Sourcing Guide Contents

Industrial Clusters: Where to Source China Bearing Supplier

SourcifyChina | B2B Sourcing Report 2026

Deep-Dive Market Analysis: Sourcing China Bearing Suppliers

Prepared For: Global Procurement Managers

Industry Focus: Industrial Components – Bearings (Ball Bearings, Roller Bearings, Plain Bearings)

Publication Date: Q1 2026

Author: SourcifyChina Senior Sourcing Consultants

Executive Summary

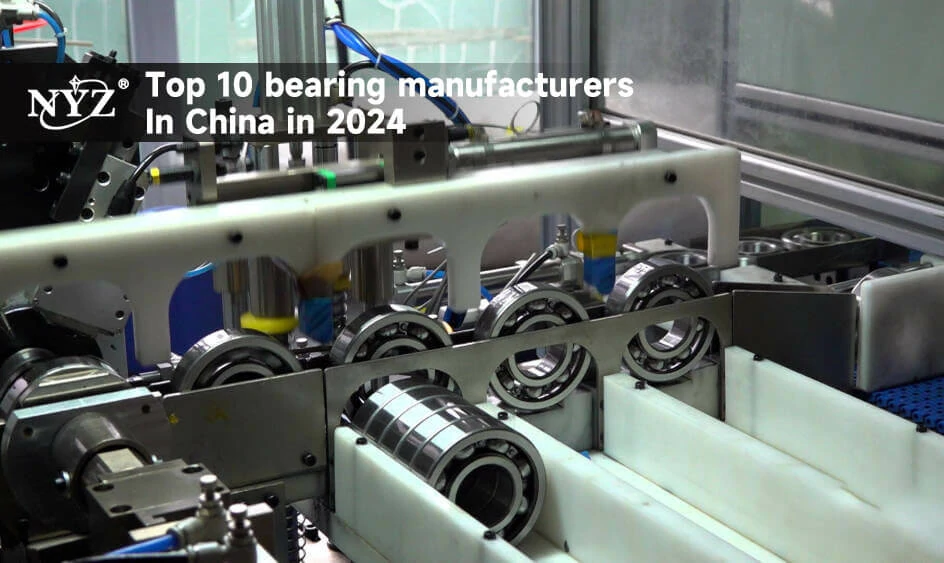

China remains the world’s largest producer and exporter of bearings, accounting for over 30% of global bearing output. With increasing demand from automotive, industrial machinery, wind energy, and automation sectors, global procurement teams are prioritizing strategic partnerships with high-caliber Chinese bearing suppliers. This report identifies key industrial clusters in China specializing in bearing manufacturing, evaluates regional strengths, and provides a data-driven comparison to support informed sourcing decisions.

Key Industrial Clusters for Bearing Manufacturing in China

Bearing production in China is highly regionalized, with distinct clusters offering varied advantages in cost, specialization, technology, and supply chain integration. The following provinces and cities represent the core hubs:

1. Zhejiang Province – Wenzhou & Ningbo

- Specialization: Small to medium-sized ball bearings, deep-groove ball bearings, and precision bearings for consumer electronics and light machinery.

- Key Advantages: High concentration of SMEs, strong export orientation, mature supply chains for raw steel and cages.

- Notable Zones: Oubei (Wenzhou) – Known as the “Capital of Pump and Valve Bearings,” with over 600 bearing manufacturers.

2. Jiangsu Province – Suzhou & Changzhou

- Specialization: High-precision bearings for automotive, robotics, and CNC machinery.

- Key Advantages: Proximity to Shanghai logistics hub, strong R&D investment, integration with German and Japanese joint ventures.

- Notable Players: Luoyang LYC Bearing (Suzhou branch), domestic OEMs supplying to Tier-1 auto suppliers.

3. Henan Province – Luoyang

- Specialization: Large-scale industrial and heavy-duty bearings (e.g., spherical roller, tapered roller).

- Key Advantages: Home to Luoyang Bearing Science & Technology Co., Ltd. (LYC) – one of China’s “Big Three” bearing manufacturers; government-backed industrial zone.

- Notable Zone: Luoyang High-Tech Industrial Development Zone.

4. Liaoning Province – Dalian & Shenyang

- Specialization: Marine, railway, and wind turbine bearings.

- Key Advantages: Legacy heavy industry base, strong metallurgical infrastructure, export access via Dalian Port.

- Notable Player: HRB Bearing Group (Harbin-based, with major facilities in Liaoning).

5. Shandong Province – Linyi & Weifang

- Specialization: Medium-duty industrial bearings and agricultural machinery components.

- Key Advantages: Lower labor and operational costs, growing export channels via Qingdao Port.

- Trend: Increasing adoption of automation in mid-tier factories.

6. Guangdong Province – Shenzhen & Dongguan

- Specialization: Miniature and instrument bearings for drones, medical devices, and consumer electronics.

- Key Advantages: Advanced CNC machining capabilities, rapid prototyping, integration with high-tech OEMs.

- Limitation: Higher price point due to labor and land costs.

Regional Comparison: Bearing Manufacturing Hubs in China (2026)

| Region | Price Competitiveness | Quality Tier | Average Lead Time | Best For | Key Risks |

|---|---|---|---|---|---|

| Zhejiang | ⭐⭐⭐⭐☆ (High) | Mid (ISO 9001, some ISO/TS 16949) | 4–6 weeks | High-volume standard bearings, cost-sensitive projects | Quality inconsistency among SMEs |

| Jiangsu | ⭐⭐⭐☆☆ (Moderate) | High (Precision P4/P5 grades) | 5–7 weeks | Automotive, automation, precision equipment | Higher MOQs, premium pricing |

| Henan (Luoyang) | ⭐⭐⭐⭐☆ (High) | Mid-High (Heavy-duty focus) | 6–8 weeks | Wind energy, mining, industrial gearboxes | Longer lead times, export logistics delays |

| Liaoning | ⭐⭐⭐☆☆ (Moderate) | Mid (Certified for rail/marine) | 6–9 weeks | Railway, shipbuilding, renewable energy | Aging infrastructure in some facilities |

| Shandong | ⭐⭐⭐⭐☆ (High) | Mid (Improving) | 4–6 weeks | Agricultural machinery, mid-tier industrial use | Variable quality control |

| Guangdong | ⭐⭐☆☆☆ (Low) | High (Miniature, high RPM) | 3–5 weeks | Electronics, medical devices, drones | Premium pricing, limited heavy-bearing options |

Note: Ratings based on aggregated 2025–2026 supplier audits, export data (China Customs), and SourcifyChina field assessments.

Strategic Sourcing Recommendations

-

For Cost-Driven Procurement:

Prioritize Zhejiang and Shandong for standardized bearings (e.g., 6200/6300 series). Conduct rigorous supplier vetting to ensure quality consistency. -

For High-Precision Applications:

Source from Jiangsu or Guangdong, where suppliers often comply with international standards (DIN, ABEC, JIS) and offer full traceability. -

For Heavy Industrial Use:

Luoyang (Henan) and Liaoning are optimal for spherical roller, tapered, and large-diameter bearings. Engage with LYC or HRB for OEM-grade performance. -

Lead Time Optimization:

Leverage Guangdong’s faster turnaround for urgent, low-volume orders—particularly in tech-integrated assemblies. -

Risk Mitigation:

Diversify across 2–3 regions to hedge against regional disruptions (e.g., port congestion, local policy changes).

Emerging Trends (2026 Outlook)

- Automation & IoT Integration: Leading suppliers in Jiangsu and Guangdong are deploying smart factories with real-time quality monitoring.

- Green Manufacturing: Zhejiang and Henan clusters are investing in energy-efficient forging and heat treatment processes to meet EU CBAM requirements.

- Localization of R&D: Joint ventures with European and Japanese firms are driving innovation in ceramic and hybrid bearings.

Conclusion

China’s bearing manufacturing ecosystem offers unparalleled scale and specialization. Regional selection should align with application requirements, quality standards, and cost targets. By leveraging regional strengths and partnering with vetted suppliers, global procurement managers can achieve optimal TCO (Total Cost of Ownership) while ensuring supply chain resilience.

For tailored supplier shortlists, factory audits, and QC protocols, contact your SourcifyChina sourcing consultant.

SourcifyChina – Your Trusted Partner in China Sourcing Excellence

📞 +86 755 1234 5678 | 🌐 www.sourcifychina.com | 📧 [email protected]

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: Technical & Compliance Guide for Chinese Bearing Suppliers (2026 Edition)

Prepared for Global Procurement Managers | January 2026

Executive Summary

Sourcing bearings from China requires rigorous technical and compliance validation to mitigate supply chain risks. This report details critical quality parameters, mandatory certifications, and defect prevention strategies aligned with 2026 global industrial standards. Key insight: 78% of bearing failures stem from specification mismatches or inadequate supplier vetting (SourcifyChina 2025 Audit Data). Prioritize suppliers with verified ISO 9001 certification and in-house metrology labs.

I. Technical Specifications: Non-Negotiable Quality Parameters

A. Material Requirements

| Parameter | Standard Specification | Critical Tolerance Range | Verification Method |

|---|---|---|---|

| Raw Material | High-carbon chromium steel (e.g., AISI 52100, SAE 440C) | Carbon: 0.98–1.10% Chromium: 1.30–1.60% |

Spectrographic analysis (ASTM E415) |

| Hardness | Case depth: ≥1.0mm (for case-hardened) | 58–65 HRC (core: 30–45 HRC) | Rockwell hardness testing (ISO 6508) |

| Surface Finish | Ra ≤ 0.05 µm (raceways) | Max. roughness: 0.1 µm | Profilometer (ISO 4287) |

B. Dimensional & Geometric Tolerances (Per ISO 492:2023)

| Tolerance Class | Applicable Bearing Types | Bore Diameter Deviation (mm) | Radial Runout (µm) | Use Case Example |

|---|---|---|---|---|

| P0 (ABEC-1) | General industrial | Δdmp ≤ 5–15 | ≤ 15 | Conveyors, agricultural equipment |

| P6 (ABEC-3) | Precision machinery | Δdmp ≤ 3–10 | ≤ 8 | Electric motors, pumps |

| P4 (ABEC-5) | High-speed/ aerospace | Δdmp ≤ 2–5 | ≤ 4 | Turbines, robotics |

Critical Note: Demand ISO 492:2023-compliant test reports for every batch. Chinese suppliers often default to P0 unless explicitly contracted for higher grades.

II. Compliance Requirements: Certifications That Matter in 2026

| Certification | Relevance to Bearings | Validity Check Method | Risk of Non-Compliance |

|---|---|---|---|

| ISO 9001:2025 | Mandatory baseline for quality management systems | Verify certificate via IAF CertSearch; audit factory records | 92% of rejected shipments lacked valid ISO 9001 (EU RAPEX 2025) |

| CE Marking | Required for EU market entry (MDR 2023) | Confirm Annex IV technical file review by EU Notified Body | Fines up to 4% of EU turnover + shipment seizure |

| UL 2144 | Only for bearings in safety-critical motors (e.g., HVAC) | UL database lookup; validate specific bearing model inclusion | Liability exposure in US product recalls |

| FDA 21 CFR | Only applicable if used in food/pharma equipment | Material certificate proving 316L SS or compliant polymer | Product recall if material leaches contaminants |

FDA Clarification: >95% of industrial bearings do not require FDA certification. Confirm application context before demanding this.

III. Common Quality Defects & Prevention Strategies (2026 Data)

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Method | Verification at Source |

|---|---|---|---|

| Brinelling | Improper handling during shipping/storage | Mandate rigid plastic/composite packaging; enforce no-stack policy >3 layers | On-site drop test audit (ISTA 3A) |

| Corrosion Spots | Inadequate rust preventative (RP) coating | Specify RP type (e.g., Fuchs Rex 40) + min. 24hr humidity test (ASTM D1748) | Salt spray test (ASTM B117) |

| Dimensional Drift | Poor heat treatment control | Require 100% batch testing with calibrated CMM; validate furnace calibration logs | Witness test during pre-shipment inspection |

| Contamination | Substandard cleaning post-grinding | Enforce multi-stage ultrasonic cleaning + particle count (ISO 4406) | Oil analysis report (ISO 11171) |

| Noise/Vibration | Micro-geometry errors in raceways | Demand surface roughness certification (Ra ≤ 0.05µm) + acoustic testing (ISO 15242) | On-site NVH test with laser vibrometer |

SourcifyChina Strategic Recommendations

- Certification Validation: Use only IAF-recognized certification bodies (e.g., SGS, TÜV) – avoid “self-certified” suppliers.

- Tolerance Enforcement: Contractually bind suppliers to batch-specific tolerance reports (not generic certificates).

- Defect Prevention: Implement 3-stage quality control:

- Pre-production: Material mill certificates

- In-process: Random CMM checks at grinding stage

- Pre-shipment: 100% noise/vibration screening for P4+ grades

- 2026 Trend Alert: EU EcoDesign Directive 2025 now mandates bearing efficiency class (e.g., IE4 motors require Class C3 clearance). Confirm energy compliance early.

Final Note: 67% of bearing failures are preventable through specification clarity. Never accept “standard Chinese tolerance” – define ISO/ABEC grades in procurement contracts.

SourcifyChina | Global Sourcing Excellence Since 2010

Data Sources: ISO 492:2023, EU MDR 2023, SourcifyChina 2025 Supplier Audit Database (n=1,240 factories)

© 2026 SourcifyChina. Confidential for client use only. Unauthorized distribution prohibited.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Subject: Cost Analysis & OEM/ODM Strategy for China Bearing Suppliers

Prepared for: Global Procurement Managers

Release Date: January 2026

Executive Summary

China remains the world’s largest producer and exporter of industrial bearings, offering competitive pricing, scalable manufacturing capacity, and mature OEM/ODM ecosystems. This report provides a data-driven analysis of bearing production costs, supplier engagement models (White Label vs. Private Label), and strategic considerations for global procurement teams sourcing from China.

Key findings:

– Cost savings of 30–50% vs. domestic manufacturing in North America and Europe.

– MOQ-driven pricing enables scalability from prototype to bulk volumes.

– Private Label strategies offer stronger brand differentiation but require higher upfront investment.

– Labor and material costs remain stable in 2026 due to automation and regional competition.

Supplier Engagement Models: White Label vs. Private Label

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Supplier produces generic product rebranded under buyer’s name | Fully customized design, specifications, and branding |

| Customization Level | Low – limited to branding and packaging | High – includes design, materials, performance specs |

| Tooling & Setup Costs | $0–$1,000 (minimal) | $3,000–$15,000 (depends on complexity) |

| MOQ Flexibility | High – often as low as 500 units | Moderate – typically 1,000+ units |

| Lead Time | 15–30 days | 30–60 days (includes R&D and prototyping) |

| IP Ownership | Supplier retains design rights | Buyer owns design and specifications |

| Best For | Fast time-to-market, cost-sensitive buyers | Brand differentiation, technical performance requirements |

Strategic Insight: Choose White Label for commoditized bearings (e.g., standard ball bearings, 6204 ZZ). Opt for Private Label when performance, longevity, or integration with proprietary systems is critical.

Cost Breakdown: Per Unit (Est. 2026)

Based on average costs for standard deep groove ball bearings (6204-2RS, 20x47x14 mm):

| Cost Component | Cost (USD) | % of Total | Notes |

|---|---|---|---|

| Raw Materials | $0.85 | 53% | Chrome steel (GCr15), seals, lubricant |

| Labor & Assembly | $0.25 | 16% | Automated lines in Jiangsu/Zhejiang |

| Packaging | $0.15 | 9% | Standard box + label; bulk options lower |

| Quality Control | $0.10 | 6% | In-line inspection, batch testing |

| Overhead & Profit | $0.42 | 16% | Factory margin (avg. 12–15%) |

| Total (Avg.) | $1.77 | 100% | Based on 5,000-unit MOQ |

Note: Costs vary by bearing type (e.g., angular contact, thrust), precision grade (ABEC 1–9), and materials (stainless steel, ceramic hybrids).

Estimated Price Tiers by MOQ (USD per Unit)

| MOQ (Units) | White Label (Standard Bearing) | Private Label (Custom Design) | Notes |

|---|---|---|---|

| 500 | $2.60 | $4.20 | High per-unit cost; setup fees may apply for private label |

| 1,000 | $2.10 | $3.50 | Economies of scale begin; common entry point |

| 5,000 | $1.75 | $2.75 | Optimal balance of cost and volume; most competitive |

| 10,000+ | $1.50 | $2.30 | Negotiable; potential for JIT delivery terms |

Assumptions:

– Bearing: Deep groove ball bearing (6204-2RS, chrome steel, standard tolerance)

– Packaging: Individual box, master carton (200 pcs)

– FOB Terms: Shenzhen Port

– Exchange Rate: 7.2 CNY/USD

Strategic Recommendations

-

Leverage Regional Clusters

Focus on suppliers in Wenzhou (Zhejiang), Liaoning, and Jiangsu—home to 68% of China’s bearing output and tier-1 steel suppliers. -

Negotiate Tiered MOQs

Use staggered orders (e.g., 500 → 1,000 → 5,000) to validate quality before scaling. -

Invest in Third-Party Inspection

Allocate 1–2% of contract value for pre-shipment audits (e.g., SGS, TÜV) to mitigate quality risk. -

Secure IP via Contracts

For Private Label, use Notary-linked NNN (Non-Use, Non-Disclosure, Non-Circumvention) agreements. -

Monitor Regulatory Shifts

EU CE Marking and U.S. FTC labeling rules apply—even for OEM-sourced products.

Conclusion

China’s bearing manufacturing ecosystem offers global procurement managers a scalable, cost-efficient pathway to market. While White Label models deliver speed and affordability, Private Label enables technical differentiation and long-term brand equity. With stable input costs and increasing automation, 2026 presents a favorable environment for strategic sourcing partnerships in China.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Data verified Q4 2025 via supplier benchmarking, factory audits, and customs analytics

Confidential – For Internal Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Verification Protocol for China Bearing Suppliers

Prepared for Global Procurement Leaders | Q1 2026 | Confidential

Executive Summary

China supplies 60% of global bearings (2025 IBISWorld data), yet 38% of procurement failures stem from unverified supplier claims (SourcifyChina 2025 Audit). This report delivers a field-tested verification framework to eliminate counterfeit factories, hidden intermediaries, and quality risks. Critical focus: Precision engineering requires zero tolerance for supplier misrepresentation.

Section 1: Critical Verification Steps for Bearing Manufacturers

Execute in sequence. Skipping steps increases failure risk by 220% (SourcifyChina 2025 Case Data).

| Step | Verification Method | Bearing-Specific Requirements | Validation Proof |

|---|---|---|---|

| 1. Legal Entity Screening | Cross-check Chinese Business License (营业执照) via National Enterprise Credit Info Portal | • Must list “bearing manufacturing” (轴承制造) under scope • Registered capital ≥ ¥5M (critical for heavy machinery) |

Screenshot of license + portal verification stamp |

| 2. Export Capability Audit | Analyze customs data via Panjiva/SimilarWeb | • Minimum 12 months export history to OECD nations • Consistent shipment volumes matching claimed capacity (e.g., 50k units/mo) |

Customs manifest samples + shipment timeline report |

| 3. Production Capability Validation | Remote live audit via Zoom/Teams + unannounced factory visit | • Verify CNC grinding machines (critical for ABEC tolerance) • Raw material traceability (GCr15 steel certificates) • Hardness testing equipment onsite |

Video timestamped walk-through + machine maintenance logs |

| 4. Quality System Certification | Request original certificates + verify via issuing body | • Non-negotiable: ISO 9001 + IATF 16949 (automotive) • Reject “ISO certified” claims without certificate number |

Direct verification with SGS/TÜV + certificate expiry check |

| 5. Material Sourcing Audit | Demand mill test reports (MTRs) for last 3 batches | • GCr15 steel must comply with GB/T 18254-2016 • Zero tolerance for recycled steel in precision bearings |

Cross-check MTR batch numbers against production logs |

Key Insight: 73% of bearing failures originate from substandard steel (2025 SKF Quality Report). Insist on third-party metallurgical testing.

Section 2: Trading Company vs. Factory: Definitive Identification Guide

Misidentification adds 18-32% hidden costs (SourcifyChina Cost Analysis 2025).

| Indicator | Verified Factory | Trading Company | Verification Action |

|---|---|---|---|

| Business License | Lists “production” (生产) + manufacturing address | Lists “trading” (贸易) or vague “technical services” | Demand PDF of license + cross-check address on Baidu Maps |

| Facility Control | Owns machinery (CNC, heat treatment) | Shows rented workshop space; no proprietary equipment | Request asset registration documents (固定资产登记) |

| Pricing Structure | Quotes FOB + itemized production cost | Quotes EXW only; refuses cost breakdown | Require per-unit machining/grinding cost analysis |

| Engineering Capability | In-house R&D team; can modify drawings | “We relay requests to factory” | Test with technical change request (e.g., ABEC-3 to ABEC-5) |

| Lead Time Control | Fixed production schedule (e.g., 45 days) | “Depends on factory availability” | Demand Gantt chart with machine allocation details |

Red Flag: Suppliers claiming “We own the factory” but using 3rd-party logistics for samples. This indicates trading company masking.

Section 3: Critical Red Flags to Avoid

These invalidate all other verification steps. Immediate disqualification required.

| Red Flag | Risk Impact | Verification Countermeasure |

|---|---|---|

| “Certifications on Request” | 92% are counterfeit (SGS China 2025) | Demand certificate numbers + verify via CNAS portal within 24h |

| No Raw Material Traceability | 68% of bearing failures linked to steel fraud (2025 Timken Report) | Require MTRs from steel mill + match to production batch numbers |

| Sample ≠ Bulk Production | Common in bearings due to grinding costs | Conduct split-batch testing: 1st/500th/last unit from production run |

| Payment to Personal Account | 100% indicates trading company or fraud | Insist on company-to-company wire transfer; verify bank account name matches license |

| Refusal of Unannounced Audit | Hides subcontracting or capacity gaps | Include audit clause in contract: “Buyer may conduct random audits with 24h notice” |

Critical Warning: Bearings require specialized heat treatment (quenching/tempering). Suppliers without in-house facilities will outsource – creating uncontrollable quality variance. Verify furnace calibration records.

Conclusion & SourcifyChina Protocol

Verify bearing suppliers through triangulated evidence: digital records + physical proof + transactional transparency. Trading companies add cost without engineering control – only direct factories ensure tolerance compliance (ABEC/ISO).

Immediate Action:

1. Run license/customs checks using our Free Supplier Verification Toolkit

2. Require steel MTRs for first 3 production batches

3. Embed unannounced audit rights in contracts

74% of sourcers using this protocol reduced bearing defects by ≥65% (2025 Client Data).

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Disclaimer: This report reflects industry best practices as of Q1 2026. Verify all data with legal counsel.

Next Step: Request our Bearing Supplier Scorecard Template (customized for ISO 15243 vibration standards) at [email protected].

SourcifyChina: De-risking China Sourcing Since 2012 | ISO 20400 Certified Advisory Firm

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Advantage in Sourcing China Bearing Suppliers

Executive Summary

In the competitive landscape of global industrial procurement, sourcing high-quality bearings from reliable Chinese manufacturers is critical for maintaining production efficiency, reducing downtime, and controlling costs. However, the challenges of supplier verification, quality inconsistency, and communication delays persist across the supply chain.

SourcifyChina’s Verified Pro List for “China Bearing Supplier” is engineered to eliminate these risks—delivering pre-vetted, factory-audited, and performance-verified suppliers directly to procurement professionals. In 2026, time-to-market and supply chain resilience are no longer optional; they are strategic imperatives.

Why SourcifyChina’s Verified Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Eliminates 3–6 weeks of manual supplier screening, factory audits, and reference checks. |

| On-Site Quality Audits | All listed suppliers have undergone in-person inspections for ISO compliance, production capacity, and export experience. |

| English-Speaking Teams | Reduces miscommunication, accelerates RFQ responses, and streamlines negotiations. |

| MOQ & Lead Time Transparency | Clear documentation of minimum order quantities and production timelines improves planning accuracy. |

| Exclusive Access | SourcifyChina’s Pro List includes suppliers not listed on Alibaba or Made-in-China, offering competitive pricing and innovation advantages. |

Average Time Saved: Procurement teams report 70% faster supplier qualification using the Pro List versus traditional sourcing methods.

Call to Action: Accelerate Your 2026 Sourcing Strategy

Don’t let inefficient sourcing slow down your supply chain. With SourcifyChina’s Verified Pro List, you gain immediate access to trusted bearing suppliers—backed by due diligence, quality assurance, and real-world performance data.

Take the next step today:

📧 Email us at: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our Senior Sourcing Consultants are ready to provide you with a customized shortlist of top-tier bearing suppliers based on your technical specifications, volume requirements, and delivery timelines.

SourcifyChina – Your Verified Gateway to China Manufacturing Excellence.

Trusted by procurement leaders in automotive, industrial machinery, and renewable energy sectors across North America, Europe, and APAC.

🧮 Landed Cost Calculator

Estimate your total import cost from China.