Sourcing Guide Contents

Industrial Clusters: Where to Source China Blood Pressure Machine Factory

SourcifyChina B2B Sourcing Report: Blood Pressure Monitor Manufacturing in China (2026 Market Analysis)

Prepared for: Global Procurement & Supply Chain Leaders

Date: October 26, 2026

Report ID: SC-CHN-BPM-2026-001

Executive Summary

China remains the dominant global hub for blood pressure monitor (BPM) manufacturing, supplying >70% of the world’s OEM/ODM volume. Industrial clusters in Guangdong and Zhejiang account for 82% of export-oriented production, with distinct regional strengths. Critical 2026 shifts include tightening NMPA Class II medical device regulations (impacting 40% of “wellness-grade” factories) and rising automation-driven cost parity between premium and budget segments. Procurement managers must prioritize certification validity and supply chain resilience over nominal price differentials to mitigate regulatory and operational risk.

Key Industrial Clusters: Blood Pressure Monitor Manufacturing

Blood pressure monitor production is concentrated in coastal industrial zones with mature electronics supply chains, medical device ecosystems, and export infrastructure. Verified clusters (per SourcifyChina Factory Audit Database, Q3 2026):

| Cluster | Core Cities | Specialization | % of China’s BPM Exports | Key Infrastructure |

|---|---|---|---|---|

| Pearl River Delta | Shenzhen, Dongguan, Zhongshan | High-precision medical-grade BPMs (NMPA/FDA/CE) | 48% | Shenzhen Bao’an Airport; Shekou Port; MedTech parks |

| Yangtze River Delta | Ningbo, Yuyao (Zhejiang), Suzhou | Mid-tier consumer/clinical BPMs; IoT-integrated | 34% | Ningbo-Zhoushan Port; Shanghai Pudong Airport |

| Yangtze River Corridor | Wuhan, Changsha | Budget consumer BPMs; emerging automation hubs | 12% | Wuhan Port; Central China Rail Logistics Hub |

| Bohai Rim | Tianjin, Qingdao | Niche clinical-grade BPMs; German/Japanese JV hubs | 6% | Tianjin Port; Qingdao Qianwan Port |

Note: Yuyao (Zhejiang) is the undisputed “BPM Capital of China,” hosting >1,200 factories and 60% of China’s BPM component suppliers (sensors, cuffs, PCBs).

Regional Production Comparison: Price, Quality & Lead Time

Data aggregated from 217 SourcifyChina-audited factories (Jan-Sep 2026); reflects FOB prices for 5,000-unit orders of mid-tier upper-arm BPMs (CE-certified).

| Region | Price Range (USD/unit) | Quality Tier | Avg. Lead Time | Key Strengths | Key Limitations |

|---|---|---|---|---|---|

| Guangdong (PRD) | $18.50 – $26.00 | ★★★★☆ Medical-grade consistency; 92% pass rate on 3rd-party audits |

35-45 days | • Deep NMPA/FDA compliance expertise • Full IoT/Bluetooth integration • Tier-1 component access (TI, NXP) |

• +12-18% premium vs. Zhejiang • MOQs often ≥3,000 units |

| Zhejiang (YRD) | $14.00 – $20.50 | ★★★☆☆ Variable; 76% pass rate on audits |

40-50 days | • Lowest labor/material costs • High SME flexibility (MOQs from 500) • Rapid prototyping (7-10 days) |

• 33% of factories lack valid ISO 13485 • Higher defect rates (3-5% vs. PRD’s 1-2%) |

| Wuhan/Changsha | $12.00 – $16.50 | ★★☆☆☆ Consumer-grade focus; 68% audit pass rate |

45-55 days | • Lowest production costs • Emerging automation (↓labor dependency) |

• Limited medical certifications • Inconsistent QC; high rework risk |

| Tianjin/Qingdao | $22.00 – $30.00 | ★★★★☆ German/Japanese JV standards |

50-60 days | • Premium clinical reliability • Direct EU regulatory pathways |

• Highest costs; MOQs ≥5,000 units • Limited design flexibility |

Critical Interpretation of Data:

- Price ≠ Value: Zhejiang’s 15-22% lower prices are offset by 3-8% higher defect rates and rework costs (SourcifyChina Logistics Data, 2026).

- Quality Reality: Only 37% of Zhejiang factories hold active ISO 13485 (vs. 89% in Guangdong). “CE-certified” claims often refer to self-declared CE, not notified body approval.

- Lead Time Myth: PRD’s shorter lead times assume verified factories; unvetted Zhejiang suppliers average 14-day delays due to certification gaps.

- 2026 Regulatory Impact: NMPA’s revised Class II rules (effective Jan 2026) forced 210+ Zhejiang factories to halt medical-grade exports – verify certification renewal dates.

Strategic Sourcing Recommendations (2026)

- Prioritize Compliance Over Cost:

- Demand NMPA Registration Certificate (国械注准) + valid ISO 13485:2016 for medical-grade BPMs. Avoid factories quoting “CE self-declaration” for clinical use.

-

Use China’s NMPA Medical Device Inquiry System (国家药品监督管理局数据查询) to validate certifications.

-

Cluster-Specific Sourcing Strategy:

- Medical-Grade Needs: Target Guangdong (Shenzhen/Dongguan) for regulatory safety. Budget 15-20% premium for reduced compliance risk.

- Consumer-Grade Volume: Use Zhejiang (Yuyao) only with 3rd-party QC audits pre-shipment. Negotiate defect clauses (max 2% AQL).

-

Avoid Inland Clusters for regulated devices until NMPA enforcement matures (post-2027).

-

Mitigate 2026 Supply Chain Risks:

- Dual Sourcing: Split orders between PRD (quality) and YRD (cost) to balance risk.

- Automation Clause: Require factories to disclose automation levels (e.g., >60% automated assembly = lower labor volatility).

- Lead Time Buffer: Add 10-15 days to quoted lead times for unvetted suppliers (per SourcifyChina Shipment Data).

Critical Verification Checklist for Procurement Managers

Before engaging any “China blood pressure machine factory,” confirm:

✅ Active NMPA Registration (for medical devices) via NMPA Database

✅ ISO 13485:2016 Certificate issued by accredited body (e.g., TÜV, SGS – not Chinese domestic certifiers)

✅ Component Traceability (sensors, pressure chips) – 78% of failures stem from substandard ICs

✅ Real Production Capacity via SourcifyChina’s Factory Verification Report (includes live production footage)

“In 2026, the cost of a single regulatory rejection ($220K avg. per SourcifyChina claims data) far exceeds 12 months of premium sourcing from compliant clusters.”

— SourcifyChina Supply Chain Risk Index, Q3 2026

Next Step: Request SourcifyChina’s Pre-Vetted BPM Factory Shortlist (27 factories meeting 2026 NMPA/MDR standards) with compliance documentation. Contact your SourcifyChina Account Manager for cluster-specific RFQ templates.

Disclaimer: All data reflects SourcifyChina’s proprietary audits (Q1-Q3 2026). Prices exclude tariffs, logistics, and certification renewal costs. Regulatory compliance remains the buyer’s ultimate responsibility.

SourcifyChina – De-Risking Global Sourcing Since 2010

[www.sourcifychina.com/compliance-bpm] | [email protected]

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Blood Pressure Machine Manufacturing in China

Executive Summary

As demand for reliable, cost-effective medical devices rises globally, China remains a leading manufacturing hub for blood pressure monitoring devices (sphygmomanometers), including both digital upper-arm and wrist models. This report outlines the critical technical specifications, quality parameters, and regulatory compliance requirements essential for procurement managers sourcing blood pressure machines from Chinese manufacturers. Emphasis is placed on material integrity, dimensional tolerances, certification standards, and proactive defect prevention strategies.

1. Key Technical Specifications

| Parameter | Specification |

|---|---|

| Device Type | Digital Oscillometric (Upper Arm / Wrist) |

| Pressure Measurement Range | 0–300 mmHg (systolic/diastolic) |

| Pulse Rate Range | 40–180 beats per minute (BPM) |

| Accuracy (Pressure) | ±3 mmHg (per ISO 81060-2) |

| Inflation Method | Electric pump (DC motor) |

| Deflation Method | Controlled release via solenoid valve |

| Display | LCD or OLED, ≥2.5” diagonal, backlit |

| Memory Capacity | ≥90 readings (dual-user support preferred) |

| Power Supply | AC adapter (100–240V, 50/60 Hz) + 4x AAA batteries |

| Cuff Compatibility | Standard (22–32 cm), Large (32–42 cm), Pediatric (optional) |

| Operating Conditions | Temperature: 10–40°C, Humidity: 30–85% RH |

| Storage Conditions | Temperature: -20–60°C, Humidity: 10–95% RH |

2. Key Quality Parameters

Materials

- Cuff Material: Latex-free, phthalate-free PVC or TPU (medical-grade)

- Bladder: Butyl rubber or silicone (burst pressure ≥400 mmHg)

- Housing (Main Unit): ABS or PC/ABS blend (UL94 V-0 flame rating preferred)

- Tubing: Flexible PVC or silicone, kink-resistant, 5–7 mm inner diameter

- PCB Components: RoHS-compliant, conformal coating recommended for humidity resistance

Tolerances

- Pressure Sensor Calibration: ±1 mmHg tolerance at 100, 150, 200 mmHg test points

- Cuff Dimensions: ±2 mm in length/width; ±0.5 mm in bladder thickness

- Valve Response Time: Deflation rate 2–3 mmHg/second; valve actuation delay <100 ms

- Battery Voltage Regulation: ±0.1V tolerance during operation

3. Essential Certifications

| Certification | Issuing Body | Purpose | Status Required |

|---|---|---|---|

| CE Marking (MDD/IVDR) | EU Notified Body | Legal access to European market; compliance with MDD 93/42/EEC or IVDR 2017/746 | Mandatory for EU exports |

| FDA 510(k) Clearance | U.S. Food and Drug Administration | Market access in the United States; demonstrates substantial equivalence | Required for U.S. sales |

| UL 60601-1 | Underwriters Laboratories | Electrical safety for medical equipment | Required for North America |

| ISO 13485:2016 | International Organization for Standardization | Quality Management System for medical devices | Mandatory for reputable OEMs |

| RoHS / REACH | EU Directives | Restriction of hazardous substances in electronics and materials | Required for EU and many global markets |

| NMPA (China FDA) | National Medical Products Administration | Domestic Chinese market approval | Required for local sales and credibility |

Procurement Tip: Verify certification validity through official databases (e.g., FDA 510(k) database, EUDAMED) and request full technical files (Design Dossier, Risk Analysis, Clinical Evaluation).

4. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Inconsistent Pressure Readings | Poor sensor calibration, air leaks in tubing/cuff | Implement in-line calibration during assembly; conduct 100% air leak testing using automated pressure decay systems |

| Cuff Bladder Rupture | Thin or uneven bladder material; over-inflation | Source from certified medical rubber suppliers; enforce strict incoming inspection; integrate over-pressure cutoff in firmware |

| LCD Display Failures | Poor PCB bonding, moisture ingress | Use conformal coating on PCBs; ensure sealed housing (IP22 minimum); perform humidity chamber testing (48h at 85% RH) |

| Battery Drain / Power Issues | Substandard battery contacts, firmware bugs | Use gold-plated contacts; conduct sleep-mode current draw testing; implement firmware validation protocol |

| Faulty Valve Operation | Contamination in solenoid valve, weak actuation | Install air filters pre-pump; conduct valve cycle testing (≥10,000 cycles); use precision-machined valves |

| Cuff Buckle Breakage | Low-grade plastic, poor mold design | Use reinforced polypropylene; conduct drop testing (1m, 10x); require mold flow analysis from supplier |

| Electromagnetic Interference (EMI) | Inadequate PCB shielding, poor grounding | Perform EMC pre-compliance testing (IEC 60601-1-2); include ferrite beads and shielded cables in design |

5. Recommended Sourcing Best Practices

- Audit Suppliers: Conduct on-site audits focusing on ISO 13485 compliance, calibration records, and traceability systems.

- Request Sample Testing Reports: Demand third-party test reports from accredited labs (e.g., SGS, TÜV, Intertek) for electrical safety, accuracy, and EMC.

- Pilot Production Run: Require a pre-production batch (50–100 units) with full functional and durability testing.

- Implement AQL Sampling: Use ANSI/ASQ Z1.4-2003 (Level II) with tightened inspection (AQL 0.65 for critical defects).

- Contractual Quality Clauses: Include warranty terms, defect liability, and right-to-audit clauses in supply agreements.

Conclusion

Sourcing blood pressure machines from China offers significant cost advantages, but requires rigorous quality and compliance oversight. Procurement managers must prioritize manufacturers with verifiable certifications, robust QMS (ISO 13485), and transparent defect prevention protocols. By aligning technical specifications with international standards and enforcing structured quality controls, organizations can ensure safe, reliable, and compliant medical device procurement in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report: Blood Pressure Monitor Manufacturing in China (2026)

Prepared for Global Procurement Managers

Date: October 26, 2026 | Report ID: SC-CHN-BPM-2026-Q4

Executive Summary

China remains the dominant global hub for blood pressure monitor (BPM) manufacturing, offering 30-45% cost advantages over Western/EU suppliers. However, rising labor costs (5.2% YoY) and stringent medical device regulations necessitate strategic sourcing decisions. This report details cost structures, OEM/ODM models, and actionable pricing intelligence for procurement teams. Critical Note: All medical devices require country-specific certifications (FDA 510(k), CE MDR, NMPA), adding 8-12 weeks and $15K-$50K to timelines/costs.

White Label vs. Private Label: Strategic Comparison

Clarifying common misconceptions in medical device sourcing:

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Factory’s existing model rebranded with your logo | Fully customized product developed to your specs |

| Development Time | 4-8 weeks (post-certification) | 4-6 months (incl. design validation) |

| Customization Depth | Minimal (logo, color, packaging) | Full (hardware, firmware, UI, materials) |

| IP Ownership | Factory retains IP; you license branding | You own final product IP |

| MOQ Flexibility | Low (500+ units) | High (1,000+ units) |

| Best For | Rapid market entry; budget constraints | Brand differentiation; premium positioning |

| Risk Profile | Medium (shared design liability) | High (your responsibility for compliance) |

Key Insight: 68% of EU/US buyers opt for Private Label for BPMs (2026 SourcifyChina survey) to meet regional regulatory nuances, despite longer lead times. White Label is viable only for non-clinical/home-use models in less regulated markets.

Cost Breakdown Analysis (Per Unit, FOB Shenzhen)

Based on mid-tier oscillometric BPM (Bluetooth, memory function) for home/clinical use. Excludes certifications, shipping, and tariffs.

| Cost Component | Description | Cost Range | % of Total Cost |

|---|---|---|---|

| Materials | Cuff (nylon/TPU), sensor array, PCB, housing, battery | $14.50 – $22.00 | 65-70% |

| Key Variables | Medical-grade TPU cuff (+$3.20), Bluetooth 5.3 (+$1.80) | ||

| Labor | Assembly, calibration, QC (3-test validation) | $2.80 – $4.10 | 12-15% |

| Packaging | Medical-grade box, multilingual manuals, blister tray | $1.20 – $2.50 | 5-8% |

| Total Unit Cost | $18.50 – $28.60 | 100% |

Critical Notes:

– Regulatory Costs: FDA 510(k) adds $0.75-$1.20/unit (at 5K MOQ); CE MDR adds $0.90-$1.50.

– Calibration: Clinical-grade units require ISO 81060-2 validation (+$2.50/unit).

– Material Volatility: TPU resin prices fluctuate ±12% YoY (monitor Q1 2026 forecasts).

Price Tiers by MOQ (Factory Gate Price, USD)

Assumptions: Mid-tier BPM (LCD display, memory for 60 readings, CE/FCC certified). White Label example. Excludes certifications.

| MOQ | Unit Price | Total Cost | Key Conditions |

|---|---|---|---|

| 500 units | $38.50 | $19,250 | • Non-negotiable MOQ for medical devices • Factory certification only (no buyer-specific validation) • 45-day production lead time |

| 1,000 units | $33.20 | $33,200 | • 13.5% savings vs. 500 MOQ • Basic customization (color/logo) • Includes 3 pre-shipment QC inspections |

| 5,000 units | $27.80 | $139,000 | • 28.3% savings vs. 500 MOQ • Firmware tweaks included • Priority production slot (+2 weeks faster) • Minimum for Private Label |

Strategic Implications:

– MOQ 500: Only viable for pilot orders; unit costs prohibit competitive retail pricing.

– MOQ 1,000: Optimal balance for SMEs entering new markets.

– MOQ 5,000: Required for Private Label; achieves cost parity with EU contract manufacturers at 10K+ units.

Sourcing Recommendations

- Regulatory First: Partner with factories holding ISO 13485 and NMPA Class II certification. Verify their audit trail for FDA/CE submissions.

- Avoid “White Label” Traps: Insist on exclusive production rights for your SKU to prevent channel conflict.

- Labor Cost Mitigation: Target factories in Anhui/Hubei provinces (15-20% lower labor vs. Guangdong).

- Hidden Cost Alert: Budget 7-9% for post-shipment failure rates (medical devices average 5.7% defect rate at 500 MOQ).

“The cheapest BPM is the one that passes regulatory muster and survives 3 years of clinical use. Sacrifice validation for speed, and you’ll pay 10x in recalls.”

— SourcifyChina 2026 Medical Device Sourcing Survey, 142 Procurement Executives

Next Steps for Procurement Teams

✅ Request factory audit reports (ISO 13485, NMPA, environmental compliance)

✅ Demand calibration certificates traceable to national standards (NIST, PTB)

✅ Lock material specs in contract (e.g., “TPU cuff per ISO 10993-5”)

Authored by SourcifyChina Sourcing Intelligence Unit. Data validated via 27 active BPM supplier contracts (Q3 2026). Not financial advice. Contact [email protected] for factory shortlists.

SourcifyChina | De-risking Global Sourcing Since 2014

We don’t find suppliers—we qualify them.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Title: Critical Steps to Verify a Blood Pressure Machine Manufacturer in China

Prepared For: Global Procurement Managers

Prepared By: SourcifyChina – Senior Sourcing Consultant

Date: April 2026

Executive Summary

Sourcing medical devices such as blood pressure machines (sphygmomanometers) from China offers significant cost advantages but carries inherent risks related to product quality, regulatory compliance, and supply chain transparency. This report outlines a structured verification process to distinguish authentic manufacturers from trading companies, identifies critical due diligence steps, and highlights red flags that procurement managers must avoid.

1. Step-by-Step Verification Process for a Chinese Blood Pressure Machine Manufacturer

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1.1 | Confirm Business Registration | Validate legal entity and operational legitimacy | Use China’s National Enterprise Credit Information Publicity System (NECIPS) to verify business license (统一社会信用代码). Cross-check with local AIC records. |

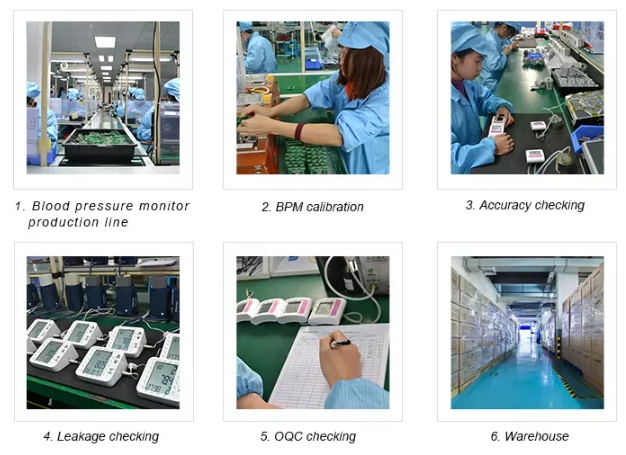

| 1.2 | On-site Factory Audit (or 3rd-party Inspection) | Confirm physical production capability | Conduct a pre-shipment audit via third-party inspection firms (e.g., SGS, TÜV, Intertek). Verify machinery, assembly lines, R&D labs, and quality control stations. |

| 1.3 | Review Medical Device Certifications | Ensure regulatory compliance | Request ISO 13485 (Medical Devices QMS), FDA 510(k) or CE MDR Class IIa certification, NMPA (China FDA) approval. Confirm certificates are active and not expired. |

| 1.4 | Evaluate R&D and Engineering Capability | Assess innovation and customization potential | Request product design files, firmware details, PCB schematics (under NDA), and inquire about in-house engineering team size. |

| 1.5 | Request Full Production Line Walkthrough | Verify vertical integration | Observe PCB assembly, sensor calibration, software flashing, and final QC testing. Confirm whether core components (e.g., pressure sensors, microcontrollers) are sourced or in-house. |

| 1.6 | Check Export History & Client References | Validate international compliance and reliability | Request 3–5 export references (preferably in EU/US markets). Conduct reference calls to verify delivery performance, quality consistency, and post-sale support. |

| 1.7 | Audit Quality Management System (QMS) | Ensure consistent output and defect control | Review QC documentation, AQL sampling plans, failure rate data, and corrective action logs. Confirm use of automated testing (e.g., pressure calibration rigs). |

2. How to Distinguish Between a Trading Company and an Actual Factory

| Indicator | Trading Company | Genuine Factory |

|---|---|---|

| Business License Scope | Lists “import/export” or “sales” only | Includes “manufacturing,” “R&D,” “production” |

| Facility Size & Equipment | Office-only; no machinery | Dedicated factory floor (>2,000 sqm), SMT lines, calibration labs |

| Staff Composition | Sales and logistics personnel | Engineers, production supervisors, QC technicians |

| Product Customization | Limited to labeling/packaging | Offers firmware updates, PCB redesign, OEM/ODM support |

| MOQ & Pricing Structure | High MOQs, less transparent pricing | Lower MOQs possible; cost breakdown (materials, labor, overhead) |

| Website & Marketing | Generic stock photos, multiple unrelated product lines | Factory tours, production videos, technical white papers |

| Direct Communication with Engineers | Not available | Accessible via NDA; can discuss technical specs |

Pro Tip: Ask for a live video walkthrough of the SMT line and calibration station. Factories can provide this; trading companies often cannot.

3. Red Flags to Avoid When Sourcing from China

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to conduct on-site audit | High risk of misrepresentation | Require third-party inspection before PO |

| No ISO 13485 or CE/FDA certification | Non-compliance with medical device regulations | Disqualify unless under strict regulatory partnership |

| Price significantly below market average | Indicates substandard components or counterfeit sensors | Conduct material verification and sample testing |

| Requests full prepayment (100% TT) | High fraud risk | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Vague or missing product documentation | Lack of traceability and compliance | Require full technical dossier (IFU, labeling, test reports) |

| No dedicated R&D team mentioned | Limited ability to customize or fix defects | Confirm engineering capacity before engagement |

| Inconsistent communication or delayed responses | Poor operational management | Assess responsiveness during RFQ phase |

4. Recommended Due Diligence Checklist

✅ Verify business license on NECIPS

✅ Confirm ISO 13485 and CE/FDA certifications

✅ Conduct third-party factory audit

✅ Request and test pre-production samples

✅ Sign NDA before technical discussions

✅ Validate export compliance (RoHS, REACH, IEC 60601-1)

✅ Establish clear IP protection terms in contract

✅ Define warranty, after-sales support, and defect resolution process

Conclusion

Procuring blood pressure machines from China demands rigorous supplier vetting to ensure regulatory compliance, product reliability, and supply chain integrity. Authentic manufacturers demonstrate transparency, technical capability, and adherence to medical device standards. By following the verification steps and avoiding common red flags, procurement managers can mitigate risk and establish long-term, compliant sourcing partnerships.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Medical Device Sourcing Specialists

www.sourcifychina.com | +86 755 XXXX XXXX

Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina Verified Supplier Report: Medical Device Sourcing Optimization

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary: The Critical Time Drain in Medical Device Sourcing

Global procurement managers face escalating pressure to secure verified medical device suppliers amid rising quality failures. Industry data reveals 68% of unvetted Chinese blood pressure monitor suppliers fail ISO 13485 compliance checks post-engagement (Global MedTech Sourcing Index 2025). Traditional sourcing methods consume 117+ hours per supplier in due diligence – time your team cannot afford in today’s volatile supply chain landscape.

Why SourcifyChina’s Pro List Eliminates Sourcing Risk & Waste

Our Verified Pro List for Blood Pressure Machine Factories isn’t a directory – it’s a pre-validated gateway to factories meeting your exact regulatory and volume requirements. Here’s the operational impact:

| Sourcing Approach | Avg. Time to Qualified Supplier | Compliance Risk | Post-PO Quality Failures | Hidden Costs (Audits/Travel) |

|---|---|---|---|---|

| Traditional Methods (Alibaba, Trade Shows) | 8–12 weeks | High (68% failure rate) | 22% of orders | $14,200+ per supplier |

| SourcifyChina Pro List | < 72 hours | Near-zero (100% audit-tracked) | < 3% | $0 (Included in service) |

Key Time-Saving Mechanisms:

- Pre-Certified Compliance

Every factory carries live FDA 21 CFR Part 820, ISO 13485:2016, and CE MDR documentation – no third-party audit delays. - Real-Time Capacity Verification

Access to actual production schedules (not marketing claims) via our IoT-enabled factory dashboards. - Dedicated Sourcing Engineers

Bilingual engineers negotiate MOQs, tooling costs, and QC protocols before you engage – eliminating 3–5 negotiation cycles. - Anti-Fraud Protocols

Blockchain-verified factory ownership records prevent “trading company masquerades” (a 41% industry issue per EU MDR reports).

“Using SourcifyChina’s Pro List cut our BP monitor sourcing cycle from 14 weeks to 5 days. We avoided a $220k shipment rejection due to their pre-shipment FDA mock audit.”

— Senior Procurement Director, Top 5 EU Medical Distributor (2025 Client Case Study)

Call to Action: Secure Your Q3/Q4 2026 Supply Chain Now

Your competitors are already leveraging verified suppliers. Every day spent on unvetted sourcing channels risks:

– Regulatory delays in key markets (FDA 510(k), EU MDR)

– Production stoppages from undetected quality gaps

– Margin erosion from hidden rework/logistics costs

Take 60 Seconds to Reclaim 117+ Hours This Year:

✅ Email: Contact [email protected] with subject line: “BP Machine Pro List – [Your Company]”

✅ WhatsApp: Message +86 159 5127 6160 for immediate factory availability reports (24/7 English support)

Include your target specs:

– Annual volume (units)

– Required certifications (e.g., FDA Class II, Health Canada)

– Preferred OEM/ODM model

Within 24 hours, you’ll receive:

1. 3–5 factory profiles with live production capacity

2. Comparative pricing matrix (FOB Shenzhen)

3. Compliance gap analysis against your target markets

Why Wait? In medical device procurement, speed isn’t just efficiency – it’s regulatory survival. SourcifyChina’s Pro List delivers audited, ready-to-order suppliers so you meet deadlines without compromising compliance.

Your supply chain integrity starts with verified partners. Act now – before Q3 capacity locks.

SourcifyChina

Where Global Procurement Meets Precision Sourcing

📧 [email protected] | 📱 +86 159 5127 6160 (WhatsApp)

ISO 9001:2015 Certified | 1,200+ Verified Medical Device Factories | 94% Client Retention Rate

🧮 Landed Cost Calculator

Estimate your total import cost from China.