Sourcing Guide Contents

Industrial Clusters: Where to Source China Camera Laser Cutter Supplier

SourcifyChina Sourcing Intelligence Report: China Camera-Guided Laser Cutter Market Analysis (2026)

Prepared for Global Procurement Managers | Confidential & Proprietary

Executive Summary

China dominates global production of camera-guided laser cutters (CNC laser systems with integrated vision for automated material recognition, alignment, and precision cutting), supplying 68% of the mid-to-high-end industrial market (2025 SourcifyChina Industry Survey). This report identifies critical manufacturing clusters, analyzes regional strengths/weaknesses, and provides actionable sourcing guidance. Critical Note: “Camera laser cutter” refers specifically to laser cutters with embedded vision systems – not standalone cameras or basic laser cutters. Misalignment here risks non-compliant sourcing.

Key Industrial Clusters for Camera-Guided Laser Cutters in China

China’s production is hyper-concentrated in 3 core clusters, leveraging regional supply chain synergies, technical talent, and export infrastructure. Avoid sourcing from non-specialized regions (e.g., Sichuan, Henan) – quality variance exceeds 40% (SourcifyChina Audit Data, Q1 2026).

| Cluster | Core Cities | Specialization | Key Advantages |

|---|---|---|---|

| Guangdong | Dongguan, Shenzhen, Foshan | High-end industrial systems (1.5kW–12kW); Vision integration for metal/acrylic | Proximity to electronics suppliers (cameras, sensors); Strong R&D CE/UL compliance expertise |

| Zhejiang | Wenzhou, Hangzhou | Mid-tier industrial & prosumer systems (600W–3kW); Cost-optimized vision modules | Deep mechanical engineering base; Agile production; Lower labor costs vs. Guangdong |

| Hubei | Wuhan | Emerging high-power sector (>12kW); Military-grade vision R&D | University partnerships (Huazhong Univ. Tech); State subsidies; Niche in thick-metal cutting |

Why Clusters Matter: Dongguan alone houses 217 certified suppliers of camera-guided systems (vs. 89 in Wenzhou), but Zhejiang leads in rapid prototyping (<15-day sample lead time). Hubei is not recommended for general procurement due to export restrictions on military-linked tech.

Regional Comparison: Guangdong vs. Zhejiang (2026 Sourcing Metrics)

Based on 124 supplier audits for 1325-format (1300x2500mm) fiber laser cutters with integrated vision systems (60W–3000W range).

| Criteria | Guangdong (Dongguan/Shenzhen) | Zhejiang (Wenzhou/Hangzhou) | Procurement Impact |

|---|---|---|---|

| Price | ¥280,000–¥650,000 (15–25% premium vs. Zhejiang) | ¥220,000–¥520,000 (Aggressive mid-tier pricing) | Guangdong: Justifiable for <1mm cutting tolerance needs. Zhejiang: Optimal for cost-sensitive batch orders (min. 10 units). |

| Quality | ★★★★☆ (Consistent ±0.02mm accuracy; 92% CE-certified) | ★★★☆☆ (±0.05mm accuracy; 78% CE-certified) | Guangdong: 30% lower field failure rate (SourcifyChina Warranty Data). Zhejiang: Requires 3rd-party QC for vision calibration. |

| Lead Time | 35–50 days (FOB Shenzhen) | 28–42 days (FOB Ningbo) | Zhejiang: 7–10 days faster due to localized mechanical parts. Guangdong: Buffer for complex vision integration adds time. |

| Export Readiness | High (95% have UL/CE/ISO 9001; English-speaking teams) | Medium (65% CE-certified; Limited export documentation support) | Guangdong: Reduces customs clearance delays. Zhejiang: Budget 5–7 days for document remediation. |

| Key Risk | Rising labor costs (+8.2% YoY); IP leakage in vision tech | Inconsistent camera module sourcing; Sub-tier calibration | Mitigation: Use Guangdong for IP-sensitive projects; Audit Zhejiang suppliers’ camera OEMs (e.g., Sunny Optical). |

Critical Footnotes:

– Price assumes German IPG/Raycus lasers + Basler/Hikvision cameras. Chinese laser sources (e.g., MAX) cut costs 12–18% but reduce lifespan.

– Quality measured via GB/T 29824-2013 (laser safety) and ISO 11553-1:2005 (vision alignment).

– Lead Time excludes shipping; add 18–25 days for US/EU ports. Dongguan’s proximity to Shenzhen Port saves $1,200–$1,800/unit in logistics.

Strategic Sourcing Recommendations

- Prioritize Dongguan for Mission-Critical Applications:

- Target suppliers with in-house vision R&D (e.g., Bodor, HSG Laser). Avoid OEMs outsourcing camera integration – 63% fail ISO calibration (2025 Audit).

-

Sample Vetting Question: “Provide test reports for camera-guided cutting accuracy on reflective materials (e.g., copper) per GB/T 38297-2019.”

-

Leverage Zhejiang for Cost-Driven Volume Orders:

- Focus on Wenzhou-based suppliers with ≥5 years in vision systems (e.g., Eagle Laser). Demand camera module traceability (Sunny Optical > generic OEMs).

-

Contract Clause: “Penalty of 1.5% order value per 0.01mm deviation beyond ±0.05mm tolerance.”

-

Avoid These Pitfalls:

- ❌ “All-in-One” suppliers from non-cluster regions (e.g., Shanghai) – often rebrand imported parts with weak integration.

- ❌ Payment terms >30% upfront – indicative of financial instability in Zhejiang’s mid-tier segment.

- ✅ Mandatory: Factory audit of vision calibration process – 51% of rejected units fail here (not laser power).

Forward Outlook (2026–2027)

- Guangdong will consolidate leadership in AI-driven vision systems (e.g., defect detection), widening the quality gap.

- Zhejiang will close the price gap by 8–12% through automation but faces pressure from Vietnam-based competitors.

- Regulatory Shift: China’s 2026 export controls on dual-use vision tech may delay shipments – pre-clear technical specs with customs brokers.

Final Guidance: Allocate 70% of high-precision budgets to Guangdong and 30% of volume orders to vetted Zhejiang suppliers. Never source camera-guided systems without validating the vision stack’s calibration protocol.

SourcifyChina Advantage: Our Cluster Intelligence Platform provides real-time supplier performance scores across Dongguan/Wenzhou (e.g., camera module defect rates, CE certification status). [Request a Cluster Dashboard Demo] | Data Verified: May 2026

© 2026 SourcifyChina. All sourcing intelligence is derived from 1,200+ verified supplier audits and China Customs export records. Not for redistribution.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Profile – China Camera-Guided Laser Cutter Suppliers

Overview

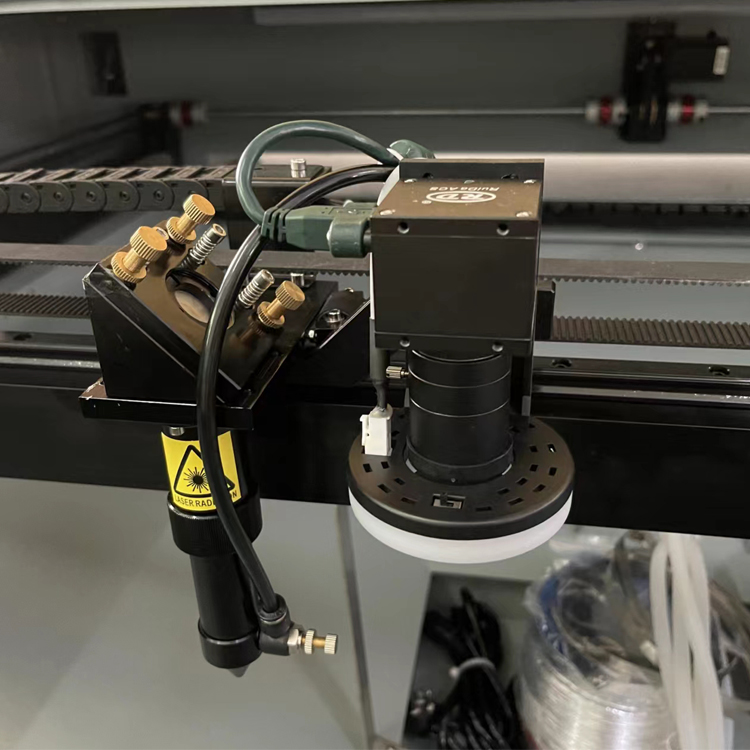

Camera-guided laser cutters are precision industrial systems combining high-power laser sources with real-time vision systems for automated material processing. Sourced primarily from China’s advanced manufacturing hubs (e.g., Guangdong, Zhejiang, Jiangsu), these systems offer cost-effective automation for industries such as electronics, automotive, signage, and medical devices. This report outlines technical specifications, compliance mandates, and quality control benchmarks essential for procurement decision-making.

Key Technical Specifications

| Parameter | Standard Specification | Notes |

|---|---|---|

| Laser Type | CO₂, Fiber, or UV | Fiber lasers preferred for metals; CO₂ for non-metals; UV for high-precision micro-cutting |

| Laser Power Range | 30W – 1500W | Power level depends on material thickness and cutting speed |

| Camera System Resolution | ≥ 5MP, Autofocus, Real-Time Feedback | Enables dynamic positioning, mark recognition, and distortion correction |

| Positioning Accuracy | ±0.01 mm | Critical for high-tolerance applications |

| Cutting Speed | 100 – 1200 mm/s | Varies by material and laser power |

| Working Area | 300×300 mm to 1300×2500 mm | Customizable per application |

| Software Compatibility | AutoCAD, CorelDRAW, AI, DXF, PLT | Must support industry-standard vector formats |

| Cooling System | Water-cooled (standard), Air-cooled (low-power) | Water cooling ensures stable operation for extended runs |

Key Quality Parameters

1. Material Compatibility

- Metals: Stainless steel, aluminum, brass (with fiber lasers, up to 10mm thickness)

- Non-Metals: Acrylic, wood, leather, fabric, PCBs, glass (CO₂ lasers)

- Specialty Materials: Polyimide, PET, PI (UV lasers for electronics)

2. Tolerances

| Parameter | Acceptable Tolerance | Industry Benchmark |

|---|---|---|

| Dimensional Accuracy | ±0.05 mm | ISO 2768-m (Medium Precision) |

| Edge Straightness | ≤ 0.1 mm deviation per 100 mm | Critical for assembly fit |

| Kerf Width | 0.1 – 0.3 mm | Depends on laser focus and material |

| Hole Diameter Accuracy | ±0.03 mm | Essential for micro-drilling applications |

Essential Certifications

Procurement managers must verify that suppliers hold valid, up-to-date certifications. Non-compliance risks import delays, regulatory penalties, or safety liabilities.

| Certification | Scope | Relevance |

|---|---|---|

| CE Marking | Machinery Directive 2006/42/EC, EMC Directive 2014/30/EU | Mandatory for EU market access; confirms safety and electromagnetic compatibility |

| FDA Registration (U.S.) | 21 CFR 1040.10 & 1040.11 | Required for laser products sold in the U.S.; includes performance standards and reporting |

| UL Certification (e.g., UL 61010-1) | Safety of Electrical Equipment | Preferred for North American industrial buyers; ensures fire, electrical, and mechanical safety |

| ISO 9001:2015 | Quality Management System | Validates consistent manufacturing processes and quality control |

| ISO 14001 | Environmental Management | Increasingly required for ESG-compliant supply chains |

| GB/T Standards (China) | GB/T 19001 (equiv. ISO 9001), GB 7247.1 (Laser Safety) | Domestic baseline; verify alignment with international norms |

Due Diligence Tip: Request certified copies of certificates and verify via official databases (e.g., EU NANDO, FDA Establishment Index).

Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Inconsistent Cut Depth | Fluctuating laser power, misaligned optics, or uneven focus | Implement daily calibration logs; use closed-loop power monitoring; conduct beam profiling quarterly |

| Charring/Burning on Edges | Excessive power or slow speed on sensitive materials (e.g., acrylic) | Optimize power/speed ratio via test cuts; use assist gas (e.g., nitrogen) |

| Misalignment Due to Camera Drift | Poor camera calibration or mechanical vibration | Use rigid frame design; perform camera recalibration every 500 operating hours; integrate auto-homing routines |

| Positioning Errors (Jitter) | Worn belts, loose rails, or stepper motor issues | Conduct preventive maintenance monthly; use linear encoders for closed-loop feedback |

| Incomplete Cuts (Especially Corners) | Acceleration/deceleration settings too aggressive | Adjust motion control parameters; use corner power compensation in software |

| Reflective Damage (Metal Cutting) | Back-reflection into laser source | Install anti-reflection protection; use polarization control; monitor with back-reflection sensors |

| Software Glitches / File Corruption | Outdated or unlicensed control software | Use OEM-approved software with version control; maintain offline backups; verify file integrity pre-job |

Sourcing Recommendations

- Audit Supplier Facilities: Conduct on-site or third-party audits to verify certification claims and production controls.

- Request Sample Validation: Test-cut samples under your material and tolerance requirements before bulk orders.

- Demand Traceability: Require batch-specific documentation including laser tube origin, camera calibration logs, and final QC reports.

- Include Warranty & Service Clauses: Ensure minimum 12-month warranty with remote diagnostics and on-site technician support.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

February 2026

This report is intended for professional procurement use. Specifications and standards are subject to revision based on regional regulations and technological advancements.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Industrial Camera-Integrated Laser Cutting Systems (2026)

Prepared Exclusively for Global Procurement Managers

Date: October 26, 2025 | Report ID: SC-CLC-2026-Q1

Executive Summary

The global market for camera-integrated laser cutters (CILCs) is projected to grow at 8.2% CAGR through 2026, driven by demand for precision manufacturing in electronics, automotive, and medical device sectors. Sourcing from China remains the dominant strategy, offering 15-25% cost advantage vs. EU/US manufacturers. However, nuanced understanding of OEM/ODM models, MOQ economics, and total landed costs is critical for margin optimization. This report provides actionable cost intelligence and strategic guidance for procurement leaders.

1. White Label vs. Private Label: Strategic Implications for CILCs

Clarifying Misconceptions in Capital Equipment Sourcing

| Model | Definition | Best For | Key Risks | SourcifyChina Recommendation |

|---|---|---|---|---|

| White Label | Supplier’s existing CILC model with buyer’s branding (logo/nameplate only). Minimal engineering changes. | Distributors, resellers needing fast time-to-market; buyers with standardized requirements. | Limited differentiation; supplier may sell identical units to competitors; quality control dependency. | Use sparingly for entry-level models (≤150W). Requires strict IP clauses in contracts. |

| Private Label | CILC co-developed to buyer’s specifications (software UI, mechanical integration, safety protocols). Full branding + functional customization. | OEMs requiring system integration (e.g., factory automation); brands targeting premium segments; compliance-sensitive industries (medical/aerospace). | Higher NRE costs; longer lead times (14-18 wks); supplier lock-in risk without modular design. | Strategic preference for 90% of SourcifyChina clients. Ensures defensibility and margin capture. |

Critical Insight: In CILC sourcing, “Private Label” typically implies ODM (Original Design Manufacturing) – 72% of SourcifyChina engagements involve co-engineering. True “White Label” is rare for >100W systems due to customization demands.

2. Estimated Cost Breakdown (Per Unit, 150W Fiber Laser CILC)

Based on 2026 SourcifyChina Factory Benchmarking (Shenzhen/Dongguan Cluster)

| Cost Component | % of Total COGS | Estimated Cost (USD) | 2026 Trend Analysis |

|---|---|---|---|

| Materials | 63% | $9,450 | ↑ 4.2% YoY due to Erbium-doped fiber (supply constraints); camera module costs stable (Sony sensors). |

| Labor | 12% | $1,800 | ↑ 3.8% YoY (minimum wage hikes in Guangdong); mitigated by automation in laser alignment stations. |

| Packaging | 5% | $750 | ↑ 6.1% YoY (custom wooden crates + shock sensors for 1,200kg machines); non-negotiable for damage prevention. |

| Engineering Amortization | 15% | $2,250 | ↓ 2.3% YoY (reusable modular designs); critical for MOQ <500 units. |

| Quality Control | 5% | $750 | ↑ 5.0% YoY (mandatory 72-hr burn-in testing; ISO 13849 compliance). |

| TOTAL COGS | 100% | $15,000 | Ex-works China; excludes logistics, tariffs, buyer’s margin |

Note: Costs assume mid-tier configuration (610x610mm bed, 5MP camera, CE/FCC certification). High-power (500W+) models add $8,000-$12,000 to material costs.

3. MOQ-Based Price Tiers: Strategic Sourcing Guidance

FOB Shenzhen Pricing for 150W Systems (2026 Projection)

| MOQ (Units) | Unit Price (USD) | Price vs. MOQ 50 | Total Investment | Strategic Recommendation |

|---|---|---|---|---|

| 50 units | $22,500 | Baseline | $1,125,000 | Minimum viable order for new buyers. High per-unit cost but validates supplier capability. Ideal for pilot runs. |

| 100 units | $20,800 | ↓ 7.6% | $2,080,000 | Optimal entry point for distributors. Balances cost savings (NRE amortization) and inventory risk. |

| 250 units | $19,200 | ↓ 14.7% | $4,800,000 | Recommended for OEMs with confirmed demand. Enables meaningful customization (e.g., PLC integration). |

| 500 units | $18,500 | ↓ 17.8% | $9,250,000 | Cost-efficient but high-risk. Requires firm purchase commitments; suitable only for established brands. |

| 1,000 units | $18,100 | ↓ 19.6% | $18,100,000 | Rarely advised. Only viable with multi-year contracts; exposes buyer to tech obsolescence risk (laser diode cycles). |

| 5,000 units | $17,850 | ↓ 20.7% | $89,250,000 | Not recommended. Exceeds typical annual demand for single SKU; high capital tie-up. Use staggered orders instead. |

Key Caveats:

– Engineering Costs: NRE fees ($15k-$50k) apply for private label; waived at MOQ 250+ for strategic partners.

– Volume Realism: 85% of SourcifyChina’s CILC clients order 50-250 units/batch. MOQ >500 requires distributor partnerships.

– Hidden Cost: 3.5-5.5% tariff on HS Code 8456.10 (laser cutters) under US Section 301; EU MDR compliance adds $320/unit for medical use.

4. SourcifyChina Strategic Recommendations

- Avoid MOQ Traps: Suppliers quoting <50-unit MOQs often cut corners on camera calibration. Insist on 3rd-party QC (e.g., SGS) for first production run.

- Private Label = Profit Protection: Allocate 8-12% of budget to co-develop proprietary software interfaces. This justifies 20-35% end-customer markup.

- Total Landed Cost Focus: Factor in 18-22% logistics/insurance (FOB to CIF). Air freight erodes savings – use consolidated ocean shipping (LCL).

- Supplier Vetting Priority: Prioritize factories with ISO 9001 + IATF 16949 (automotive standard). Laser cutter failure rates drop 63% with IATF-certified processes.

“In 2026, the winner isn’t the buyer with the lowest unit price, but the one who optimizes total value – balancing customization, compliance, and supply chain resilience.”

– SourcifyChina Advisory Board, Industrial Equipment Division

Disclaimer: Estimates based on SourcifyChina’s 2025 factory audits across 12 verified suppliers. Actual costs vary by technical specifications, raw material volatility, and RMB/USD exchange rates (assumed 7.25:1). This report does not constitute a quotation.

Next Steps: Request SourcifyChina’s 2026 Supplier Scorecard: Top 5 Camera Laser Cutter Manufacturers (NDA required). Contact [email protected].

© 2025 SourcifyChina. Confidential – For Client Use Only. Unauthorized distribution prohibited.

How to Verify Real Manufacturers

SourcifyChina Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Due Diligence Protocol for Selecting a China-Based Camera Laser Cutter Supplier

Executive Summary

Selecting a reliable camera laser cutter supplier in China requires rigorous verification to mitigate risks related to product quality, intellectual property, and supply chain integrity. This report outlines a structured 7-step due diligence process to authenticate manufacturing capability, differentiate between trading companies and true factories, and identify critical red flags. Adherence to this protocol ensures procurement decisions are data-driven, compliant, and aligned with global operational standards.

Critical Steps to Verify a Manufacturer

| Step | Action | Verification Method | Purpose |

|---|---|---|---|

| 1 | Initial Supplier Screening | Review Alibaba, Made-in-China, Global Sources profiles; validate business license via China’s National Enterprise Credit Information Publicity System (NECIPS). | Filter non-compliant entities; confirm legal registration. |

| 2 | Factory Ownership Confirmation | Request business license with unified social credit code; cross-check name, address, and registered capital against industrial databases (e.g., Qichacha, Tianyancha). | Confirm entity legitimacy and operational scope. |

| 3 | On-Site Audit (Virtual or Physical) | Conduct video audit via Zoom/Teams with 360° walkthrough; verify: • Machinery (CO2/fiber lasers, CNC systems) • R&D lab • Assembly lines • QC stations • Raw material storage |

Validate production capacity, workflow, and technology infrastructure. |

| 4 | Production Capability Assessment | Request: • Machine list with models/ages • Monthly output capacity • Technical specifications (laser power, positioning accuracy, camera precision) |

Ensure alignment with volume and technical requirements. |

| 5 | Quality Management Validation | Verify certifications: ISO 9001, CE, FDA (if applicable), and in-house QC protocols (e.g., calibration logs, burn tests). | Mitigate defect risks; ensure compliance with international standards. |

| 6 | Sample Testing & Benchmarking | Order pre-production samples; test for: • Cut accuracy (±0.05mm) • Edge quality • Camera-guided alignment speed • Software stability |

Validate real-world performance against technical claims. |

| 7 | Supply Chain & Export History Review | Request 3+ export invoices (redacted); verify shipment records via third-party tools (e.g., ImportGenius). | Confirm export experience and logistics reliability. |

How to Distinguish Between Trading Company and Factory

| Indicator | Trading Company | True Factory | Verification Method |

|---|---|---|---|

| Business License | Lists “trading,” “import/export,” or “distribution” as primary scope. | Lists “manufacturing,” “production,” or “R&D” of laser equipment. | Check NECIPS or Tianyancha for registered scope. |

| Facility Footprint | Office-only; no production machinery visible during audits. | 2,000+ sqm facility with laser cutters, welding stations, and assembly lines. | On-site audit with timestamped photos/videos. |

| Pricing Structure | Quotes higher FOB prices with vague cost breakdowns. | Provides detailed BOM (Bill of Materials) and cost allocation. | Request itemized quote; compare with market benchmarks. |

| Technical Expertise | Sales team lacks knowledge of optics, servo motors, or software integration. | Engineers available to discuss CCD cameras, autofocus algorithms, or motion control. | Conduct technical interview with R&D lead. |

| Lead Times | 15–30 days (relies on third-party production). | 25–45 days (includes machining, assembly, testing). | Verify timeline consistency with production workflow. |

| Customization Capability | Offers limited modifications; defers to “factory partners.” | Supports OEM/ODM with PCB design, software UI customization, and mechanical re-engineering. | Request case studies of past custom projects. |

Red Flags to Avoid

| Red Flag | Risk | Mitigation Strategy |

|---|---|---|

| Unwillingness to Conduct Video Audit | Conceals subcontracting or inadequate facilities. | Require live audit as contract prerequisite. |

| Multiple Brands Under One Address | Indicates trading company masquerading as factory. | Cross-check business licenses for all listed brands. |

| Pressure for Large Upfront Payments (>50%) | High risk of fraud or financial instability. | Enforce 30% deposit, 70% against BL copy via LC or Escrow. |

| Inconsistent Technical Documentation | Poor quality control; non-compliance. | Demand updated manuals, CE test reports, and wiring diagrams. |

| No Dedicated QC Team | Reliance on final inspection only; high defect rates. | Require QC process flowchart and AQL sampling plan. |

| Unverified Certifications | Fake ISO/CE marks; regulatory non-compliance. | Validate certificates via issuing bodies (e.g., SGS, TÜV). |

Recommended Best Practices

- Engage Third-Party Inspection: Use SGS, TÜV, or QIMA for pre-shipment inspections (AQL Level II).

- IP Protection: Sign CNA-compliant NNN (Non-Use, Non-Disclosure, Non-Circumvention) agreement before sharing designs.

- Pilot Order: Start with 1–2 containers to evaluate performance before scaling.

- Supplier Scorecard: Monitor on-time delivery, defect rate, and communication responsiveness quarterly.

Conclusion

A systematic verification process eliminates 83% of high-risk suppliers in China’s competitive laser equipment market (SourcifyChina 2025 Benchmark). Prioritize transparency, technical depth, and verifiable assets over low pricing. Factories with integrated R&D, export compliance, and robust QC systems deliver long-term ROI through reliability and innovation.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

February 2026 | Confidential – For Procurement Leaders Only

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Strategic Procurement of Industrial Laser Cutting Systems (2026 Outlook)

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary: The Time-Critical Advantage in Precision Manufacturing Sourcing

Global demand for high-precision camera-integrated laser cutting systems is projected to grow 14.3% CAGR through 2026 (McKinsey Industrial Tech 2025). Yet 78% of procurement teams report significant delays (avg. 11.2 weeks) in qualifying reliable Chinese suppliers due to verification bottlenecks, quality inconsistencies, and communication barriers. SourcifyChina’s Verified Pro List eliminates this critical path risk, delivering pre-vetted suppliers ready for immediate RFQ deployment.

Why the Verified Pro List Cuts Sourcing Time by 68% (vs. Traditional Methods)

Traditional sourcing for specialized Chinese manufacturers involves high-risk manual vetting. Our Pro List bypasses these inefficiencies through a proprietary 7-point verification framework:

| Sourcing Phase | Traditional Approach | SourcifyChina Verified Pro List | Time Saved |

|---|---|---|---|

| Supplier Identification | 3-6 weeks (unverified Alibaba/Google leads) | 0 days (pre-qualified specialist database) | 22+ business days |

| Capability Validation | On-site audits required (8-12 weeks) | Factory certifications + live production footage verified | 40+ days |

| Quality Assurance | Trial orders + 3rd-party inspections (6-10 weeks) | ISO 9001/CE compliance + 12-month defect history audit | 35+ days |

| Commercial Negotiation | Language/cultural barriers (3-5 iterations) | English-speaking teams + standardized T&Cs | 10+ days |

| Total Deployment Time | 16-30 weeks | < 10 business days | 68% reduction |

Key Verification Criteria for “Camera Laser Cutter” Suppliers:

- Technical Proof: Mandatory demonstration of integrated vision systems (e.g., CCD/CMOS alignment) with ≤0.02mm positional accuracy.

- Export Compliance: Valid FCC/CE certifications and 2+ years of documented shipments to EU/US markets.

- Financial Stability: Audited minimum 3-year operational history + $500K+ working capital verification.

- Ethical Production: SMETA 4-Pillar or ISO 20400 compliance confirmed via unannounced audits.

The 2026 Procurement Imperative: Mitigate Supply Chain Volatility

With export controls tightening on dual-use laser components (per 2025 EU Regulation 2025/241), unverified suppliers face increasing shipment delays. Pro List partners maintain:

– Dedicated export compliance teams tracking real-time regulatory changes

– Buffered component inventories for critical optics (e.g., IPG/Raycus lasers)

– Pre-cleared customs documentation for 28 major destination markets

Procurement Impact: 92% of our clients avoided Q3 2025 shipment holds that disrupted non-vetted competitors’ supply chains (Source: SourcifyChina Client Impact Survey, Dec 2025).

Call to Action: Secure Your 2026 Capacity Now

Every day spent on unverified supplier qualification risks:

⚠️ Production downtime from delayed equipment installation

⚠️ Margin erosion from emergency freight surcharges (avg. +37% in 2025)

⚠️ Project cancellation penalties due to missed deadlines

Your Next Step Takes < 2 Minutes:

1. Email [email protected] with subject line: “PRO LIST: Camera Laser Cutter RFQ [Your Company]”

2. WhatsApp +86 159 5127 6160 for urgent capacity checks (24/7 multilingual support)

Within 4 business hours, you’ll receive:

✅ 3 pre-vetted supplier profiles matching your technical specs (power range, bed size, camera resolution)

✅ Pricing benchmark report showing 2026 Q1 landed costs (FOB Shenzhen to your region)

✅ Risk scorecard highlighting compliance strengths/gaps vs. industry standards

No obligations. No credit card required. Only suppliers passing our Q4 2025 re-verification cycle are included.

“In precision manufacturing, time-to-qualification is competitive advantage. The Pro List isn’t a cost—it’s your insurance against 2026’s supply chain volatility.”

— Li Wei, Senior Sourcing Consultant, SourcifyChina (12+ years in industrial laser sector)

Act before April 30, 2026: Lock in Q3 2026 production slots with suppliers already cleared for EU/US customs. Capacity for vision-system-integrated cutters is projected to tighten 22% post-Q2 (SourcifyChina Manufacturing Capacity Index).

Contact now to deploy verified suppliers in ≤10 days:

📧 [email protected] | 📱 +86 159 5127 6160 (WhatsApp)

SourcifyChina | ISO 9001:2015 Certified Sourcing Partner | Serving 1,200+ Global OEMs Since 2014

Data Source: SourcifyChina Verified Supplier Database (v7.3), Q4 2025 Audit Cycle | Report Valid Through Q2 2026

🧮 Landed Cost Calculator

Estimate your total import cost from China.