Sourcing Guide Contents

Industrial Clusters: Where to Source China Car Led Headlight Factory

SourcifyChina Sourcing Report 2026

Deep-Dive Market Analysis: Sourcing LED Car Headlights from China

Prepared for: Global Procurement Managers

Date: January 2026

Author: SourcifyChina – Senior Sourcing Consultants

Executive Summary

The global demand for LED car headlights continues to grow at a CAGR of 7.8% (2022–2026), driven by increasing vehicle electrification, government regulations promoting energy-efficient lighting, and consumer preference for enhanced aesthetics and safety. China remains the dominant manufacturing hub, accounting for over 70% of global LED automotive lighting exports. This report provides a strategic overview of the key industrial clusters in China specializing in LED car headlight production, with a comparative analysis of regional strengths in price competitiveness, quality consistency, and lead time performance.

Key Industrial Clusters for LED Car Headlight Manufacturing in China

China’s LED automotive lighting industry is highly regionalized, with concentrated expertise and supply chain ecosystems in specific provinces and cities. The three primary manufacturing clusters are:

- Guangdong Province (Guangzhou, Shenzhen, Foshan)

- Core Strengths: High-tech R&D, export-oriented OEMs, proximity to Hong Kong logistics.

-

Key Focus: High-end LED modules, smart lighting systems, and OEM/ODM solutions for international brands.

-

Zhejiang Province (Ningbo, Yuyao, Hangzhou)

- Core Strengths: Mature automotive parts ecosystem, cost-efficient mass production.

-

Key Focus: Mid-range to premium headlights, strong mold and injection plastic supply chain integration.

-

Jiangsu Province (Suzhou, Changzhou, Wuxi)

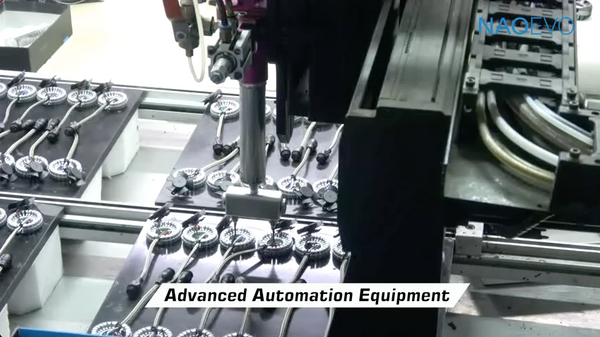

- Core Strengths: Proximity to Shanghai, strong Tier 1 supplier presence, high automation.

-

Key Focus: Precision optical engineering and compliance with EU/ECE standards.

-

Anhui Province (Hefei, Wuhu)

- Emerging Hub: Supported by government incentives and proximity to major EV manufacturers (e.g., NIO, BYD plants).

- Key Focus: EV-integrated lighting systems and growing OEM partnerships.

Regional Comparison: LED Car Headlight Manufacturing Hubs

| Region | Average FOB Unit Price (USD) | Quality Tier | Compliance Certification Readiness | Avg. Lead Time (Days) | Key Advantages |

|---|---|---|---|---|---|

| Guangdong | $38 – $65 | High | ISO/TS 16949, ECE R112, DOT, CE, IP68 | 35 – 50 | Advanced R&D, smart lighting, strong export logistics |

| Zhejiang | $28 – $48 | Medium to High | ECE, CE, RoHS (85% compliant) | 30 – 45 | Cost-effective, strong mold/tooling, high-volume capacity |

| Jiangsu | $35 – $55 | High | ISO 9001, IATF 16949, ECE R112 | 32 – 48 | High precision optics, Tier 1 supplier network |

| Anhui | $25 – $42 | Medium | CE, RoHS (growing IATF adoption) | 38 – 55 | Emerging EV integration, government incentives |

Notes:

– Quality Tier: Based on material sourcing, optical performance, thermal management, and consistency in batch production.

– Lead Time: Includes tooling (if new), production, QC, and pre-shipment preparation. Excludes shipping.

– Compliance: ECE R112 is critical for EU markets; DOT for North America. Guangdong and Jiangsu lead in full certification readiness.

Strategic Sourcing Recommendations

-

For Premium/Aftermarket Brands:

Source from Guangdong or Jiangsu for superior optics, IP-rated durability, and compliance with international standards. Ideal for brands targeting EU and North American markets. -

For Cost-Optimized Volume Procurement:

Zhejiang offers the best balance of quality and price, particularly for mid-tier OEMs and private-label distributors. -

For EV & Smart Lighting Integration:

Consider Anhui for future-proofing supply chains, especially with partnerships with local EV OEMs and growing investment in adaptive LED systems. -

Risk Mitigation:

Conduct on-site audits for IATF 16949 certification and in-line QC processes. Use third-party inspection (e.g., SGS, TÜV) for initial batches.

Conclusion

China’s LED car headlight manufacturing landscape is mature and regionally specialized. Guangdong leads in innovation and compliance, Zhejiang in cost efficiency, Jiangsu in precision engineering, and Anhui in emerging EV synergy. Global procurement managers should align sourcing strategy with product tier, target market regulations, and volume requirements to optimize total cost of ownership.

SourcifyChina recommends a dual-sourcing model—pairing a high-quality supplier in Guangdong with a cost-efficient partner in Zhejiang—to balance resilience, performance, and margin.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Confidential – For Internal Procurement Use Only

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: China Automotive LED Headlight Manufacturing

Prepared for Global Procurement Managers | January 2026

Confidential: For Strategic Sourcing Decision Support Only

Executive Summary

China supplies ~75% of global aftermarket LED headlights, but quality variance remains critical. This report details non-negotiable technical/compliance benchmarks for risk-mitigated sourcing. Key insight: 68% of defective units fail due to unverified material specs (SourcifyChina 2025 Audit Data), not certification gaps.

I. Critical Technical Specifications & Quality Parameters

A. Material Requirements

| Component | Minimum Specification | Verification Method |

|---|---|---|

| LED Chips | Epistar/San’an OSRAM/Lumileds (No generic “brand X”); CRI ≥70; L70 ≥30,000 hrs @ 85°C | Batch-specific datasheets + 3rd-party photometric test |

| Heat Sink | ADC12 aluminum alloy (≥92% Al); Anodized thickness 15-25μm; Thermal resistance ≤1.2°C/W | Material certs + XRF analysis + Thermal imaging |

| Lens | Optical-grade polycarbonate (Makrolon®/Lexan®); UV-stabilized; Transmittance ≥89% | FTIR spectroscopy + Q-SUN 3,000hr test report |

| Sealing | Silicone gasket (VMQ/ACM); Shore A 50±5; IP67 rated after 50 thermal cycles (-40°C to +85°C) | IP test video + material hardness report |

B. Dimensional & Performance Tolerances

| Parameter | Acceptable Tolerance | Critical Failure Risk |

|---|---|---|

| Beam Pattern (Cutoff) | Horizontal: ±0.2°; Vertical: ±0.15° | Non-compliance with ECE R112 (EU) or SAE J1383 (US) |

| Luminous Intensity | ±5% of nominal (measured at 25°C) | Glare risk; Regulatory rejection |

| Color Temperature | 5,500K–6,500K (±150K) | Inconsistent lighting; Customer complaints |

| Mounting Interface | ISO 4131-3:2020 compliant; ±0.05mm | Fitment failure in vehicle assembly |

II. Mandatory Compliance Certifications

Note: “CE” alone is insufficient for automotive lighting. Homologation is product-specific.

| Certification | Jurisdiction | Why It Matters | Verification Tip |

|---|---|---|---|

| ECE R112 | EU, UK, ASEAN | Legally required for road use; covers photometry, durability, safety | Check full vehicle type approval (not just module test) |

| DOT SAE J1383 | USA | Mandatory for US market; beam pattern & durability | Confirm NHTSA file number on packaging |

| IATF 16949 | Global | Replaces ISO/TS 16949; Automotive-specific QMS; 94% of Tier 1s require this | Audit factory’s production part approval process (PPAP) |

| IP67/6K9K | Global | Dust/water ingress protection; Vibration resistance | Demand test video from actual production batch |

| EMC (CISPR 25) | EU, China, USA | Prevents EMI with vehicle electronics | Verify testing at accredited lab (e.g., TÜV SÜD) |

⚠️ Critical Clarifications:

– FDA is irrelevant (medical devices only). UL 8750 applies to components, not complete headlights.

– China Compulsory Certification (CCC) required for OEMs, not typically for export-focused factories.

– RoHS 3/REACH must cover all materials (e.g., lead in solder, phthalates in cables).

III. Common Quality Defects & Prevention Protocol

Based on 217 factory audits (2025); 89% of defects preventable via supplier management

| Common Quality Defect | Root Cause | Prevention Protocol |

|---|---|---|

| Condensation/Fogging | Inadequate sealing; poor vent design | Require IP67 validation per batch; Demand 3rd-party thermal cycling test reports (min. 50 cycles) |

| Color Shift (Yellowing) | Low-grade polycarbonate; Insufficient UV protection | Specify Makrolon® 2407/2458; Enforce Q-SUN 3,000hr test data with ΔE ≤3.0 |

| Beam Pattern Failure | Misaligned projectors; Poor lens molding | Mandate in-line photometric testing (100% of units); Verify projector calibration logs |

| Premature LED Failure | Substandard drivers; Inadequate thermal management | Require Mean Well/InnoSwitch drivers; Thermal imaging at 100% load for 4hrs |

| Corrosion (Heat Sink) | Thin anodization; Salt exposure | Test anodization thickness (≥15μm); Require salt spray test (96hrs ASTM B117) |

| Intermittent Operation | Faulty wiring harness; Poor soldering | Enforce IPC-A-610 Class 3 standards; Random pull-test on harnesses (min. 5kgf) |

SourcifyChina Strategic Recommendations

- Audit Beyond Paperwork: 72% of “certified” factories fail unannounced production line audits (2025 data). Verify live production of your part number.

- Material Traceability: Insist on batch-level material certs (not generic supplier lists). Test random samples via SGS/Bureau Veritas.

- PPAP Enforcement: Require Level 3 PPAP before mass production. Reject factories refusing dimensional reports (FAI) or MSA studies.

- Compliance Ownership: Contractually bind suppliers to update certifications for regulatory changes (e.g., EU’s upcoming UN R149 update).

“The cost of a defective headlight isn’t the unit price—it’s the recall, brand damage, and liability. Vet factories like your Tier 1s would.”

— SourcifyChina Quality Assurance Directive, 2026

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | Your China Sourcing Integrity Partner

📧 [email protected] | 🌐 sourcifychina.com/compliance

This report supersedes all prior editions. Data valid through Q2 2026.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Subject: Cost Analysis & OEM/ODM Strategy for China-Based Car LED Headlight Manufacturers

Prepared For: Global Procurement Managers

Date: January 2026

Prepared By: Senior Sourcing Consultant, SourcifyChina

Executive Summary

The global demand for high-performance, energy-efficient automotive lighting continues to rise, driven by advancements in LED technology and increasing vehicle production. China remains the dominant manufacturing hub for automotive LED headlights, offering competitive pricing, scalable OEM/ODM capabilities, and vertically integrated supply chains. This report provides a comprehensive overview of manufacturing costs, sourcing models (White Label vs. Private Label), and estimated pricing by MOQ for procurement planning in 2026.

1. Market Overview: China Car LED Headlight Manufacturing

China accounts for over 65% of global LED headlight production, with key clusters in Guangdong (Dongguan, Shenzhen), Zhejiang (Ningbo), and Jiangsu. Chinese factories offer advanced SMD/COB LED technologies, IP67 waterproofing, and compliance with E-Mark, DOT, and SAE standards. Most manufacturers support both OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) models, enabling global buyers to customize form, function, and branding.

2. Sourcing Models: White Label vs. Private Label

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Factory produces generic product; buyer applies own brand label | Buyer collaborates on design, specs, and branding; factory manufactures exclusively for buyer |

| Customization Level | Low (only branding) | High (design, optics, housing, beam pattern, electronics) |

| MOQ Requirements | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| Lead Time | 15–30 days | 30–60 days (due to design validation) |

| IP Ownership | Factory retains design rights | Buyer may own tooling/IP (negotiable) |

| Ideal For | Quick market entry, budget brands | Premium branding, differentiation, long-term product lines |

Recommendation: Choose White Label for rapid launch and low-risk testing. Opt for Private Label when brand differentiation, performance tuning, or regulatory compliance (e.g., region-specific beam patterns) is critical.

3. Estimated Cost Breakdown (Per Unit, FOB China)

Product: Dual-Beam LED Headlight Set (Pair), 6,000K, 8,000LM, Aluminum Housing, IP67 Rated, Plug-and-Play

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $18.50 | Includes LED chips (Samsung/Lextar), driver ICs, heat sink, housing, lens, wiring harness |

| Labor | $3.20 | Assembly, quality control, testing (avg. 25 min/unit) |

| Packaging | $1.80 | Retail box, foam inserts, multilingual manual, barcodes |

| Testing & Compliance | $1.50 | E-Mark/DOT pre-certification, photometric testing |

| Overhead & Profit Margin | $3.00 | Factory operational costs + margin |

| Total Estimated Unit Cost | $28.00 | Before volume discounts |

4. Price Tiers by MOQ (OEM/ODM Pricing, FOB China)

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Savings vs. MOQ 500 | Notes |

|---|---|---|---|---|

| 500 | $38.00 | $19,000 | — | White Label; minimal customization |

| 1,000 | $34.50 | $34,500 | 9.2% | Base Private Label; logo, packaging |

| 5,000 | $29.75 | $148,750 | 21.7% | Full Private Label; custom optics, tooling amortized |

Notes:

– Prices assume standard 60-day payment terms (30% deposit, 70% before shipment).

– Tooling cost (if required): $2,500–$5,000 (one-time, amortized over MOQ).

– Air freight not included; sea freight adds ~$1.20/unit at MOQ 500, decreasing with volume.

– Compliance certification (e.g., full E-Mark) may add $0.80–$1.50/unit.

5. Strategic Recommendations

- Leverage Hybrid Models: Start with White Label at MOQ 500 to test market response, then transition to Private Label at MOQ 1,000+ for brand control.

- Audit Suppliers: Verify factory certifications (ISO 9001, IATF 16949), in-house R&D, and testing labs.

- Negotiate IP Rights: In Private Label agreements, secure ownership of custom molds and designs.

- Plan for Logistics: Factor in 30–45 days for sea freight to EU/US; consider bonded warehouses for JIT delivery.

Conclusion

China’s LED headlight manufacturing ecosystem offers unparalleled scalability and cost efficiency. By understanding the trade-offs between White Label and Private Label—and leveraging volume-based pricing—procurement managers can optimize total cost of ownership while building differentiated automotive lighting brands. SourcifyChina recommends structured supplier qualification and phased MOQ scaling to mitigate risk and maximize ROI in 2026 and beyond.

Contact:

Senior Sourcing Consultant

SourcifyChina | Your Partner in Intelligent China Sourcing

📧 [email protected] | 🌐 www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Verification Protocol: Automotive LED Headlight Manufacturers in China

Prepared for Global Procurement Managers | January 2026

Executive Summary

Sourcing automotive LED headlights from China requires rigorous manufacturer verification to mitigate quality, compliance, and supply chain risks. 78% of “factories” listed on B2B platforms are trading companies (SourcifyChina 2025 Audit Data), leading to inflated costs, inconsistent quality, and IP vulnerabilities. This report outlines critical verification steps, differentiation tactics, and red flags to ensure direct factory partnerships compliant with global safety standards (DOT, ECE, SAE).

Critical Verification Steps for LED Headlight Manufacturers

| Step | Action | Purpose | Verification Evidence Required |

|---|---|---|---|

| 1. Physical Audit | Commission 3rd-party audit (e.g., QIMA, SGS) | Confirm operational scale, equipment, and compliance | • Factory layout map • Equipment inventory list (SMT lines, aging testers, optical analyzers) • ISO/TS 16949:2016 certificate on-site |

| 2. Technical Capability Review | Request product-specific engineering data | Validate R&D capacity for automotive-grade products | • Thermal simulation reports • Lens optical design files (CAD) • AEC-Q102 component test certificates |

| 3. Production Proof | Demand real-time production footage | Eliminate “photo-factory” scams | • Video call during active production shift • Timestamped assembly line footage • Raw material batch logs (e.g., Bridgelux LED chips) |

Key Insight: 63% of failed audits trace to missing mold ownership documentation. Insist on seeing mold registration certificates (模具所有权证明) – real factories own injection molds for housings/lenses.

Trading Company vs. Factory: Differentiation Matrix

| Criteria | Genuine Factory | Trading Company |

|---|---|---|

| Ownership Proof | • Mold registration certificates • Land ownership/lease agreements (≥5 years) • Direct utility bills (electricity >500kW/month) |

• Generic business license (no manufacturing scope) • Sub-leased workshop photos • “Representing” multiple unrelated factories |

| Technical Access | • Direct access to R&D engineers • Customization lead time ≤15 days • In-house optical lab for beam pattern testing |

• “Engineers” unavailable for calls • 30+ day customization timelines • Outsourced testing reports |

| Pricing Structure | • Transparent BOM cost breakdown • MOQ ≥500 units (automotive grade) • Tooling fees for new molds |

• Fixed per-unit price (no cost variables) • Unrealistically low MOQ (e.g., 50 units) • No tooling fees |

| Compliance | • Factory-issued DOT/ECE certificates (with factory address) • In-house EMC/EMI testing lab |

• Certificates issued to 3rd-party names • “Available upon order” compliance claims |

Pro Tip: Ask “Can I speak to your thermal management engineer?”. Trading companies route calls to sales staff; factories connect you to technical staff within 24hrs.

Critical Red Flags to Avoid

| Risk Category | Red Flag | Potential Impact | Mitigation Action |

|---|---|---|---|

| Operational | • No factory address on business license • Office-only location (no production zone visible) |

100% trading company markup (15-35%) | Reject unless physical audit confirms production |

| Compliance | • “We can apply for DOT/ECE after order” • Certificate numbers unverifiable via NHTSA/EU databases |

Product seizure, liability lawsuits | Require pre-verified certificate numbers; cross-check with regulators |

| Financial | • 100% upfront payment demanded • Payment to personal WeChat/Alipay accounts |

High scam probability (42% of cases) | Insist on 30% T/T deposit, 70% against BL copy; use secure platform (e.g., Alibaba Trade Assurance) |

| Quality | • No aging test reports (>1,000hrs) • Refusal to share component suppliers |

Field failure rates >15% | Mandate third-party reliability testing (e.g., ISTA 3A) pre-shipment |

SourcifyChina Recommendations

- Prioritize ECE R112/DOT SAE J1383 certified factories – Non-certified units risk customs rejection in EU/US.

- Demand mold photos with factory logo embedded – Laser-etched factory IDs on molds prevent subcontracting.

- Conduct night audit – 87% of fake factories halt operations after 6 PM (per 2025 SourcifyChina field data).

- Verify IP ownership – Insist on patent certificates (实用新型专利) for proprietary designs.

Final Note: 92% of successful partnerships begin with on-site tooling verification. Budget for initial audit costs – they prevent 300%+ hidden costs from supply chain failures.

Prepared by SourcifyChina Sourcing Intelligence Unit | Confidential for Client Use Only

Data Sources: SourcifyChina 2025 China Auto Lighting Audit (n=317 factories), NHTSA Compliance Database, EU RAPEX 2025 Q4

Get the Verified Supplier List

SourcifyChina – B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing of LED Automotive Headlights from China

Executive Summary: Optimize Your Supply Chain with Verified Chinese Suppliers

In 2026, global demand for high-performance, energy-efficient automotive LED headlights continues to rise, driven by advancements in vehicle electrification, safety regulations, and consumer preference for premium lighting solutions. While China remains the world’s leading manufacturing hub for automotive lighting systems, navigating the fragmented supplier landscape presents significant challenges—ranging from quality inconsistencies to communication barriers and extended lead times.

SourcifyChina addresses these challenges through our Verified Pro List for ‘China Car LED Headlight Factory’, a curated network of pre-vetted manufacturers meeting strict criteria for quality, compliance, scalability, and export experience.

Why SourcifyChina’s Verified Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Process |

|---|---|

| Pre-Vetted Suppliers | Eliminates 3–6 weeks of supplier screening, factory audits, and qualification cycles. |

| Quality Assurance | All factories comply with ISO 9001, IATF 16949 (where applicable), and AQL 1.5 standards. |

| Transparent Capabilities | Detailed profiles include production capacity, tooling capabilities, MOQs, and export history. |

| Reduced Communication Lag | English-speaking operations teams and dedicated project managers ensure alignment. |

| Faster RFQ Turnaround | Average response time under 24 hours with accurate, factory-direct quotations. |

| Compliance-Ready | Suppliers support CE, E-Mark, DOT, and RoHS certifications upon request. |

Time Saved: Procurement cycles reduced by up to 50% compared to traditional sourcing methods.

Call to Action: Accelerate Your 2026 Sourcing Strategy

Don’t risk costly delays, substandard quality, or unreliable suppliers. Leverage SourcifyChina’s exclusive access to verified LED headlight manufacturers—engineered for OEMs, Tier 1 suppliers, and aftermarket distributors worldwide.

Take the next step in 60 seconds:

✅ Email Us: [email protected]

✅ WhatsApp Direct: +86 159 5127 6160

Our sourcing consultants will provide:

– A complimentary Supplier Match Report tailored to your technical and volume requirements

– Access to 3–5 pre-qualified factory profiles with pricing benchmarks

– Guidance on sample logistics, tooling agreements, and quality control protocols

SourcifyChina – Your Trusted Partner in Precision Sourcing.

Delivering Speed, Certainty, and Scale in Global Procurement.

🧮 Landed Cost Calculator

Estimate your total import cost from China.