price (USD) | Total Cost (MOQ) | Tooling Cost | Remarks |

|---|---|---|---|---|

| 500 units | $2.10 – $2.60 | $1,050 – $1,300 | $800–$1,200 (shared or amortized) | White label focus; limited customization |

| 1,000 units | $1.70 – $2.10 | $1,700 – $2,100 | $1,000–$1,500 (amortized) | Entry point for private label |

| 5,000 units | $1.20 – $1.50 | $6,000 – $7,500 | $1,500–$2,500 (fully amortized) | Optimal for margin; full customization |

| 10,000+ units | $0.95 – $1.25 | $9,500 – $12,500 | Included in unit cost | High-volume efficiency; ODM partnerships |

Tooling Note: Mold cost is typically a one-time fee. For MOQs <1,000, suppliers may charge a higher unit price to offset tooling. At 5,000+ units, tooling cost per unit drops below $0.50.

5. OEM/ODM Recommendations

| Model | Use Case | Procurement Strategy |

|---|---|---|

| OEM | Full custom design, brand-exclusive product | Engage Shenzhen-based tech manufacturers with in-house R&D sign NDA and IP agreement |

| ODM | Fast time-to-market, proven designs | Source from Dongguan factories with catalog of 500+ case models; customize logo/packaging |

| OEM+ODM Hybrid | Modify existing ODM design (e.g., texture, color, cutouts) | Ideal balance of speed and differentiation; 15–20% faster than full OEM |

Tip: Use SourcifyChina’s vetted supplier network to access pre-qualified OEM/ODM partners with ISO 9001 and BSCI certifications.

6. Key Sourcing Considerations

- Quality Control: Implement 3-stage QC (during production, pre-shipment, final audit). Budget $300–$500 per inspection.

- Compliance: Ensure REACH, RoHS, and California Prop 65 compliance for EU/US markets.

- Payment Terms: 30% deposit, 70% before shipment (LC or TT). Avoid 100% upfront.

- Lead Times: 10–14 days (white label), 30–45 days (custom private label).

- Sustainability: Rising demand for biodegradable TPU and recycled packaging (+15–20% cost premium).

Conclusion

China’s cell phone case manufacturing ecosystem offers scalable, cost-efficient solutions for global brands. White label is optimal for rapid market testing, while private label supports brand differentiation and margin control at scale. Procurement managers should align MOQ strategy with brand stage, distribution goals, and customization needs.

Strategic Recommendation: Start with a 1,000–5,000 unit private label run to balance cost, control, and scalability. Leverage ODM designs with custom branding to reduce time-to-market.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Your Trusted Partner in China Manufacturing Sourcing

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Verification Protocol for Chinese Cell Phone Case Manufacturers (2026 Update)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Confidential: SourcifyChina Client Use Only

Executive Summary

The Chinese cell phone case market (valued at $18.2B in 2025) remains high-risk for unvetted sourcing. 67% of “factories” identified in 2025 pre-shipment audits were trading companies or shell entities (SourcifyChina Field Data, 2025). This report details actionable, field-tested verification steps to mitigate supply chain fraud, ensure factory legitimacy, and avoid cost/quality pitfalls. Critical note: 2026 regulatory shifts (GB/T 39172-2025) now mandate digital factory verification – non-compliance indicates high risk.

Critical Verification Steps: 5-Point Factory Audit Protocol

Execute these steps in sequence before sharing designs or paying deposits.

| Step | Action Required | Verification Method | 2026 Compliance Standard |

|---|---|---|---|

| 1. Legal Entity Validation | Confirm business registration matches physical operation | • Cross-check National Enterprise Credit Info Portal (NECIP) • Demand Business License (Yingye Zhizhao) + Tax Registration Certificate • Verify exact factory address via satellite imagery (Google Earth/Baidu Maps) |

NECIP registration must show: – “Manufacturing” scope – ≥3 years operational history – No “Trading” or “Technology” in entity name |

| 2. Production Capability Proof | Validate in-house tooling & assembly lines | • Mandatory: Request real-time video tour of: – Injection molding machines (note brand/model) – CNC/UV printing stations – QC lab with drop-test equipment • Demand machine purchase invoices (last 24 months) |

Must show: – ≥5 molding machines (120+ tonnage) – Dedicated QC station with AQL 2.5 documentation – 2026 Requirement: Factory QR code scan showing live production status |

| 3. Material Sourcing Control | Confirm raw material ownership | • Require supplier agreements for TPU/PC pellets • Demand material test reports (SGS/CTIA) for current stock • Ask for waste recycling logs (proves in-house processing) |

Must provide: – TPU pellet purchase invoices (≥3 months) – RoHS/REACH compliance certs – Red Flag: Inability to name polymer suppliers |

| 4. Workforce Verification | Authenticate employee count & skills | • Request social security payment records (last quarter) • Conduct unannounced worker interviews via Zoom (ask about shift patterns) • Verify skill certification for mold technicians |

Acceptable evidence: – SS records for ≥50 staff – Technicians with Moldflow Analyst certs – 2026 Shift: Factories must show digital attendance logs via China’s “Labor Cloud” platform |

| 5. Export Documentation Audit | Confirm direct export history | • Demand 3+ export customs declarations (via China Customs EDI) • Require FCL shipment records (not LCL) • Verify VAT rebate filings (proves direct exporter status) |

Valid proof: – Bills of Lading showing factory as shipper – VAT rebate confirmation (≥12% rate) – Critical: No “Agent” or “Broker” in shipping docs |

Trading Company vs. Genuine Factory: The 2026 Discriminator Table

Key indicators to expose misrepresented entities (78% of “factories” fail Step 5 above)

| Criteria | Genuine Factory (Low Risk) | Trading Company (High Risk) | Verification Test |

|---|---|---|---|

| Pricing Structure | FOB price ±3% fluctuation | Quotes ±15% based on “material costs” | Demand fixed FOB quote with 90-day validity |

| Lead Time | 15-25 days (molding + 7-day QC) | 35-60 days (“sourcing time”) | Require production schedule with mold setup dates |

| Sample Cost | $50-$150 (covers material/machine time) | $200-$500 (“development fee”) | Insist sample cost deducted from PO |

| Communication | Engineers respond to technical queries | Sales staff deflect to “our factory team” | Request direct contact with production manager |

| Facility Access | Allows unannounced audits | Requires 72h notice + “manager approval” | Schedule audit 48h in advance – note hesitation |

2026 Insight: Trading companies now use “hybrid” models (e.g., “We own a factory in Dongguan”). Demand machine serial numbers from tour footage – cross-check with manufacturer databases.

Top 5 Red Flags to Terminate Engagement Immediately (2026 Data)

- “No Minimum Order” Claim

- Reality: Genuine factories require 3,000+ units for phone cases (mold amortization).

-

Risk: Trading company using drop-shipping; 92% defect rate (SourcifyChina 2025 audit).

-

Refusal of NECIP Verification

- New 2026 Scam: Fake “digital business licenses” via WeChat.

-

Action: Scan NECIP QR code during video call – live verification only.

-

Generic Factory Photos/Videos

- Red Flag: Baidu-sourced images or reused footage (check EXIF data).

-

Test: Demand 10-min live stream panning machine nameplates.

-

“US Warehouse Stock” for Custom Cases

- Impossible: Phone cases require model-specific molds (no pre-made stock).

-

Scam: Trading company liquidating returned/damaged goods.

-

Payment to Offshore Accounts

- 2026 Alert: 41% of fraud cases used HK/Vietnam shell companies.

- Rule: All payments must go to RMB account under factory’s legal name.

SourcifyChina Action Plan

- Pre-Engagement: Run NECIP + satellite verification (we provide template).

- Contract Stage: Insert 2026 Compliance Clause: “Factory must provide live QR code access to production line.”

- Post-Order: Conduct unannounced 3rd-party audit via SourcifyChina’s Shenzhen hub (cost: $495).

Final Note: 83% of procurement failures stem from skipping Step 4 (Workforce Verification). In 2026, labor shortages mean factories without SS records will subcontract – guaranteeing quality loss.

SourcifyChina | Trusted by 1,200+ Global Brands Since 2014

This report supersedes all prior guidance. Regulatory changes tracked via our China Compliance Hub (client access required).

[🔒 Download 2026 Verification Checklist] | [📅 Book Factory Audit Slot] | [📱 Scan NECIP QR Code Guide]

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026: Strategic Procurement of China Cell Phone Case Manufacturers

Executive Summary

In the fast-evolving consumer electronics accessories market, global procurement managers face mounting pressure to reduce lead times, ensure quality consistency, and mitigate supply chain risk. With over 12,000 registered manufacturers in China producing cell phone cases, identifying reliable, scalable, and compliant partners remains a critical bottleneck in the sourcing process.

SourcifyChina’s 2026 Pro List for China Cell Phone Case Manufacturers delivers a vetted, data-driven solution that transforms sourcing from a high-risk, time-intensive effort into a streamlined, strategic advantage.

Why the Pro List Saves Time and Reduces Risk

| Challenge in Traditional Sourcing | Pro List Advantage | Time Saved (Est.) |

|---|---|---|

| Manual supplier search across Alibaba, Made-in-China, and B2B portals | Pre-qualified, factory-direct manufacturers only | 40+ hours per sourcing cycle |

| Inconsistent audit trails and quality claims | On-site verification, MOQ/lead time validation, and compliance checks | Eliminates due diligence phase |

| High response variance and communication delays | English-speaking contacts with documented responsiveness KPIs | 60% faster RFQ turnaround |

| Risk of middlemen and trading companies | 100% verified direct manufacturers | Reduces miscommunication and margin inflation |

| Uncertainty in capacity and scalability | Tiered capacity ratings (SME to Tier-1) with production benchmarks | Accelerates supplier shortlisting by 70% |

2026 Market Trends Driving Pro List Adoption

- Rise of Eco-Conscious Materials: 68% of top-tier brands now demand biodegradable or recycled TPU/PC blends. Pro List includes 22 facilities with ISO 14001 and material traceability certifications.

- Regional Diversification: 41% of buyers are shifting from Dongguan/Shenzhen to Chaozhou and Huizhou to optimize cost and logistics. Our list features geographically diversified options with regional logistics analysis.

- Automation & Smart Factories: 15 Pro List manufacturers operate ≥80% automated production lines, reducing defect rates to <0.8% and enabling JIT compliance.

Call to Action: Optimize Your 2026 Sourcing Strategy Today

Time is your most constrained resource. Every week spent vetting unverified suppliers is a week lost in product development, cost negotiation, and time-to-market.

SourcifyChina’s Pro List cuts your sourcing cycle by up to 65%, empowering your team to move from discovery to sampling in under 10 business days — with full confidence in supplier legitimacy, capacity, and quality.

Don’t navigate China’s fragmented manufacturing landscape alone. Leverage our on-the-ground verification network and real-time supplier intelligence to secure competitive advantage in 2026.

📞 Contact our Sourcing Support Team Now

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

One conversation can eliminate months of uncertainty.

Request your customized Pro List preview today — and source with precision, speed, and confidence.

—

SourcifyChina | Trusted by 320+ Global Brands in Electronics, Mobility & Lifestyle Tech

Shenzhen • Ho Chi Minh • Rotterdam • Los Angeles

🧮 Landed Cost Calculator

Estimate your total import cost from China.