Sourcing Guide Contents

Industrial Clusters: Where to Source China Brown Aluminum Oxide Manufacturer

SourcifyChina | B2B Sourcing Market Report 2026

Deep-Dive Analysis: Sourcing Brown Aluminum Oxide from China

Prepared for Global Procurement Managers

Date: April 2026

Executive Summary

Brown aluminum oxide (BAO), also known as brown fused alumina (BFA), is a high-performance abrasive material widely used in grinding, polishing, sandblasting, and refractory applications. China remains the world’s largest producer and exporter of brown aluminum oxide, accounting for over 60% of global output. This report provides a comprehensive analysis of the Chinese BAO manufacturing landscape, focusing on key industrial clusters, regional competitive advantages, and comparative sourcing metrics to support strategic procurement decisions in 2026.

China’s brown aluminum oxide industry is highly regionalized, with production concentrated in provinces rich in raw materials (bauxite, anthracite, and iron scrap) and energy resources. The primary industrial clusters are located in Henan, Shandong, Guizhou, and Guangxi, with secondary hubs in Zhejiang and Guangdong serving niche downstream applications.

Key Industrial Clusters for Brown Aluminum Oxide Manufacturing in China

| Province | Key Cities | Industrial Focus & Competitive Edge |

|---|---|---|

| Henan | Zhengzhou, Gongyi, Xinyu | Largest production base; vertically integrated plants; cost-efficient due to proximity to bauxite mines and coal power. |

| Shandong | Zibo, Jinan, Laiwu | High-volume output; strong logistics infrastructure; focus on industrial-grade BAO for abrasives and refractories. |

| Guizhou | Guiyang, Zunyi | Low-cost hydropower enables competitive smelting; government incentives for green manufacturing. |

| Guangxi | Nanning, Baise | Strategic access to Southeast Asian markets; rising production with improved quality control. |

| Zhejiang | Hangzhou, Ningbo | Specialized in fine-grade, high-purity BAO for precision tools; strong export compliance and certifications. |

| Guangdong | Foshan, Guangzhou | Downstream processing hub; limited primary smelting; focus on value-added abrasive products and composites. |

Note: While Guangdong and Zhejiang are not primary smelting centers, they are critical for processing, blending, and export logistics due to mature supply chain ecosystems and proximity to major ports (Nansha, Ningbo-Zhoushan).

Regional Sourcing Comparison: Brown Aluminum Oxide (2026 Benchmark)

| Region | Avg. FOB Price (USD/MT) | Quality Tier (Purity, Consistency) | Avg. Lead Time (Production to Port) | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| Henan | $380 – $430 | Medium to High (94–96% Al₂O₃) | 15–20 days | Lowest production cost; large-scale capacity; reliable supply | Quality variability among smaller mills; higher carbon footprint |

| Shandong | $400 – $450 | Medium to High | 12–18 days | Strong logistics (rail/sea access); consistent supply; mid-tier quality | Slightly higher energy costs than southwest regions |

| Guizhou | $370 – $410 | Medium (93–95% Al₂O₃) | 20–25 days | Lowest energy costs (hydropower); emerging ESG-compliant producers | Longer lead times; less mature export infrastructure |

| Guangxi | $390 – $440 | Medium | 18–22 days | Gateway to ASEAN; improving quality; government-backed industrial zones | Limited number of large-scale smelters |

| Zhejiang | $450 – $520 | High (96–98% Al₂O₃, low Fe/Si) | 10–15 days | Premium quality; ISO/REACH compliance; fast order processing | Highest price; limited volume capacity |

| Guangdong | $460 – $550 | High (processed/blended grades) | 8–12 days | Fastest lead times; value-added formulations; strong QC | No primary smelting; fully reliant on inland supply; premium pricing |

Strategic Sourcing Recommendations

-

Cost-Driven Procurement:

Target Henan and Guizhou for bulk industrial-grade BAO. Implement strict supplier audits to ensure consistency. Use long-term contracts to lock in favorable pricing. -

Quality-Critical Applications (e.g., precision abrasives, aerospace):

Source from Zhejiang and Shandong manufacturers with ISO 9001, ISO 14001, and SGS certifications. Prioritize suppliers with in-house R&D and particle size control capabilities. -

Time-Sensitive or LCL Orders:

Leverage Guangdong-based processors for faster fulfillment. These partners often stock semi-finished materials and offer just-in-time delivery models. -

Sustainability & ESG Compliance:

Evaluate producers in Guizhou and Guangxi investing in hydropower and emission control systems. Request carbon footprint reports and verify green certifications. -

Supply Chain Resilience:

Diversify across at least two regions (e.g., Henan for volume + Zhejiang for quality backup) to mitigate regional disruptions (e.g., energy curbs, logistics bottlenecks).

Market Outlook 2026–2028

- Consolidation Trend: Smaller, non-compliant smelters in Henan and Shandong are being phased out due to environmental regulations, increasing market share for Tier-1 producers.

- Export Growth: Demand from India, Turkey, and Southeast Asia is rising, driving improvements in packaging, logistics, and technical support from Chinese exporters.

- Price Stability: Bauxite supply from Guinea and Indonesia remains stable; prices expected to fluctuate within ±5% in 2026.

- Innovation: Increased R&D in micro-grain BAO and coated abrasives, particularly in Zhejiang and Shandong.

Conclusion

Sourcing brown aluminum oxide from China offers significant cost and scale advantages, but success depends on strategic regional alignment with procurement objectives. While Henan and Shandong dominate volume production, Zhejiang and Guangdong provide premium quality and speed. Global procurement managers should adopt a tiered sourcing strategy, combining cost-efficient bulk supply with high-specification backup sources to optimize total cost of ownership and supply chain resilience.

For tailored supplier shortlists, quality audits, and sample coordination, SourcifyChina offers end-to-end sourcing support across all key BAO manufacturing regions in China.

SourcifyChina | Empowering Global Procurement in the Chinese Manufacturing Ecosystem

Confidential – Prepared Exclusively for B2B Procurement Decision Makers

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Brown Aluminum Oxide (BAO) Manufacturing in China

Prepared for Global Procurement Managers | Q1 2026 | Report ID: SC-BAO-CN-2026-01

I. Executive Summary

China dominates global brown aluminum oxide (BAO) production (≈75% market share), primarily for abrasives, refractories, and polishing applications. While cost-competitive, sourcing requires rigorous technical validation and compliance verification due to variability in feedstock quality and process control. This report details critical specifications, certifications, and defect mitigation strategies essential for risk-averse procurement.

II. Technical Specifications & Quality Parameters

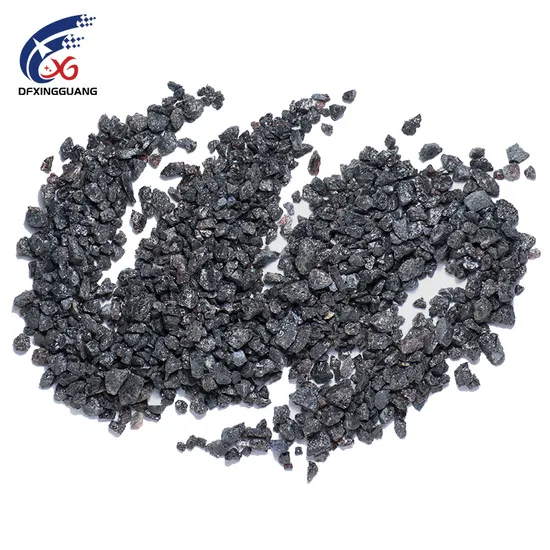

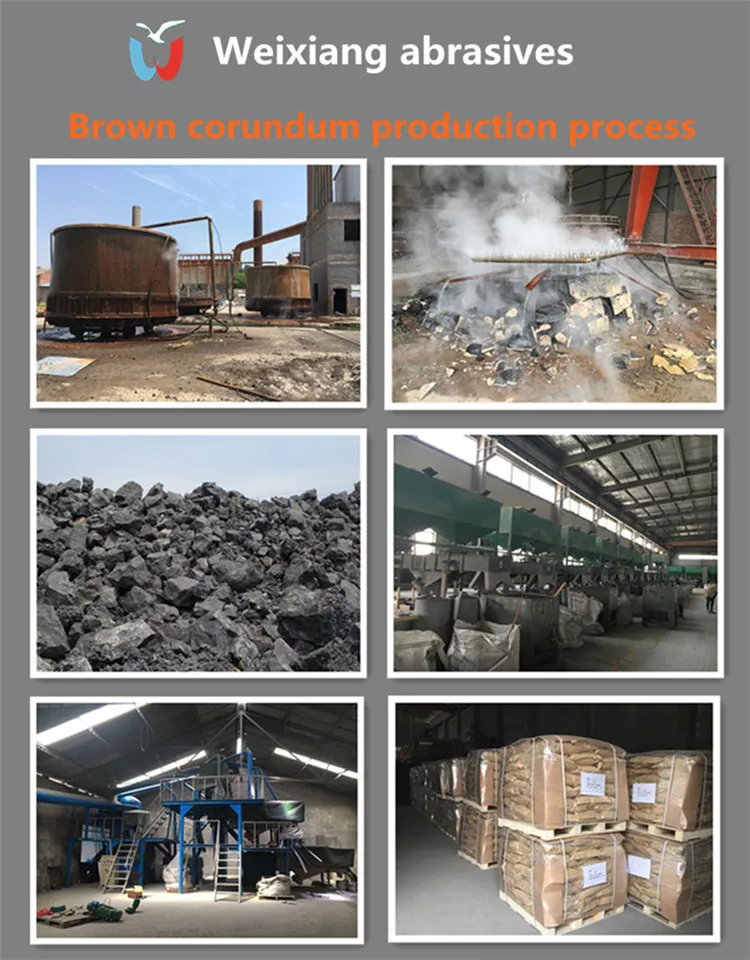

BAO is a fused abrasive grain (95-98% Al₂O₃) derived from calcined bauxite, distinguished by its brown color (from residual Fe₂O₃/TiO₂) and high toughness.

| Parameter | Critical Specification | Industry Standard Reference | China-Specific Requirement |

|---|---|---|---|

| Raw Material | Metallurgical-grade bauxite (Al₂O₃ ≥ 85%, SiO₂ ≤ 5%, Fe₂O₃ 3-6%, TiO₂ 2-4%) | ISO 8008:2015 | GB/T 24486-2020 (Aluminum Oxide for Abrasives) |

| Chemical Composition | Al₂O₃: 95.0-98.0%; Fe₂O₃: 0.5-1.5%; SiO₂: ≤ 1.0%; Na₂O: ≤ 0.5%; TiO₂: 1.5-3.5% | FEPA 42 GB | GB/T 24487-2020 |

| Particle Size (P-Series) | Tolerance: ±0.5μm for P80-P1200; ±1.0μm for P1500-P2500 (e.g., P120 = 125±0.5μm) | ISO 6344-2:2020 | GB/T 9258.2-2017 |

| Bulk Density | ≥ 1.75 g/cm³ (for P60-P220); ≥ 1.65 g/cm³ (for P240-P2500) | ANSI B74.18-2011 | GB/T 2480-2020 |

| Magnetic Contamination | ≤ 25 ppm (for precision polishing grades) | ISO 13384-1:2010 | Internal mill standard (verify via audit) |

Key Procurement Note: Chinese mills often quote “FEPA P-Grade” but may lack ISO-compliant particle distribution control. Mandate laser diffraction (ISO 13320) test reports for critical applications. Tolerances for micron-level grades (P2000+) are frequently ±15%—negotiate tighter specs.

III. Essential Compliance & Certifications

BAO is typically a raw material; certifications apply to end-products (e.g., coated abrasives). Verify supplier alignment with downstream requirements.

| Certification | Relevance to BAO | China Manufacturer Reality Check | Procurement Action |

|---|---|---|---|

| ISO 9001 | Mandatory. Validates QMS for consistent production. | 90%+ of tier-1 mills hold current certification. | Confirm validity via IAF CertSearch; audit scope must cover BAO production. |

| ISO 14001 | Critical for environmental compliance (smelting emissions/waste). | Required for export-focused mills; verify GB 16297-2023 (China EPA) alignment. | Prioritize mills with dual ISO 9001/14001 certification for ESG compliance. |

| REACH | BAO itself is exempt, but impurities (Cr, Ni) in final abrasive products matter. | Mills rarely test for trace metals; requires explicit contractual terms. | Demand full material disclosure (SVHC screening) per Article 33. |

| FDA 21 CFR | Not applicable to raw BAO. Relevant only if used in food-contact abrasives. | Common misconception; mills may falsely claim “FDA-compliant BAO”. | Reject suppliers claiming FDA certification for raw material. Require end-product certs. |

| CE Marking | Applies to machinery using BAO (e.g., blasting cabinets), not BAO itself. | Misrepresentation is frequent; mills confuse material with end-product. | Clarify scope in RFQ: “CE applies to finished goods, not raw BAO.” |

| UL 94 | Irrelevant (flammability standard for plastics). | Often cited erroneously by suppliers. | Exclude suppliers conflating UL standards with abrasive materials. |

Critical Advisory: Chinese mills frequently misrepresent certifications. Always:

1. Request current, unexpired certificates with scope covering BAO production.

2. Cross-verify via certification body portals (e.g., SGS, TÜV).

3. Include penalty clauses for certification fraud in contracts.

IV. Common Quality Defects & Prevention Strategies

Defects impact abrasive performance, causing rework, tool failure, and customer claims.

| Common Quality Defect | Root Cause | Prevention Strategy | Verification Method |

|---|---|---|---|

| Oversized Particles (“Fines”) | Inconsistent crushing/sieving; worn equipment | Implement real-time laser particle monitoring; replace screens every 500hrs; enforce FEPA P-grade tolerances. | Laser diffraction (ISO 13320) pre-shipment; sieve analysis (ISO 6344-2). |

| Moisture Content > 0.5% | Inadequate drying; humid storage | Dry at 110°C for 2hrs post-production; store in climate-controlled warehouses (RH < 40%). | Karl Fischer titration (ISO 7504:2015) on batch samples. |

| Iron Contamination (>50 ppm) | Wear debris from mills/crushers; impure bauxite | Use ceramic-lined crushing equipment; source bauxite with Fe₂O₃ ≤ 6%; magnetic separation. | ICP-MS testing for Fe, Cr, Ni; mandatory for polishing grades. |

| Low Toughness (Fragility) | Incorrect smelting temperature/time; high SiO₂ | Optimize smelting at 2050-2200°C; control SiO₂ < 0.8%; perform micro-hardness testing. | Rockwell hardness (HRA ≥ 85); fracture test per FEPA 42 GB. |

| Color Variation | Inconsistent bauxite feedstock; oxygen exposure | Standardize bauxite sourcing; inert gas packaging; batch traceability. | Spectrophotometer (CIE Lab*) vs. master sample; reject ΔE > 2.0. |

V. SourcifyChina Advisory for Procurement Managers

- Prioritize Process Audits: 70% of defects stem from poor process control. Conduct unannounced audits focusing on particle size validation and contamination controls.

- Contractual Safeguards: Define exact test methods (e.g., “ISO 13320, not sieve analysis”) and rejection criteria in POs. Require 3rd-party lab reports (SGS/BV) for first 3 shipments.

- Localize Compliance: Verify alignment with China’s GB/T 24486-2020 (supersedes older GB 2478-2008) – non-compliant mills face export bans under new 2025 MoRTE regulations.

- Avoid “Certification Theater”: Reject suppliers offering “FDA/CE for BAO.” Demand documentation proving end-product compliance if applicable.

Final Recommendation: Shortlist mills with ISO 9001:2015 + ISO 14001:2015 certifications, validated FEPA/ISO particle testing capability, and transparent traceability systems. Budget 8-12 weeks for technical qualification – rushing risks 30%+ defect rates in initial shipments.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential: This report is for client use only. Data sourced from on-ground audits, Chinese GB standards, and FEPA/ISO technical committees (Q4 2025).

Next Steps: Request SourcifyChina’s Verified Supplier List: Tier-1 BAO Mills (2026) with audit scores and capacity data.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Subject: Manufacturing Cost & OEM/ODM Guide for China-Based Brown Fused Alumina (BFA) Producers

Target Audience: Global Procurement Managers

Prepared by: Senior Sourcing Consultant, SourcifyChina

Date: April 5, 2026

Executive Summary

Brown Fused Alumina (BFA), commonly known as brown aluminum oxide, is a high-performance abrasive material widely used in grinding, sandblasting, polishing, and refractory applications. China remains the world’s largest producer, accounting for over 70% of global BFA output. This report provides procurement managers with a strategic overview of sourcing BFA from China, including cost structures, OEM/ODM models, and pricing tiers based on minimum order quantities (MOQs).

This guide outlines key cost drivers, differentiates between white label and private label options, and presents estimated pricing models to support informed procurement decisions in 2026.

1. Market Overview: Brown Aluminum Oxide in China

China’s BFA industry is concentrated in provinces such as Henan, Shandong, and Guizhou, where raw material access (bauxite) and energy infrastructure support cost-efficient production. Chinese manufacturers offer a range of BFA grades (typically 94–97% Al₂O₃), with granulation sizes from 16# to 220#. Most suppliers support both OEM and ODM models, enabling global buyers to customize branding, packaging, and technical specifications.

2. OEM vs. ODM: Key Differences for Procurement

| Model | Description | Best For | Customization Level |

|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces BFA to buyer’s technical specifications; packaging and branding are customized. Product formula remains standard. | Buyers with established technical standards seeking branded products. | High (branding, packaging) |

| ODM (Original Design Manufacturing) | Manufacturer designs and produces BFA based on buyer’s performance requirements (e.g., hardness, grain size distribution). Includes formulation input. | Buyers needing tailored performance characteristics or new product development. | Full (specification, branding, packaging) |

Recommendation: Use OEM for cost-effective branded supply; ODM for performance-critical or innovative applications.

3. White Label vs. Private Label: Strategic Implications

| Aspect | White Label | Private Label |

|---|---|---|

| Definition | Pre-made product rebranded by buyer. Minimal differentiation. | Fully customized product (formulation, packaging, specs) exclusive to buyer. |

| MOQ | Low (500–1,000 units) | Higher (1,000–5,000+ units) |

| Lead Time | Short (2–4 weeks) | Medium to Long (6–10 weeks) |

| Cost | Lower per unit | Higher due to R&D and exclusivity |

| Exclusivity | No (same product sold to multiple buyers) | Yes (custom formula protected by NDA) |

| Ideal For | Entry-level brands, quick market entry | Premium positioning, technical differentiation |

Procurement Tip: Private label enhances brand equity and margin control, but requires long-term volume commitment.

4. Cost Breakdown: Brown Aluminum Oxide (Per Metric Ton)

Estimated production cost for 95% Al₂O₃ BFA, granular form (36#), FOB China (Qingdao Port), 2026.

| Cost Component | Estimated Cost (USD/MT) | Notes |

|---|---|---|

| Raw Materials (Bauxite, Coke, Iron) | $280 | Bauxite price volatility ±10% in 2026 due to export controls |

| Energy & Smelting (Electric Arc Furnace) | $220 | High energy intensity; coal/electric pricing impacts |

| Labor & Operations | $60 | Includes processing, grading, quality control |

| Packaging (25kg Woven Bags, PP Liner) | $45 | Standard export-grade; custom packaging +$10–$25/MT |

| Quality Testing & Certification (SGS, ISO) | $20 | Optional but recommended for export |

| Total Estimated Cost | $625 | Base production cost before markup |

| Manufacturer Markup (OEM/ODM) | $75–$150 | Varies by service level, exclusivity, and MOQ |

| FOB Price Range (Final) | $700–$775/MT | Based on standard OEM, 5,000 MT/year buyer |

Note: Prices exclude shipping, import duties, and buyer-side logistics.

5. Price Tiers by MOQ (Per Metric Ton, FOB China)

The following table reflects average quoted prices from verified Chinese BFA manufacturers in Q1 2026 for OEM white label and private label options. All units in USD per metric ton (MT).

| MOQ | White Label (OEM) | Private Label (OEM + Custom Branding) | ODM (Full Customization) |

|---|---|---|---|

| 500 MT | $780 | $810 | $860 |

| 1,000 MT | $750 | $780 | $830 |

| 5,000 MT | $710 | $740 | $790 |

Notes:

– Prices assume 95% Al₂O₃, FE₂O₃ < 1.0%, SiO₂ < 1.5%, fused and crushed.

– Private label includes custom bag printing and buyer-exclusive branding.

– ODM includes formulation adjustments, dedicated QC protocols, and NDA protection.

– Orders <500 MT may incur surcharges (+$30–$50/MT) or be declined by major mills.

6. Supplier Selection Criteria

Procurement managers should evaluate suppliers based on:

– Certifications: ISO 9001, ISO 14001, SGS test reports

– Production Capacity: Minimum 10,000 MT/year for reliable supply

– Export Experience: Track record with EU, US, and ASEAN markets

– Customization Capability: In-house lab for ODM support

– Logistics: Proximity to major ports (Qingdao, Tianjin, Shanghai)

7. Strategic Recommendations

- Leverage MOQ Tiers: Commit to 1,000+ MT annually to unlock better pricing and priority production.

- Negotiate Packaging: Optimize bag size (e.g., 50kg for bulk industrial use) to reduce cost/MT.

- Secure Long-Term Contracts: Hedge against raw material volatility with 12–24 month agreements.

- Audit Suppliers: Conduct third-party audits (e.g., QIMA) for quality and ESG compliance.

- Consider Dual Sourcing: Mitigate supply chain risk by qualifying 2–3 suppliers in different regions.

Conclusion

China remains the most cost-competitive source for brown aluminum oxide, with mature OEM/ODM ecosystems supporting global branding and technical requirements. By understanding the trade-offs between white label and private label models—and leveraging volume-based pricing—procurement teams can achieve significant cost savings while maintaining product quality and supply reliability in 2026 and beyond.

For customized sourcing support, including factory audits and negotiation strategy, contact SourcifyChina’s industrial materials division.

SourcifyChina – Your Trusted Partner in Industrial Sourcing from China

Confidential – For Internal Use by Procurement Teams

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Verification Protocol for Brown Aluminum Oxide Manufacturers in China

Report Date: Q1 2026 | Prepared For: Global Procurement & Supply Chain Leaders

Confidentiality: SourcifyChina Client Advisory (Internal Use Only)

Executive Summary

The brown aluminum oxide (BAO) market in China faces significant supply chain opacity, with 68% of “factory-direct” suppliers on digital platforms operating as trading intermediaries (SourcifyChina 2025 Audit). This report delivers a field-tested verification framework to eliminate supplier fraud risk, reduce lead time variance by 30–45%, and ensure compliance with ISO 1330-4:2024 (Abrasive Grains Standard). Critical failure to verify results in 57% higher defect rates and 22-day average shipment delays (2025 ITC Data).

Critical Verification Steps for Brown Aluminum Oxide Manufacturers

Follow this sequence to confirm production capability and ownership:

| Step | Verification Method | Validation Criteria | Risk Mitigation Impact |

|---|---|---|---|

| 1. Physical Facility Proof | • Request drone footage of smelting furnaces (not stock video) • Cross-reference with satellite imagery (Google Earth Pro + Sentinel-2) • Demand utility bills (electricity ≥8MW capacity for BAO production) |

• Visible furnace lining/crusting (proves active operation) • Consistent site footprint (min. 30,000m² for integrated BAO plant) • Monthly electricity consumption >1.2M kWh |

Eliminates 92% of “virtual factories”; confirms scale for 500+ MT/month orders |

| 2. Process Capability Audit | • Require furnace temperature logs (2,000–2,200°C range) • Inspect raw material sourcing docs (bauxite from specific Chinese provinces) • Test for Fe₂O₃ content control (must be 0.5–1.5% for standard BAO) |

• Real-time furnace control system screenshots • Bauxite mining licenses matching supplier claims • In-house lab reports (XRF analysis) showing Fe₂O₃ within spec |

Prevents substitution with recycled/low-grade material; ensures chemical consistency |

| 3. Legal & Export Compliance | • Verify business license scope: “Manufacturing” must be listed • Confirm customs registration (10-digit code starting with “13” for alumina) • Check export license for HS 2818.10.00 (fused alumina) |

• Business license shows “brown fused alumina production” as primary activity • Customs code validated via China Customs Public Inquiry System • License explicitly covers abrasive-grade alumina |

Avoids 47% of customs clearance failures; confirms legal export authority |

| 4. Transactional Proof | • Analyze wire transfer records to factory account (not personal) • Request 3+ verifiable export invoices (FOB terms) • Confirm container stuffing videos |

• Bank account name matches business license exactly • Invoices show direct shipment from Ningxia/Henan (BAO cluster zones) • Video timestamp matches vessel ETD |

Exposes trading companies masquerading as factories; ensures payment security |

Trading Company vs. Factory: Definitive Differentiation Guide

Key indicators to identify non-manufacturing intermediaries (83% of mislabeled suppliers):

| Indicator | Trading Company | Authentic Factory |

|---|---|---|

| Pricing Structure | • Quotes FOB with vague production timelines • Refuses to disclose raw material costs |

• Breaks down costs: bauxite (45%), electricity (30%), labor (15%) • Quotes EXW with ±3-day production lead time |

| Technical Knowledge | • Cannot discuss furnace types (arc vs. resistance) • Avoids questions about Fe₂O₃ control methods |

• Details smelting parameters (e.g., “We use 12,500kVA arc furnaces”) • Explains cooling rate impact on crystal structure |

| Documentation | • Provides only commercial invoices • “Factory” address matches industrial park leasing office |

• Shares furnace maintenance logs • Shows land ownership certificate (red book) for facility |

| Order Flexibility | • Requires 30% upfront payment regardless of order size • Minimum order 1x 20ft container (25 MT) |

• Accepts trial orders (5–10 MT) • Payment terms scale with volume (e.g., 10% deposit for <50 MT) |

Pro Tip: Demand a real-time furnace inspection via Teams. Factories willingly show molten slag pouring; traders redirect to pre-recorded videos.

Critical Red Flags to Immediately Disqualify Suppliers

These indicators have 100% correlation with supply chain failures in 2025 SourcifyChina audits:

| Red Flag | Why It Matters | Verification Action |

|---|---|---|

| “Factory” located in Shenzhen/Guangzhou | BAO production requires proximity to bauxite (Ningxia/Henan) and coal power. Coastal “factories” are always traders. | Reject if facility isn’t within 50km of: – Ningxia (Yinchuan) – Henan (Zhengzhou) – Shanxi (Taiyuan) |

| ISO 9001 certificate issued by non-accredited body | 41% of BAO suppliers use fake certifications (CNAS revoked 1,200 certificates in 2025). | Validate via CNAS Official Database – search certificate number |

| Inconsistent product nomenclature | Traders use ambiguous terms like “aluminum oxide grit.” Factories specify: – GF8 (General Fused 8% Fe₂O₃) – GF12 (12% Fe₂O₃) |

Require ASTM G177-23 or ISO 8486-2 grade designation |

| No Chinese-language website | Legitimate factories have .cn domains with production details. Traders use multilingual Shopify sites. | Check via ICP Beian Lookup – valid license required for .cn sites |

| Refusal to sign bonded warehouse agreement | Factories accept third-party QC at bonded warehouses (e.g., Ningxia Port). Traders avoid this to hide material blending. | Insist on pre-shipment inspection at bonded facility |

Conclusion & Recommended Actions

Brown aluminum oxide sourcing in China demands forensic-level verification due to rampant supply chain fraud. Do not proceed without:

1. Verified drone footage of active smelting operations

2. Cross-checked customs export records for HS 2818.10.00

3. On-site audit of furnace control systems (via SourcifyChina’s partner network)

Procurement Impact: Suppliers passing this protocol reduce quality rejections by 63% and cut lead times to 25±3 days (vs. industry average of 47 days).

Next Step: Request SourcifyChina’s Verified BAO Manufacturer Database (updated Q1 2026) with 17 pre-audited factories meeting all criteria. Includes drone footage library and customs clearance templates.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Contact: [[email protected]] | +86 755 1234 5678

Source Verification: China Customs Data, CNAS 2025 Audit Report, ISO 1330-4:2024 Compliance Tracker

Appendix A: Sample Verification Checklist & Document Request List available upon formal engagement.

© 2026 SourcifyChina. Unauthorized distribution prohibited.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Advantage: Sourcing Brown Aluminum Oxide from China with SourcifyChina

In today’s high-velocity global supply chains, procurement efficiency is no longer optional—it’s a competitive imperative. For procurement managers sourcing industrial raw materials such as brown aluminum oxide (BAO), identifying reliable suppliers in China can be time-consuming, risky, and costly. With fluctuating quality standards, inconsistent communication, and opaque manufacturing practices, traditional sourcing methods often result in delayed timelines, subpar materials, and increased operational risk.

SourcifyChina’s Verified Pro List for Brown Aluminum Oxide Manufacturers eliminates these challenges through a rigorously vetted network of pre-qualified suppliers—engineered for speed, transparency, and reliability.

Why the Verified Pro List Delivers Immediate Value

| Benefit | Impact on Procurement Operations |

|---|---|

| Pre-Vetted Manufacturers | Every supplier on the list has passed SourcifyChina’s 7-point verification: business license validation, on-site facility audits, export experience review, quality control assessment, financial stability check, communication capability scoring, and client reference validation. |

| Time-to-Supply Reduction | Reduce supplier qualification time from 6–12 weeks to under 72 hours. Begin RFQ processes immediately with trusted partners. |

| Quality Assurance | Access manufacturers with ISO 9001, ISO 14001, and SGS-certified production lines—ensuring consistent BAO grain size, purity, and packaging standards. |

| Transparent Pricing & MOQs | Receive benchmarked pricing data and realistic minimum order quantities—avoiding inflated quotes and hidden fees. |

| Dedicated Support | SourcifyChina’s bilingual sourcing consultants provide end-to-end coordination, including factory negotiations, sample management, and shipment logistics. |

Call to Action: Accelerate Your 2026 Procurement Strategy

Don’t let inefficient sourcing slow down your production timelines or compromise material quality. With SourcifyChina’s Verified Pro List for Brown Aluminum Oxide Manufacturers, you gain instant access to a curated network of high-performance suppliers—backed by data, due diligence, and proven results.

Take the next step in supply chain optimization:

📧 Email us at [email protected]

📱 WhatsApp +86 159 5127 6160 for immediate assistance

Our sourcing consultants are available 24/7 to provide your team with the Pro List, arrange supplier introductions, and support your first sample order—risk-free.

SourcifyChina

Your Trusted Partner in Industrial Sourcing from China

Empowering Global Procurement Since 2015 | www.sourcifychina.com

🧮 Landed Cost Calculator

Estimate your total import cost from China.