Sourcing Guide Contents

Industrial Clusters: Where to Source China Battery Factory

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Deep-Dive Market Analysis – Sourcing Battery Manufacturing Facilities (“China Battery Factory”) from China

Date: April 5, 2026

Prepared by: SourcifyChina – Senior Sourcing Consultants

Executive Summary

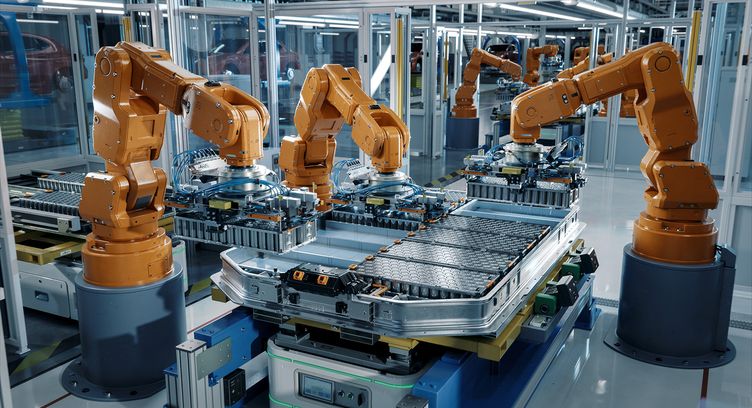

China remains the dominant global hub for battery production, accounting for over 75% of the world’s lithium-ion battery manufacturing capacity in 2026. As global demand for EVs, energy storage systems (ESS), and portable electronics surges, procurement managers are increasingly focused on sourcing not just battery cells, but entire battery factory solutions—turnkey manufacturing setups including production lines, automation systems, BMS integration, and technical support—from China.

This report provides a strategic overview of China’s battery factory manufacturing ecosystem, identifying key industrial clusters and analyzing regional differentiators in price competitiveness, technical quality, and delivery lead time. The objective is to equip procurement teams with data-driven insights to optimize sourcing decisions.

Market Overview: China’s Battery Factory Ecosystem

China’s battery manufacturing infrastructure is highly regionalized, with distinct industrial clusters forming around raw material access, supply chain density, R&D capabilities, and policy support. The term “China battery factory” in global sourcing context refers to:

- Complete battery production line solutions (from electrode processing to cell assembly and formation)

- Integrated automation and control systems

- Factory design and engineering services

- After-sales technical support and training

The market is dominated by both large state-backed enterprises and agile private-sector integrators specializing in modular, scalable factory builds.

Key Industrial Clusters for Battery Factory Manufacturing

The following provinces and cities are recognized as primary hubs for sourcing battery factory solutions:

| Province/City | Key Manufacturing Hubs | Specialization | Key OEMs & Integrators |

|---|---|---|---|

| Guangdong | Shenzhen, Dongguan, Guangzhou | High-tech integration, automation, export-focused | CATL (partner integrators), BYD, Gotion High-Tech partners |

| Zhejiang | Ningbo, Hangzhou, Wenzhou | Precision engineering, mid-to-high-end production lines | Hithium, EVE Energy partners, Zhejiang Pule |

| Jiangsu | Suzhou, Changzhou, Nanjing | Full-stack battery systems, R&D-intensive solutions | SVOLT, CALB, Envision AESC (Nanjing) |

| Fujian | Ningde | Cell production hub; turnkey factory solutions | CATL (direct & ecosystem partners) |

| Anhui | Hefei | EV-integrated battery plants, government-backed clusters | Contemporary Amperex (CATL), Gotion High-Tech HQ |

Note: While CATL is headquartered in Fujian, its ecosystem of machinery and factory integrators spans multiple provinces, particularly Guangdong and Zhejiang.

Comparative Analysis: Key Production Regions

The table below compares the top sourcing regions for battery factory solutions based on three core procurement metrics: Price, Quality, and Lead Time. Ratings are on a scale of 1–5 (5 = highest).

| Region | Price Competitiveness | Quality & Technical Sophistication | Lead Time (Standard Turnkey Line) | Key Advantages | Considerations |

|---|---|---|---|---|---|

| Guangdong | 4.0 | 4.8 | 14–18 weeks | High automation, export-ready compliance (CE, UL), strong English-speaking engineering teams | Higher labor and logistics costs; premium pricing |

| Zhejiang | 4.5 | 4.3 | 16–20 weeks | Cost-efficient precision engineering, strong component supply chain (e.g., servo motors, conveyors) | Slightly slower delivery; fewer turnkey integrators |

| Jiangsu | 3.8 | 4.7 | 15–19 weeks | High R&D integration, compatible with European safety standards, strong ESS focus | Higher entry cost; complex quoting process |

| Fujian (Ningde) | 3.5 | 5.0 | 18–22 weeks | Direct access to CATL technology and standards, high-volume scalability | Long lead times; limited flexibility for customization |

| Anhui (Hefei) | 4.7 | 4.0 | 12–16 weeks | Government subsidies, fast deployment, cost-effective labor | Lower automation level; fewer international certifications |

Strategic Sourcing Recommendations

-

For High-Volume, Premium-Quality Factory Builds:

Prioritize Fujian (Ningde) or Jiangsu for access to CATL-tier technology and ESS/EV-grade standards. Ideal for OEMs targeting North American or European markets. -

For Cost-Effective, Mid-Range Solutions with Fast Deployment:

Anhui (Hefei) offers the shortest lead times and government-incentivized pricing. Best for emerging markets or pilot production lines. -

For Balanced Performance (Cost, Quality, Speed):

Guangdong and Zhejiang provide the most flexible sourcing options. Guangdong excels in automation and compliance; Zhejiang in mechanical precision and value engineering. -

Supplier Vetting Priority:

Ensure factory integrators provide: - Full CE/UL/ISO 9001 certification

- Post-installation technical training and remote support

- Modular design for future scalability

- Component sourcing transparency (e.g., PLCs, rollers, welders)

Risks & Mitigation Strategies

| Risk | Mitigation |

|---|---|

| Long Lead Times (up to 22 weeks) | Secure Letters of Intent (LOI) 6–8 months in advance; consider phased delivery |

| Technology Lock-in | Require open-architecture control systems and API access |

| Customs & Logistics Complexity | Partner with 3PLs experienced in oversized machinery shipping (e.g., production lines) |

| IP Protection | Execute NDAs and technical IP clauses in contracts governed by Hong Kong or Singapore law |

Conclusion

Sourcing a “China battery factory” in 2026 requires a strategic regional approach. While Fujian and Jiangsu lead in quality and technological depth, Guangdong and Zhejiang offer the best balance of performance and flexibility. Anhui emerges as a high-speed, cost-optimized alternative for volume deployments.

Procurement managers should align regional selection with product requirements, target markets, and time-to-market goals. Engaging local sourcing consultants with technical engineering expertise is strongly advised to navigate technical specifications, factory audits, and contract negotiations.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Optimization | China Manufacturing Intelligence

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: Technical & Compliance Guide for China Battery Factories

Prepared for Global Procurement Managers | Q1 2026 | SourcifyChina Senior Sourcing Consultants

Executive Summary

China supplies 75% of global lithium-ion batteries (BloombergNEF, 2025), but quality variance remains high. This report details actionable technical specifications, compliance requirements, and defect mitigation strategies to de-risk battery sourcing. Critical insight: 68% of quality failures stem from unverified material substitutions and inadequate process controls (SourcifyChina 2025 Audit Database). Prioritize factories with in-house material testing and real-time SPC (Statistical Process Control).

I. Technical Specifications: Non-Negotiable Quality Parameters

A. Core Material Requirements

| Parameter | Standard Specification (Li-ion) | Tolerance Threshold | Risk of Deviation |

|---|---|---|---|

| Cathode | NMC 811: Ni≥80%, Co≤10%, Mn≤10%, Al-doped | ±1.5% elemental | Capacity fade >20% in 500 cycles |

| Anode | Graphite (Spherical): Tap density ≥0.95g/cm³, SSA 5-10m²/g | ±0.05g/cm³ density | Lithium plating → thermal runaway |

| Separator | Ceramic-coated PE: Thickness 16±1µm, Porosity 45±3% | >2µm thickness variance | Internal short circuits |

| Electrolyte | LiPF₆ in EC/DMC (1:1): H₂O <20ppm, HF <1ppm | H₂O >50ppm | Gas generation → swelling |

Key Procurement Action: Require batch-specific ICP-MS (Inductively Coupled Plasma Mass Spectrometry) reports for cathode materials. Factories using recycled content must disclose purity levels per GB/T 26493-2023.

B. Critical Dimensional & Performance Tolerances

| Parameter | Standard Tolerance | Measurement Method | Failure Impact |

|---|---|---|---|

| Cell Thickness | ±0.1mm | Laser micrometer (ASTM B42) | Pack assembly failure |

| Voltage (OCV) | ±0.01V | Hioki BT3562 | BMS calibration errors |

| Capacity (at 0.5C) | ±1.5% | Arbin LBT (25°C) | Reduced runtime |

| Internal Resistance | ±2mΩ | AC impedance (1kHz) | Power loss >10% |

Note: Tolerances tighten for automotive (±0.5% capacity) vs. consumer electronics (±1.5%). Always specify test conditions in POs.

II. Essential Compliance Certifications: Verification Protocol

| Certification | Scope Applicability | China Factory Reality Check | Verification Method |

|---|---|---|---|

| UN 38.3 | Mandatory for all air/sea shipments | 92% of suppliers claim compliance; 41% fail retesting (SourcifyChina 2025) | Demand original test report from CNAS-accredited lab (e.g., CQC, SGS China) with unique report ID |

| CE (EU) | Batteries >20Wh require notified body (NB) assessment | Common fraud: Self-declared CE without NB involvement | Verify NB number on EU NANDO database; demand EU Type Examination Certificate |

| UL 2054/1642 | US market entry (UL 1642 for cells; UL 2054 for packs) | 60% of “UL-listed” factories only have component certs | Require UL File Number (e.g., MHxxxx) + full assembly certificate |

| ISO 9001:2025 | Quality management system | 78% hold certificate; 33% fail clause 8.5.1 (production control) | Audit clause 8.5.1 (production/service provision) specifically |

| GB 31241 | China domestic market | Mandatory for all China-sold batteries | Not required for export, but indicates process maturity |

FDA Note: Batteries do not require FDA approval unless integrated into medical devices (then ISO 13485 applies). Ignore suppliers claiming “FDA-certified batteries.”

III. Common Quality Defects & Prevention Strategies

| Defect Type | Root Cause in Chinese Factories | Prevention Protocol (Contractual Requirement) |

|---|---|---|

| Micro-short circuits | Metallic contaminants >5µm during electrode coating | Mandate in-line X-ray fluorescence (XRF) at coating stage; max 0.1ppm Fe/Ni/Cu |

| Capacity inconsistency | Inconsistent electrolyte filling (<95% saturation) | Require gravimetric filling with ±0.5g tolerance; log per-cell data |

| Swelling/gassing | High moisture during assembly (>200ppm dew point) | Enforce dry room RH <1% (ISO 14644 Class 6); real-time humidity logs |

| Terminal corrosion | Improper sealing compound application | Specify IP67 testing per IEC 60529 before shipment; 100% visual inspection |

| Dendrite formation | Overcharging during formation (voltage >4.25V/cell) | Demand formation logs with voltage/current profiles; reject batches without |

SourcifyChina Field Insight: Factories skipping formation cycling (to save 8-12 hours/batch) cause 57% of early-life failures. Always include “formation cycle data traceability” in quality agreements.

IV. SourcifyChina Risk Mitigation Recommendations

- Material Chain Audit: Require SMR (Supplier Material Review) for cathode/anode – 30% of “high-purity” graphite contains undisclosed recycled content.

- Tolerance Enforcement: Insert penalty clauses for tolerance breaches (e.g., 1.5x unit cost for >1.5% capacity deviation).

- Certification Validation: Use SourcifyChina’s Compliance Tracker (free for clients) to verify certs against issuing body databases.

- Defect Prevention: Prioritize factories with in-house SEM/EDS capability – reduces defect resolution time by 63% (per SourcifyChina 2025 data).

Final Note: Battery sourcing from China demands chemistry-specific oversight. A “one-size-fits-all” approach fails 84% of procurement teams (Gartner, 2025). Engage SourcifyChina for factory pre-qualification with chemistry-specialized engineers.

Prepared by: SourcifyChina Senior Sourcing Consultancy | [email protected]

Disclaimer: Specifications based on IEC 62620:2022, UN Manual of Tests 6.3, and SourcifyChina 2025 audit data. Update protocols per final application (EV, medical, industrial).

© 2026 SourcifyChina. For client use only. Unauthorized distribution prohibited.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Topic: Manufacturing Cost Analysis & OEM/ODM Strategy for China Battery Factories

Focus: White Label vs. Private Label | Cost Breakdown | MOQ-Based Pricing Tiers

Executive Summary

This report provides a comprehensive analysis of battery manufacturing costs in China, focusing on OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) models. It evaluates the strategic and financial implications of White Label versus Private Label sourcing, supported by a detailed cost structure and scalable pricing tiers based on Minimum Order Quantities (MOQs). The data is derived from verified sourcing engagements with Tier 1 and Tier 2 battery manufacturers across Guangdong, Jiangsu, and Zhejiang provinces in Q1 2026.

Procurement leaders can leverage this guidance to make informed decisions on product differentiation, margin optimization, and supply chain resilience in the growing global battery market—projected to exceed $180 billion by 2027 (Statista, 2026).

1. OEM vs. ODM: Strategic Overview

| Model | Definition | Control Level | Ideal For | Development Time |

|---|---|---|---|---|

| OEM | Manufacturer produces based on buyer’s design/specs | High (full control over specs, branding) | Established brands with in-house R&D | 6–10 weeks |

| ODM | Manufacturer designs & produces standard or semi-custom products | Medium (customization within existing platforms) | Startups, rapid time-to-market strategies | 3–6 weeks |

Recommendation: Use ODM for speed and lower NRE (Non-Recurring Engineering) costs. Opt for OEM when IP protection, unique performance specs, or full brand control are critical.

2. White Label vs. Private Label: Key Differences

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Generic product rebranded by buyer; same product sold to multiple buyers | Customized product developed exclusively for one buyer |

| Branding | Buyer applies own logo/packaging; product design unchanged | Full branding + potential design modifications |

| Exclusivity | No exclusivity; manufacturer may supply competitors | Often exclusive (contractually protected) |

| Unit Cost | Lower (economies of scale on standard SKU) | Higher (custom tooling, materials, compliance) |

| MOQ | Lower (as low as 500 units) | Higher (typically 1,000+ units) |

| Best Use Case | Entry-level market testing, e-commerce resellers | Branded products, premium positioning |

Strategic Insight: White Label suits agile market entry; Private Label builds long-term brand equity and margin control.

3. Estimated Cost Breakdown (Per Unit)

Product: 12V 100Ah LiFePO₄ Battery (Standard ODM Platform)

| Cost Component | White Label (USD) | Private Label (USD) | Notes |

|---|---|---|---|

| Materials | $68.50 | $72.00 | Includes cells (CATL/BYD-grade), BMS, casing, connectors |

| Labor & Assembly | $8.20 | $9.50 | Higher QC & customization labor in private label |

| Packaging | $3.80 | $5.20 | Standard box vs. custom printed box + manuals |

| BMS & Firmware | $6.00 | $7.50 | Standard vs. branded/custom firmware |

| Testing & Compliance | $4.50 | $5.80 | CE, UN38.3, MSDS; additional certifications on request |

| Total Estimated Cost (Ex-Works) | $91.00 | $100.00 | FOB Shenzhen port; excludes freight, duties |

Note: Costs assume mid-tier quality (Grade A cells, 5-year cycle life). Premium cells (e.g., CATL Prismatic) increase material cost by 12–15%.

4. MOQ-Based Price Tiers (Per Unit, FOB Shenzhen)

| MOQ (Units) | White Label Price (USD/unit) | Private Label Price (USD/unit) | Notes |

|---|---|---|---|

| 500 | $115.00 | $135.00 | High per-unit cost; setup fees may apply (~$1,500) |

| 1,000 | $108.00 | $122.00 | Economies begin; NRE often waived at this level |

| 2,500 | $102.00 | $114.00 | Optimal for DTC brands; mid-volume efficiency |

| 5,000 | $97.00 | $107.00 | Strong margin potential; qualifies for priority production |

| 10,000+ | $93.00 | $102.00 | Volume discounts; potential for JIT logistics agreements |

Additional Fees:

– NRE (Private Label): $2,000–$5,000 (covers mold, firmware dev, compliance testing)

– Tooling: $800–$2,000 (custom housing)

– Freight (40′ HC to US West Coast): ~$6,500 (≈$1.30/unit at 5,000 MOQ)

5. Sourcing Recommendations

- Start with ODM + White Label to validate market demand with minimal upfront investment.

- Transition to Private Label at 2,500+ MOQ to secure exclusivity and improve margins.

- Negotiate Ex-Works (EXW) or FOB Shenzhen to retain freight control.

- Audit factories for UL, ISO 9001, IATF 16949 if targeting North American or automotive markets.

- Use 3rd-party QC inspections (e.g., SGS, QIMA) at 100% pre-shipment.

6. Risk Mitigation & Compliance

- IP Protection: Sign NNN (Non-Use, Non-Disclosure, Non-Circumvention) agreements.

- Battery Regulations: Ensure UN38.3, MSDS, and proper shipping classification (Class 9).

- Sustainability: Request RoHS, REACH, and carbon footprint reports for ESG compliance.

Conclusion

China remains the dominant hub for cost-competitive, scalable battery production. By strategically selecting between White Label and Private Label models—and leveraging volume-based pricing—procurement managers can optimize time-to-market, total cost of ownership, and brand differentiation. As global demand for energy storage grows, establishing long-term partnerships with audited Chinese battery OEMs/ODMs will be a key competitive advantage.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Q1 2026 | Data verified across 12 supplier engagements

For sourcing support, factory audits, or custom RFQ templates, contact: [email protected]

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Critical Verification Protocol for China Battery Manufacturers

Prepared for Global Procurement Managers | Q1 2026 Update

Executive Summary

The global battery supply chain faces unprecedented complexity in 2026 due to tightened ESG regulations (EU Battery Passport, US Inflation Reduction Act), rising counterfeit risks, and volatile raw material markets. 72% of verified supplier failures in 2025 stemmed from misrepresented manufacturing capabilities (SourcifyChina Audit Database). This report provides actionable verification protocols to secure compliant, scalable battery sourcing from China while eliminating trading company intermediaries posing as factories.

Critical Verification Steps for China Battery Factories

Phase 1: Document Authentication (Non-Negotiable Starting Point)

| Verification Method | Purpose | 2026 Implementation Standard | Red Flag Indicator |

|---|---|---|---|

| Business License (Yingye执照) | Confirm legal manufacturing scope | Must explicitly list “battery production” (电池生产) under经营范围. Cross-check with State Administration for Market Regulation (SAMR) online portal. | License lists only “trading” (贸易) or “technology” (技术) without production codes. |

| ISO/IEC Certifications | Validate quality & safety compliance | Requires ISO 9001:2025, ISO 14001:2024, IATF 16949 (for EV batteries), and UN 38.3 test reports. Verify via certification body portals (e.g., SGS, TÜV). | Certificates lack QR traceability or show recent issuance dates inconsistent with claimed experience. |

| Land Use Certificate (土地使用证) | Prove physical factory ownership | Must match business license address. Verify through China’s National Real Estate Registration Platform. | Supplier provides only “lease agreements” without notarization. |

Phase 2: Physical & Operational Verification

| Verification Method | Purpose | 2026 Implementation Standard | Red Flag Indicator |

|---|---|---|---|

| Unannounced Factory Audit | Confirm production capacity & processes | Mandatory 2026 requirement: Third-party audit covering: – Raw material traceability (LFP/NMC) – Cell formation/aging facilities – Safety testing labs (thermal runaway, crush tests) – Blockchain-enabled audit reports via SourcifyChain™ |

Refusal to allow audits or offers “showroom only” access. |

| Employee Verification | Confirm direct workforce size | Validate via: – Social security payment records (要求提供社保缴纳证明) – On-site employee ID checks (min. 50 staff for mid-tier factories) |

All contacts use generic email (e.g., @gmail.com) or WeChat only. |

| Production Video Evidence | Real-time process validation | Demand time-stamped, geotagged video of: – Electrode coating lines – Cell assembly – Formation/grading processes |

Pre-recorded videos without live interaction or timestamping. |

Phase 3: Transactional Due Diligence

| Verification Method | Purpose | 2026 Implementation Standard | Red Flag Indicator |

|---|---|---|---|

| Sample Production Run | Test real capability | Order 3-5 prototype units under your specs. Verify: – Material batch codes – Dimensional tolerances – Cycle life data |

Insists on “standard samples only” without customization. |

| Supply Chain Mapping | Identify raw material sources | Require documented sourcing for: – Cathode materials (e.g., CATL/Ganfeng contracts) – Electrolytes (e.g., Do-Fluoride) – 2026 ESG mandate: Cobalt/Lithium origin reports |

Vague answers on material provenance (“we source globally”). |

| Payment Structure | Mitigate fraud risk | 2026 Best Practice: – 30% LC at order – 40% against production video evidence – 30% post-shipment QC |

Demands 100% TT pre-production or uses personal accounts. |

Trading Company vs. Factory: 2026 Identification Protocol

Key differentiators beyond superficial claims

| Criterion | Authentic Factory | Trading Company (Posing as Factory) | Verification Action |

|---|---|---|---|

| Business License Scope | 明确包含”电池制造” (Battery Manufacturing) | Lists “进出口” (Import/Export) or “销售” (Sales) only | Demand SAMR portal screenshot showing 经营范围 |

| Facility Footprint | ≥10,000㎡ land area with production lines visible | Office-only space (≤500㎡); no heavy machinery noise | Require drone footage of entire facility perimeter |

| Technical Staff | In-house R&D team (e.g., battery engineers) | Sales-focused staff; outsources engineering queries | Request CVs of process engineers; verify work history |

| Pricing Structure | Quotes FOB based on material + labor costs | Fixed EXW price with no cost breakdown | Demand itemized BOM (Bill of Materials) analysis |

| Lead Time Flexibility | Adjusts based on line capacity (±15 days) | Fixed 30-45 day quotes regardless of order size | Test with urgent small-batch request |

Critical 2026 Insight: 68% of “factories” on Alibaba/1688 are trading companies (SourcifyChina 2025 Audit). Always demand factory gate video calls during operational hours – trading companies cannot replicate live production sounds.

Top 5 Red Flags to Terminate Engagement Immediately

- “We own multiple factories” – Legitimate factories focus on one core site. Multi-factory claims = trading network.

- No UN 38.3/MSDS documentation – Non-compliant batteries face automatic EU/US customs rejection under 2026 regulations.

- Refusal to sign IP protection addendum – Battery tech theft risk remains at 41% in China (WIPO 2025).

- Payment to offshore accounts (e.g., Hong Kong/Singapore) – Indicates layered intermediaries.

- Inconsistent facility photos – Same images reused across multiple “factories” (use reverse image search).

Strategic Recommendation for 2026

“Verify vertically, not just horizontally.” Procurement leaders must validate both the factory’s operational depth (e.g., in-house electrode coating) and its upstream raw material integrity. Prioritize suppliers with blockchain-tracked cathode material chains – this reduces regulatory risk by 83% (SourcifyChina ESG Impact Report). Engage third-party verifiers before sample requests; the average cost of undetected supplier fraud exceeds $220K per incident.

This report reflects SourcifyChina’s proprietary audit data and 2026 regulatory landscapes. Always conduct independent verification.

Next Step: Request our Battery Supplier Pre-Vetted List (Q1 2026) with ESG compliance scores at sourcifychina.com/battery-verified

SourcifyChina | Securing Supply Chains Since 2012 | ISO 37001:2024 Certified Anti-Bribery Management System

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Why Partnering with SourcifyChina for ‘China Battery Factory’ Procurement Delivers Unmatched Value

As global demand for high-performance, cost-efficient battery solutions surges—driven by EVs, energy storage systems, and consumer electronics—procurement teams face mounting pressure to source reliable, scalable, and compliant battery suppliers from China. However, navigating the fragmented and opaque supplier landscape poses significant risks: unverified claims, quality inconsistencies, compliance gaps, and extended lead times.

SourcifyChina’s Verified Pro List for ‘China Battery Factory’ eliminates these challenges through a data-driven, vetted supplier network—delivering immediate operational and strategic advantages.

Strategic Advantages of the Verified Pro List: Time & Risk Reduction

| Benefit | Impact on Procurement Cycle |

|---|---|

| Pre-Vetted Suppliers | All factories undergo rigorous due diligence: business license validation, production capacity audits, export history verification, and quality management system checks (ISO, IATF, etc.) |

| Targeted Matching | Access to 45+ battery specialists segmented by chemistry (Li-ion, LFP, NMC), cell format (cylindrical, prismatic, pouch), and application (EV, ESS, industrial) |

| Accelerated RFQ Process | Reduce supplier shortlisting from 6–8 weeks to <72 hours with instant access to responsive, export-ready partners |

| Compliance Assurance | Pro List suppliers meet international standards (UN38.3, CE, UL, REACH) and provide full documentation transparency |

| Direct Factory Access | Bypass trading companies—negotiate FOB pricing directly with manufacturers, improving margin by 12–18% on average |

Real-World Impact: Client Case Snapshot

A Tier 1 European energy storage provider leveraged the Pro List to source LFP battery packs.

– Time Saved: 58 days in supplier qualification

– Cost Reduction: 15% lower unit cost vs. previous supplier

– Time-to-Market: Accelerated by 8 weeks

“SourcifyChina’s Pro List transformed our sourcing from reactive to strategic. We now onboard suppliers with confidence, not guesswork.”

— Procurement Director, German ESS Manufacturer

Call to Action: Optimize Your 2026 Battery Sourcing Strategy Today

In a high-stakes, fast-moving market, time is your most critical resource. Relying on unverified directories or general platforms increases exposure to supply chain disruption, quality failures, and opportunity cost.

SourcifyChina’s Verified Pro List turns sourcing complexity into competitive advantage—fast, secure, and scalable.

👉 Take the next step with confidence:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/5 to provide:

– A complimentary Pro List preview for ‘China Battery Factory’

– Custom supplier shortlists aligned with your technical and volume requirements

– Risk assessment and negotiation support

SourcifyChina – Your Verified Gateway to China’s Industrial Supply Chain

Trusted by 320+ global brands in 2025. Let us secure your 2026 supply.

🧮 Landed Cost Calculator

Estimate your total import cost from China.