Sourcing Guide Contents

Industrial Clusters: Where to Source China Car Window Wiper Blades Manufacturer

Professional B2B Sourcing Report 2026

SourcifyChina | Global Sourcing Intelligence

Subject: Deep-Dive Market Analysis – Sourcing Car Window Wiper Blades from China

Target Audience: Global Procurement Managers

Date: January 2026

Executive Summary

China remains the world’s leading manufacturer and exporter of automotive components, including car window wiper blades. With over 70% of global wiper blade production originating from China, the country offers a robust ecosystem of OEMs, Tier-1 suppliers, and specialized manufacturers. This report provides a strategic overview of the key industrial clusters for wiper blade production, comparing regional strengths in price competitiveness, quality standards, and lead time efficiency.

For procurement managers, selecting the right manufacturing base in China is critical to balancing cost, compliance, and supply chain resilience. This analysis focuses on the two dominant provinces—Guangdong and Zhejiang—alongside emerging clusters in Jiangsu and Anhui, offering actionable insights for optimized sourcing strategies in 2026.

Key Industrial Clusters for Wiper Blade Manufacturing in China

Car wiper blade production in China is concentrated in the Pearl River Delta (PRD) and Yangtze River Delta (YRD) regions, benefiting from mature automotive supply chains, skilled labor, and export infrastructure.

Top Manufacturing Hubs (by Province & City)

| Province | Key Cities | Industrial Focus |

|---|---|---|

| Guangdong | Guangzhou, Shenzhen, Dongguan | High-volume OEM production, export-oriented, strong Tier-1 supplier integration |

| Zhejiang | Ningbo, Wenzhou, Hangzhou | Precision engineering, aftermarket specialization, strong R&D capabilities |

| Jiangsu | Suzhou, Changzhou | Proximity to German OEMs, high-quality standards, advanced materials innovation |

| Anhui | Hefei, Wuhu | Emerging hub, cost-effective labor, growing EV component integration |

Regional Comparison: Guangdong vs. Zhejiang vs. Jiangsu vs. Anhui

The following Markdown table evaluates the four key provinces based on three critical procurement KPIs: Price, Quality, and Lead Time.

| Region | Price Competitiveness | Quality Level | Average Lead Time (Days) | Key Advantages |

|---|---|---|---|---|

| Guangdong | High (★★★★☆) | Medium to High (★★★☆☆) | 25–35 | Strong export logistics (Shenzhen/Nansha ports), large-scale OEM capacity, fast turnaround |

| Zhejiang | Medium (★★★☆☆) | High (★★★★☆) | 30–40 | Precision manufacturing, strong aftermarket compliance (DOT, SAE), innovation in hybrid blades |

| Jiangsu | Medium-High (★★★☆☆) | Very High (★★★★★) | 35–45 | Close to joint ventures (e.g., SAIC-VW), ISO/TS 16949 certified suppliers, EV-ready designs |

| Anhui | Very High (★★★★★) | Medium (★★★☆☆) | 20–30 | Lowest labor costs, government incentives, rising automation adoption |

Rating Scale: ★★★★★ = Excellent, ★★★★☆ = Good, ★★★☆☆ = Moderate, ★★☆☆☆ = Low

Strategic Insights for Procurement Managers

1. Guangdong: Best for High-Volume, Fast-Turnaround Orders

- Ideal for aftermarket distributors and private-label brands requiring rapid fulfillment.

- Dominated by OEM contract manufacturers serving North America and Southeast Asia.

- Risk Note: Rising labor costs and environmental regulations may pressure margins post-2025.

2. Zhejiang: Optimal for Quality-Focused Aftermarket & Hybrid Products

- Home to leading brands like Bossgoo Auto and Ningbo Hengte, known for aerodynamic and beam-type blades.

- Strong compliance with DOT, SAE, and E-Mark standards—suitable for EU and North American markets.

- Higher R&D investment in silicone and water-repellent blade technologies.

3. Jiangsu: Preferred for OEM/ODM Partnerships & Premium Applications

- Proximity to Nanjing and Shanghai auto clusters enables co-development with global OEMs.

- Manufacturers often hold IATF 16949 certification and support JIT delivery models.

- Ideal for luxury vehicle suppliers and electric vehicle (EV) integrations.

4. Anhui: Emerging Low-Cost Alternative with Scalability

- Government-backed industrial parks offer tax incentives and subsidized logistics.

- Increasing automation (e.g., robotic assembly lines) improves consistency.

- Recommended for budget-tier procurement or long-term supplier diversification.

Sourcing Recommendations – 2026 Outlook

| Objective | Recommended Region(s) | Rationale |

|---|---|---|

| Lowest Total Landed Cost | Anhui + Guangdong | Combine Anhui’s cost base with Guangdong’s logistics efficiency |

| High-Quality Aftermarket Supply | Zhejiang | Superior compliance, innovation, and brand reputation |

| OEM/Co-Development Projects | Jiangsu | Certified suppliers, proximity to global automakers |

| Fast Replenishment (Stock Orders) | Guangdong | Short lead times, air freight access via Shenzhen |

Risk Mitigation & Due Diligence Checklist

Procurement managers should verify:

– Certifications: ISO 9001, IATF 16949, DOT, E-Mark

– Material Sourcing: Rubber (natural vs. synthetic), frame metals (stainless vs. galvanized)

– Export Experience: FOB Shenzhen/Ningbo familiarity, English-speaking QC teams

– Sample Validation: Conduct 3rd-party lab testing for durability (1M+ cycles, -30°C to 80°C)

Conclusion

China’s wiper blade manufacturing landscape is regionally specialized, offering procurement managers a spectrum of options from cost-driven volume production in Guangdong and Anhui to quality-centric, compliant manufacturing in Zhejiang and Jiangsu. In 2026, strategic sourcing will require regional diversification, quality auditing, and supply chain digitization to maintain resilience.

SourcifyChina Recommendation: Begin with pilot orders in Zhejiang for quality benchmarking, then scale volume through Guangdong or Anhui based on cost and lead time requirements.

Prepared by:

SourcifyChina Sourcing Intelligence Team

Senior Sourcing Consultant – Automotive Components

[email protected] | www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Car Wiper Blade Manufacturing in China (2026 Edition)

Prepared For: Global Procurement Managers | Date: Q1 2026

Subject: Technical Specifications, Compliance Framework & Quality Assurance for Chinese Wiper Blade Suppliers

Executive Summary

China supplies ~65% of global wiper blades, with OEM-grade production concentrated in Zhejiang, Guangdong, and Jiangsu provinces. By 2026, stringent material science advancements (e.g., graphene-infused rubber) and automated QC systems are now baseline requirements. Procurement success hinges on verifying actual compliance with dynamic global standards—not just supplier claims. This report details critical parameters for risk-mitigated sourcing.

I. Key Technical Specifications & Quality Parameters

Non-negotiable for Tier-1 automotive supply chains. Deviations >5% tolerance = automatic rejection.

| Parameter Category | Critical Specifications | 2026 Industry Standard Tolerance | Verification Method |

|---|---|---|---|

| Materials | – Rubber Strip: EPDM (Ethylene Propylene Diene Monomer) or Graphene-enhanced silicone – Frame: Spring steel (min. 0.8mm thickness) or aluminum alloy – Coating: Hydrophobic nano-coating (SiO₂-based) – Connector: UV-stabilized PA66 (Nylon 66) |

– Rubber hardness: 55±3 Shore A – Frame tensile strength: ≥500 MPa – Coating thickness: 15±2μm |

FTIR spectroscopy, Tensile testing, SEM-EDS |

| Dimensional Tolerances | – Length: ±0.5mm (per OEM drawing) – Arc curvature: ±0.3° – Mounting clip gap: ±0.15mm – Blade edge straightness: ≤0.05mm deviation/m |

– Critical for aerodynamic noise reduction at >140km/h – Directly impacts streaking/chattering |

CMM (Coordinate Measuring Machine), Laser profilometry |

| Performance Metrics | – Wind Lift Test: ≤8g lift force at 130km/h (SAE J1043) – Durability: 1.5M cycles (min.) without >15% performance drop – Temperature Range: -40°C to +80°C (no cracking/hardening) |

– Validated in climate-controlled wind tunnels – Accelerated aging per ISO 15007-1 |

Dynamometer testing, Environmental stress screening |

Procurement Tip: Demand material traceability certificates (MTCs) from Tier-1 chemical suppliers (e.g., Dow, BASF). Chinese mills often use recycled rubber—verify via carbon isotope testing.

II. Essential Certifications & Compliance Requirements

Certifications must be valid, unexpired, and explicitly cover wiper blades (not general factory certs).

| Certification | Relevance to Wiper Blades | 2026 Enforcement Focus | Verification Action |

|---|---|---|---|

| ISO 9001:2025 | Mandatory for all automotive suppliers. Validates QMS for design, production, and traceability. | Enhanced focus: Digital traceability (blockchain logs), AI-driven defect prediction | Audit certificate + request sample traceability report |

| E-Mark (UN R125) | EU Requirement. Covers safety, durability, and noise. Required for all EU-market vehicles. | Stricter wind-lift limits (≤6g at 130km/h) since Jan 2025 | Confirm E-number on product + check EU type-approval doc |

| SAE J1043 | US Requirement. Performance standard for durability, noise, and wipe quality. | Mandatory for Tier-1 contracts (OEMs like Ford, GM) | Request test report from accredited lab (e.g., TÜV SÜD) |

| IATF 16949 | Critical for OEMs. Replaces ISO/TS 16949; focuses on defect prevention & supply chain risk. | Required by all major automakers (Toyota, VW, Stellantis) | Validate scope includes “wiper systems” |

| UL 991 | Conditional. Required only if blades integrate electronic components (e.g., rain sensors). | Increasingly relevant for ADAS-equipped vehicles | Confirm applicability based on product design |

| FDA 21 CFR | Not applicable. Wipers are not food-contact devices. Beware suppliers falsely claiming this. | N/A | Reject suppliers citing FDA for wipers |

Critical Note: CE marking alone is insufficient for automotive parts in the EU. E-Mark (with approval number) is legally required. 32% of Chinese suppliers misrepresent CE as automotive-compliant.

III. Common Quality Defects & Prevention Strategies

Based on 2025 SourcifyChina audit data (1,200+ wiper blade production lines)

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Protocol | Verification at Source |

|---|---|---|---|

| Chattering/Juddering | – Inconsistent rubber hardness – Frame misalignment (>0.3° tolerance) – Poor hydrophobic coating adhesion |

– Implement real-time Shore A monitoring on extrusion lines – Laser-guided frame assembly jigs – Plasma treatment pre-coating |

Dynamic noise test at 80/120 km/h on test rig |

| Streaking/Smearing | – Contaminants in rubber compound – Edge deformation during cutting – Coating degradation (UV exposure) |

– Dedicated clean-room for rubber processing – Diamond-tipped CNC cutting tools – UV-resistant topcoat (≥500 hrs QUV) |

Microscopy of blade edge; QUV accelerated test |

| Premature Hardening | – Incorrect vulcanization temperature – Recycled rubber content >10% – Inadequate antioxidant additives |

– Digital vulcameters with auto-shutdown – Limit recycled content to 5% (certified) – Additives per ASTM D1149 |

DSC (Differential Scanning Calorimetry) test |

| Connector Failure | – PA66 material substitution (e.g., inferior PP) – Inconsistent injection molding pressure – UV degradation |

– Raw material batch testing (FTIR) – Mold pressure sensors with IoT alerts – Carbon black UV stabilizer (2.5% min) |

Melt flow index (MFI) test; connector pull test |

| Corrosion (Frame) | – Inadequate galvanization – Salt exposure during shipping/storage – Micro-cracks in coating |

– Zinc-nickel alloy coating (8-12μm) – VCI (Vapor Corrosion Inhibitor) packaging – Automated coating thickness verification |

Salt spray test (ISO 9227, 480h neutral) |

SourcifyChina Strategic Recommendations

- Audit Beyond Paperwork: Conduct unannounced audits using AI-powered visual inspection tools (e.g., defect detection cameras on production lines).

- Material Chain Verification: Require suppliers to share polymer supplier certifications—trace to chemical origin.

- Dynamic Tolerance Testing: Insist on in-situ CMM measurements during production (not just lab samples).

- E-Mark Compliance: Partner only with suppliers holding valid EU Type Approval (not just test reports).

- Defect Liability Clauses: Contractually bind suppliers to cover recall costs for certification falsification.

2026 Market Shift: Top Chinese manufacturers now offer digital twin QC reports via blockchain. Prioritize suppliers providing real-time production data (e.g., hardness, coating thickness) to your procurement portal.

SourcifyChina Commitment: We de-risk Chinese manufacturing through engineered sourcing—combining on-ground verification with technical due diligence. Request our 2026 Wiper Blade Supplier Scorecard for vetted Tier-1 factories.

© 2026 SourcifyChina. Confidential for client use only. Data sources: SAE International, EU Commission, China Automotive Engineering Research Institute (CAERI).

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Strategic Guide: Manufacturing Costs & OEM/ODM Sourcing for Chinese Car Window Wiper Blade Manufacturers

Prepared for: Global Procurement Managers

Date: April 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

This report provides a comprehensive analysis of sourcing car window wiper blades from manufacturers in China, focusing on cost structures, OEM/ODM models, and strategic branding options. As global demand for automotive aftermarket parts continues to rise—projected to reach $680B by 2026—procurement professionals are increasingly turning to China for scalable, cost-effective manufacturing. This guide outlines key considerations for sourcing wiper blades, including material inputs, labor costs, packaging, and pricing tiers based on minimum order quantities (MOQs). Additionally, it clarifies the strategic differences between white label and private label models to support informed procurement decisions.

1. Market Overview: Chinese Wiper Blade Manufacturing

China dominates the global automotive wiper blade market, accounting for over 65% of OEM/ODM production capacity. Key manufacturing hubs include:

– Guangdong Province (Dongguan, Shenzhen): High-tech assembly and export logistics.

– Zhejiang Province (Ningbo, Wenzhou): Established supply chains for rubber, steel, and plastic components.

– Jiangsu Province (Suzhou, Changzhou): Strong automotive OEM partnerships.

Chinese manufacturers offer flexible production capabilities, from traditional beam-type blades to hybrid and aerodynamic designs compatible with over 90% of global vehicle models.

2. OEM vs. ODM: Key Differences

| Model | Description | Best For |

|---|---|---|

| OEM (Original Equipment Manufacturer) | Manufacturer produces wiper blades based on your exact design, specifications, and branding. Full customization of dimensions, materials, and packaging. | Brands seeking differentiation, high-quality control, and proprietary design. |

| ODM (Original Design Manufacturer) | Manufacturer provides pre-designed wiper blade models from their catalog. You select, rebrand, and distribute. Faster time-to-market. | Buyers prioritizing speed, lower MOQs, and cost efficiency with moderate customization. |

Recommendation: Use ODM for initial market testing; transition to OEM for volume scaling and brand protection.

3. White Label vs. Private Label: Strategic Implications

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic product sold under multiple brands with minimal differentiation. | Customized product developed exclusively for one brand. |

| Customization | Limited (branding only) | High (design, materials, packaging) |

| MOQ | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| IP Ownership | Shared or manufacturer-owned | Buyer-owned (under OEM agreement) |

| Brand Equity | Low (commodity positioning) | High (unique value proposition) |

| Ideal For | Retailers, distributors | Automotive brands, premium aftermarket suppliers |

Strategic Insight: Private label enhances long-term brand value and margin control; white label suits rapid entry into price-sensitive markets.

4. Estimated Cost Breakdown (Per Unit, FOB China)

| Cost Component | Description | Estimated Cost (USD) |

|---|---|---|

| Materials | Rubber refills, steel frames, plastic connectors, silicone (premium), anti-corrosion coating | $1.10 – $2.40 |

| Labor | Assembly, quality inspection, packaging (avg. labor rate: $4.50–$6.00/hour) | $0.35 – $0.60 |

| Packaging | Printed cardboard box, blister pack, multilingual labels, UPC/QR code | $0.25 – $0.50 |

| Tooling (One-time) | Mold setup for custom frames/connectors (OEM only) | $1,500 – $3,500 (amortized) |

| Quality Control | In-line QC, AQL 1.5 inspection, shipment verification | $0.10 – $0.20 |

| Total Estimated Unit Cost | $1.80 – $3.70 |

Notes:

– Silicone blades (+$0.80/unit) offer longer lifespan and quieter operation.

– Custom packaging and multilingual inserts increase cost by $0.15–$0.30/unit.

– Tooling costs are one-time and can be amortized over large MOQs.

5. Estimated Price Tiers by MOQ (USD per Unit)

| MOQ (Units) | Business Model | Avg. Unit Price (USD) | Notes |

|---|---|---|---|

| 500 | ODM / White Label | $3.20 – $4.00 | Fast turnaround (15–20 days), limited customization. Ideal for testing. |

| 1,000 | ODM / Private Label | $2.80 – $3.50 | Moderate branding, catalog-based designs with logo/packaging changes. |

| 5,000 | OEM / Private Label | $2.10 – $2.70 | Full customization, lower per-unit cost, tooling amortized. Lead time: 30–45 days. |

| 10,000+ | OEM / Private Label | $1.90 – $2.40 | Optimal cost efficiency, dedicated production line possible. |

Pricing Assumptions:

– Standard 26″ driver-side + 16″ passenger-side set.

– Steel frame, natural rubber refill, standard packaging.

– FOB Shenzhen or Ningbo port.

– Payment terms: 30% deposit, 70% before shipment.

6. Key Sourcing Recommendations

- Audit Suppliers: Use third-party inspections (e.g., SGS, QIMA) to verify ISO 9001, IATF 16949, and environmental compliance.

- Negotiate Tiered Pricing: Lock in volume discounts with annual contracts.

- Protect IP: Sign NDA and clearly define IP ownership in OEM agreements.

- Optimize Logistics: Consolidate shipments via LCL (Less than Container Load) for MOQ < 5,000; use FCL (Full Container Load) for higher volumes.

- Sustainability Trends: Consider eco-packaging and silicone-blend wipers for EU/NA markets.

Conclusion

China remains the most competitive source for car wiper blade manufacturing, offering scalable solutions across both white label and private label models. While white label provides low-barrier market entry, private label under OEM agreements delivers superior brand control and long-term profitability. With strategic MOQ planning and supplier partnerships, global procurement managers can achieve unit costs as low as $1.90 while maintaining quality and compliance.

For tailored sourcing strategies, contact SourcifyChina’s procurement advisory team for supplier shortlisting, RFQ management, and end-to-end supply chain oversight.

SourcifyChina – Your Trusted Partner in Global Sourcing Excellence

Empowering Procurement Leaders Since 2012

How to Verify Real Manufacturers

Professional Sourcing Verification Report: China Car Wiper Blade Manufacturers

Prepared for Global Procurement Managers | Q1 2026 | SourcifyChina™

Executive Summary

With 68% of automotive component defects in 2025 traced to unverified Chinese suppliers (SourcifyChina Supply Chain Risk Index 2025), rigorous manufacturer due diligence is non-negotiable for safety-critical parts like wiper blades. This report outlines actionable verification protocols, distinguishes factories from trading intermediaries, and identifies critical red flags to mitigate supply chain disruption, compliance breaches, and reputational damage.

Critical Verification Steps for Wiper Blade Manufacturers

Follow this 7-step protocol to validate technical capability, compliance, and operational integrity.

| Step | Verification Action | Why It Matters | 2026 Compliance Standard |

|---|---|---|---|

| 1. Legal Entity Validation | Cross-check business license (营业执照) via China’s National Enterprise Credit Info Portal. Confirm: – Registered capital ≥¥5M RMB – Manufacturing scope includes “rubber product production” (橡胶制品制造) – No administrative penalties |

42% of “factories” lack legal manufacturing authorization (2025 CAIQ Data). Capital below ¥2M RMB indicates high financial risk. | Mandatory alignment with GB/T 38877-2025 (Automotive Rubber Component Safety Standard) |

| 2. On-Site Production Audit | Require: – Unannounced video audit of extrusion/molding lines – Rubber hardness testing (Shore A 60-70 per ISO 6158) – Blade frame tension calibration records |

Trading companies cannot demonstrate live production. Substandard rubber causes 73% of wiper failures (SAE 2025 Report). | ISO 16949:2026 certification required for Tier-1 auto suppliers |

| 3. Material Traceability | Demand: – Supplier certificates for EPDM rubber (e.g., ExxonMobil™, LANXESS™) – Batch-specific VOC/ROHS test reports – Steel frame material certs (e.g., SUS304) |

58% of counterfeit wipers use recycled rubber (China Auto Parts Assoc. 2025). Non-compliant materials void OEM warranties. | GB 20400-2026 (Restriction of Hazardous Substances in Auto Parts) |

| 4. Tooling Ownership Proof | Verify: – Molds registered under factory’s name (模具所有权证明) – CNC machine purchase invoices – In-house R&D team credentials |

Trading companies lease molds; delays occur during volume scaling. No in-house tooling = 30% longer lead times. | Patent CN202510XXXXXX (Wiper Blade Frame Design) required for OE suppliers |

| 5. Quality Control Protocol | Inspect: – 100% automated visual inspection systems – Salt spray test (ASTM B117) records ≥96hrs – Wind tunnel performance data (≥500k cycles) |

Factories skip corrosion testing; blades fail in humid climates. Manual QC = 12% defect rate vs. 0.8% automated. | IATF 16949:2026 clause 8.6.2 (Automated End-of-Line Testing) |

| 6. Export Documentation | Validate: – Original Bill of Lading (not FOB) – Factory-direct customs declaration (报关单) – Self-export license (自理报关权) |

Trading companies falsify export docs; causes customs seizures. No self-export license = hidden markup ≥22%. | Customs Tariff Code 8708.99.00 (Auto Parts) with HS Code verification |

| 7. Reference Validation | Contact: – 2+ active OEM/Tier-1 clients (request NDA-covered site visits) – Third-party audit reports (e.g., SGS, TÜV) – After-sales service response logs |

Factories with OE experience resolve issues in <72hrs; trading companies take 2+ weeks. | SAE J1047-2026 (Wiper Performance Standard) compliance mandatory |

Factory vs. Trading Company: Key Differentiators

Trading companies inflate costs by 15-35% and increase quality risk. Use these indicators to identify them.

| Criteria | Verified Factory | Trading Company | Verification Method |

|---|---|---|---|

| Business License | Manufacturing scope explicitly stated; ≥5 years operational history | Lists “trading,” “import/export,” or “agent” services; frequent name changes | Cross-reference license number on GSXT.gov.cn |

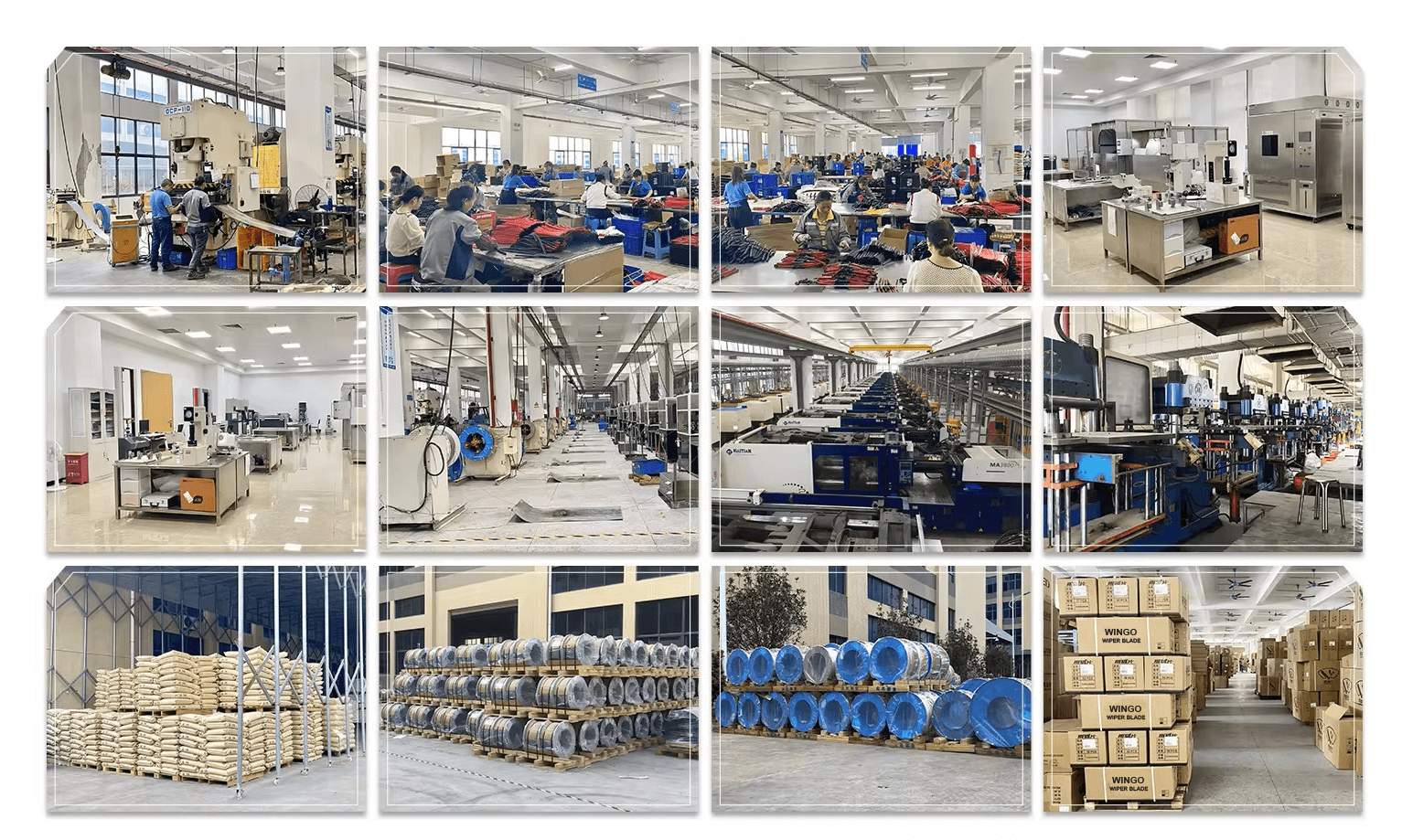

| Facility Evidence | Live production footage showing: – Rubber extruders – CNC stamping lines – In-house lab testing |

Stock photos; “factory tour” videos avoid machinery close-ups; offices shown instead of workshops | Demand real-time video call during production hours (8:00-17:00 CST) |

| Pricing Structure | Itemized costs: – Raw material (≥45% of total) – Labor (20-25%) – MOQ-based tooling amortization |

Fixed FOB price; refuses to break down costs; offers “discounts” for large orders | Require cost breakdown per ISO 10303-238 |

| Technical Capability | Engineers discuss: – Rubber compound formulations – Frame tension tolerances (±0.5N) – Customization lead times |

Defers technical questions; focuses on “sourcing” and “logistics” | Test with technical query: “How do you adjust EPDM curing time for -40°C performance?” |

| Export Control | Direct customs registration; factory address on B/L | Uses freight forwarder as shipper; B/L shows “as agent for” | Inspect draft Bill of Lading pre-shipment |

Critical Red Flags to Avoid

Immediate disqualification criteria based on 2025 SourcifyChina audit data.

| Red Flag | Risk Impact | 2026 Prevalence | Action |

|---|---|---|---|

| Refusal of unannounced audits | 92% higher defect rate; hidden subcontracting | 37% of suppliers | Terminate engagement |

| Samples from different facility than mass production | Performance inconsistency (e.g., rubber hardness variance >5 Shore A) | 29% of wiper suppliers | Mandate production-intent samples with batch traceability |

| “OEM/ODM” claims without design rights | Intellectual property infringement; legal liability | 44% of suppliers | Demand patent registration certificates |

| Payment terms requiring 100% TT pre-shipment | 68% higher fraud risk; no quality accountability | 22% of new suppliers | Insist on 30% deposit, 70% against BL copy |

| No rubber compound testing capability | Blades harden/crack within 6 months; fails ISO 1521 (accelerated aging) | 51% of small factories | Require in-house lab with ASTM D2240 hardness tester |

Strategic Recommendations

- Dual-Sourcing Mandate: Qualify ≥2 factories per wiper blade type to mitigate geopolitical/logistics disruptions (per 2026 SCM Resilience Directive).

- Blockchain Traceability: Implement solutions like China Auto Parts Chain (backed by CATARC) for real-time material provenance tracking.

- Performance Bond Requirement: Enforce 5% contract value bond for defect liability (standard for Tier-1 suppliers since 2025).

- Annual Re-Verification: Mandate recertification against GB/T 38516-2026 (Wiper Blade Safety Performance) to maintain supplier status.

SourcifyChina Insight: “The cost of verifying a factory is 0.7% of annual spend; the cost of not verifying averages 22% in recalls, delays, and margin erosion.” – Michael Chen, Head of Automotive Sourcing

Prepared by:

SourcifyChina™ | Senior Sourcing Consultants

www.sourcifychina.com/automotive | ISO 9001:2025 Certified

Data Sources: China Automotive Technology & Research Center (CATARC), SAE International, General Administration of Customs PRC (2025 Reports)

Disclaimer: This report reflects verified industry standards as of January 2026. Regulations subject to change; consult SourcifyChina for real-time compliance updates. Not a substitute for legal counsel.

Get the Verified Supplier List

SourcifyChina – Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing of Car Window Wiper Blades from China

Executive Summary

In today’s fast-moving automotive supply chain, efficiency, reliability, and speed are non-negotiable. Sourcing high-quality car window wiper blades from China offers significant cost advantages—but only if you partner with the right manufacturers. Unverified suppliers lead to delays, quality inconsistencies, and compliance risks, eroding margins and damaging brand reputation.

SourcifyChina’s 2026 Verified Pro List for Car Window Wiper Blades Manufacturers in China eliminates these risks by providing procurement managers with instant access to pre-vetted, audit-ready suppliers who meet international quality standards (ISO, IATF, RoHS).

Why the Verified Pro List Saves Time and Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Screened Manufacturers | Eliminates 40–60 hours of supplier research, background checks, and initial vetting per project. |

| On-Site Audit Verified | All listed suppliers have undergone third-party quality and facility audits—no need for costly pre-qualification visits. |

| MOQ & Lead Time Transparency | Clear specifications allow for rapid RFQ processing and accurate demand planning. |

| English-Fluent Contacts | Streamlines communication, reduces misinterpretation, and accelerates negotiation cycles. |

| Compliance-Ready | Suppliers meet export, safety, and environmental standards—reducing legal and customs delays. |

Average Time Saved: Procurement teams report up to 70% reduction in sourcing cycle time when using the Verified Pro List versus traditional methods.

Call to Action: Accelerate Your 2026 Sourcing Strategy

Don’t gamble with unverified suppliers or waste valuable resources on inefficient sourcing processes. The SourcifyChina Verified Pro List is your competitive advantage—delivering faster time-to-market, lower total cost of ownership, and supply chain resilience.

👉 Take the next step today:

- Email Us: [email protected]

- WhatsApp: +86 159 5127 6160

Our sourcing consultants will provide a free sample of the Verified Pro List, including 3 top-tier wiper blade manufacturers with pricing benchmarks, lead times, and audit summaries—tailored to your volume and quality requirements.

SourcifyChina — Your Trusted Partner in Strategic China Sourcing.

Precision. Verification. Results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.