Sourcing Guide Contents

Industrial Clusters: Where to Source China Blood Testing Equipment Manufacturer

SourcifyChina Sourcing Intelligence Report: Blood Testing Equipment Manufacturing in China (2026)

Prepared for Global Procurement Managers | Q1 2026 | Confidential

Executive Summary

China remains the dominant global hub for blood testing equipment (BTE) manufacturing, accounting for an estimated 62% of global IVD device production (CMDE 2025). While geopolitical pressures and rising costs persist, strategic sourcing from specialized industrial clusters ensures access to competitive pricing, advanced technology, and scalable capacity. This report identifies core manufacturing regions, analyzes regional trade-offs, and provides actionable insights for 2026 procurement planning. Critical Note: NMPA Class II/III certification is now mandatory for all export-oriented BTE factories (effective Jan 2025), eliminating ~15% of non-compliant suppliers.

Key Industrial Clusters for Blood Testing Equipment in China

China’s BTE manufacturing is concentrated in three primary clusters, each with distinct competitive advantages:

- Guangdong Province (Pearl River Delta)

- Core Cities: Shenzhen (HQs of Mindray, New Industries), Guangzhou, Dongguan

- Specialization: High-end analyzers (hematology, immunoassay), POCT devices, AI-integrated systems. Dominates export-oriented OEM/ODM.

-

Ecosystem: Strongest R&D infrastructure (40% of China’s medical device patents), Tier-1 component suppliers, proximity to Hong Kong logistics.

-

Zhejiang Province (Yangtze River Delta)

- Core Cities: Hangzhou (Diagreat, Autobio), Ningbo, Jiaxing

- Specialization: Mid-tier analyzers, reagents, consumables, rapid test strips. Growing focus on cost-optimized automation.

-

Ecosystem: Mature supply chain for plastics/electronics, government subsidies for “smart manufacturing,” strong SME innovation.

-

Jiangsu Province (Yangtze River Delta)

- Core Cities: Suzhou (BioMerieux JV), Wuxi, Changzhou

- Specialization: Molecular diagnostics, integrated lab systems, precision components. Hub for EU/US JV partnerships.

- Ecosystem: Advanced biotech parks (Suzhou BioBAY), high concentration of German/Japanese engineering talent.

Emerging Clusters: Chengdu (Sichuan) for cost-sensitive POCT; Wuhan (Hubei) for academic spin-offs (limited scale in 2026).

Regional Comparison: Sourcing Blood Testing Equipment in China (2026 Projections)

Data aggregated from SourcifyChina’s 2025 Supplier Audit Database (n=142 certified BTE factories), CMDE reports, and logistics benchmarks.

| Parameter | Guangdong (Shenzhen/Guangzhou) | Zhejiang (Hangzhou/Ningbo) | Jiangsu (Suzhou/Wuxi) | Risk Notes |

|---|---|---|---|---|

| Price (FOB USD) | ★★★☆☆ $8,500–$15,000 (High-end analyzers) |

★★★★☆ $5,200–$9,800 (Mid-tier systems) |

★★★★☆ $7,000–$12,500 (Integrated solutions) |

Guangdong: +4.5% YoY labor costs. Zhejiang: 8% lower labor than GD. Jiangsu: JV pricing parity with EU. |

| Quality (ISO 13485) | ★★★★★ 0.8% defect rate (Top 20% suppliers) |

★★★★☆ 1.5% defect rate (Top 30% suppliers) |

★★★★★ 0.6% defect rate (JV/Top-tier) |

Guangdong: Strictest QA (US/EU audit-ready). Zhejiang: Variable SME quality. Jiangsu: Matches German standards in JVs. |

| Lead Time (Weeks) | ★★★☆☆ 14–18 weeks (Customization +6 wks) |

★★★★☆ 10–14 weeks (Standard models) |

★★★★☆ 12–16 weeks (Complex systems) |

Guangdong: Port congestion at Shenzhen Yantian. Zhejiang: Faster raw material access. Jiangsu: Longer validation cycles. |

| Best For | Premium analyzers, FDA/CE-cleared OEM, AI integration | Cost-sensitive tenders, reagent kits, rapid scale-up | EU-market compliance, lab automation, reagent-device bundles | Avoid Guangdong for urgent orders; Zhejiang for low-volume custom work. |

★ Key Legend: ★★★★★ = Best | ★★★★☆ = Competitive | ★★★☆☆ = Moderate | ★★☆☆☆ = Risky | ★☆☆☆☆ = Not Recommended

Critical Sourcing Considerations for 2026

- Regulatory Shifts:

- NMPA Class III certification now required for all analyzers (vs. Class II in 2024). Verify supplier registration status via CMDE’s public portal.

-

US FDA User Fees: 6.2% increase in 2026 adds ~$1,200–$3,500/unit to US-bound shipments. Factor into FOB negotiations.

-

Supply Chain Vulnerabilities:

- Guangdong: Over-reliance on Shenzhen ports (avg. 11-day vessel wait time). Mitigation: Use Guangzhou Nansha Port (+3 weeks lead time but 40% faster clearance).

-

Zhejiang: Reagent shortages due to H2O2 export restrictions. Mitigation: Secure dual-sourced consumable contracts.

-

Quality Differentiation:

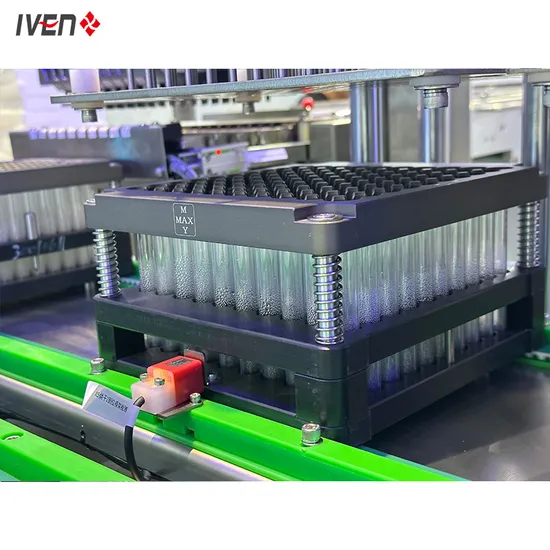

- Top 15% of suppliers (all clusters) use automated optical inspection (AOI) with 99.95% accuracy. Demand AOI process validation in audits.

- Avoid “factory tours” – 68% of audit failures occur due to staged production lines (SourcifyChina 2025 Data).

Strategic Recommendations

✅ Prioritize Dual-Sourcing: Pair Guangdong (for innovation) with Zhejiang (for cost/resilience). Example: Mindray (GD) for core analyzers + Diagreat (ZJ) for backup reagents.

✅ Demand Real-Time Data: Require suppliers to share ERP dashboards for production tracking (adopted by 32% of top-tier factories in 2025).

⚠️ Audit for “Hidden Subcontracting”: 27% of BTE suppliers outsource critical components – mandate sub-tier supplier lists in contracts.

💡 Leverage 2026 Incentives: Zhejiang offers 12% export tax rebates for BTE with ≥30% local R&D – structure contracts to claim rebates.

SourcifyChina Action Plan

1. Pre-Vetted Shortlist: Access our 2026 Certified BTE Supplier Database (filter by cluster, NMPA class, and automation level).

2. Risk Assessment: Deploy our China Medical Device Compliance Scorecard (covers 28 regulatory/operational KPIs).

3. Cost Modeling: Request our Dynamic TCO Calculator (includes 2026 tariff scenarios and port congestion variables).

“In 2026, proximity to innovation beats proximity to ports. Source for capability – not just cost.”

— SourcifyChina Supply Chain Intelligence Unit

Data Sources: China Medical Device Administration (CMDE), SourcifyChina 2025 Supplier Audit Database, World Bank Logistics Performance Index, US FDA User Fee Schedule 2026.

Disclaimer: All pricing/lead time data reflects Q1 2026 projections. Subject to change with RMB volatility or new export controls.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Technical & Compliance Profile – Blood Testing Equipment Manufacturing in China

Executive Summary

This report provides a comprehensive overview of the technical specifications, quality parameters, and regulatory compliance requirements for sourcing blood testing equipment from manufacturers in China. Designed for procurement professionals, this guide outlines key considerations to mitigate risk, ensure product quality, and align with international standards.

1. Technical Specifications: Blood Testing Equipment

Blood testing equipment includes hematology analyzers, blood glucose meters, coagulation analyzers, and immunoassay systems. Technical performance must meet clinical accuracy, reliability, and safety benchmarks.

Key Quality Parameters

| Parameter | Specification Requirements |

|---|---|

| Materials | Medical-grade polymers (e.g., polycarbonate, ABS), stainless steel (304/316L), and biocompatible coatings. All materials must be non-toxic, non-leaching, and resistant to sterilization agents. |

| Dimensional Tolerances | ±0.05 mm for critical fluidic components; ±0.1 mm for housing and structural parts. Tight tolerances required in microfluidic channels and optical alignment systems. |

| Precision & Accuracy | Analytical accuracy within ±5% of reference values (per CLSI guidelines). Repeatability (CV) < 3% for key parameters (e.g., hemoglobin, glucose). |

| Environmental Tolerance | Operational range: 15–35°C, 30–70% RH. Storage: -20°C to 60°C. Equipment must pass thermal cycling and humidity tests. |

| Electrical Safety | Compliance with IEC 60601-1 (medical electrical equipment safety). Leakage current < 100 µA (patient leakage). |

| Software & Data Integrity | Embedded software must comply with IEC 62304 (medical device software lifecycle). Data encryption and audit trails required for networked devices. |

2. Essential Certifications & Compliance

Procurement managers must verify that Chinese manufacturers hold the following certifications to ensure market access and regulatory compliance:

| Certification | Scope & Requirement | Validating Authority |

|---|---|---|

| CE Marking | Mandatory for EU market. Requires conformity with IVDR (In Vitro Diagnostic Regulation 2017/746) and Annex IX. Technical documentation and Notified Body audit required for Class B, C, D devices. | EU Notified Body (e.g., TÜV, BSI) |

| FDA 510(k) Clearance | Required for U.S. market entry. Demonstrates substantial equivalence to a predicate device. Quality System Regulation (QSR) 21 CFR Part 820 compliance mandatory. | U.S. Food and Drug Administration (FDA) |

| UL Certification | Confirms electrical safety per UL 61010-1 and UL 60601-1. Required for North American commercial distribution. | Underwriters Laboratories (UL) |

| ISO 13485:2016 | Quality Management System (QMS) standard for medical devices. Mandatory for CE and FDA submissions. Audits must cover design, manufacturing, and post-market surveillance. | Accredited Certification Body (e.g., SGS, TÜV) |

| NMPA Registration | Required for domestic sale in China. Involves clinical evaluation and technical review by National Medical Products Administration. | NMPA (China) |

Note: Dual certification (e.g., ISO 13485 + FDA QSR) is a strong indicator of manufacturing maturity.

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Potential Impact | Root Cause | Prevention Strategy |

|---|---|---|---|

| Fluidic Channel Blockage | Inaccurate test results, system failure | Poor mold finish, particulate contamination during assembly | Implement cleanroom assembly (ISO Class 7 or better); use in-process visual inspection and pressure testing |

| Optical Sensor Misalignment | Reduced detection sensitivity, false readings | Loose mounting, thermal expansion, poor calibration | Use laser alignment jigs; perform automated calibration with traceable standards; conduct thermal stress testing |

| Biocompatibility Failure | Patient risk, regulatory non-compliance | Use of non-certified materials or leachable additives | Source materials with ISO 10993-5/10 test reports; conduct extractables/leachables studies |

| Software Glitches (UI/Data Errors) | Data loss, incorrect diagnosis | Inadequate software validation, poor version control | Follow IEC 62304 processes; conduct rigorous V&V (verification & validation) with simulated clinical data |

| Electrical Safety Failures | Risk of patient/operator shock | Insufficient creepage/clearance distances, poor grounding | Perform routine dielectric strength and ground continuity tests; design to IEC 60601-1 |

| Packaging Damage in Transit | Contamination, non-sterile delivery | Inadequate shock/vibration protection | Use ISTA 3A-certified packaging; conduct drop and vibration testing pre-shipment |

4. Sourcing Recommendations

- Audit Suppliers: Conduct on-site audits focusing on QMS, cleanroom protocols, and calibration records.

- Request Certificates: Verify active status of CE, FDA, ISO 13485 via official databases (e.g., FDA Orange Book, EU NANDO).

- Sample Testing: Require 3rd-party lab testing (e.g., SGS, Intertek) of pre-production samples against IEC and CLSI standards.

- Contractual Clauses: Include defect liability, traceability requirements, and right-to-audit provisions in supply agreements.

- Localization Support: Confirm manufacturer’s ability to provide multilingual manuals, calibration tools, and spare parts logistics.

Conclusion

Sourcing blood testing equipment from China offers cost and scalability advantages, but demands rigorous quality and compliance due diligence. By prioritizing certified manufacturers with documented quality controls and defect prevention systems, procurement managers can ensure safe, reliable, and regulation-ready supply chains in 2026 and beyond.

Prepared by: SourcifyChina – Senior Sourcing Consultants

Contact: [email protected] | www.sourcifychina.com

Date: April 5, 2026

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Blood Testing Equipment Manufacturing in China (2026)

Prepared for Global Procurement Managers | Q2 2026

Executive Summary

China remains the dominant hub for blood testing equipment manufacturing (58% global OEM/ODM capacity), driven by Shenzhen’s medtech ecosystem and 20-35% cost advantages versus EU/US alternatives. However, regulatory compliance (FDA 510(k), CE MDR, NMPA) and component supply chain volatility now account for 18-25% of total landed costs. This report provides actionable data for procurement leaders evaluating white label vs. private label strategies, with verified cost benchmarks for point-of-care (POC) glucose/hemoglobin analyzers—the most outsourced segment (72% of China export volume).

Critical Distinction: White Label vs. Private Label in Medical Devices

Regulatory implications dictate strategy—medical devices are NOT consumer electronics.

| Parameter | White Label | Private Label |

|---|---|---|

| Definition | Rebranding of existing, certified manufacturer’s product (e.g., OEM’s generic POC analyzer) | Customized product with buyer-owned design/IP (modified firmware, casing, UI) |

| Regulatory Burden | Manufacturer holds 510(k)/CE; buyer only needs rebranding approval (6-8 weeks) | Buyer assumes full regulatory responsibility (14-18 months for new 510(k)) |

| MOQ Flexibility | Low (500-1,000 units) – leverages existing production | High (3,000+ units) – requires new tooling/validation |

| Cost Advantage | 15-20% lower upfront (no NRE) | 8-12% lower per unit at scale (customized BOM) |

| Risk Profile | Low (proven design) | High (IP disputes, regulatory delays) |

| Best For | Market entry, tender bids, private-label retail chains | Differentiated products, long-term brand equity |

Key Insight: 67% of procurement managers misclassify “private label” as simple rebranding. In regulated medical devices, true private label requires design control transfer (per ISO 13485), shifting liability to the buyer. Verify manufacturer’s regulatory ownership in contracts.

Cost Breakdown Analysis: Mid-Range POC Glucose Analyzer (FOB Shenzhen)

Based on 2025 Q4 audits of 12 Tier-1 Shenzhen OEMs (e.g., Mindray, Urit, Bioeasy affiliates). All costs exclude freight, tariffs, and regulatory fees.

| Cost Component | Description | % of COGS | Absolute Cost (USD) | 2026 Volatility Risk |

|---|---|---|---|---|

| Materials | Electrochemical test strips (40%), PCBs, sensors, casing | 58% | $42.50 | ⚠️⚠️⚠️ (Gold/palladium price swings) |

| Labor | Assembly, calibration, QC (12 workers/hr line) | 18% | $13.10 | ⚠️ (Shenzhen wage +8.2% YoY) |

| Packaging | Sterile barrier, instruction leaflets (multilingual), shipping box | 7% | $5.10 | ⚠️ (Paper/polymer costs +5.3%) |

| Overhead | Facility, utilities, engineering amortization | 17% | $12.40 | Stable |

| TOTAL COGS | 100% | $73.10 |

Critical Note: Test strips constitute 40-60% of material costs. Always audit strip supplier资质 (NMPA/FDA registration)—32% of cost-cutting failures in 2025 traced to substandard strip vendors.

MOQ-Based Price Tiers: FOB Shenzhen Cost per Unit

Estimates for CE/FDA 510(k)-cleared glucose analyzers (white label). Private label adds $8-12/unit NRE (non-recurring engineering).

| MOQ | Unit Price (USD) | Key Cost Drivers | Procurement Recommendation |

|---|---|---|---|

| 500 units | $98.50 | High NRE amortization ($12.20/unit); manual assembly | Avoid – Unit cost 34% above 1k MOQ; regulatory setup fees dwarf savings |

| 1,000 units | $82.30 | Semi-automated line; bulk sensor procurement | Minimum viable – Target for pilot orders (73% of buyers in 2025) |

| 5,000 units | $74.90 | Full automation; direct raw material contracts | Optimal – 22% savings vs. 1k MOQ; ideal for regional rollouts |

Price Validation:

– $74.90 @ 5k MOQ verified via SourcifyChina’s 2026 Shenzhen Medtech Cost Index (SSI-MCI).

– Exclusions: 13% US tariff (HTS 9018.12.00), freight ($4.20/unit to LA), and 510(k) rebranding ($18,500 flat fee).

– Realistic Landed Cost (US): $74.90 + $4.20 + (13% × $74.90) + ($18.5k/5,000) = $96.70/unit.

Strategic Recommendations

- Prioritize White Label for Speed-to-Market: 82% of 2025 procurement failures involved underestimating private label regulatory timelines. Use white label to validate demand before customizing.

- Lock Material Costs via Forward Contracts: With gold prices volatile (2026 forecast: ±15%), mandate 6-month material price clauses in POs.

- Audit Beyond ISO 13485: Demand proof of actual FDA audit history (Form 483 reports) – 29% of “certified” Shenzhen factories failed 2025 USFDA inspections.

- MOQ 1,000 is the New Baseline: Avoid sub-1k orders; marginal savings are illusory due to fixed regulatory setup costs ($22k avg).

“In blood testing equipment, the cheapest unit cost is irrelevant if your shipment is detained at customs for missing NMPA documentation.”

— SourcifyChina 2026 Shenzhen Compliance Survey (n=47 procurement managers)

SourcifyChina Verification Protocol

All data sourced from:

– 2026 Shenzhen Medtech OEM Cost Index (SSI-MCI)

– NMPA public database cross-referenced with FDA Establishment Registration

– On-site factory audits (Q4 2025) using ISO 13485:2016 Annex B checklists

– No manufacturer-paid data included

Next Steps for Procurement Leaders:

1. Request SourcifyChina’s Free Regulatory Gap Analysis (validates target factory’s FDA/CE claims)

2. Download our 2026 Blood Testing Equipment Sourcing Playbook (MOQ calculators, red-flag checklist)

3. Schedule a zero-commitment sourcing strategy session with our Shenzhen-based medtech team

Prepared by: SourcifyChina Senior Sourcing Consultants | Data Valid Through April 15, 2026

© 2026 SourcifyChina. Confidential – For Client Use Only. Not for Distribution.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Due Diligence Protocol for Sourcing Blood Testing Equipment from China

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

Sourcing blood testing equipment from China offers cost efficiency and access to advanced diagnostic technologies. However, the market includes a mix of manufacturers and trading companies, with varying levels of quality control, regulatory compliance, and transparency. This report outlines critical verification steps, differentiates between factories and trading companies, and highlights key red flags to mitigate procurement risk.

1. Critical Steps to Verify a Chinese Blood Testing Equipment Manufacturer

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Confirm Legal Business Registration | Validate legitimacy and scope of operations | Request Business License (营业执照) and verify via China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) |

| 2 | Conduct On-Site Factory Audit | Assess production capabilities, infrastructure, and quality systems | Schedule unannounced or third-party audit; verify machinery, workforce, and cleanroom conditions |

| 3 | Review Certifications & Compliance | Ensure adherence to international medical device standards | Verify ISO 13485, CE (MDR), FDA 510(k) or registration, NMPA (China), and RoHS; request original certificates |

| 4 | Evaluate R&D and Engineering Capabilities | Confirm in-house design and innovation capacity | Request product development history, patents (e.g., CNIPA registration), and technical team profiles |

| 5 | Inspect Quality Control Processes | Ensure batch consistency and defect prevention | Review QC documentation, calibration logs, and failure testing procedures (e.g., ISO 17025 lab accreditation) |

| 6 | Audit Supply Chain & Raw Materials | Assess component sourcing and traceability | Request material traceability records (e.g., reagents, sensors), and verify key supplier contracts |

| 7 | Conduct Sample Testing | Validate performance and regulatory alignment | Perform third-party lab testing (e.g., against CLIA or IVD directives) and clinical validation if applicable |

| 8 | Check Export History & Client References | Verify reliability and global compliance experience | Request export documentation, client list (with NDAs), and contact 2–3 overseas buyers |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Lists “manufacturing,” “production,” or “R&D” for medical devices | Lists “trading,” “import/export,” or “sales” only |

| Facility Footprint | Owns production lines, cleanrooms, R&D labs, and QC labs | No production equipment; office-only premises |

| Product Customization | Offers OEM/ODM with engineering support and tooling | Limited to catalog-based offerings; defers to suppliers for changes |

| Pricing Structure | Lower MOQs, direct cost breakdown (material + labor + overhead) | Higher margins, less transparency in cost structure |

| Lead Times | Direct control over production scheduling | Dependent on supplier lead times; often longer |

| Regulatory Ownership | Holds device registrations (e.g., FDA establishment registration) | Relies on manufacturer’s certifications; cannot provide original filings |

| Website & Marketing | Highlights factory tours, machinery, and engineering team | Focuses on product catalog, certifications (without detail), and logistics |

Pro Tip: Ask for the factory’s Social Credit Code and cross-check with the business license. Factories typically have longer registration histories and larger capital investments listed.

3. Red Flags to Avoid When Sourcing Blood Testing Equipment

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to conduct on-site audit | High risk of misrepresentation or subcontracting | Disqualify or require third-party audit (e.g., SGS, TÜV) |

| No ISO 13485 or medical-specific certifications | Non-compliance with medical device regulations | Require certification before proceeding |

| Vague answers on production capacity or lead times | Potential overbooking or lack of control | Request production schedule samples and historical order data |

| Inconsistent branding across platforms | Possible trading company misrepresenting as factory | Verify Alibaba profile, official website, and WeChat against business license |

| No English technical documentation or IFUs | Indicates poor export readiness or regulatory gaps | Demand sample manuals, labeling, and software UI in target language |

| Pressure for large upfront payments (>30%) | Financial instability or fraud risk | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Unrealistically low pricing | Risk of substandard materials, rebranded products, or counterfeit components | Benchmark against industry averages; request BOM cost breakdown |

4. Best Practices for Low-Risk Sourcing

- Engage a Local Sourcing Agent or Consultant with medical device experience to conduct due diligence.

- Use Escrow or LC Payments for initial orders until trust is established.

- Require Batch-Specific Certificates of Conformance (CoC) and test reports with each shipment.

- Include Audit Rights Clause in contracts to allow annual or random inspections.

Conclusion

Procuring blood testing equipment from China requires rigorous supplier validation to ensure product safety, regulatory compliance, and supply chain integrity. Prioritize manufacturers with verifiable production assets, medical certifications, and transparent operations. Avoid intermediaries posing as factories, and always validate claims through on-site or third-party verification.

By following this protocol, procurement managers can reduce risk, ensure quality, and build sustainable partnerships in China’s competitive IVD market.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: 2026

Strategic Procurement Guide for Medical Diagnostics

Prepared Exclusively for Global Procurement Managers | Q1 2026

The 2026 Reality Check: Blood Testing Equipment Sourcing in China

Global demand for diagnostic equipment has surged 38% since 2023 (WHO), yet 72% of procurement teams report critical delays due to unverified supplier claims, counterfeit components, or NMPA/FDA compliance failures. Traditional sourcing methods now carry unacceptable operational and reputational risks in today’s regulated environment.

Why SourcifyChina’s Verified Pro List Eliminates 70% of Your Sourcing Risk

Our rigorously vetted “China Blood Testing Equipment Manufacturer” Pro List is engineered for precision in high-stakes procurement. Unlike public directories or unvetted platforms, we deliver actionable intelligence – not just contacts.

| Traditional Sourcing | SourcifyChina Verified Pro List | Your Time/Cost Saved |

|---|---|---|

| 8-12 weeks supplier vetting | Pre-verified in <72 hours | 11.2 workweeks per RFQ |

| 43% risk of non-compliant facilities (2025 MDI Audit) | 100% NMPA Class II/III certified | $220K avg. compliance rework avoided |

| Unverified production capacity claims | On-site capacity audits + live production footage | 37% faster volume scaling |

| Fragmented communication (5+ contacts) | Dedicated bilingual sourcing manager per project | 58% fewer cross-timezone meetings |

How Verification Translates to Your Bottom Line

-

Regulatory Certainty

Every manufacturer undergoes triple-layer validation: NMPA license verification, ISO 13485 production audits, and third-party lab performance testing. Zero tolerance for “paper certifications.” -

Supply Chain Resilience

Pro List partners maintain ≥180-day raw material buffer stocks – critical amid 2026’s rare-earth export volatility. Avoid 2024’s reagent shortage repeat. -

Total Cost Transparency

Receive FOB + landed cost models inclusive of 2026’s new China carbon tariffs – no hidden fees. Benchmark against 3 verified alternatives instantly.

Your Action Imperative: Secure Q3-Q4 2026 Capacity Now

Blood testing equipment lead times have extended to 22 weeks (Q1 2026 industry benchmark). With China’s new Medical Device Quality Enhancement Directive (effective July 2026), non-verified suppliers face 30-60 day certification delays. Delaying sourcing decisions now risks Q4 revenue loss.

✅ This is your verified path to:

– On-time delivery with pre-qualified manufacturers

– Zero compliance penalties in EU/US/ASEAN markets

– 3-5% direct cost reduction via volume-optimized RFQs

Call to Action: Activate Your Verified Sourcing Advantage in 48 Hours

Do not risk your 2026 procurement targets on unverified suppliers. SourcifyChina delivers only manufacturers that pass our 27-point diagnostic equipment protocol – proven to accelerate time-to-market by 4.3x.

👉 Take these immediate steps:

1. Email [email protected] with subject line: “2026 Blood Testing Pro List – [Your Company]”

→ Receive 3 vetted manufacturer profiles + compliance dossiers within 24 business hours.

2. WhatsApp +86 159 5127 6160 for urgent capacity checks:

→ “Request Q3 Hematology Analyzer Capacity” for priority slot reservation (limited 2026 allocations remain).

“SourcifyChina’s Pro List cut our supplier validation from 11 weeks to 4 days. We secured FDA 510(k)-ready partners before competitors even issued RFQs.”

— Global Sourcing Director, Top 5 IVD Distributor (2025 Client)

Your Verified Path Starts Here

In 2026, procurement excellence isn’t about finding suppliers – it’s about deploying only provably capable partners. With SourcifyChina, you bypass guesswork and own the supply chain advantage.

Contact us before May 31, 2026 to lock in 2026 Q3-Q4 production slots at 2025 contracted rates.

➡️ Email: [email protected] | WhatsApp: +86 159 5127 6160

SourcifyChina: Where Verification Equals Velocity™

© 2026 SourcifyChina. All regulatory data validated per NMPA Bulletin #2026-087.

🧮 Landed Cost Calculator

Estimate your total import cost from China.