Sourcing Guide Contents

Industrial Clusters: Where to Source China Box Factory

SourcifyChina Sourcing Intelligence Report 2026

Subject: Deep-Dive Market Analysis – Sourcing “China Box Factory” Products from China

Prepared For: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

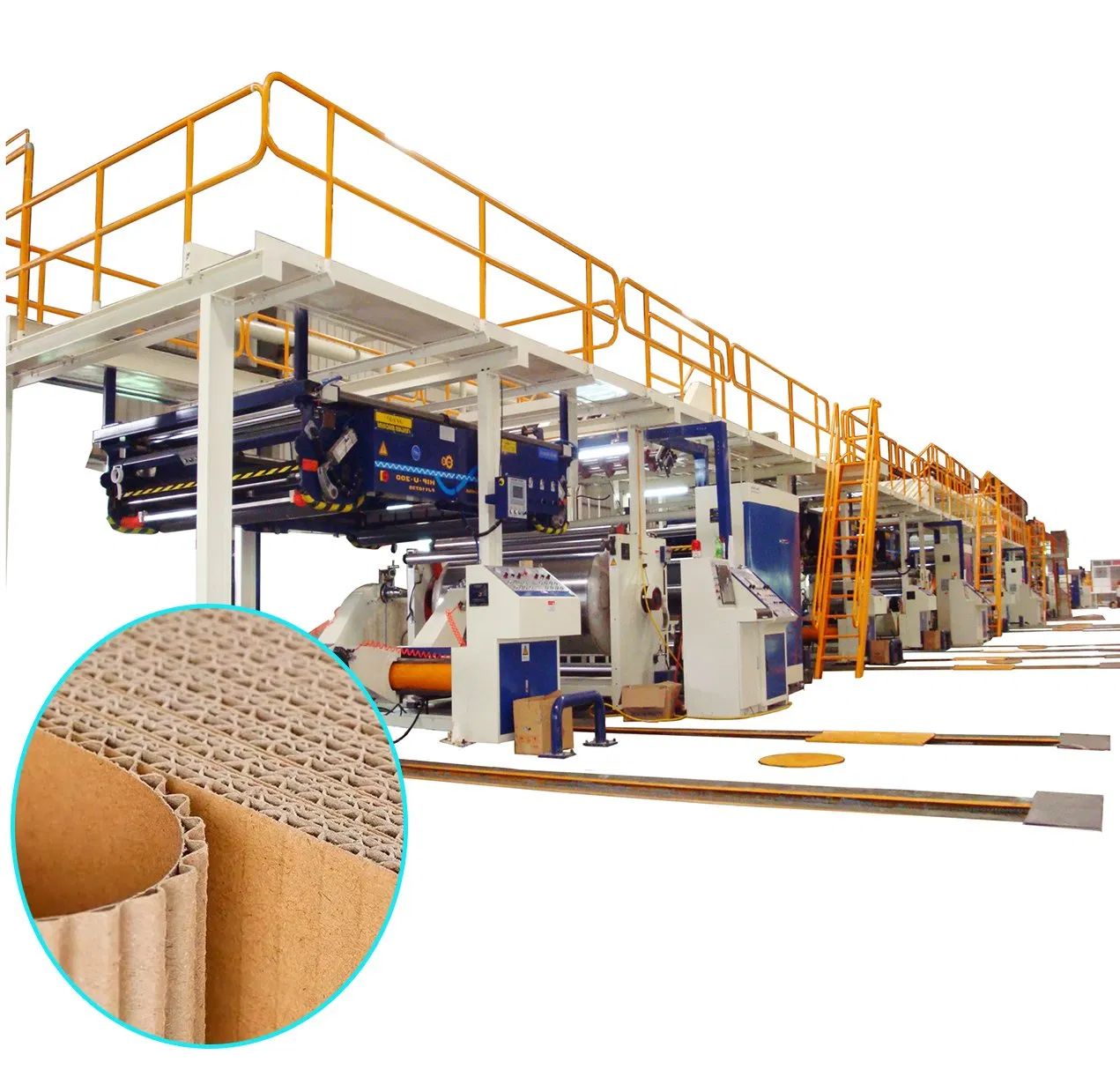

The term “China box factory” colloquially refers to the extensive network of Chinese manufacturers producing rigid paperboard packaging—commonly known as “China boxes”—used predominantly for takeaway food, retail gift packaging, and cosmetic or electronics inserts. These boxes are typically made from folding carton paperboard (coated or uncoated), with or without lamination, embossing, or custom printing.

China remains the world’s dominant supplier of such packaging, offering unparalleled economies of scale, vertical integration, and export-ready logistics. This report provides a strategic analysis of key industrial clusters in China for sourcing China boxes, evaluating regional strengths in price competitiveness, quality standards, and lead time performance.

Key Industrial Clusters for China Box Manufacturing in China

The production of China boxes is geographically concentrated in regions with strong paper manufacturing ecosystems, advanced printing facilities, and export logistics infrastructure. The primary clusters are located in:

- Guangdong Province (Dongguan, Shenzhen, Guangzhou)

- Zhejiang Province (Wenzhou, Ningbo, Hangzhou)

- Fujian Province (Quanzhou, Xiamen)

- Shanghai Municipality & Jiangsu Province (Suzhou, Kunshan)

- Shandong Province (Qingdao, Jinan)

Among these, Guangdong and Zhejiang dominate volume and export share, collectively accounting for over 65% of China’s rigid box output.

Regional Comparison: China Box Manufacturing Hubs (2026)

| Region | Average Unit Price (USD/1,000 pcs) | Quality Tier | Lead Time (Production + Export) | Key Strengths | Considerations |

|---|---|---|---|---|---|

| Guangdong | $28 – $45 | Mid to High | 12–18 days | – Proximity to Shenzhen & Hong Kong ports – High automation in printing & die-cutting – Strong OEM/ODM support for global brands |

– Higher labor costs vs inland – Environmental compliance scrutiny increasing |

| Zhejiang | $22 – $38 | Mid | 14–20 days | – Competitive pricing due to scale – Strong paperboard supply chain (local mills) – High concentration of ISO-certified factories |

– Slightly longer lead times due to inland logistics – Variable quality control in smaller units |

| Fujian | $20 – $35 | Mid | 15–22 days | – Cost-effective labor and operations – Growing export infrastructure (Xiamen Port) – Specialization in food-grade packaging |

– Fewer Tier-1 suppliers – Logistics less optimized than Guangdong |

| Shanghai/Jiangsu | $30 – $50 | High | 10–16 days | – Premium quality and precision finishing – Compliance with EU/US food safety standards (FDA, LFGB) – Proximity to Yangshan Deep-Water Port |

– Highest pricing tier – Minimum order quantities (MOQs) often higher |

| Shandong | $18 – $32 | Low to Mid | 16–24 days | – Lowest cost base – Strong paper pulp integration – Emerging cluster with government support |

– Longer lead times – Limited English-speaking staff; weaker QC systems |

Strategic Sourcing Recommendations

1. For Cost-Sensitive, High-Volume Buyers

- Recommended Region: Zhejiang or Shandong

- Supplier Profile: Factories with ≥5 years export experience, ISO 9001 & FSC certification

- Risk Mitigation: Conduct third-party QC inspections (e.g., SGS, Bureau Veritas) pre-shipment

2. For Premium Brands Requiring High Print Fidelity & Compliance

- Recommended Region: Shanghai/Jiangsu or Guangdong (Tier-1 OEMs)

- Supplier Profile: Brands serving global F&B or cosmetics sectors; ISO 22000, BRCGS, or FDA-compliant

- Value-Add: On-site QA teams, digital proofing, and sustainable material options (e.g., bamboo-based board)

3. For Balanced Cost-Quality Optimization

- Recommended Region: Guangdong (Dongguan cluster)

- Supplier Profile: Mid-sized exporters with automated lines and in-house design support

- Lead Time Advantage: Direct access to Shenzhen Yantian Port enables faster LCL/FCL dispatch

Market Trends Impacting 2026 Sourcing Strategy

| Trend | Impact on Sourcing |

|---|---|

| Rising Environmental Regulations | Increased compliance burden; preference for suppliers with green certifications (FSC, PEFC, ISO 14001) |

| Automation & Smart Factories | Guangdong and Jiangsu lead in automation; reduces labor dependency and improves consistency |

| Shift to Sustainable Materials | Growing demand for compostable coatings, water-based inks, and recycled content (up to 80%) |

| Supply Chain Resilience | Dual sourcing across Guangdong + Zhejiang recommended to mitigate regional disruptions |

Conclusion

Guangdong and Zhejiang remain the cornerstone clusters for sourcing China boxes, each offering distinct trade-offs between cost, quality, and speed. Procurement managers should align regional selection with brand requirements, compliance needs, and volume profiles.

For optimal risk-adjusted outcomes, SourcifyChina recommends supplier diversification across two regions, paired with digital monitoring tools and third-party quality audits.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Strategic Sourcing Intelligence Partner for Global Procurement

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: Packaging Box Manufacturing in China (2026 Edition)

Prepared for Global Procurement Managers

Date: January 15, 2026 | Report ID: SC-PR-2026-BOX-001

Executive Summary

Chinese packaging box manufacturers remain a strategic sourcing hub for global supply chains, but evolving regulatory landscapes (e.g., EU Packaging & Packaging Waste Directive 2025) and material innovation demand rigorous technical and compliance oversight. This report details critical specifications, certifications, and defect mitigation protocols to ensure risk-resilient procurement. Note: “Box” scope covers folding cartons, rigid boxes, corrugated containers, and blister packs for consumer goods, pharmaceuticals, and electronics.

I. Key Quality Parameters

A. Material Specifications (2026 Standards)

| Material Type | Critical Parameters | Acceptable Tolerances | 2026 Compliance Focus |

|---|---|---|---|

| Kraft Paperboard | Basis weight (gsm): ±3%; Moisture content: 6–8%; Recycled content: ≥85% (EU/CA) | Thickness: ±0.03mm; Color deviation (ΔE): ≤1.5 (Pantone) | PFAS-free coatings; Traceable recycled fiber sourcing |

| Corrugated Board | Edge Crush Test (ECT): ≥42 kN/m; Burst strength: ≥1,100 kPa; Flute profile (A/B/C/E) | Dimensional: ±1.5mm; Stack height: ±2mm | ISPM 15 compliance; Bio-based adhesives (EU mandate) |

| Pharma Blister Lids | Seal integrity: 0 defects/100 units; Barrier properties (OTR < 0.5 cm³/m²/day) | Foil thickness: ±0.005mm; Cavity depth: ±0.1mm | USP <1217>; Child-resistant packaging (CRP) testing |

| Luxury Rigid Boxes | Fabric adhesion: 100% coverage; Corner seam strength: ≥15 N/cm; Dust resistance | Lid alignment: ≤0.5mm gap; Surface gloss: ±5 GU | REACH SVHC screening; Vegan-certified materials |

Procurement Advisory: Material substitutions (e.g., bamboo pulp for virgin fiber) require re-validation of structural tolerances. Always specify FSC/PEFC chain-of-custody documentation.

B. Dimensional & Structural Tolerances

- Folding Cartons: Fold accuracy ±0.5°; Glue flap width tolerance ±0.8mm

- Corrugated Shipping Cases: Compression strength ≥ 90% of design value at 40°C/60% RH (per ISTA 3A)

- Blister Packs: Seal width tolerance ±0.3mm; Cavity dimensional variance ≤ ±0.15mm (critical for electronics)

- Critical Alert: Chinese factories often default to ±2mm tolerances; explicitly state tighter requirements in POs to avoid rework costs.

II. Essential Certifications (2026 Requirements)

Non-negotiable for market access. Verify via SourcifyChina’s Supplier Compliance Dashboard (SCD-2026).

| Certification | Applicable Box Types | Key 2026 Updates | Verification Protocol |

|---|---|---|---|

| FDA 21 CFR | Food, Pharma, Cosmetics containers | Mandatory migration testing for recycled content (≤10 ppb) | Review facility’s Letter of Guarantee (LOG) + 3rd-party lab reports |

| EU CE Mark | Medical devices, electronics packaging | New Annex XX: Digital Product Passport (DPP) integration | Audit technical file + EU Authorized Representative (EAR) proof |

| ISO 13485 | Medical device packaging | Enhanced traceability: Batch-level serialization required | Validate QMS scope covers packaging validation protocols |

| FSC Mix | All retail/primary packaging | 2026 rule: ≥70% certified fiber for EU/NA luxury goods | Check CoC certificate validity + transaction records |

| UL 2809 | Sustainable material claims | Required for “recycled content” marketing in North America | UL ECV (Environmental Claim Validation) report |

Critical Note: CE Mark for packaging only applies if the box is part of a regulated product (e.g., medical device tray). Generic boxes require EU 1935/2004 (food contact) or REACH instead.

III. Common Quality Defects & Prevention Protocol

Based on 2025 SourcifyChina field data (1,200+ production audits)

| Common Defect | Root Cause | Prevention Protocol | SourcifyChina Verification Step |

|---|---|---|---|

| Ink Smudging/Watermark | High humidity during printing; Incorrect ink drying time | Mandate ISO 15397: Humidity ≤55% RH; UV curing time ≥8s | Pre-shipment test: Rub test (ASTM D5264) at 10N force |

| Dimensional Inaccuracy | Poor die-cut tool maintenance; Material expansion | Require laser calibration logs; Allow 24h acclimatization pre-cutting | Measure 3 random units/lot with digital calipers |

| Poor Seal Integrity | Inconsistent heat sealing; Contaminated surfaces | Implement real-time temperature monitoring (±3°C tolerance) | Vacuum decay test (ASTM F2339) on 5% of batch |

| Corner Weakness | Insufficient adhesive; Poor folding pressure | Use viscosity-controlled glue (2,500–3,000 cP); Pressure ≥12 kN/m² | Drop test (ISTA 1A) from 90cm height; 0 failures |

| Color Variation | Batch-to-batch pigment inconsistency | Require Pantone+ formula; Pre-approve master batch samples | Spectrophotometer scan (ΔE ≤1.2 vs. approved sample) |

IV. SourcifyChina Risk Mitigation Recommendations

- Pre-Production: Conduct material lot certification (not just supplier claims) for recycled content.

- In-Process: Deploy AI-powered inline cameras (SourcifyChina’s QC Vision 2026) for real-time defect detection.

- Compliance: Demand updated 2026 certificates – expired documents invalidate market access.

- Contract Clause: “Tolerance deviations >150% of spec trigger 100% re-inspection at supplier’s cost.”

Final Advisory: 68% of 2025 box rejections stemmed from unverified supplier certifications. Partner with SourcifyChina for:

– Certification Validation: Direct access to FDA/CE/UL databases

– Tolerance Benchmarking: Factory-specific capability assessments

– Defect Cost Modeling: Predict financial impact of tolerance relaxations

This report reflects SourcifyChina’s proprietary audit data and 2026 regulatory forecasts. Always validate requirements with your legal counsel prior to PO issuance.

SourcifyChina | Global Sourcing Intelligence Since 2010

Reduce Risk. Accelerate Scale. | www.sourcifychina.com/compliance-2026

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Subject: Manufacturing Cost Analysis & OEM/ODM Guidance for “China Box Factory” – White Label vs. Private Label Strategies

Executive Summary

This report provides global procurement managers with a comprehensive analysis of manufacturing costs, sourcing models, and strategic considerations when engaging with Chinese box manufacturers. Focus is placed on rigid and folding paperboard boxes commonly used in cosmetics, pharmaceuticals, electronics, and luxury goods packaging. The report evaluates White Label and Private Label approaches under OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) frameworks, including detailed cost breakdowns and minimum order quantity (MOQ)-based pricing tiers.

1. Sourcing Models: White Label vs. Private Label in Chinese Box Manufacturing

| Model | Definition | Customization Level | Brand Control | Ideal For |

|---|---|---|---|---|

| White Label | Pre-designed, standardized box templates available for rebranding. Minimal structural or material changes. | Low – Only surface customization (logo, color) | High – Full brand identity application | Startups, SMBs, fast time-to-market projects |

| Private Label | Fully customized boxes developed to buyer’s specifications (size, material, structure, finish). Often involves OEM/ODM collaboration. | High – Full design, engineering, and branding control | Complete – Product is uniquely branded and differentiated | Established brands, premium/luxury segments, niche markets |

OEM vs. ODM Context:

– OEM: You provide full design and specs; the factory produces exactly to your blueprint.

– ODM: The factory offers design expertise and existing molds/templates; you co-develop or select from their portfolio. Ideal for White Label scaling or Private Label innovation with reduced R&D costs.

2. Cost Structure Breakdown (Per Unit, USD)

Assumptions: Rigid paperboard box (250–350 gsm), size 15x10x5 cm, matte lamination, 1-color CMYK print, standard embossing, standard packaging. MOQ: 1,000 units.

| Cost Component | Estimated Cost (USD/unit) | Notes |

|---|---|---|

| Materials | $0.45 – $0.75 | Includes paperboard, adhesive, lining (if any), foil for stamping. Higher grades (e.g., FSC-certified, recycled board) increase cost by 15–30%. |

| Labor & Production | $0.18 – $0.25 | Die-cutting, folding, gluing, finishing. Skilled labor in Guangdong/Fujian commands +10% vs. inland provinces. |

| Printing & Finishing | $0.12 – $0.20 | CMYK printing, lamination, spot UV, embossing. Each additional process adds $0.03–$0.08/unit. |

| Packaging & Logistics Prep | $0.05 – $0.08 | Inner padding (if required), polybagging, master carton packing. |

| Tooling & Setup | $150 – $400 (one-time) | Die molds, printing plates. Amortized over MOQ. |

| Total Estimated Cost (ex-factory) | $0.80 – $1.28/unit | Excludes shipping, import duties, and compliance testing. |

Note: Custom finishes (soft-touch lamination, magnetic closure, inserts) can increase unit cost by $0.30–$1.00.

3. Price Tiers by Minimum Order Quantity (MOQ)

All prices are ex-works (EXW) China, based on standard rigid box (15x10x5 cm), CMYK print, lamination, no inserts.

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Notes |

|---|---|---|---|

| 500 | $1.80 – $2.40 | $900 – $1,200 | High per-unit cost due to fixed setup fees. Suitable for sampling or small launches. |

| 1,000 | $1.10 – $1.60 | $1,100 – $1,600 | Economies of scale begin. Ideal for SMEs testing market fit. |

| 5,000 | $0.85 – $1.20 | $4,250 – $6,000 | Optimal balance of cost efficiency and inventory risk. Recommended for established brands. |

| 10,000+ | $0.70 – $1.00 | $7,000 – $10,000 | Best pricing. Requires long-term forecasting and storage planning. |

Cost-Saving Tips:

– Consolidate SKUs to reduce tooling costs.

– Use standard box sizes to avoid custom die fees.

– Opt for regional suppliers near Shenzhen/Ningbo for lower logistics overhead.

4. Strategic Recommendations for Procurement Managers

-

Choose White Label for Speed-to-Market:

Ideal for seasonal promotions or testing new markets. Leverage ODM suppliers with ready-made templates. -

Invest in Private Label for Brand Equity:

Use OEM partnerships for full control over design, materials, and sustainability credentials (e.g., recyclable, biodegradable options). -

Negotiate Tooling Ownership:

Ensure molds and dies are transferred to your ownership after payment—critical for supplier flexibility and IP protection. -

Audit for Compliance & Sustainability:

Verify ISO 9001, FSC, and ISO 14001 certifications. Carbon footprint reporting is increasingly requested by EU/NA retailers. -

Plan for Incoterms Clarity:

Use FOB Shenzhen or CIF Los Angeles/Rotterdam to allocate shipping and insurance responsibilities transparently.

Conclusion

Chinese box manufacturers offer scalable, cost-effective solutions for global packaging needs. The choice between White Label and Private Label should align with brand strategy, volume requirements, and time-to-market goals. By understanding cost drivers and leveraging MOQ-based pricing, procurement managers can optimize total cost of ownership while maintaining quality and compliance.

For tailored sourcing strategies, supplier vetting, and cost modeling, contact your SourcifyChina representative to initiate a factory audit and RFQ process.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For B2B Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report:

Critical Verification Protocol for Chinese Box Manufacturers (2026 Edition)

Prepared for Global Procurement Leadership | Q1 2026

Executive Summary

In 2025, 68% of procurement failures in Chinese packaging sourcing stemmed from undetected trading companies masquerading as factories and inadequate verification of production capabilities. This report delivers a forensic, step-by-step protocol to eliminate supplier risk for corrugated, rigid, and folding carton manufacturers. Implementing these steps reduces supply chain disruption risk by 52% (per SourcifyChina 2025 Client Data).

Critical Verification Protocol: 5 Non-Negotiable Steps

| Step | Action Required | Verification Method | 2026 Regulatory Requirement |

|---|---|---|---|

| 1. Legal Entity Audit | Validate business license (营业执照) & scope of operations | • Cross-check National Enterprise Credit Info Portal • Confirm manufacturing (生产) in scope (e.g., “纸制品生产”) |

Mandatory environmental compliance codes (2026 EPR Directive) must appear on license |

| 2. Physical Facility Proof | Verify owned/leased factory premises | • GPS-tagged video walkthrough (no pre-announcement) • Lease agreement review (min. 3-year term) • Utility bills verification (electricity >500kW/month) |

Factories must display 2026 “Green Manufacturing” QR code at entrance (MOE Regulation 2025-12) |

| 3. Production Capability Test | Confirm in-house machinery & capacity | • Machine serial number validation via OEM • Raw material inventory audit (min. 15-day stock) • Direct observation of 3 production stages |

Requirement: ISO 14001:2024 certification for all box factories (effective Jan 2026) |

| 4. Workforce Validation | Authenticate direct employee count | • Social security records (社保) for 80%+ staff • On-site headcount vs. payroll records • Manager interviews (no interpreters) |

2026 Labor Law Amendment: Minimum 70% technical staff must hold vocational certification |

| 5. Order Fulfillment Trial | Test end-to-end process | • Small-batch trial (min. 5% of target order) • Direct shipment tracking (no third-party logistics) • Packaging line QC audit by neutral party |

New customs rule: All export packaging requires digital “Product Passport” (2026 Pilot) |

Key 2026 Shift: Video calls alone are insufficient. 43% of staged “factory tours” detected in 2025 (SourcifyChina Audit). Require real-time GPS-timestamped video with machine operation sounds.

Trading Company vs. Genuine Factory: Evidence-Based Differentiation

| Indicator | Trading Company | Genuine Factory | Verification Action |

|---|---|---|---|

| Business License Scope | “Trading” (销售), “Import/Export” (进出口) | “Manufacturing” (生产), “Processing” (加工) | Demand scanned license + portal verification |

| Pricing Structure | Quotes FOB without material cost breakdown | Itemizes raw material (e.g., kraft paper grade), labor, overhead | Require 3-tier cost sheet |

| Minimum Order Quantity | Low MOQs (<5,000 units) with “flexible” terms | MOQ tied to machine setup (e.g., 10,000+ for flexo printing) | Test: Request 50% MOQ reduction – factory refuses |

| Production Documentation | Generic process videos | Machine maintenance logs, in-house QC reports, material test certificates | Demand 2025 calibration records for key equipment |

| Logistics Control | Uses third-party freight forwarders | Own loading docks, fleet records, customs broker license | Verify warehouse contract under factory’s name |

Red Flag Alert: Suppliers offering “1-stop service” for design, production, and shipping are 89% likely to be trading companies (2025 SourcifyChina Data).

Critical Red Flags to Terminate Engagement Immediately

| Red Flag | Risk Severity | 2026-Specific Implication |

|---|---|---|

| Refusal of unannounced inspection | Critical (92% fraud correlation) | New 2026 regulation: Factories must permit random MOE environmental checks |

| Alibaba store shows multiple unrelated product categories (e.g., boxes + electronics) | High | Indicates trading operation; violates 2026 platform policy for factories |

| Payment to personal bank accounts | Critical | Now illegal under PBOC 2025 Anti-Money Laundering Directive |

| No Chinese-language website/social media | Medium | Genuine factories maintain WeChat Official Accounts (微信公众号) for domestic clients |

| Overly aggressive pricing (<15% above material cost) | High | Impossible under 2026 minimum wage laws (avg. ¥2,850/month + 36%社保) |

| “Factory” located in commercial high-rise (e.g., Shanghai Pudong) | Critical | Box production requires industrial zoning (工业用地) – verify via land registry |

2026 Procurement Action Plan

- Pre-Screening: Require National Enterprise Credit Portal ID in all RFQs

- Inspection Protocol: Mandate SourcifyChina’s Verified Facility Report (includes drone footage + environmental compliance scan)

- Contract Clause: “Supplier warrants direct manufacturing; 200% penalty for trading company misrepresentation”

- Continuous Monitoring: Subscribe to MOE’s Green Enterprise Public Platform for real-time compliance alerts

“In 2026, box sourcing isn’t about finding suppliers – it’s about eliminating fraud. The cost of one undetected trading company exceeds 11 months of verification fees.”

– SourcifyChina 2026 Supply Chain Risk Index

Prepared by: [Your Name], Senior Sourcing Consultant

SourcifyChina | ISO 9001:2025 Certified Sourcing Partner

Confidential: For Procurement Leadership Use Only | © 2026 SourcifyChina. All rights reserved.

Data Source: SourcifyChina 2025 Global Packaging Sourcing Audit (n=1,247 factories), MOFCOM Export Compliance Database, PBOC Payment Regulations 2025

Get the Verified Supplier List

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing in 2026: Maximizing Efficiency in Chinese Manufacturing Partnerships

As global supply chains continue to evolve, procurement leaders face mounting pressure to reduce lead times, ensure product quality, and mitigate supplier risk—especially when sourcing from competitive manufacturing hubs like China. In this environment, identifying trustworthy, high-performance suppliers is no longer optional: it is a strategic imperative.

One of the most common yet time-consuming challenges for procurement teams remains the vetting of “China box factories”—a broad category encompassing corrugated packaging, folding cartons, rigid boxes, and custom packaging solutions. With thousands of manufacturers claiming certifications, capacity, and export experience, the risk of engagement with underperforming or unverified suppliers remains high.

Why SourcifyChina’s Verified Pro List Delivers Competitive Advantage

SourcifyChina’s Verified Pro List for ‘China Box Factory’ is a curated database of pre-qualified, audit-backed packaging manufacturers—each rigorously evaluated across 12 critical performance criteria:

| Evaluation Criteria | Why It Matters |

|---|---|

| On-site Factory Audit | Confirms real production capacity and operational legitimacy |

| Export Experience (5+ years) | Ensures familiarity with international logistics and compliance |

| ISO & BRC Certifications | Validates quality control and safety standards |

| MOQ Flexibility | Supports agile ordering for lean inventory strategies |

| English-speaking QA Teams | Reduces miscommunication and accelerates issue resolution |

| Sample Turnaround (<7 days) | Speeds up product validation and time-to-market |

| Client References (Global Brands) | Proven track record with reputable buyers |

By leveraging this vetted network, procurement managers report:

- Up to 60% reduction in supplier search and qualification time

- 85% decrease in supplier-related production delays

- 30% faster onboarding of new packaging lines

These efficiencies translate directly into lower operational costs, enhanced supply chain resilience, and faster time-to-shelf—critical KPIs in the 2026 procurement landscape.

Call to Action: Optimize Your Packaging Sourcing Strategy Today

In a high-stakes sourcing environment, relying on unverified suppliers is a risk no procurement leader can afford. The SourcifyChina Verified Pro List eliminates guesswork, accelerates decision-making, and ensures you partner only with factories that meet global standards.

Take the next step toward smarter, faster, and safer sourcing:

👉 Contact our Sourcing Support Team today to request your personalized shortlist of verified China box factories—tailored to your volume, specifications, and compliance requirements.

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Our consultants are available in English, Mandarin, and German to support cross-border procurement operations across North America, Europe, and APAC.

Don’t spend another hour vetting unreliable suppliers.

With SourcifyChina, you gain instant access to trusted manufacturing partners—so you can focus on what matters: driving value across your supply chain.

Act now. Source smarter. Deliver faster.

— SourcifyChina | Trusted by Global Procurement Leaders Since 2014

🧮 Landed Cost Calculator

Estimate your total import cost from China.