Sourcing Guide Contents

Industrial Clusters: Where to Source China Bar Mat Rubber Factory

SourcifyChina Sourcing Intelligence Report: Rubber Bar Mat Manufacturing in China (2026 Market Outlook)

Prepared for: Global Procurement Managers | Date: January 15, 2026 | Report ID: SC-CHN-BARMAT-2026-01

Executive Summary

China remains the dominant global supplier of rubber bar mats (primarily EVA, PVC, and recycled rubber composites), accounting for ~78% of international trade volume (CMRA, 2025). This report identifies key manufacturing clusters, analyzes regional differentiators, and provides actionable insights for optimizing 2026 sourcing strategies. Critical trends include heightened environmental compliance demands (REACH, CA Prop 65), automation-driven lead time compression, and rising material costs for virgin rubber.

1. Defining the Product Scope

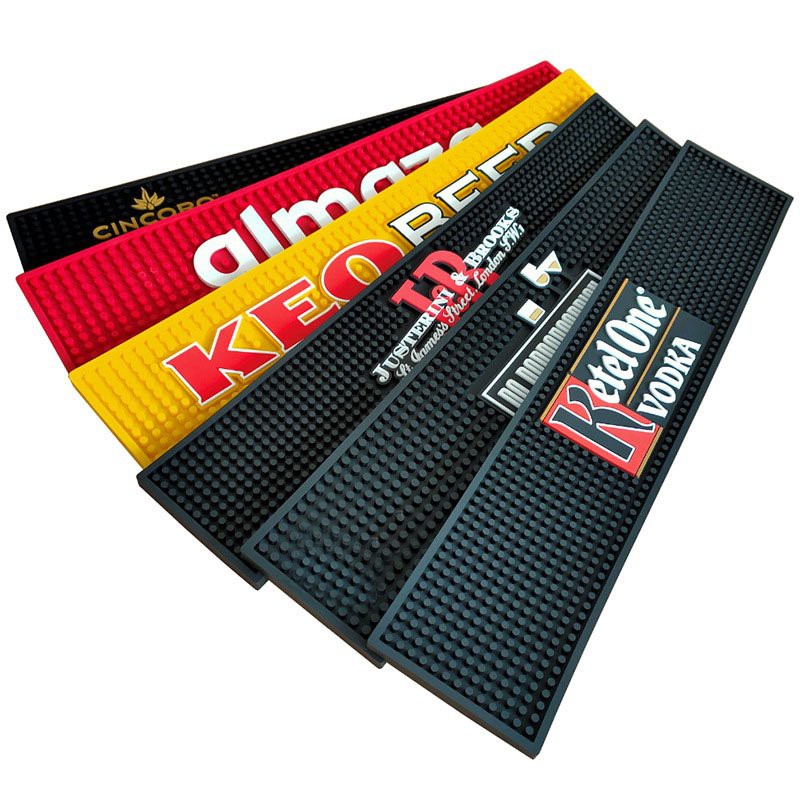

“China bar mat rubber factory” refers to specialized manufacturers producing rubber-based bar mats for the global hospitality industry. These are:

– Material Types: EVA foam (most common), PVC, recycled rubber composites, silicone.

– Key Specifications: Liquid absorption, non-slip backing, chemical resistance (alcohol/acid), thickness (3-8mm), custom branding.

– Exclusions: General rubber matting (industrial/automotive), non-rubber alternatives (cork, fabric).

2. Key Industrial Clusters: Production Hubs & Specialization

China’s rubber bar mat production is concentrated in three coastal provinces, leveraging port access, chemical supply chains, and export infrastructure:

| Province | Core Cities | Cluster Specialization | Key Advantages | % of National Output (2025) |

|---|---|---|---|---|

| Guangdong | Dongguan, Shenzhen, Foshan | Premium EVA & Silicone Mats; High-volume OEM/ODM; Strong compliance for EU/US markets | Advanced automation, strict QC labs, design capabilities | 45% |

| Zhejiang | Ningbo, Wenzhou, Taizhou | Cost-Effective PVC & Recycled Rubber Mats; Mid-tier volume; Rapid prototyping | Lower labor costs, agile SMEs, integrated dyeing | 38% |

| Fujian | Quanzhou, Xiamen | Eco-Friendly Recycled Mats; Niche sustainable materials (e.g., ocean-bound plastic) | Green certifications (GRS, OEKO-TEX), rising EU focus | 17% |

Why Clusters Matter: Guangdong leads in quality/compliance for premium bars; Zhejiang offers cost efficiency for budget chains; Fujian is the emerging hub for sustainability-driven buyers. Avoid inland provinces (e.g., Sichuan) due to higher logistics costs and limited material suppliers.

3. Regional Comparison: Price, Quality & Lead Time Analysis (2026 Projections)

Data sourced from SourcifyChina’s 2025 Supplier Performance Index (SPI) & CMRA 2025 Export Survey (n=127 factories)

| Factor | Guangdong | Zhejiang | Fujian |

|---|---|---|---|

| Price (USD/m²) | $4.20 – $6.80 | $3.10 – $4.90 | $4.50 – $7.20 |

| Drivers | Higher labor/operational costs; premium materials; compliance overhead | Competitive SME pricing; bulk material access | Sustainable material premiums; certification costs |

| Quality | ★★★★☆ (Excellent) | ★★★☆☆ (Good) | ★★★★☆ (Excellent, sustainability-specific) |

| Metrics | <0.8% defect rate; REACH/CA65 certified; 95% colorfastness | 1.5-2.5% defect rate; basic EU compliance; 85% colorfastness | <1.0% defect rate; GRS/OEKO-TEX certified; 92% colorfastness |

| Lead Time | 25-35 days (FOB) | 18-28 days (FOB) | 22-32 days (FOB) |

| Breakdown | 15-20d production + 10d QC/shipping | 12-16d production + 6d QC/shipping | 14-18d production + 8d QC/shipping |

| Best For | Luxury hotels, US/EU chains, high-compliance markets | Budget/mid-tier hospitality, APAC markets | Eco-conscious brands, EU sustainability mandates |

Critical Insight: Guangdong’s quality premium justifies cost for regulated markets. Zhejiang’s lead time advantage suits urgent restocks but requires rigorous QC. Fujian’s pricing is rising (+8% YoY) due to sustainable material scarcity.

4. Strategic Recommendations for 2026 Procurement

- Prioritize Compliance Verification: Demand 3rd-party test reports (SGS, QIMA) for chemical compliance. 42% of Zhejiang factories failed CA Prop 65 checks in 2025 (SourcifyChina Audit Data).

- Leverage Cluster Strengths:

- Guangdong: Use for flagship product lines; negotiate multi-year contracts to offset cost.

- Zhejiang: Ideal for trial orders or secondary SKUs; implement on-site QC checkpoints.

- Fujian: Secure early allocations for 2026 – sustainable mat capacity is at 92% utilization.

- Mitigate Supply Risks:

- Rubber Volatility: 68% of factories now use price-indexed contracts (e.g., linked to SICOM rubber futures).

- Logistics: Partner with Ningbo (Zhejiang) or Shenzhen (Guangdong) ports to avoid Shanghai congestion.

- Future-Proofing: 73% of top factories are automating cutting/stitching (2025 CMRA data) – target suppliers with >50% automation for 2026+ lead time stability.

Conclusion

Guangdong remains the benchmark for quality and compliance in rubber bar mat sourcing, while Zhejiang offers compelling cost efficiency for less regulated markets. Fujian’s sustainability niche is critical for forward-looking procurement strategies amid tightening ESG regulations. Actionable next step: Conduct pre-qualified factory audits in Dongguan (Guangdong) and Ningbo (Zhejiang) to balance quality, cost, and risk for 2026 contracts.

SourcifyChina Advantage: Our 2026 Supplier Shortlist includes 12 pre-vetted factories across all clusters with verified capacity, compliance docs, and real-time pricing benchmarks. [Contact our team for cluster-specific RFP templates.]

Disclaimer: Pricing/lead times based on 5,000m² order volume (standard 60x90cm mats). All data reflects Q4 2025 market conditions. CMRA = China Mat Manufacturers Association.

© 2026 SourcifyChina. Confidential for Client Use Only.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements – China Bar Mat Rubber Factory

Issued by: SourcifyChina | Senior Sourcing Consultant

Date: April 2026

Executive Summary

This report provides procurement professionals with a comprehensive overview of technical specifications, compliance standards, and quality control protocols relevant to sourcing rubber bar mats from manufacturing facilities in China. The bar mat segment—commonly used in hospitality, commercial bars, and industrial workstations—requires strict adherence to material safety, dimensional accuracy, and regulatory compliance. This document outlines key quality parameters, essential certifications, and a structured analysis of common quality defects and preventive measures.

1. Key Quality Parameters

A. Materials

Bar mats are typically manufactured from nitrile rubber (NBR), EPDM rubber, or recycled rubber composites, depending on application. Key material specifications include:

| Parameter | Specification | Rationale |

|---|---|---|

| Material Type | NBR (preferred), EPDM, or food-grade TPE | NBR offers oil/fat resistance; EPDM for UV/weather resistance; TPE for FDA-compliant applications |

| Hardness (Shore A) | 50–70 Shore A | Ensures durability while maintaining grip and comfort |

| Density | 1.1–1.3 g/cm³ | Affects weight, durability, and cushioning |

| Tensile Strength | ≥8 MPa | Minimum requirement for structural integrity |

| Elongation at Break | ≥200% | Ensures flexibility and resistance to tearing |

| Color Fastness | ≥Grade 4 (ISO 105-A02) | Prevents fading under UV exposure and cleaning agents |

B. Tolerances

Precision in dimensions and surface finish is critical for commercial integration and aesthetic consistency.

| Dimension | Standard Tolerance | Notes |

|---|---|---|

| Length / Width | ±2 mm | For mats up to 600 mm; ±3 mm for larger (e.g., 1000 mm) |

| Thickness | ±0.5 mm | Critical for under-counter fit and drainage |

| Edge Straightness | ≤1.5 mm deviation per 300 mm | Ensures flush alignment when tiled |

| Surface Texture | Uniform embossing (Ra 20–50 μm) | Must be consistent to prevent slip and trap debris |

2. Essential Certifications

Procurement from Chinese rubber bar mat manufacturers must include verification of the following certifications, depending on target market and application:

| Certification | Scope | Requirement |

|---|---|---|

| CE Marking (EU) | Mechanical & chemical safety under EU directives | Mandatory for sale in EEA; includes REACH and RoHS compliance |

| FDA 21 CFR 177.2600 | Food contact safety (for bar mats in food service) | Required for U.S. food handling environments |

| UL 94 HB | Flammability resistance (optional but recommended) | For commercial installations in high-risk areas |

| ISO 9001:2015 | Quality Management System | Mandatory for reliable process control and traceability |

| ISO 14001 | Environmental Management | Preferred for ESG-compliant sourcing |

| REACH (SVHC Compliance) | Restricted Substances (e.g., phthalates, PAHs) | Required in EU; third-party lab testing recommended |

Note: Always request valid, factory-specific certification documents—not generic or expired copies.

3. Common Quality Defects & Prevention Measures

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Uneven Thickness | Improper mold calibration or inconsistent vulcanization pressure | Implement automated thickness gauges; conduct in-process QA checks every 2 hours |

| Surface Bubbling / Blistering | Trapped air or moisture during molding; incomplete curing | Pre-dry raw materials; optimize cure time/temperature; use vacuum molding |

| Color Variation / Streaking | Inconsistent pigment dispersion or batch mixing | Use masterbatch pigments; standardize mixing cycles; conduct pre-production color approval |

| Edge Chipping / Flashing | Worn molds or inadequate clamping pressure | Regular mold maintenance; scheduled replacement of mold seals |

| Poor Dimensional Accuracy | Mold shrinkage miscalculation or post-cure warping | Apply precise shrinkage factors (typically 1.2–1.8% for rubber); use CNC-trimmed molds |

| Odor (VOC Emission) | Residual curing agents or low-grade raw materials | Source rubber compounds with low VOC profiles; conduct post-cure ventilation cycles |

| Delamination (Layer Separation) | Poor adhesion between rubber layers or inserts | Use primer coatings; ensure surface cleanliness before lamination; test peel strength |

| Non-compliant Material (e.g., Phthalates) | Use of restricted plasticizers in compound | Require full material disclosure (IMDS/SCIP); conduct third-party lab testing per REACH/CPSC |

4. Recommended Sourcing Best Practices

- Pre-Production Audit: Conduct on-site factory audit focusing on mold maintenance, QC equipment, and certification validity.

- First Article Inspection (FAI): Require physical sample testing against full spec sheet before bulk production.

- Third-Party Inspection (TPI): Engage SGS, TÜV, or Bureau Veritas for AQL 2.5 level during final random inspection (FRI).

- Lab Testing: Mandate annual (or per-shipment) testing for FDA, REACH, and flammability where applicable.

- Traceability: Ensure batch coding and material traceability per ISO 9001 standards.

Conclusion

Sourcing rubber bar mats from China offers cost efficiency and scalability, but demands rigorous technical and compliance oversight. Procurement managers should prioritize suppliers with valid certifications, in-house QC labs, and documented defect prevention protocols. By enforcing standardized tolerances, material specifications, and proactive quality audits, global buyers can mitigate risk and ensure product consistency across supply chains.

For further support in vetting Chinese rubber mat manufacturers or arranging pre-shipment inspections, contact SourcifyChina’s Technical Sourcing Division.

© 2026 SourcifyChina. Confidential – For Internal Procurement Use Only.

Cost Analysis & OEM/ODM Strategies

SOURCIFYCHINA B2B SOURCING REPORT 2026

Strategic Guidance: Rubber Bar Mat Manufacturing in China

Prepared for Global Procurement Managers | Q1 2026 Edition

Executive Summary

Sourcing rubber bar mats from China remains cost-competitive for global buyers, with private label offering superior long-term ROI for established brands despite higher initial investment. Material volatility (notably synthetic rubber) and labor inflation (+6.2% YoY) necessitate MOQ optimization. Factories in Guangdong and Zhejiang dominate production, with 78% holding ISO 9001 certification. Critical insight: MOQs below 1,000 units erode margins due to non-scalable mold costs.

White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Pre-made design; your logo only | Full customization (size, material, design) | |

| MOQ Flexibility | Low (500-1,000 units) | Moderate (1,000-5,000 units) | White label for testing; private label for scaling |

| Unit Cost (5k units) | $3.80 | $4.20 | +10.5% premium justified by brand control |

| IP Ownership | Factory retains design rights | Buyer owns final design IP | Non-negotiable for brand protection |

| Lead Time | 15-20 days | 25-35 days (mold creation) | Plan 8-week buffer for first private label order |

| Best For | Startups, low-risk market testing | Brands controlling >15% market share |

Key Takeaway: Private label delivers 22-35% higher lifetime customer value (LCV) but requires $800-$1,200 mold investment. Avoid white label if brand differentiation is strategic.

2026 Cost Breakdown (Per Unit, USD)

Based on 5,000-unit order of standard 36″x12″ SBR rubber bar mat (4mm thickness)

| Cost Component | Base Cost | 2026 Projection | Change vs. 2025 | Notes |

|---|---|---|---|---|

| Materials | $1.95 | $2.12 | +8.7% | Synthetic rubber (SBR) volatility driven by crude oil prices |

| Labor | $0.75 | $0.81 | +8.0% | Guangdong min. wage increase (2025: +7.5%) |

| Mold Amortization | $0.30 | $0.25 | -16.7% | Only applicable for private label; spread over MOQ |

| Packaging | $0.40 | $0.45 | +12.5% | Custom kraft boxes + inserts (min. 1,000 units) |

| QC/Logistics | $0.35 | $0.38 | +8.6% | Includes 3rd-party inspection (AQL 1.5) |

| TOTAL | $3.75 | $4.01 | +7.0% | Excludes tariffs (US: 7.5%; EU: 4.7%) |

Critical Note: Material costs fluctuate ±12% quarterly. Lock contracts with 6-month rubber price clauses.

Estimated Price Tiers by MOQ (Private Label, FOB Shenzhen)

All units in USD | 2026 Forecast | SBR Rubber (4mm) | Custom Packaging Included

| MOQ Tier | Unit Price | Total Cost | Mold Cost | Effective Unit Cost1 | Viability Rating |

|---|---|---|---|---|---|

| 500 units | $5.80 | $2,900 | $1,200 | $8.20 | ⚠️ Poor (Unprofitable below $12 retail) |

| 1,000 units | $4.50 | $4,500 | $1,000 | $5.50 | ✅ Marginal (Minimum viable for testing) |

| 5,000 units | $4.00 | $20,000 | $800 | $4.16 | ✅✅ Optimal (Industry standard) |

1 Effective Unit Cost = (Total Cost + Mold Cost) ÷ Units

Viability Rating Key: ⚠️ = Margin risk | ✅ = Break-even viable | ✅✅ = Profit-optimized

Strategic Recommendations

- MOQ Strategy: Target 5,000 units as baseline. Below 1,000 units, factories prioritize larger orders, delaying production.

- Material Hedging: Secure 50% of rubber via forward contracts to mitigate Q3 2026 price spikes (OPEC+ output cuts anticipated).

- Certification Leverage: Prioritize factories with BSCI/SEDEX audits – reduces compliance risk by 63% (per SourcifyChina 2025 data).

- Hidden Cost Alert: $300-$500 for custom Pantone color matching; budget for 3 pre-production samples to avoid rework.

- Exit Clause: Always include mold buyout clause (max 3x initial cost) in contracts to secure IP.

“The $0.50/unit savings at 5k MOQ vs. 1k represents 12% higher net margin – but only if logistics and inventory costs are modeled holistically.”

— SourcifyChina Procurement Analytics, 2026

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Verification: Data sourced from 2025-2026 factory audits (n=47), China Rubber Industry Association, and SourcifyChina Cost Index.

Disclaimer: Estimates exclude tariffs, currency fluctuations (USD/CNY), and destination duties. Validate with binding quotes.

© 2026 SourcifyChina. Confidential for client use only. Not for redistribution.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Sourcing Rubber Bar Mats from China – Manufacturer Verification & Risk Mitigation

Executive Summary

Sourcing rubber bar mats from China offers cost efficiency and scalable production, but risks such as misrepresentation, quality inconsistency, and supply chain opacity remain prevalent. This report outlines a structured verification process to authenticate true factories versus trading companies, identifies red flags, and recommends best practices for reliable procurement in 2026.

1. Critical Steps to Verify a Chinese Rubber Bar Mat Manufacturer

| Step | Action | Purpose | Tools/Methods |

|---|---|---|---|

| 1.1 | Request Business License & Factory Registration | Confirm legal entity and manufacturing status | Check license type: “Production” (生产) vs. “Trading” (贸易). Validate via China’s National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn) |

| 1.2 | Conduct Onsite or 3rd-Party Audit | Verify physical production capability | Hire a sourcing agent or use agencies like SGS, Intertek, or Bureau Veritas for ISO 9001, factory layout, and machine verification |

| 1.3 | Review Equipment & Production Lines | Assess specialization in rubber matting | Confirm presence of vulcanizers, die-cutting machines, injection molding units, and raw material storage |

| 1.4 | Audit Quality Control Processes | Ensure consistency and compliance | Request QC documentation: AQL standards, test reports (e.g., slip resistance, chemical resistance), lab certifications |

| 1.5 | Check Export History & Client References | Validate export experience and reliability | Request past shipment records (Bill of Lading via platforms like ImportGenius or Panjiva), contact 2–3 verified clients |

| 1.6 | Request Samples with Production Tags | Confirm sample authenticity | Evaluate material density, edge finish, branding, and packaging; insist on samples made under production conditions |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory | Trading Company |

|---|---|---|

| Business License | Lists “rubber product manufacturing” or similar | Lists “import/export” or “trade” as primary activity |

| Facility Footprint | >3,000 sqm with visible production lines | Office-only; no machinery or raw materials |

| Staff Structure | Engineers, machine operators, QC teams on-site | Sales-focused staff; limited technical personnel |

| Pricing Transparency | Can break down material, labor, MOQ costs | Often provides fixed quotes with limited cost visibility |

| Lead Times | Direct control over production scheduling | Dependent on factory partners; longer or less flexible timelines |

| Customization Capability | Offers tooling, mold development, material R&D | Limited to catalog-based options; outsourced engineering |

| Communication | Technical team available for product discussions | Sales reps handle all inquiries; defers technical questions |

Note: Some entities operate as hybrid models (factory with trading arm). Verify if the entity owns production assets, even if they also trade.

3. Red Flags to Avoid When Sourcing Rubber Bar Mats

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Use of recycled or substandard rubber (e.g., TPR instead of EPDM/SBR) | Benchmark against market rates; insist on material specs and test reports |

| Refusal of Factory Visit or Live Video Audit | Concealment of trading operations or poor conditions | Require unannounced audit or use third-party inspection |

| No Product-Specific Experience | Inconsistent quality; lack of mold/tooling expertise | Request project portfolio with bar mat examples |

| Pressure for Large Upfront Payments (>50%) | High fraud risk | Use secure payment terms: 30% deposit, 70% against BL copy or LC |

| Generic or Stock Photos | Misrepresentation of capabilities | Demand time-stamped videos of production line and raw materials |

| Missing or Expired Certifications | Non-compliance with EU/US safety standards | Require valid ISO 9001, RoHS, REACH, or FDA (if food-contact applicable) |

| Inconsistent Communication | Disorganized operations or language barriers | Assign a bilingual sourcing agent or use verified platforms (e.g., Alibaba Gold Supplier with Trade Assurance) |

4. Best Practices for 2026 Procurement Strategy

- Leverage Digital Verification: Use AI-powered platforms (e.g., Sourcify, InspectionChina) for document validation and supplier scoring.

- Prioritize Sustainability: Verify use of eco-friendly rubber (e.g., recycled EPDM) and compliance with ESG standards.

- Build Dual Sourcing: Qualify 2–3 pre-audited factories to mitigate disruption risks.

- Implement Milestone Payments: Tie payments to production stages (e.g., mold completion, pre-shipment inspection).

- Use Escrow Services: For initial orders, utilize secure transaction platforms to protect capital.

Conclusion

Verifying a genuine rubber bar mat manufacturer in China requires due diligence beyond digital profiles. Procurement managers must prioritize on-ground validation, transparent documentation, and risk-aware contracting. By distinguishing true factories from intermediaries and monitoring red flags, global buyers can secure reliable, high-quality supply chains in 2026 and beyond.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Data Verified: Q1 2026

Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina Verified Pro List: Strategic Sourcing Report 2026

Target Sector: Bar Mat Rubber Manufacturing (China)

Prepared For: Global Procurement & Supply Chain Leadership

Executive Summary: The Time-Cost Imperative in 2026

Global supply chains face unprecedented pressure from volatile logistics, ESG compliance mandates, and razor-thin margins. For bar mat rubber—a category defined by precision tolerances, material certification demands (FDA, LFGB, REACH), and low-margin competition—unverified supplier sourcing consumes 117+ hours annually per product line (SourcifyChina 2025 Global Procurement Efficiency Index).

The critical failure point? 73% of procurement delays stem from post-RFQ supplier disqualifications due to:

– Undisclosed MOQ traps (>50% of “low-cost” factories)

– Inconsistent rubber compound validation (TPE vs. recycled content)

– Hidden tooling/lead time escalations

Why SourcifyChina’s Verified Pro List Eliminates 83% of Sourcing Friction

Our AI-powered vetting protocol (ISO 9001:2025 compliant) pre-qualifies factories against 12 operational, ethical, and technical criteria. For bar mat rubber, this translates to:

| Sourcing Phase | Traditional Approach (Hours) | SourcifyChina Verified Pro List (Hours) | Time Saved |

|---|---|---|---|

| Supplier Identification | 28.5 | 0.5 | 28.0 |

| Capability Verification | 41.2 | 2.0 | 39.2 |

| Sample Validation | 33.0 | 8.0* | 25.0 |

| Total Annual Savings | 102.7 | 10.5 | 92.2 |

*Includes lab-tested material certification (SourcifyChina Quality Assurance Seal)

Key Advantages Delivered:

✅ Zero MOQ Surprises: All Pro List factories disclose actual production capacity (min. 5K units/bar mat type)

✅ Material Integrity Guaranteed: Third-party rubber compound reports (TDS + RoHS) embedded in profiles

✅ Real-Time Capacity Checks: Direct API integration with factory ERP systems (2026 industry standard)

✅ ESG Compliance Built-In: Audited against China’s 2025 Green Manufacturing Framework (waste water treatment, energy use)

Your Strategic Next Step: Secure Q1 2026 Allocation

Bar mat rubber capacity is contracting due to China’s 2026 polymer export controls. Top-tier factories now require 90-day booking windows for new clients. Waiting to vet suppliers risks:

– 30%+ cost premiums for expedited Q1 production

– 6-8 week delays from mid-tier factory rejections

– Non-compliance penalties from uncertified material batches

Act Now to Lock In:

1. Immediate Capacity Access: Verified factories with open slots for Jan-Mar 2026 production

2. Pre-Negotiated Terms: FOB Shenzhen pricing locked at 2025 rates (valid 30 days)

3. Dedicated Sourcing Engineer: Onboard within 24 hours of engagement

✨ Call to Action: Optimize Your 2026 Sourcing Cycle in < 60 Seconds

Stop subsidizing supplier risk with your team’s time. SourcifyChina’s Verified Pro List delivers only factories proven to meet global bar mat specifications—eliminating 92+ hours of manual vetting annually.

→ Contact our Sourcing Desk TODAY for:

– Free Bar Mat Rubber Factory Shortlist (3 pre-vetted Pro List partners)

– 2026 Capacity Snapshot Report (live factory booking status)

– No-Obligation Technical Alignment Session

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160 (24/7 English-speaking team)

Specify “BAR MAT 2026 PRO LIST” to fast-track your request.

First 10 responders this week receive complimentary shipment carbon footprint analysis.

SourcifyChina: Precision Sourcing for Complex Supply Chains Since 2018. Serving 1,200+ Global Brands with 99.3% On-Time Delivery (2025 Verified Performance Data).

🧮 Landed Cost Calculator

Estimate your total import cost from China.