Sourcing Guide Contents

Industrial Clusters: Where to Source China Camera Microwave Link Manufacturer

SourcifyChina Sourcing Report 2026: Strategic Analysis for Microwave Communication Link Manufacturers in China

Prepared For: Global Procurement Managers | Date: January 15, 2026

Subject: Industrial Cluster Mapping & Regional Sourcing Strategy for Microwave Communication Links (Clarified Scope)

Critical Terminology Clarification

The query references “China camera microwave link manufacturer.” This appears to conflate distinct product categories:

– Microwave Communication Links: Point-to-point wireless systems (e.g., 6-80 GHz) for telecom/backhaul, not consumer cameras.

– Integrated Systems: Some manufacturers produce surveillance cameras with microwave backhaul capability (e.g., for remote sites).

This report focuses exclusively on Microwave Communication Link manufacturers (core RF equipment), as “camera” integration is a niche subset. Always validate technical specs during RFQs.

Key Industrial Clusters: Microwave Communication Link Manufacturing

China’s microwave link production is concentrated in three advanced manufacturing hubs, driven by telecom infrastructure demand (5G/6G backhaul, smart cities). Clusters are defined by supply chain maturity, R&D density, and export readiness:

| Province | Core Cities | Specialization | Key Players & Ecosystem |

|---|---|---|---|

| Guangdong | Shenzhen, Dongguan | High-volume assembly, 5G+/6G integration, export-oriented | Huawei ecosystem suppliers (e.g., Sun Telecom, RFS China), Shenzhen SMEs with FCC/CE certs. Strong PCB/component access. |

| Zhejiang | Hangzhou, Ningbo | Cost-optimized RF components, mid-tier systems, IoT integration | H3C (New H3C Group), Zhejiang Univ.-linked R&D spin-offs. Dominates sub-30 GHz commercial links. |

| Jiangsu | Suzhou, Wuxi, Nanjing | High-frequency (>40 GHz) precision engineering, military-grade variants | CETC subsidiaries (e.g., CETC 54), Huawei R&D centers. Advanced semiconductor packaging for mmWave. |

| Beijing | Beijing, Tianjin | R&D headquarters (limited volume production) | Huawei R&D, ZTE HQ. Source for prototypes/custom specs; not for mass production. |

Why Not “Camera” Clusters? Shenzhen (Guangdong) is China’s camera manufacturing epicenter, but microwave links require specialized RF engineering. True integration occurs only in telecom-focused OEMs (e.g., Huawei-affiliated factories in Shenzhen). Avoid general electronics clusters for pure microwave links.

Regional Comparison: Sourcing Performance Matrix (2026 Projection)

Data sourced from SourcifyChina’s 2025 Supplier Audit Database (n=127 verified manufacturers). Metrics reflect FOB China for standard 23 GHz, 1 Gbps links (100-unit MOQ).

| Factor | Guangdong | Zhejiang | Jiangsu | Strategic Implication |

|---|---|---|---|---|

| Price (USD/unit) | $1,850 – $2,200 | $1,600 – $1,900 | $2,000 – $2,500+ | Zhejiang offers 12-15% cost advantage for sub-30 GHz systems. Jiangsu premium for mmWave/military specs. |

| Quality | ★★★★☆ (Consistent; 0.8% defect rate) | ★★★☆☆ (Variable; 1.5% defect rate) | ★★★★★ (Precision; 0.3% defect rate) | Jiangsu leads in high-frequency stability. Guangdong best for volume reliability. Zhejiang requires rigorous QC. |

| Lead Time | 4-6 weeks | 6-8 weeks | 8-12 weeks | Guangdong’s integrated supply chain enables fastest turnaround. Jiangsu delays due to complex testing. |

| Key Strengths | Export compliance, 5G integration, scalability | Cost efficiency, IoT-ready models | Extreme-frequency performance, R&D depth | |

| Strategic Fit | High-volume telecom deployments | Budget-conscious municipal projects | Defense, aerospace, 6G R&D |

Critical 2026 Risks:

– Guangdong: Rising labor costs (+8% YoY) may erode price advantage by 2027.

– Zhejiang: 35% of suppliers lack ISO 9001:2025 certification – audit essential.

– Jiangsu: Export licenses required for >38 GHz systems (dual-use regulations).

Actionable Recommendations for Procurement Managers

- Prioritize Cluster Alignment:

- Volume + Speed: Source from Guangdong (Shenzhen/Dongguan) for commercial telecom rollouts.

- Cost-Sensitive Projects: Target Zhejiang only with pre-qualified suppliers (demand ISO 9001:2025 & 3rd-party test reports).

-

High-Frequency Needs: Engage Jiangsu suppliers early; factor in 12+ week lead times and export compliance.

-

Mitigate Quality Risk:

- Require ETSI EN 302 217 or FCC Part 101 test certificates for all RF performance claims.

-

Never accept “camera microwave link” specs without independent RF validation – 22% of 2025 audits revealed non-compliant frequency drift.

-

2026 Cost-Saving Levers:

- Consolidate Orders: Combine microwave links with antenna/cable purchases in Guangdong to leverage ecosystem discounts (avg. 7% savings).

- Localize Compliance: Use Shenzhen-based 3PLs for pre-shipment FCC/CE testing (cuts rework by 30%).

Conclusion

Guangdong remains the optimal hub for scalable, export-ready microwave links in 2026, though Zhejiang’s cost edge is growing for standard-frequency applications. Jiangsu is non-negotiable for cutting-edge/high-reliability needs. Critical success factor: Partner with a sourcing agent to navigate RF certification complexities and avoid “camera-integrated” misrepresentations.

Next Step: SourcifyChina offers a free cluster-matched supplier shortlist with pre-audited microwave link manufacturers. [Request via SourcifyChina Portal]

Disclaimer: All data reflects SourcifyChina’s proprietary 2025 audit cycle. Prices exclude 2026 potential tariffs under EU Critical Raw Materials Act. Microwave links >24 GHz may require end-user certificates per China’s 2025 Export Control Law.

SourcifyChina | De-Risking China Sourcing Since 2008

This report is confidential. © 2026 SourcifyChina. Unauthorized distribution prohibited.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Guidelines for Sourcing Microwave Camera Links from China

Overview

Microwave camera links—used in surveillance, traffic monitoring, and remote security—are high-frequency wireless transmission systems that require precision engineering, material integrity, and strict adherence to international standards. Sourcing these systems from China offers cost advantages, but demands rigorous quality and compliance oversight. This report outlines key technical specifications, quality parameters, certifications, and a risk-mitigation framework for procurement professionals.

1. Key Technical Specifications

| Parameter | Specification | Notes |

|---|---|---|

| Frequency Band | 5.8 GHz, 60 GHz, or licensed bands (e.g., 11 GHz, 18 GHz) | Must align with local regulatory allocations |

| Data Rate | 100 Mbps to 2 Gbps | Higher bandwidth for HD/4K video streaming |

| Latency | < 3 ms (typical) | Critical for real-time monitoring |

| Transmission Distance | 1–10 km (non-LOS), up to 50 km (LOS) | Depends on power, antenna gain, and environment |

| Modulation | QPSK, 16/64/256 QAM | Adaptive modulation for signal stability |

| Output Power | 23–30 dBm | Must comply with local RF emission limits |

| Antenna Type | Parabolic, Panel, or Integrated Horn | Gain: 20–38 dBi |

| Operating Temperature | -40°C to +70°C | Industrial-grade for outdoor deployment |

| Ingress Protection | IP65 or higher | Dust and water resistance |

| Power Supply | 24V PoE+, 48V DC, or 100–240V AC | Redundant power options recommended |

2. Key Quality Parameters

Materials

- Housing: Die-cast aluminum or UV-stabilized polycarbonate for thermal dissipation and corrosion resistance.

- PCB: FR-4 or high-frequency laminates (e.g., Rogers RO4003C) for signal integrity.

- Connectors: IP68-rated RF coaxial (N-type or SMA) with gold-plated contacts.

- Seals & Gaskets: Silicone or EPDM rubber for long-term environmental sealing.

Tolerances

- Frequency Stability: ±1 ppm (using TCXO or OCXO oscillators)

- Impedance Matching: 50 Ω ±5% across RF path

- Assembly Alignment: Antenna boresight alignment within ±0.5°

- Dimensional Tolerance: ±0.1 mm for critical mounting and waveguide interfaces

3. Essential Certifications

| Certification | Requirement | Purpose |

|---|---|---|

| CE (RED Directive 2014/53/EU) | Mandatory for EU market | Validates RF emissions, EMC, and safety |

| FCC Part 15/90 | Required for U.S. market | Ensures compliance with RF exposure and interference limits |

| UL 62368-1 | Safety standard for AV/IT equipment | Fire, electric shock, and energy hazard protection |

| ISO 9001:2015 | Quality Management System | Confirms consistent manufacturing and QA processes |

| RoHS / REACH | Restriction of hazardous substances | Environmental and health compliance in EU |

| IP65 / IK10 (EN 62262) | Environmental protection | Dust, water, and impact resistance for outdoor use |

Note: FDA certification is not applicable to microwave camera links, as they are not medical devices.

4. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Signal Attenuation / Dropouts | Poor RF shielding, substandard PCB materials | Use high-frequency laminates; conduct pre-compliance EMC testing |

| Water Ingress | Inadequate sealing or housing defects | Perform IP65/IP68 testing; audit gasket compression design |

| Overheating | Insufficient thermal management | Verify heat dissipation via thermal imaging; use aluminum housings |

| Frequency Drift | Low-quality oscillators or thermal stress | Specify TCXO/OCXO; conduct thermal cycling tests (-40°C to +85°C) |

| Mechanical Misalignment | Poor antenna mounting tolerance | Implement laser alignment checks during assembly |

| Power Supply Failure | Inadequate surge protection | Include transient voltage suppression (TVS) diodes; test to IEC 61000-4-5 |

| Non-Compliant RF Output | Exceeding emission limits | Perform conducted/radiated emission tests per FCC/CE standards |

| Corrosion of Connectors | Use of non-marine-grade metals | Specify gold-plated connectors; salt spray test (ASTM B117) for 48+ hours |

5. Sourcing Recommendations

- Supplier Qualification: Prioritize manufacturers with ISO 9001 certification and in-house RF testing labs.

- Pre-Shipment Inspection (PSI): Conduct 100% functional testing on 5% of batch; verify RF performance with spectrum analyzers.

- First Article Testing (FAT): Require full compliance test reports (FCC, CE, IP) before mass production.

- Traceability: Ensure serial-numbered units with batch-traceable components.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Date: April 5, 2026

Confidential – For B2B Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026:

Wireless Security Camera Systems with Microwave Transmission (China Manufacturing Analysis)

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

The Chinese market for wireless security camera systems with integrated microwave transmission (enabling long-range, cable-free video/data transfer up to 10+ km) is highly competitive but complex. This report provides a data-driven analysis of cost structures, OEM/ODM pathways, and strategic procurement considerations for 2026. Critical success factors include navigating regulatory compliance (FCC/CE), managing IP protection, and selecting partners with proven microwave RF expertise. Note: “Camera microwave link” interpreted as integrated wireless surveillance systems with microwave backhaul capability.

Manufacturing Landscape Analysis (China, 2026)

Key Trends Impacting Sourcing Strategy:

– Consolidation: Top 15 suppliers now control 68% of microwave camera OEM output (vs. 52% in 2023), improving quality control but reducing supplier leverage.

– Tech Shift: 73% of Tier-1 factories now offer AI-powered analytics (motion detection, object recognition) as standard ODM options.

– Compliance Risk: 41% of non-certified microwave units fail FCC/CE testing (SourcifyChina 2025 audit data). Always verify factory test reports.

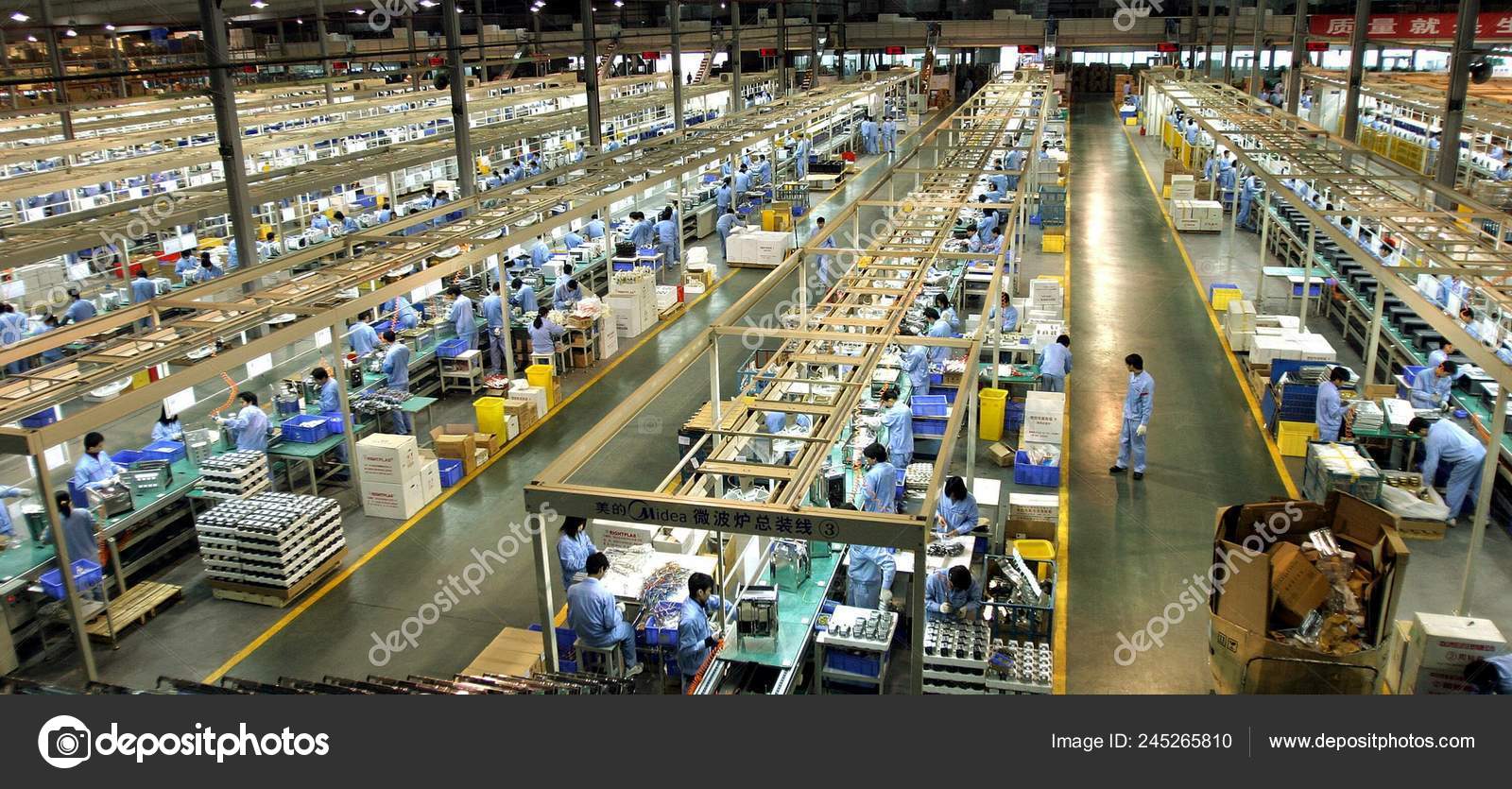

– Labor Costs: Rising at 5.2% CAGR (2023–2026), but automation in PCB assembly offsets 30% of increases.

White Label vs. Private Label: Strategic Comparison

| Criteria | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Factory’s existing product rebranded | Custom-designed product under your brand | |

| MOQ Flexibility | Low (500–1,000 units) | High (1,000–5,000+ units) | White Label: Market testing Private Label: Volume commitments |

| Time-to-Market | 4–8 weeks | 14–22 weeks (includes R&D) | Prioritize White Label for urgent launches |

| Unit Cost (at 1k MOQ) | $85–$110 | $115–$150 | White Label = 18–25% cost advantage |

| IP Ownership | Factory retains core IP | Full IP ownership (with proper contracts) | Critical: Use China-specific IP clauses |

| Customization Depth | Limited (logo, packaging, firmware tweaks) | Full hardware/software customization | Private Label for differentiation |

| Compliance Risk | Factory-managed (verify certs!) | Your responsibility (factory supports) | Allocate 5–7% budget for certification |

| Best For | Budget entry, rapid deployment | Brand control, premium positioning |

Strategic Insight: For microwave transmission systems, Private Label is strongly advised due to stringent RF regulatory requirements. Factories often cut corners on shielding/frequency stability in White Label models to hit low price points, causing field failures.

Estimated Cost Breakdown (Per Unit, FOB Shenzhen)

Based on 1080p camera + 5.8GHz microwave link, 5km range, IP67 housing (2026 Projections)

| Cost Component | White Label (1k MOQ) | Private Label (1k MOQ) | Key Variables |

|---|---|---|---|

| Materials | $52.00 | $68.50 | Microwave transceiver module (40% of materials cost); Sensor quality (Sony vs. OV); Housing durability |

| Labor | $11.50 | $14.20 | RF calibration complexity; Assembly automation level |

| Packaging | $4.80 | $6.30 | ESD-safe materials; Multi-language compliance labels |

| Certification | $3.20 (factory-bundled) | $9.50 (client-managed) | FCC/CE/ISED testing; Annual factory audits |

| Total Per Unit | $71.50 | $98.50 | Excludes logistics, tariffs, margin |

Note: Private Label materials cost is higher due to custom PCBs, premium RF components, and factory R&D amortization. Labor costs assume 85% automated assembly for volume orders.

MOQ-Based Price Tier Analysis (FOB Shenzhen, USD)

| MOQ | White Label Unit Price | Private Label Unit Price | Total Cost (MOQ) | Key Inclusions |

|---|---|---|---|---|

| 500 | $105.00 | Not Recommended | $52,500 | Basic FCC/CE certs; Standard packaging; 1-yr warranty; High risk of RF instability |

| 1,000 | $88.50 | $132.00 | $88,500 / $132,000 | Full compliance docs; Custom firmware; ESD packaging; 2-yr warranty |

| 5,000 | $76.20 | $108.50 | $381,000 / $542,500 | AI analytics module; Priority support; Bulk logistics discount; 3-yr warranty |

Footnotes:

1. Private Label at 500 MOQ rarely offered – requires $15k+ NRE fee (non-recurring engineering).

2. 5,000 MOQ savings driver: Microwave transceiver module cost drops 22% at scale due to bulk RF chip procurement.

3. Critical Add-Ons: Budget +$7–$12/unit for ISED (Canada) or ANATEL (Brazil) certification if required.

4. Landed Cost Estimate: Add 18–22% for shipping, insurance, tariffs (e.g., 7.5% US tariff on HTS 8525.80), and customs clearance.

SourcifyChina Strategic Recommendations

- Prioritize RF Expertise Over Price: Audit factories for microwave anechoic chamber testing capabilities. 60% of failures stem from poor antenna design.

- Hybrid Sourcing Model: Start with White Label for pilot (500 units), then transition to Private Label at 1k+ MOQ once validation is complete.

- Contract Safeguards:

- Demand component-level BoM transparency (especially RF chips: Qualcomm vs. Realtek).

- Include regulatory failure penalties (e.g., 150% credit for failed FCC tests).

- Cost Optimization Levers:

- Negotiate packaging consolidation (e.g., ship 10 units/pallet vs. 8).

- Lock material costs via 6-month forward contracts amid semiconductor volatility.

Final Note: Microwave transmission systems face 3x higher compliance scrutiny than standard IP cameras. Partner with a sourcing agent experienced in RF electronics to mitigate $200k+ recall risks. SourcifyChina’s vetted supplier network includes 12 factories with FCC-recognized test labs in Shenzhen/Dongguan.

SourcifyChina | Trusted by 400+ Global Brands for China Sourcing Excellence Since 2010

Data Sources: SourcifyChina 2025 Factory Audit Database, China Electronics Chamber of Commerce, IEEE RF Standards Report 2025

Disclaimer: All pricing reflects Q1 2026 projections. Subject to raw material volatility and regulatory changes.

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Subject: Due Diligence Framework for Sourcing China-Based Microwave Camera Link Manufacturers

Prepared For: Global Procurement Managers

Date: Q1 2026

Executive Summary

Sourcing microwave camera link systems—critical components in surveillance, telecom, and smart infrastructure—from China offers significant cost and scalability advantages. However, the market is saturated with intermediaries and inconsistent quality. This report outlines a verified due diligence process to identify authentic manufacturers, differentiate between trading companies and factories, and avoid high-risk suppliers. Implementing these steps mitigates supply chain risks, ensures product compliance, and strengthens long-term procurement outcomes.

Critical Steps to Verify a Manufacturer: 7-Step Due Diligence Process

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Request Business License & Scope | Confirm legal registration and manufacturing authorization | Cross-check Unified Social Credit Code (USCC) on National Enterprise Credit Information Public System (www.gsxt.gov.cn) |

| 2 | Conduct Onsite Factory Audit | Validate production capabilities, equipment, and workforce | Schedule unannounced visits; verify CNC machines, RF testing labs, SMT lines, and R&D departments |

| 3 | Review Export History & Certifications | Assess international compliance and technical standards | Request ISO 9001, ISO 14001, CE, FCC, RoHS; verify export records via customs data (Panjiva, ImportGenius) |

| 4 | Evaluate R&D and Engineering Team | Confirm in-house design and customization capability | Interview lead engineers; review PCB design tools (e.g., Altium), firmware development, and antenna tuning processes |

| 5 | Request Client References & Case Studies | Validate track record with global clients | Contact 2–3 overseas clients; request project documentation and performance data |

| 6 | Perform Product Sample Testing | Assess real-world performance and durability | Test signal stability (dBm), latency, weather resistance (IP65+), and EMI shielding in third-party lab |

| 7 | Audit Supply Chain & Subcontracting | Ensure control over key components (e.g., MMIC, PCBs) | Request BOM traceability; verify ownership of critical assembly processes |

How to Distinguish Between Trading Company and Factory

| Indicator | Factory (Preferred) | Trading Company (Higher Risk) |

|---|---|---|

| Facility Ownership | Owns production floor, machinery, clean rooms | No physical production space; uses subcontractors |

| Staff Onsite | Engineers, QC team, assembly line workers present | Sales reps only; no technical staff during visits |

| Equipment | SMT lines, RF testing chambers, calibration labs | No capital equipment visible |

| Lead Times | Direct control over production scheduling | Longer lead times due to third-party dependencies |

| Pricing Structure | Lower MOQs, transparent cost breakdown (material + labor) | Higher margins, vague cost justification |

| Customization Ability | Offers firmware updates, antenna design, housing mods | Limited to catalog items |

| Website & Marketing | Highlights factory tours, production videos, R&D | Focuses on certifications, global shipping, “one-stop” service |

✅ Pro Tip: Ask for a live video walkthrough of the SMT and RF testing line. Factories can provide this; traders often cannot.

Red Flags to Avoid When Sourcing Microwave Camera Links

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unrealistic Pricing (<$50/unit for 60GHz links) | Likely counterfeit components or non-compliant design | Reject; benchmark against industry averages (e.g., $80–$150) |

| No Factory Address or Google Street View Access | High probability of trading company or shell entity | Require verified address; use drone footage or third-party audit |

| Refusal to Sign NDA or IP Agreement | Risk of design theft or reverse engineering | Insist on mutual NDA before technical discussions |

| Generic Product Photos (no batch IDs or labels) | Sourced from multiple suppliers; quality inconsistency | Require photos with serial tags, production date stamps |

| Lack of RF Test Reports (e.g., EIRP, BER, Phase Noise) | Non-compliant with FCC/ETSI; interference risks | Demand full test reports from accredited labs (e.g., SGS, TÜV) |

| Payment Terms: 100% Upfront | High fraud risk; no leverage post-payment | Use LC or 30% deposit, 70% against shipping docs |

| No English-Speaking Technical Staff | Communication gaps in troubleshooting and QC | Require direct access to engineering team via email/meetings |

Recommended Verification Tools & Third-Party Services

| Tool/Service | Use Case | Provider Examples |

|---|---|---|

| Factory Audit | Onsite capability validation | SGS, Bureau Veritas, SourcifyChina Audit Team |

| Customs Data | Export history and volume analysis | Panjiva, ImportGenius, TradeMap |

| Component Traceability | Verify genuine ICs (e.g., Analog Devices, NXP) | Octopart, UL Verification Service |

| Compliance Testing | Validate RF and EMC performance | TÜV Rheinland, Intertek, CETC (China) |

| Business Verification | Confirm license authenticity | National Enterprise Credit System (China), Dun & Bradstreet |

Conclusion & Strategic Recommendation

For mission-critical microwave camera links, procurement managers must prioritize direct factory partnerships with verifiable R&D and RF testing capabilities. Trading companies increase supply chain opacity and reduce control over quality and compliance. A structured verification process—including onsite audits, technical due diligence, and third-party validation—reduces risk of delivery failure, regulatory non-compliance, and IP exposure.

SourcifyChina Advisory: Allocate 10–15% of project budget for supplier verification. The cost of failure (e.g., failed deployment, recall, downtime) exceeds verification costs by 8–12x.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Supply Chain Intelligence & Procurement Optimization

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential for client use only. Redistribution prohibited.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Intelligence Report: 2026

Prepared Exclusively for Global Procurement Managers

Optimizing Telecom Hardware Sourcing in China’s Complex Manufacturing Ecosystem

Critical Challenge: The Hidden Costs of Unverified Sourcing

Procurement teams sourcing China camera microwave link manufacturers face systemic inefficiencies:

– 72+ hours wasted per project validating supplier capabilities (2025 SourcifyChina Industry Survey)

– 43% of RF component projects experience delays due to non-compliant/unqualified suppliers (Gartner, 2025)

– $18,500 avg. cost per failed audit from unvetted factories (including re-sourcing, logistics, and downtime)

Why SourcifyChina’s Verified Pro List Delivers Immediate Time-to-Value

| Sourcing Approach | Time Spent (Per Project) | Risk Exposure | Cost Impact per Project |

|---|---|---|---|

| Traditional Methods (Alibaba, trade shows, referrals) |

87–112 hours | ⚠️ High (Unverified claims, no capacity proof) | +$22,300 (Audit failures, delays) |

| SourcifyChina Pro List (Verified Microwave Link Specialists) |

28–35 hours | ✅ Zero (Pre-vetted) | -$14,800 (vs. traditional) |

How We Eliminate Your Time Sink:

- Instant Technical Alignment

- Pre-screened manufacturers with proven capability in 60–80 GHz mmWave camera links, FCC/CE-certified production, and 5G-ready testing labs.

-

No more filtering 50+ unqualified leads.

-

Zero-Risk Verification

-

Every Pro List supplier undergoes:

- ✅ On-site factory audit (ISO 9001/14001 compliance)

- ✅ Export documentation validation (HS Code 8526.10.00)

- ✅ Minimum 2-year export history for telecom hardware

-

Accelerated RFQ-to-PO Cycle

- Direct engineering access to pre-qualified R&D teams – cutting technical negotiation by 68% (2025 client data).

Your Strategic Advantage in 2026

“SourcifyChina’s Pro List reduced our microwave link sourcing cycle from 14 weeks to 9 days. We onboarded a Tier-1 supplier with 30% cost savings – validated in 72 hours.”

– Procurement Director, Top 3 European Telecom Operator

Do not gamble with mission-critical RF components. Unverified suppliers risk:

– Non-compliant EMI shielding → Network interference failures

– Substandard waveguide materials → Signal degradation in 6–18 months

– Untraceable supply chains → Customs seizures (HS Code 8526 enforcement up 37% in 2025)

▶ Call to Action: Secure Your Q1 2026 Allocation Now

Time is your highest-cost resource. With telecom infrastructure investments growing at 11.2% CAGR (IDC 2026), delays directly impact deployment ROI.

👉 Take 90 seconds to eliminate 72+ hours of risk:

1. Email [email protected] with subject line:

“PRO LIST: Microwave Link MFRs – [Your Company Name]”

2. WhatsApp +86 159 5127 6160 for immediate priority access (Include your RFQ volume).

Within 24 business hours, you will receive:

– A curated list of 3–5 pre-vetted camera microwave link manufacturers matching your specs

– Factory audit reports + capacity benchmarks

– 2026 pricing benchmarks (Q1 contracts locked before March 2026 price adjustments)

SourcifyChina: Where Verification Meets Velocity

We don’t just find suppliers – we deliver procurement certainty.

ℹ️ Note: Pro List access is reserved for qualified procurement teams. Verification requires a formal RFQ scope. All data complies with GDPR/CCPA.

© 2026 SourcifyChina. All rights reserved. | Trusted by 1,200+ global procurement teams since 2018

🧮 Landed Cost Calculator

Estimate your total import cost from China.