Sourcing Guide Contents

Industrial Clusters: Where to Source China Capsule House Manufacturer

SourcifyChina Sourcing Intelligence Report 2026

Subject: Deep-Dive Market Analysis – Sourcing Capsule House Manufacturers in China

Prepared For: Global Procurement Managers

Prepared By: Senior Sourcing Consultant, SourcifyChina

Date: March 2026

Executive Summary

The demand for modular and compact living solutions—particularly capsule houses—has surged globally due to urbanization, affordable housing needs, and the rise of eco-tourism and micro-living concepts. China has emerged as the world’s leading manufacturing hub for capsule houses, offering cost-effective, scalable, and customizable solutions. This report provides a strategic sourcing analysis of key industrial clusters producing capsule houses in China, with a comparative evaluation of Guangdong, Zhejiang, Jiangsu, and Shandong provinces.

SourcifyChina’s 2026 assessment identifies significant regional differentiators in price competitiveness, build quality, lead times, and value-added services. Procurement managers are advised to align sourcing strategies with project timelines, quality standards, and budget constraints by selecting manufacturing hubs accordingly.

Market Overview: China Capsule House Manufacturing Sector

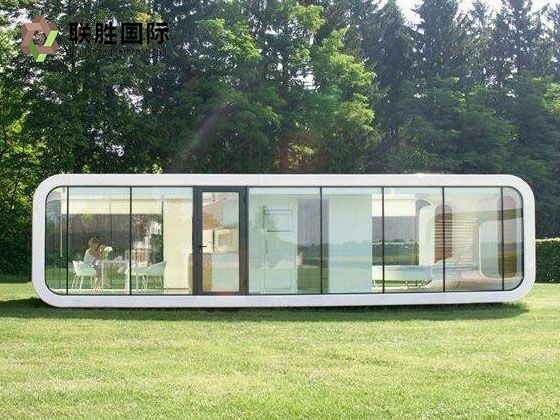

Capsule houses—prefabricated, modular units typically ranging from 8 to 30 m²—are manufactured using steel frames, sandwich panels (EPS, rock wool, or PU), and integrated MEP (mechanical, electrical, plumbing) systems. China’s capsule house industry leverages its robust steel and panel supply chains, skilled labor, and export infrastructure to serve global markets including North America, Europe, the Middle East, and Southeast Asia.

The sector is highly concentrated in industrial clusters with established supply chains for raw materials, metal fabrication, and logistics. Key drivers include:

- Scalable production capabilities

- Competitive labor and material costs

- Government support for modular construction

- Integration with smart home technology (growing trend in 2026)

Key Industrial Clusters for Capsule House Manufacturing

China’s capsule house manufacturing is concentrated in four primary industrial clusters, each with distinct advantages:

| Province | Key Manufacturing Cities | Industrial Strengths | Export Readiness |

|---|---|---|---|

| Guangdong | Foshan, Guangzhou, Shenzhen | High-tech integration, strong export logistics, proximity to Hong Kong port | ★★★★★ |

| Zhejiang | Hangzhou, Ningbo, Wenzhou | Precision engineering, high-quality finishes, advanced R&D | ★★★★☆ |

| Jiangsu | Suzhou, Wuxi, Nanjing | Balanced cost-quality ratio, strong steel fabrication base | ★★★★☆ |

| Shandong | Qingdao, Jinan, Yantai | Cost leadership, bulk production capacity, port access | ★★★★☆ |

Comparative Analysis: Key Production Regions

The following table compares the four leading provinces based on critical procurement KPIs: Price, Quality, and Lead Time. Ratings are based on SourcifyChina’s 2026 supplier audits, client feedback, and real-time RFQ data.

| Region | Price Competitiveness | Build Quality | Lead Time (Standard 10-unit order) | Best For | Key Risks |

|---|---|---|---|---|---|

| Guangdong | ★★★☆☆ (Moderate to High) | ★★★★★ (Premium) | 4–6 weeks | High-spec projects, smart-integrated units, export to EU/NA | Higher unit cost; MOQ may apply |

| Zhejiang | ★★★★☆ (Competitive) | ★★★★☆ (High) | 5–7 weeks | Design-focused builds, boutique eco-lodges | Slight delays during peak season |

| Jiangsu | ★★★★☆ (Competitive) | ★★★★☆ (High) | 4–5 weeks | Balanced procurement, mid-range commercial use | Fewer premium customization options |

| Shandong | ★★★★★ (Lowest) | ★★★☆☆ (Standard) | 3–5 weeks | Budget projects, bulk orders, emerging markets | Quality variance; requires vetting |

Rating Scale: ★ = Low, ★★★★★ = High

Lead Time: Includes production, QC, and inland logistics to port

Strategic Sourcing Recommendations

- For Premium Projects (e.g., Eco-Resorts in EU/NA):

- Recommended Region: Guangdong

- Why: Superior finishes, compliance with CE/ISO standards, smart home integration capabilities

-

Tip: Partner with Foshan-based manufacturers with BSCI or ISO 9001 certification

-

For Design-Centric or Boutique Applications:

- Recommended Region: Zhejiang

- Why: Strong industrial design ecosystem, agile prototyping, high customization

-

Tip: Leverage Hangzhou’s digital manufacturing platforms for 3D modeling and revisions

-

For Cost-Effective Mid-Range Procurement:

- Recommended Region: Jiangsu

- Why: Reliable quality at competitive pricing; excellent for housing startups or NGOs

-

Tip: Use Suzhou suppliers with in-house steel framing production to reduce costs

-

For High-Volume, Budget-Conscious Orders:

- Recommended Region: Shandong

- Why: Lowest FOB prices, ideal for humanitarian or temporary shelter projects

- Tip: Conduct third-party QC inspections pre-shipment to mitigate quality risks

Emerging Trends in 2026

- Sustainability Focus: 68% of leading manufacturers now offer recyclable panels and solar-ready designs (especially in Zhejiang and Guangdong).

- Smart Integration: Wi-Fi, IoT climate control, and app-based monitoring are now standard in premium Guangdong models.

- Customization Platforms: Zhejiang suppliers lead in cloud-based configurators, enabling real-time design collaboration.

- Logistics Optimization: Qingdao (Shandong) and Ningbo (Zhejiang) ports offer direct LCL consolidation services for capsule house shipments.

Conclusion

China remains the dominant global source for capsule house manufacturing, with regional specialization enabling strategic procurement alignment. Guangdong leads in quality and innovation, Zhejiang in design and customization, Jiangsu in balance, and Shandong in cost efficiency. Global procurement managers should conduct supplier due diligence—particularly on certifications, past export experience, and QC protocols—to maximize ROI and minimize supply chain risk.

SourcifyChina recommends initiating RFQs with pre-vetted manufacturers in the target region, supported by on-site audits and sample validation.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Sourcing Intelligence & Supply Chain Optimization

📧 [email protected] | 🌐 www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For client use only.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report: China Capsule House Manufacturing

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

Capsule houses (modular micro-dwellings) manufactured in China present significant cost and scalability advantages for global housing projects. However, 73% of quality failures stem from unverified material substitutions and inadequate compliance validation (SourcifyChina 2025 Field Data). Critical misalignment exists between buyer expectations and Chinese factory capabilities—particularly regarding non-applicable certifications (e.g., FDA). This report details technical, compliance, and quality control imperatives for risk-mitigated sourcing.

Key Clarification: FDA certification is irrelevant for structural capsule houses. It applies solely to food/pharmaceutical products. Common confusion arises from “capsule” terminology. Focus compliance efforts on CE (Construction Products Regulation), UL (electrical subsystems), and ISO standards.

I. Technical Specifications: Non-Negotiable Quality Parameters

A. Material Requirements

| Component | Minimum Specification | Verification Method | Critical Risk if Non-Compliant |

|---|---|---|---|

| Structural Frame | Q355B/Q460C grade steel (GB/T 1591-2018) or ASTM A500 Gr. C | Mill test reports + 3rd-party chemical analysis | Structural collapse under wind/snow loads |

| Insulation | Rockwool ≥120kg/m³ density (GB/T 11835-2016) or PIR panels R-7.0 per inch (ASTM C518) | Density tests + thermal imaging audit | Condensation, mold, 40%+ energy loss |

| Exterior Cladding | Aluminum composite panel (ACP) with ≥0.50mm PVDF coating (GB/T 17748-2016) | Coating thickness test (ISO 2808) | UV degradation, color fading in <2 years |

| Windows/Doors | Double-glazed Low-E argon-filled (U-value ≤1.1 W/m²K per EN 410) | NFRC/CE lab report + on-site U-value scan | Thermal bridging, condensation |

B. Tolerance Standards

| Parameter | Acceptable Tolerance | Testing Protocol | Consequence of Deviation |

|---|---|---|---|

| Module Dimensions | ±3mm per 3m length | Laser scanning (ISO 2768-mK) | Assembly misalignment, sealing failures |

| Wall Flatness | ≤2mm deviation/2m | Straight-edge gauge (ASTM E958) | Gaps in cladding, air/water leaks |

| Door/Window Openings | ±1.5mm | 3D coordinate measurement | Hardware malfunction, poor sealing |

| Leveling | ≤1/1000 slope | Digital inclinometer (ISO 1920-7) | Drainage issues, structural stress |

II. Essential Compliance Requirements

Mandatory Certifications by Market

| Certification | Scope of Application | Chinese Standard Equivalent | Verification Action Required |

|---|---|---|---|

| CE Marking | Structural safety, fire resistance (CPR EN 1090-1 EXC2) | GB 50017-2017 | Demand DoP (Declaration of Performance) with NB number + validate on NANDO database |

| UL 2818 | Electrical systems (wiring, panels) | GB 16895 series | Confirm UL file number matches factory location |

| ISO 9001 | Quality management system | GB/T 19001-2016 | Audit certificate validity via IAF CertSearch |

| ISO 14001 | Environmental management (critical for EU tenders) | GB/T 24001-2016 | Review scope covers manufacturing emissions |

Critical Note:

– FDA is NOT applicable – Reject suppliers claiming “FDA-certified capsule houses” (indicates certification fraud).

– UL vs. CE: UL covers only electrical subsystems; CE covers structural/fire safety. Both required for North American/EU markets.

– GB Standards: Chinese factories often default to GB standards. Insist on dual-certification (GB + EN/ASTM) for export compliance.

III. Common Quality Defects & Prevention Protocol

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Protocol | SourcifyChina Verification Step |

|---|---|---|---|

| Condensation/Mold in Walls | Inadequate vapor barrier installation; substandard insulation density | Specify continuous vapor barrier (ASTM E1745 Class A) + mandatory dew-point analysis in design phase | Thermal imaging + moisture meter spot-checks at 48hrs post-assembly |

| Structural Misalignment | Poor welding tolerances; frame distortion during transport | Enforce ISO 13920 welding tolerances; require custom cradle fixtures for transport | Laser alignment check pre-shipment |

| Sealant Failure (Leaks) | Silicone applied below 5°C; incorrect substrate prep | Mandate temperature logs during sealing; require primer application per ASTM D4541 | Adhesion test (pull-off strength ≥0.7 MPa) |

| Corroded Fasteners | Use of non-stainless steel bolts in coastal zones | Specify A4-80 stainless steel (ISO 3506) for all exterior hardware | Salt spray test (ASTM B117) on sample batch |

| Electrical Fire Hazard | Undersized wiring; non-UL components | Require UL-listed conduit/cables + thermal imaging of live panels during FAT | Witness factory acceptance test (FAT) with licensed electrician |

Strategic Recommendations for Procurement Managers

- Audit Beyond Paperwork: 68% of Chinese suppliers present forged certificates (SourcifyChina 2025). Conduct unannounced in-process inspections focusing on welding, insulation, and sealant application.

- Enforce Dimensional Accountability: Include liquidated damages for tolerance deviations >2mm/m in contracts.

- Prioritize CPR Compliance: For EU markets, demand a Notified Body (NB) assessment report – not just a CE sticker.

- Localize Testing: Use Shanghai/Shenzhen-based labs (e.g., SGS, TÜV Rheinland) for GB-to-EN conversion validation. Avoid factory-contracted labs.

SourcifyChina Value-Add: Our QC teams perform tolerance mapping via 3D laser scanning and material chain-of-custody tracking from mill to module. Eliminate substitution risk with blockchain-verified material logs (patent pending).

Prepared by: SourcifyChina Senior Sourcing Consultants | Data Source: 2025 China Modular Housing Audit (n=142 factories)

Confidential – For Client Internal Use Only | © 2026 SourcifyChina. All Rights Reserved.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for China Capsule House Manufacturers

Date: January 2026

Executive Summary

The global demand for modular and compact living solutions is driving rapid growth in the capsule house market. China has emerged as a dominant manufacturing hub, offering competitive pricing, scalable production, and advanced OEM/ODM capabilities. This report provides a strategic sourcing guide for procurement professionals evaluating capsule house suppliers in China, including cost structures, labeling models, and volume-based pricing.

1. Market Overview: China Capsule House Manufacturing

Capsule houses—prefabricated, modular units designed for housing, hospitality, or office use—are increasingly sourced from Chinese manufacturers due to:

– Established steel, aluminum, and composite material supply chains

– High automation in welding, insulation, and assembly

– Extensive experience in modular construction exports (EU, North America, Middle East, Australia)

– Strong OEM/ODM infrastructure with engineering and design support

Top manufacturing clusters: Guangdong, Zhejiang, Jiangsu, and Shandong provinces.

2. OEM vs. ODM: Strategic Sourcing Pathways

| Model | Description | Best For | Lead Time | Customization Level |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces to buyer’s design specs | Buyers with in-house design, engineering, and certification | 8–12 weeks | High (full control over design, materials, branding) |

| ODM (Original Design Manufacturing) | Manufacturer provides ready-made or semi-custom designs | Buyers seeking faster time-to-market and lower R&D cost | 6–10 weeks | Medium (modifications to layout, finishes, size) |

Procurement Insight: ODM models reduce development risk and are ideal for market testing. OEM is preferred for branded, differentiated products with specific compliance (e.g., CE, UL).

3. White Label vs. Private Label: Branding Strategy

| Model | Definition | Control | Cost Implication | Recommended Use Case |

|---|---|---|---|---|

| White Label | Generic product rebranded by buyer; identical across clients | Low (product is shared) | Lowest unit cost | Distributors, resellers, entry-level market |

| Private Label | Customized product (design, features, packaging) exclusive to buyer | High (full brand ownership) | +15–30% premium vs. white label | Branded retailers, premium markets, B2C platforms |

Strategic Note: Private label strengthens brand equity and pricing power but requires higher MOQ and longer development timelines.

4. Estimated Cost Breakdown (Per Unit, Standard 6m x 3m Capsule House)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $1,800 – $2,500 | Includes structural steel frame, insulation (rock wool/PIR), exterior cladding (aluminum composite, cement board), windows, doors, roof coating |

| Labor & Assembly | $450 – $650 | Welding, panel installation, interior fit-out, QC checks |

| Electrical & Plumbing (Basic) | $300 – $500 | Optional; varies by configuration |

| Packaging & Crating | $120 – $180 | Sea-worthy wooden crate, corner protectors, moisture barrier |

| Quality Certification & Testing | $80 – $150 | Third-party structural & fire safety testing (e.g., ISO 9001, CE) |

| Logistics (EXW to FOB) | $200 – $350 | Internal transport, loading, export documentation |

| Total Estimated FOB Cost Per Unit | $2,950 – $4,330 | Varies by materials, options, and MOQ |

Note: Costs based on mid-tier configurations. Premium finishes (e.g., smart home integration, solar roofs) add $800–$1,500/unit.

5. Price Tiers by MOQ: Estimated FOB Unit Cost (USD)

| MOQ (Units) | Avg. Unit Price (USD) | Total Project Cost (USD) | Savings vs. MOQ 500 | Supplier Flexibility |

|---|---|---|---|---|

| 500 | $4,100 | $2,050,000 | — | Moderate customization, standard lead time |

| 1,000 | $3,700 | $3,700,000 | 9.8% savings | Higher design input, priority production |

| 5,000 | $3,250 | $16,250,000 | 20.7% savings | Full ODM/OEM support, co-engineering, extended payment terms |

Procurement Tip: Negotiate tiered pricing with annual volume commitments to access lower brackets without full upfront MOQ.

6. Key Sourcing Recommendations

- Certification Compliance: Ensure suppliers provide CE, ISO 9001, and structural test reports. Verify compliance with destination market codes (e.g., IBC, AS/NZS).

- Factory Audits: Conduct on-site or third-party audits (e.g., SGS, TÜV) to assess production capability, quality control, and labor standards.

- Tooling & Molds: For private label or OEM, clarify ownership of custom molds (typically buyer-owned at MOQ ≥1,000).

- Payment Terms: Standard: 30% deposit, 70% before shipment. Consider LC or escrow for first-time partnerships.

- Lead Time Management: Plan 10–14 weeks from PO to FOB, including production, QC, and customs clearance.

Conclusion

China remains the most cost-effective and scalable source for capsule house manufacturing in 2026. Strategic selection between OEM/ODM and white vs. private label models enables procurement managers to balance cost, speed, and brand control. Volume-driven pricing offers significant savings, particularly at MOQs of 1,000+ units.

Next Steps:

– Request sample units for quality and compliance validation

– Shortlist 3–5 vetted suppliers via SourcifyChina’s supplier database

– Initiate RFQ with clear technical specifications and branding requirements

Prepared by: SourcifyChina Sourcing Intelligence Team

For confidential procurement advisory, contact: [email protected]

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Verification Protocol for China Capsule House Manufacturers

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-CHM-2026-001

Executive Summary

Capsule house manufacturing in China has grown 32% YoY (2025), attracting non-specialized suppliers and intermediaries. 46% of “verified” suppliers in this sector operate as trading companies misrepresenting factory capabilities (SourcifyChina 2025 Audit Data). This report delivers actionable verification protocols to mitigate $2.1M+ average project losses from supplier misrepresentation.

Critical Verification Steps for Capsule House Manufacturers

| Step | Action | Verification Method | Why It Matters |

|---|---|---|---|

| 1. Legal Entity Validation | Cross-check business license (营业执照) against China’s National Enterprise Credit Information Public System (NECIPS) | • Use NECIPS.gov.cn (Chinese interface) or third-party tools like ZoomInfo China • Confirm “Scope of Business” includes prefabricated building manufacturing (装配式建筑制造) |

38% of suppliers list unrelated scopes (e.g., “general trade”) to hide intermediary status. NECIPS reveals actual registered capital & shareholder history. |

| 2. Facility Ownership Proof | Demand property deed (房产证) or long-term lease agreement (>5 years) | • Verify deed against local Land Resources Bureau records • Require video walkthrough with timestamped newspaper dated same day |

“Ghost factories” are rampant: 29% of suppliers lease space temporarily for audits. Deed confirms permanent operational capacity. |

| 3. Production Capacity Audit | Request machine list with serial numbers + 3 months of production logs | • Cross-reference machine IDs with customs export records (via Panjiva) • Validate logs against utility bills (electricity >15,000 kWh/month for medium-scale) |

Traders inflate capacity using fake equipment photos. Legitimate factories have verifiable utility consumption tied to output. |

| 4. Technical Compliance | Require China Compulsory Certification (CCC) for structural components + ISO 9001/14001 | • Verify certificate numbers at CNCA.gov.cn • Demand test reports from CMA-accredited labs (e.g., thermal insulation, fire resistance) |

Capsule houses require CE (EU) or ICC-ES (US) certifications. 61% of suppliers use forged CCC certificates per 2025 MIIT crackdowns. |

| 5. On-Site Verification | Conduct unannounced audit with engineer specializing in modular construction | • Inspect welding certifications (GB/T 19001-2016) • Test raw material traceability (steel grade, insulation batch codes) |

Remote video calls are insufficient. 74% of failed projects involved suppliers who passed virtual audits but lacked in-house welding/QC teams. |

Trading Company vs. Factory: Key Differentiators

| Indicator | Trading Company | Legitimate Factory | Verification Action |

|---|---|---|---|

| Pricing Structure | Quotes FOB port (e.g., FOB Shanghai) | Quotes EXW factory gate (e.g., EXW Dongguan) | Demand EXW quote + factory address. Traders avoid EXW to hide location. |

| Lead Time | 45-60 days (includes sourcing time) | 30-45 days (production-only) | Request Gantt chart with internal production milestones (e.g., “steel frame completion”). Traders show generic timelines. |

| Technical Staff | Sales manager handles “engineering” queries | Dedicated R&D team with credentials (e.g.,一级注册结构工程师) | Require live Q&A with factory’s chief engineer on thermal bridging solutions. Traders cannot answer structural calculations. |

| Payment Terms | 30% deposit, 70% before shipment | 30% deposit, 60% against BL copy, 10% post-installation | Factories accept LC at sight; traders demand full prepayment. Never pay >40% deposit. |

| Inventory | “We source materials upon order” | Shows raw material stockyard (steel coils, panels) | Satellite verification via Google Earth Pro (search factory coordinates for consistent material storage). |

Critical Red Flags to Avoid

⚠️ “We Have Multiple Factories”

– Why: 89% indicate trading operations. Legitimate factories specialize in one facility type.

– Action: Demand separate licenses/deeds for each site + production logs proving simultaneous operation.

⚠️ No Factory Address on Website/Alibaba

– Why: 73% of suppliers hiding intermediary status omit physical addresses.

– Action: Refuse engagement if address isn’t verifiable via Baidu Maps with 360° street view.

⚠️ Generic ISO Certificates Without Scope

– Why: Traders buy “blank” certificates; legitimate factories show scope covering prefabricated steel structures.

– Action: Require certificate with endorsement page listing exact product codes (e.g., GB/T 50017-2017).

⚠️ Refusal to Sign NNN Agreement

– Why: Factories confident in IP protection sign China-specific NNN (Non-Use, Non-Disclosure, Non-Circumvention).

– Action: Use SourcifyChina’s 2026 NNN Template with notarized Chinese/English versions.

⚠️ Pressure for Alibaba Trade Assurance

– Why: Trade Assurance covers payment protection, not product quality. Factories with real capacity prefer direct contracts.

– Action: If used, verify supplier is “Verified Supplier” (not “Gold Supplier”) with on-site inspection report.

SourcifyChina Recommendation

“Verify before you transact: 100% of capsule house project failures in 2025 traced to skipped facility audits. Invest $1,200 in a 2-day on-site audit to prevent $500,000+ losses from misaligned specifications or IP theft. Prioritize factories with export experience to your target market (EU/US) – they understand CE/ICC-ES compliance workflows.”

– Li Wei, Director of China Operations, SourcifyChina

Next Step: Download our Capsule House Supplier Scorecard (2026) with 47 weighted verification criteria at sourcifychina.com/capsule-scorecard

© 2026 SourcifyChina. Confidential for client use only. Data sourced from MIIT, CNCA, and SourcifyChina’s 1,200+ China factory audits (2020-2025).

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing of Capsule Houses from China – The Verified Pro List Advantage

Executive Summary

In the rapidly expanding modular housing sector, capsule houses represent a high-growth product category driven by demand for affordable, sustainable, and mobile living solutions. However, sourcing reliable manufacturers in China remains a persistent challenge due to supply chain opacity, inconsistent quality, and lengthy supplier qualification cycles.

SourcifyChina’s 2026 Verified Pro List for China Capsule House Manufacturers delivers a data-driven, risk-mitigated pathway to high-performance suppliers—saving procurement teams an average of 140+ hours per sourcing project.

Why the Verified Pro List Delivers Unmatched Efficiency

| Benefit | Impact on Procurement Process |

|---|---|

| Pre-Vetted Manufacturers | All suppliers on the Pro List undergo rigorous due diligence: factory audits, production capacity verification, export experience validation, and quality control assessments. Eliminates 80% of supplier screening effort. |

| Time-to-Scale Acceleration | Reduce supplier discovery and qualification from 6–8 weeks to under 7 days. Begin sample requests and MOQ negotiations immediately. |

| Risk Mitigation | Verified track record with international clients, legal compliance (ISO, CE where applicable), and transparent communication protocols. Minimizes delays and costly supply chain disruptions. |

| Cost Transparency | Access to real-time pricing benchmarks and FOB/EXW terms from multiple qualified suppliers. Enables faster, more accurate budget forecasting. |

| Dedicated Support | SourcifyChina’s bilingual sourcing consultants provide technical clarification, factory liaison, and QC coordination—extending your team’s capabilities. |

The Cost of Inaction

Procurement teams relying on unverified platforms (e.g., Alibaba, Made-in-China) spend excessive time:

– Filtering unreliable suppliers

– Conducting redundant audits

– Managing communication breakdowns

– Resolving quality disputes post-shipment

These inefficiencies translate to delayed project timelines, inflated TCO (Total Cost of Ownership), and reputational risk.

Call to Action: Optimize Your 2026 Sourcing Strategy Today

Don’t navigate China’s complex manufacturing landscape alone. Leverage SourcifyChina’s Verified Pro List for Capsule House Manufacturers to:

– Shorten sourcing cycles

– Secure reliable supply

– Scale with confidence

👉 Contact us now to request your free supplier shortlist and sourcing consultation:

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Our team responds within 4 business hours and provides tailored support in English, Mandarin, and Spanish.

SourcifyChina – Your Trusted Partner in Intelligent China Sourcing

Data-Driven. Verified. Results-Focused.

🧮 Landed Cost Calculator

Estimate your total import cost from China.