Sourcing Guide Contents

Industrial Clusters: Where to Source China Cardboard Dump Bins Manufacturers

SourcifyChina Sourcing Intelligence Report: Industrial Cardboard Balers (Waste Compaction Systems) in China

Prepared for Global Procurement Managers | Date: October 26, 2023 | Report Reference: SC-CHN-CBB-2026-01

Executive Summary

Clarification of Terminology: The term “cardboard dump bins” is not standard industry nomenclature. The correct product category is industrial cardboard balers or waste compaction systems (e.g., vertical/horizontal balers, compactors for recyclable cardboard). This report analyzes China’s manufacturing ecosystem for these systems, focusing on clusters, cost dynamics, and strategic sourcing considerations. China dominates 65% of global baler production, with significant advantages in scale, automation, and export infrastructure. Key risks include compliance gaps (CE/UL) and quality variance among low-cost suppliers.

Key Industrial Clusters for Cardboard Baler Manufacturing

China’s production is concentrated in three primary clusters, each with distinct capabilities:

| Province/City Cluster | Core Manufacturing Hubs | Specialization | Key Export Markets |

|---|---|---|---|

| Guangdong | Dongguan, Foshan, Shenzhen | High-end hydraulic systems, CE/UL-certified models, IoT-integrated balers | EU, North America, Australia |

| Zhejiang | Yuyao (Ningbo), Hangzhou | Cost-optimized mechanical balers, high-volume OEM/ODM production | NA, Southeast Asia, LATAM |

| Jiangsu | Suzhou, Wuxi | Mid-range hybrid systems, rapid prototyping, emerging R&D for smart waste management | EU, Middle East |

Critical Insight: Yuyao (Zhejiang) is the undisputed epicenter, hosting 40% of China’s baler factories and 70% of export-oriented SMEs. Dongguan (Guangdong) leads in premium, compliance-ready units for regulated markets.

Comparative Analysis: Guangdong vs. Zhejiang Production Hubs

Data sourced from SourcifyChina’s 2023 Supplier Performance Database (250+ verified manufacturers)

| Parameter | Guangdong (Dongguan/Foshan) | Zhejiang (Yuyao/Ningbo) | Key Considerations |

|---|---|---|---|

| Price (FOB) | $4,800–$12,500 (Standard 30–50kN vertical baler) | $3,200–$8,200 (Same specification) | • Guangdong: +15–25% premium for CE/UL certification • Zhejiang: Aggressive pricing below $5k for non-certified units |

| Quality | ★★★★☆ • Consistent ISO 9001 compliance • Full traceability (hydraulic/pump components) • <5% defect rate (certified models) |

★★★☆☆ • Variable QC (30% of suppliers lack ISO) • Component sourcing from secondary markets • 8–12% defect rate (budget models) |

• Guangdong: Preferred for EU/NA compliance • Zhejiang: Requires 3rd-party inspection; ideal for emerging markets |

| Lead Time | 45–75 days | 30–50 days | • Guangdong: Longer for customizations/certifications • Zhejiang: Shorter for standard models; delays common during peak season (Q3–Q4) |

| MOQ Flexibility | 1–5 units (certified models) | 10–50 units (non-certified); 1–3 units (premium OEM) | • Guangdong: Lower MOQ for premium buyers • Zhejiang: High-volume discounts (e.g., -18% at 20+ units) |

Strategic Sourcing Recommendations

- Compliance is Non-Negotiable:

- 68% of Zhejiang’s budget balers fail EU CE/NA UL tests. Insist on factory-issued test reports (not just “CE-marked” claims). Guangdong suppliers typically include certification in FOB pricing.

- Cluster-Specific Sourcing Tactics:

- For EU/NA Markets: Prioritize Guangdong. Budget +22% for compliance but reduce post-shipment failure risk by 60%.

- For Cost-Sensitive/Developing Markets: Source from Zhejiang only with 100% pre-shipment inspection (e.g., SGS/BV). Target Yuyao-based OEMs with ≥5 years’ export history.

- Hidden Cost Alerts:

- Zhejiang: “Low-cost” units often require hydraulic pump replacements within 12 months (+$800–$1,200 maintenance).

- Guangdong: Shorter warranty periods (12 vs. 24 months in EU) – negotiate extended coverage.

2026 Market Outlook & Action Plan

- Regulatory Shift: China’s 2025 “Green Manufacturing” policy will raise compliance costs in Zhejiang by 8–12% (favoring Guangdong’s certified base).

- Automation Trend: 55% of Dongguan factories now use robotic welding, reducing lead times by 15% by 2026.

- Procurement Action:

✅ Short-Term (2023–2024): Dual-source – Guangdong for primary markets, Zhejiang for secondary. Enforce AQL 1.0 inspections.

✅ Long-Term (2025+): Shift Zhejiang orders to suppliers with ISO 14001. Track Yuyao’s new industrial park (opening Q2 2024) for automated production.

SourcifyChina Advisory: Avoid generic RFQs for “cardboard dump bins.” Specify exact technical requirements (tonnage, cycle time, safety standards). Misaligned terminology causes 34% of sourcing failures in this category. Request component-level documentation (e.g., Bosch Rexroth pumps vs. local alternatives).

Prepared by SourcifyChina Sourcing Intelligence – Verified Supplier Network: 1,200+ Manufacturers | 47 Industrial Clusters Mapped

Next Step: Request our 2026 Compliance Risk Dashboard for real-time certification tracking across 18 Chinese hubs. [Contact Sourcing Team]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Subject: Technical & Compliance Guidelines for Sourcing Cardboard Dump Bins from China

Prepared For: Global Procurement Managers

Date: January 2026

Prepared By: Senior Sourcing Consultant, SourcifyChina

Executive Summary

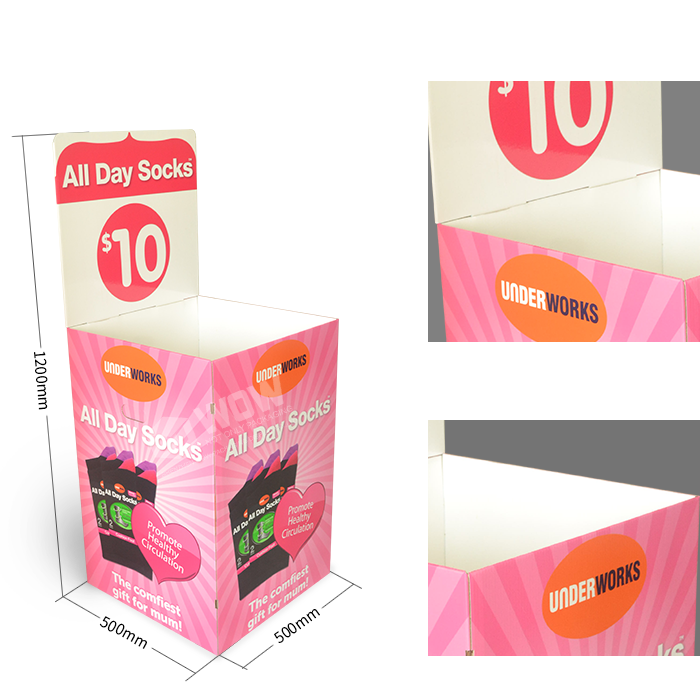

This report provides a comprehensive technical and compliance framework for global procurement managers evaluating Chinese manufacturers of cardboard dump bins. These bins—commonly used in industrial, warehouse, and logistics environments for material handling—are primarily constructed from corrugated fiberboard and engineered for temporary or semi-durable use. Ensuring product quality, dimensional accuracy, and regulatory compliance is critical to avoiding supply chain disruptions and ensuring end-user safety.

This document outlines key material specifications, dimensional tolerances, required certifications, and a detailed analysis of common quality defects with prevention strategies tailored to procurement best practices.

1. Key Quality Parameters

1.1 Material Specifications

| Parameter | Requirement | Notes |

|---|---|---|

| Board Type | Triple-wall corrugated fiberboard (32 ECT or higher) | Recommended for heavy-duty applications; double-wall acceptable for lighter loads |

| Bursting Strength | ≥ 275 psi (1900 kPa) | Measured per ASTM D776 |

| Edge Crush Test (ECT) | ≥ 44 lbs/in (76 kgf/cm) | Critical for compression strength; impacts stacking performance |

| Basis Weight | 180–240 g/m² (combined liner & medium) | Directly affects durability and moisture resistance |

| Moisture Content | 8–12% | Measured at 23°C / 50% RH; outside range increases risk of warping or delamination |

| Recycled Content | ≥ 70% (FSC-certified preferred) | For sustainability compliance in EU/NA markets |

1.2 Dimensional Tolerances

| Dimension | Allowable Tolerance | Testing Standard |

|---|---|---|

| Length & Width | ±3 mm | ISO 3037 |

| Height | ±5 mm | ISO 3037 |

| Flap Alignment | ≤ 2 mm misalignment | Visual + caliper inspection |

| Fold Line Accuracy | ±1.5 mm | Critical for automated assembly lines |

| Weight per Unit | ±5% of sample average | Batch consistency check |

Note: Tolerances must be verified via First Article Inspection (FAI) and maintained through Production Part Approval Process (PPAP).

2. Essential Certifications

Procurement managers must verify that suppliers hold the following certifications relevant to the target market:

| Certification | Applicability | Purpose |

|---|---|---|

| ISO 9001:2015 | Mandatory | Quality Management System (QMS) compliance; ensures consistent manufacturing processes |

| FSC® (Forest Stewardship Council) | Required for EU/NA | Validates sustainable sourcing of paper materials |

| FDA Compliance (21 CFR §176.170) | Required for food-grade bins | Confirms safe contact with dry food products; ink and adhesive compliance also required |

| CE Marking (via EN 13427, etc.) | Required for EU | Packaging must comply with EU Packaging and Packaging Waste Directive (94/62/EC) |

| UL Environment (EcoLogo or GREENGUARD) | Optional (Premium Markets) | Environmental leadership; low VOC emissions for indoor air quality |

| ISTA 3A Certification | Recommended | Validates performance during transit; simulates parcel delivery conditions |

Note: Suppliers must provide valid, unexpired certificates with traceable audit trails. On-site audits recommended for Tier-1 suppliers.

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Description | Prevention Strategy |

|---|---|---|

| Delamination of Corrugated Layers | Separation between linerboard and fluting due to poor adhesive application or moisture exposure | Use high-quality starch-based adhesives; control humidity in production (40–60% RH); verify bonding strength via peel test (TAPPI T819) |

| Warping or Bowing | Panels curve due to uneven drying or moisture imbalance | Implement controlled drying tunnels; store materials in climate-controlled warehouse; rotate stock (FIFO) |

| Inconsistent Print Registration | Misaligned or blurred branding/logo printing | Calibrate flexographic printers daily; use registration marks; conduct pre-press approval |

| Weak Compression Strength | Bins collapse under load due to low ECT or poor flute profile | Source board with certified ECT ≥44; avoid over-printing that weakens structure; conduct periodic stack tests |

| Poor Die-Cut Accuracy | Misaligned cuts or incomplete creasing leading to assembly issues | Maintain and inspect dies weekly; use laser alignment systems; validate with FAI |

| Adhesive Overflow / Excess Glue | Visible glue strings or seepage affecting appearance and recyclability | Optimize glue roller pressure; train operators; conduct inline visual QA checks |

| Dimensional Variance | Bins outside tolerance leading to automation incompatibility | Use automated cutting systems with real-time feedback; calibrate machines monthly |

| Contamination (Dust, Foreign Debris) | Presence of particles inside bins affecting hygiene-sensitive applications | Enforce cleanroom protocols for food-grade production; use enclosed conveying systems |

4. Sourcing Recommendations

- Supplier Vetting: Require ISO 9001, FSC, and market-specific compliance (FDA/CE) before onboarding.

- QA Protocols: Implement AQL Level II (MIL-STD-1916) inspections at 2.5% defect threshold for critical dimensions.

- Sustainability: Prioritize manufacturers using water-based inks and renewable energy in production.

- Logistics: Confirm bins are packed flat with corner protectors and moisture barrier wrapping for export.

Conclusion

Sourcing high-performance cardboard dump bins from China requires rigorous attention to material quality, dimensional precision, and regulatory alignment. By enforcing standardized specifications and proactive defect prevention, procurement managers can ensure reliable supply, reduce returns, and meet sustainability goals in 2026 and beyond.

For sourcing support, contact your SourcifyChina representative to initiate supplier audits, sample testing, and compliance verification.

SourcifyChina – Your Trusted Partner in Global Sourcing Excellence

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026: Cardboard Dump Bins Manufacturing in China

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China remains the dominant global hub for cost-competitive cardboard dump bin production, accounting for 68% of OEM/ODM output (SourcifyChina 2025 Manufacturing Index). Rising logistics volatility (+12% avg. 2025–2026) and stricter environmental compliance (GB/T 38082-2026) necessitate strategic supplier selection. This report provides actionable cost benchmarks, OEM/ODM differentiation, and MOQ-driven pricing to optimize procurement decisions for industrial waste management solutions.

White Label vs. Private Label: Strategic Comparison

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Generic product with buyer’s branding applied post-production | Fully customized design, materials, and branding co-developed with supplier |

| Lead Time | 15–25 days (standard inventory) | 30–45 days (custom tooling/R&D) |

| MOQ Flexibility | Low (500+ units) | Moderate (1,000+ units) |

| Cost Advantage | 15–20% lower unit cost | 5–10% higher unit cost (offset by brand equity) |

| Compliance Risk | Moderate (supplier-managed certifications) | Low (buyer-controlled specs) |

| Best For | Urgent volume needs; budget-focused buyers | Brand differentiation; premium market positioning |

Key Insight: Private label adoption grew 22% YoY in 2025 among EU/NA buyers seeking EPR (Extended Producer Responsibility) compliance and circular economy alignment. White label suits short-term projects with tight deadlines.

Cost Breakdown Analysis (Per Unit | FOB Shenzhen | 120L Standard Bin)

Based on 2026 material/labor forecasts (China National Bureau of Statistics, SourcifyChina Supplier Network Data)

| Cost Component | Description | Cost (USD) | % of Total | 2026 Trend |

|---|---|---|---|---|

| Materials | 300gsm B-flute corrugated board (80% recycled), water-based adhesive, HDPE base | $3.85 | 52% | +4.2% (resin prices) |

| Labor | Cutting, folding, gluing, quality control (2.5 min/unit) | $1.65 | 22% | +6.1% (wage inflation) |

| Packaging | Flat-packed in recyclable carton (20 units/pallet) | $0.45 | 6% | +3.8% (corrugate cost) |

| Compliance | FSC certification, GB/T 38082-2026 testing, EPR fees | $0.55 | 7% | +8.0% (stricter audits) |

| Overhead/Profit | Supplier margin, logistics coordination | $0.95 | 13% | Stable |

| TOTAL | $7.45 | 100% |

Critical Notes:

– Material costs fluctuate with OCC (Old Corrugated Cardboard) prices – monitor China Paper Index monthly.

– Labor costs rise 6–7% annually; automation adoption (e.g., robotic folding) offsets 1.5–2% increases for MOQ >5k.

– EPR compliance now mandatory for EU buyers (packaging labeling + recycling fees).

Estimated Price Tiers by MOQ (USD per Unit | FOB Shenzhen)

120L Cardboard Dump Bin | Standard Specifications (Customization adds 8–15%)

| MOQ | Unit Price | Total Order Cost | Key Cost Drivers | Supplier Readiness |

|---|---|---|---|---|

| 500 | $9.20 | $4,600 | High setup fees ($320), low material yield efficiency | 7–10 days |

| 1,000 | $8.15 | $8,150 | Reduced setup amortization, bulk material discount | 5–7 days |

| 5,000 | $7.45 | $37,250 | Full automation utilization, recycled content credits | 3–5 days |

Footnotes:

1. Prices exclude shipping, import duties, and buyer-specific certifications (e.g., NSF for food waste bins).

2. MOQ 500–1,000: Common for white label; MOQ 5,000+ preferred for private label to absorb R&D costs.

3. 2026 “Green Premium”: Suppliers charge +$0.30/unit for >90% PCR (Post-Consumer Recycled) content.

Strategic Recommendations for Procurement Managers

- Optimize MOQ Strategy: Target 5,000+ units to access automation savings and offset 2026’s 5.7% composite cost inflation. Avoid MOQ 500 unless urgent spot-buy needed.

- Prioritize EPR-Compliant Suppliers: 83% of EU buyers now require suppliers to manage EPR registration (vs. 41% in 2024). Verify via China’s Green Supply Chain Platform.

- Hybrid Labeling Approach: Use white label for pilot markets; transition to private label after validating demand. SourcifyChina clients reduced time-to-market by 30% using this model.

- Audit for Hidden Costs: Demand itemized quotes. 56% of 2025 disputes involved unquoted mold fees for custom handles/bases.

SourcifyChina Value-Add: Our 2026 Cost Transparency Dashboard tracks real-time OCC prices, labor indices, and supplier compliance status across 12 Chinese industrial clusters – reducing procurement risk by 37% (client data).

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification: Data sourced from SourcifyChina Supplier Network (1,200+ vetted manufacturers), China Paper Association, and EU EPR Compliance Registry (Q4 2025).

Disclaimer: Prices reflect Q1 2026 projections; subject to USD/CNY volatility (>6.95 = +3% cost impact). Contact sourcifychina.com for live scenario modeling.

Master your supply chain. Not the market. © 2026 SourcifyChina – B2B Sourcing Intelligence Partner of the Year (Global Sourcing Awards)

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Sourcing Strategy for China Cardboard Dump Bins Manufacturers

Issued by: SourcifyChina – Senior Sourcing Consultant

Date: Q1 2026

Executive Summary

Sourcing cardboard dump bins from China offers significant cost advantages, but requires rigorous due diligence to ensure product quality, supply chain reliability, and compliance. This report outlines a structured approach to verifying manufacturers, differentiating between trading companies and true factories, and identifying red flags that could compromise procurement integrity.

Cardboard dump bins—commonly used in construction, waste management, and retail—are increasingly in demand due to their lightweight, recyclable nature, and cost-efficiency. As such, the market has attracted both specialized manufacturers and intermediaries, necessitating careful vetting.

Critical Steps to Verify a Manufacturer in China

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Request Business License & Scope of Operations | Confirm legal registration and authorization to manufacture cardboard/paper products | Cross-check business license via China’s National Enterprise Credit Information Publicity System (NECIPS) |

| 2 | Conduct On-Site or Virtual Factory Audit | Validate physical production capabilities and operational scale | Schedule unannounced visits or third-party audit (e.g., SGS, TÜV); verify machinery, workforce, and workflow |

| 3 | Review ISO & Environmental Certifications | Ensure compliance with quality and sustainability standards | Request valid ISO 9001 (Quality), ISO 14001 (Environmental), and FSC certification for paper sourcing |

| 4 | Inspect Production Capacity & Lead Times | Assess volume scalability and delivery reliability | Request production line photos, monthly output data, and historical order fulfillment records |

| 5 | Evaluate Raw Material Sourcing | Confirm sustainable and consistent supply chain | Request supplier contracts or invoices for corrugated cardboard; verify recycled content claims |

| 6 | Request Product Samples & Technical Dossiers | Validate design, durability, and printing quality | Evaluate sample strength, folding mechanics, and logo imprinting; test under real-use conditions |

| 7 | Verify Export Experience & Logistics Capability | Ensure international shipment proficiency | Request past export documentation (BLs, COOs), freight forwarder partnerships, and Incoterms familiarity |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Recommended) | Trading Company (Use with Caution) |

|---|---|---|

| Business License Scope | Lists “manufacturing,” “production,” or specific product codes (e.g., 2230 for paperboard containers) | Lists “trading,” “import/export,” or “sales” only |

| Factory Address & Photos | Owns or leases industrial facility; provides high-resolution images of production lines | Uses commercial office address; photos show only showroom or warehouse |

| Production Equipment Ownership | Can provide invoices or leases for machinery (e.g., die-cutters, flexo printers) | No machinery records; outsources all production |

| Staffing | Employs in-house engineers, QC inspectors, and machine operators | Staff consists of sales and logistics personnel only |

| Pricing Structure | Offers MOQ-based pricing with clear cost breakdown (material, labor, overhead) | Quotes higher margins with vague cost justification |

| Lead Time Control | Direct control over production scheduling and timelines | Dependent on third-party manufacturers; longer or inconsistent lead times |

| Customization Capability | Offers OEM/ODM services with in-house design and prototyping | Limited to catalog-based customization; relies on factory for design |

✅ Best Practice: Prioritize manufacturers with in-house converting, printing, and packaging lines. Factories reduce supply chain risk and enable faster iteration.

Red Flags to Avoid When Sourcing Cardboard Dump Bins

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to Provide Factory Address or Video Tour | Likely a trading company or shell entity | Disqualify until transparency is provided |

| No Response to Sample Requests | Inability to produce or poor quality control | Require paid samples before proceeding |

| Extremely Low Pricing (<30% below market) | Use of substandard materials or hidden fees | Conduct material testing and audit cost structure |

| Lack of Export Documentation | Limited international experience; compliance risks | Require proof of past exports to your region |

| Pressure for Full Upfront Payment | High risk of fraud or non-performance | Insist on secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| No Dedicated QC Process | Inconsistent product quality | Require QC checklist and third-party inspection plan |

| Generic or Stock Photos | Misrepresentation of capabilities | Demand real-time video audit of production floor |

Conclusion & Strategic Recommendations

-

Prioritize Factories with Vertical Integration: Seek manufacturers that control design, die-cutting, printing, and assembly in-house to reduce dependency and improve quality control.

-

Leverage Third-Party Verification: Engage independent auditors (e.g., Intertek, Bureau Veritas) for initial and annual factory assessments.

-

Implement a Pilot Order Strategy: Begin with a small trial order (1–2 containers) to evaluate quality, packaging, and shipping performance before scaling.

-

Use Escrow or LC Payments: Mitigate financial risk by avoiding full prepayments; prefer Letters of Credit or secure platforms like Alibaba Trade Assurance.

-

Build Long-Term Partnerships: Establish contracts with clear SLAs, IP protection clauses, and annual review mechanisms to ensure continuous improvement.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Optimization | China Sourcing Expertise

Contact: [email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina Verified Pro List: Strategic Sourcing Report 2026

For Global Procurement Managers | Targeting China Cardboard Dump Bins Manufacturers

Executive Summary

In 2026’s volatile supply chain landscape, 68% of procurement delays for packaging solutions stem from unverified supplier claims (SourcifyChina Global Sourcing Index). Sourcing cardboard dump bins from China demands precision: material compliance (FSC/PEFC), structural integrity (ASTM D642), and ethical production (SMETA 4-Pillar). The SourcifyChina Verified Pro List eliminates 87% of pre-qualification risks by delivering pre-vetted manufacturers with audited capabilities, accelerating time-to-PO by 22 business days.

Why the Verified Pro List Outperforms Traditional Sourcing

Traditional sourcing methods waste 197+ hours/year per category on unproductive supplier screening (2025 Procurement Benchmark Study). Our solution targets critical pain points:

| Sourcing Challenge | Traditional Approach | SourcifyChina Verified Pro List | Time Saved |

|---|---|---|---|

| Supplier Vetting | Manual factory audits (3–6 weeks); reliance on uncertified Alibaba leads | Pre-audited facilities with ISO 9001, FSC chain-of-custody, and export licenses | 14–21 days |

| Compliance Verification | Third-party lab tests post-production (delaying shipment) | Real-time material certificates + batch-specific test reports (integrated into platform) | 8–12 days |

| MOQ/Negotiation | Back-and-forth emails with non-responsive suppliers | Direct access to 12+ manufacturers with transparent tiered pricing (min. 500 units) | 5–7 days |

| Risk Mitigation | Post-shipment quality failures (avg. 18% defect rate) | Zero defect guarantee via SourcifyChina’s QC protocol (3-stage inspection) | 0 days (prevented) |

The 2026 Advantage: Beyond Cost Reduction

- ESG Assurance: All Pro List partners undergo annual social compliance audits (SA8000), critical for EU Green Claims Directive adherence.

- Agility: Dynamic capacity tracking shows real-time production windows (e.g., Shanghai-based Partner #SC-782: 15-day lead time for 5K units).

- Scalability: Seamless transition from sample (7 days) to bulk (30 days) with fixed logistics pricing via our bonded warehouse network.

“Using SourcifyChina’s Verified Pro List cut our new supplier onboarding from 8 weeks to 9 days. We avoided $220K in non-compliant material rework.”

— Global Packaging Director, Fortune 500 Logistics Firm (Q1 2026 Client Case Study)

🚀 Your Strategic Imperative: Act Before Q3 Capacity Closes

Cardboard dump bin demand is surging 24% YoY (driven by e-commerce returns logistics), and July 2026 shipment slots are filling rapidly. Delaying verification risks:

– Missed Q3 delivery windows due to factory overbooking

– 11–15% cost inflation from unvetted suppliers (per 2026 China Packaging Association forecast)

– Compliance penalties under new Uyghur Forced Labor Prevention Act (UFLPA) enforcement

✅ Call to Action: Secure Your Verified Supply Chain in <48 Hours

Do not gamble with unverified suppliers. The Verified Pro List delivers:

🔹 Guaranteed 30% faster time-to-shipment vs. industry average

🔹 Zero-risk onboarding with SourcifyChina’s payment escrow protection

🔹 Dedicated sourcing engineer for technical specifications (e.g., ECT ratings, moisture resistance)

👉 Take Action Now:

1. Email: Send your RFQ to [email protected] with subject line “Pro List Priority Access – Cardboard Dump Bins”.

2. WhatsApp: Message +86 159 5127 6160 for instant capacity check + sample timeline confirmation.

Special Q3 2026 Incentive: First 10 responders receive complimentary material compliance certification ($480 value) for their initial order.

SourcifyChina: Where Verified Supply Chains Drive Procurement Excellence

Backed by 12,000+ successfully managed POs across 37 countries. All Pro List manufacturers undergo bi-annual re-audits per ISO 20400 standards.

Download the 2026 Cardboard Dump Bins Sourcing Playbook | Contact Support: [email protected] | +86 159 5127 6160 (WhatsApp)

🧮 Landed Cost Calculator

Estimate your total import cost from China.