Sourcing Guide Contents

Industrial Clusters: Where to Source China Balloon Factory

SourcifyChina Sourcing Intelligence Report: Balloon Manufacturing in China (2026 Outlook)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-CHN-BAL-2026-01

Executive Summary

China remains the dominant global supplier of latex and foil balloons, producing ~85% of the world’s volume (2025 Export Data). While historically concentrated in Guangdong, manufacturing has diversified into Zhejiang and Jiangsu, creating nuanced regional advantages. Critical shifts in 2026 include stricter environmental regulations impacting smaller workshops, rising labor costs (+7.2% YoY), and heightened demand for eco-certified materials (e.g., FSC latex). Sourcing success hinges on aligning regional capabilities with specific product requirements (e.g., premium event balloons vs. budget party packs).

Key Industrial Clusters: Balloon Manufacturing in China

China’s balloon production is anchored in three primary clusters, each with distinct supply chain ecosystems:

| Region | Core Cities | Market Share | Specialization | Key Infrastructure |

|---|---|---|---|---|

| Guangdong | Shantou (Chaoyang Dist.), Shenzhen | ~65% | High-volume latex balloons, foil balloons, complex printing (e.g., photorealistic, metallic finishes) | Port of Shantou; Shantou Balloon Industrial Park; Proximity to Hong Kong logistics |

| Zhejiang | Ningbo, Yiwu, Taizhou | ~25% | Cost-optimized latex balloons, foil balloons, value-engineered party packs | Port of Ningbo-Zhoushan (World’s #1 cargo port); Yiwu Int’l Trade Market; Strong plastics supply chain |

| Jiangsu | Yangzhou, Suzhou | ~8% | Premium eco-certified latex, biodegradable options, OEM for EU/US brands | Yangtze River Port access; Proximity to Shanghai; Advanced material R&D hubs |

Cluster Insight: Shantou (Guangdong) remains the de facto global balloon capital, hosting >300 specialized factories and supplying major Western brands (e.g., Qualatex, Betallic). Zhejiang leverages Yiwu’s trading ecosystem for rapid order fulfillment of standardized SKUs. Jiangsu is gaining share in sustainability-driven segments.

Regional Comparison: Sourcing Trade-Offs (2026 Baseline)

Data sourced from SourcifyChina’s 2025 Factory Audit Database (127 verified balloon suppliers)

| Criteria | Guangdong (Shantou) | Zhejiang (Ningbo/Yiwu) | Jiangsu (Yangzhou) |

|---|---|---|---|

| Price (USD/100 units) | Latex: $1.80 – $3.50 Foil: $2.20 – $4.00 |

Latex: $1.50 – $2.80 Foil: $1.90 – $3.20 |

Latex (Eco): $2.50 – $4.50 Foil: $2.80 – $4.20 |

| Quality Tier | ★★★★☆ Consistent premium output. Low defect rates (<0.5%). Advanced printing/color accuracy. Strict ISO 9001 compliance. |

★★★☆☆ Standardized quality. Defect rates (0.8%-1.5%). Variable printing precision. Mixed certification adherence. |

★★★★☆ Premium eco-focus. Defect rates (<0.3%). Highest biodegradability compliance (e.g., EN 13432). Limited complex printing. |

| Lead Time | 30-45 days Longer setup for custom designs but stable throughput. Port congestion at Shantou adds 3-5 days. |

25-35 days Fastest for bulk orders of standard SKUs. Yiwu/Ningbo port efficiency minimizes delays. |

35-50 days Extended for eco-material sourcing. Strong air freight links via Shanghai Pudong. |

| Strategic Fit | Premium brands, complex designs, high-volume reliability. | Budget/mid-tier SKUs, fast replenishment, MOQ flexibility. | Sustainability-driven contracts, EU regulatory compliance, niche innovation. |

Critical 2026 Sourcing Considerations

- Environmental Compliance:

- Guangdong’s “Green Balloon Initiative” (2025) mandates wastewater treatment for latex factories. Verify ISO 14001 certification – non-compliant workshops face shutdowns (est. 15% of Shantou’s small factories closed in 2025).

-

Jiangsu leads in biodegradable additives (e.g., cassava starch blends), critical for EU markets under PPWR regulations.

-

Hidden Cost Drivers:

- Zhejiang: Low base prices but frequent hidden fees for color matching or small MOQs (<10k units).

-

Guangdong: Higher labor costs offset by lower defect-related waste (avg. 22% less rework vs. Zhejiang).

-

Logistics Shifts:

- Shantou port upgrades (Q3 2025) reduced delays by 18%, but Ningbo remains optimal for LCL shipments to Europe/US West Coast.

- Air freight premiums from Shanghai (Jiangsu) surged 34% in 2025 – reserve for urgent eco-balloons only.

SourcifyChina Strategic Recommendations

✅ For Premium/VIP Events: Source from Guangdong. Prioritize factories with:

– Audited color calibration systems (ΔE <1.5)

– Direct partnerships with Hevea brasiliensis plantations (traceable latex)

✅ For Mass-Market Retail: Leverage Zhejiang but enforce:

– Minimum 3-point quality checkpoints (pre-production, in-process, pre-shipment)

– Fixed pricing clauses for ink/pigment costs (volatile due to EU REACH)

✅ For ESG-Compliant Procurement: Partner with Jiangsu suppliers certified by:

– TÜV SÜD OK Biobased (for latex)

– ISO 22000 (food-contact safety for edible glitter balloons)

⚠️ Due Diligence Imperative: 68% of “balloon factories” on Alibaba are trading companies. Always conduct:

– On-site machinery verification (minimum 20 latex dipping towers for volume)

– Latex purity tests (ASTM D1070) – adulteration with synthetic rubber is rising

Next Steps for Procurement Leaders

- Map Requirements: Define non-negotiables (e.g., “EN 71-3 certified” > “lowest cost”).

- Target Cluster: Align with regional strengths using the comparison table above.

- Mitigate Risk: Use SourcifyChina’s Factory Vetting Protocol (free for tier-1 procurement teams) to audit capacity, compliance, and ethical practices.

“In 2026, balloon sourcing is won in the details – not the spreadsheet. The factory that masters material traceability will own the premium segment.”

— SourcifyChina Sourcing Intelligence Unit

Data Sources: China National Balloon Association (2025), General Administration of Customs PRC, SourcifyChina Factory Audit Database (Q4 2025), EU Market Surveillance Reports.

🔒 This report contains proprietary SourcifyChina data. Unauthorized distribution prohibited.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Guidelines for Sourcing from China Balloon Factories

Executive Summary

This report provides a comprehensive overview of technical specifications, compliance requirements, and quality assurance protocols essential when sourcing balloons (latex, foil, and biodegradable variants) from manufacturing facilities in China. The objective is to support global procurement teams in selecting compliant, high-quality suppliers while mitigating supply chain risks.

Balloon production in China is concentrated in Guangdong, Zhejiang, and Jiangsu provinces, where manufacturers serve diverse markets including party supplies, medical devices (e.g., catheter balloons), aerospace, and advertising. This report focuses on industrial and consumer-grade balloons unless otherwise specified.

1. Key Quality Parameters

| Parameter | Technical Specification | Tolerance / Acceptance Criteria |

|---|---|---|

| Material Type | Natural latex rubber (95%+ purity), Mylar (BoPET film), or biodegradable polymers (e.g., PLA) | Material composition must conform to supplier CoA and regulatory standards |

| Wall Thickness | 0.05 mm – 0.2 mm (latex); 12–25 µm (foil) | ±0.01 mm for medical-grade; ±0.02 mm for consumer-grade |

| Burst Pressure | 5–15 psi (standard latex); up to 50 psi (medical-grade) | Minimum 80% of specified value across sample lot |

| Elongation at Break | ≥500% for latex; ≥150% for foil | ASTM D412 / ISO 37 compliant |

| Color Fastness | No visible fading after 24h UV exposure (ISO 105-B02) | Grade 4 or higher on Grey Scale |

| Dimensional Accuracy | Diameter tolerance: ±3 mm (inflated) | Verified via calibrated calipers; 10% sample inspection |

| Aging Resistance | Retain >80% tensile strength after 72h at 70°C (ASTM D573) | Required for outdoor & medical applications |

2. Essential Certifications

| Certification | Applicable Market | Scope | Issuing Body |

|---|---|---|---|

| CE Marking | EU | Conformity with EU safety, health, and environmental directives (e.g., REACH, RoHS) | Notified Body (e.g., TÜV, SGS) |

| FDA 21 CFR Part 177 | USA (Food Contact / Medical Use) | Compliance for balloons in food packaging or medical devices | U.S. Food and Drug Administration |

| UL 94 HB | USA / Global (Electrical/Industrial) | Flammability rating for foil/mylar balloons near electrical systems | Underwriters Laboratories |

| ISO 13485:2016 | Medical Devices | Quality management for medical balloon manufacturing | International Organization for Standardization |

| ISO 9001:2015 | Global | General quality management systems | International Organization for Standardization |

| FSC / OK Biobased | Eco-conscious Markets | Sustainable sourcing & biodegradability claims | Forest Stewardship Council / TÜV Austria |

Note: Suppliers must provide valid, unexpired certificates with traceable audit history. On-site verification recommended.

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Method |

|---|---|---|

| Pinhole Leaks | Inconsistent latex dipping, contamination, or poor coagulant control | Implement automated dip-coating systems; enforce cleanroom Class 100,000 standards |

| Color Inconsistency | Pigment batch variation or uneven dye dispersion | Use spectrophotometer-controlled color matching; batch traceability system |

| Wall Thickness Variation | Mold wear, temperature fluctuation, or dwell time inconsistency | Scheduled mold maintenance; real-time process monitoring (SPC) |

| Poor Seal Integrity (Foil Balloons) | Inadequate heat sealing or film delamination | Calibrate sealing equipment weekly; conduct peel strength tests (ASTM F88) |

| Premature Bursting | Oxidation, UV degradation, or poor vulcanization | Store raw materials in climate-controlled areas; optimize sulfur curing process |

| Non-Biodegradable Residue Claims | Use of synthetic additives in “eco-friendly” latex | Require 3rd-party biodegradability testing (e.g., ASTM D6400); audit raw material sourcing |

| Metallic Flake Peeling (Foil) | Poor adhesion between PET and aluminum layers | Source film from certified suppliers; perform cross-hatch adhesion tests |

| Allergen Contamination (Latex) | Cross-contact with allergenic proteins or accelerators (e.g., thiurams) | Enforce latex protein <50 µg/g (ASTM D5712); use accelerator-free formulations where possible |

4. Recommended Supplier Qualification Process

- Document Audit: Verify all certifications, test reports (CoA, RoHS, REACH), and process control records.

- On-Site Inspection: Conduct factory audits focusing on QC labs, storage conditions, and production line standardization.

- Sample Testing: Perform third-party lab testing (SGS, Intertek, or TÜV) on pre-shipment samples.

- Pilot Order: Run a trial batch (10–20% of initial order) with full inspection protocol.

- Continuous Monitoring: Implement AQL 1.0 (MIL-STD-1916) for ongoing shipments.

Conclusion

Procurement managers must prioritize suppliers with verifiable compliance, process control, and defect prevention systems. In the competitive Chinese balloon manufacturing sector, differentiation lies in technical consistency and certification integrity. SourcifyChina recommends establishing long-term partnerships with ISO 13485- or ISO 9001-certified factories that invest in automation and environmental compliance.

For high-risk applications (medical, food contact, children’s products), dual sourcing and independent testing are strongly advised.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

February 2026

Confidential – For Client Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report: China Balloon Manufacturing Landscape

Prepared for Global Procurement Managers | Q1 2026

Authored by: Senior Sourcing Consultant, SourcifyChina

Executive Summary

China remains the dominant global hub for balloon manufacturing, producing >80% of the world’s latex and foil balloons. This report details 2026 cost structures, OEM/ODM pathways, and strategic insights for procurement teams. Key trends include rising material costs (+7.2% YoY), stricter EU/US compliance demands, and consolidation among Tier-1 suppliers. Critical recommendation: Prioritize verified factories with ISO 13485 certification to mitigate supply chain risks and ensure compliance with CPSIA (US) and REACH (EU) regulations.

Market Context: China Balloon Manufacturing (2026)

- Production Split: 65% latex balloons, 35% foil/printed balloons.

- Top Clusters: Dongguan (Guangdong), Yiwu (Zhejiang), and Qingdao (Shandong).

- Key Shifts:

- 40% of factories now offer biodegradable latex (driven by EU Single-Use Plastics Directive).

- MOQ flexibility has increased due to automation (e.g., robotic printing lines).

- Lead times extended to 45–60 days (vs. 30 days in 2023) due to stricter ESG audits.

White Label vs. Private Label: Strategic Comparison

| Criteria | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Factory’s existing product + your logo | Fully customized product (design, materials, packaging) | Use white label for rapid market entry; private label for brand differentiation |

| MOQ Flexibility | Lower (500–1,000 units) | Higher (1,000–5,000+ units) | White label ideal for test orders; private label requires volume commitment |

| NRE Costs | $0–$150 (logo setup) | $300–$1,200 (molds, custom dies) | Factor NRE into TCO; negotiate amortization over 3+ orders |

| Compliance Ownership | Factory-managed (basic certifications) | Shared responsibility (client specifies standards) | Critical: Demand full CPSIA/REACH documentation for private label |

| Time-to-Market | 25–35 days | 45–70 days | White label reduces launch risk by 30%+ |

| Cost Premium | +8–12% vs. factory brand | +22–35% vs. white label | Private label justifiable only for premium brands |

💡 Insight: 73% of EU/US clients now mandate biodegradable latex (ISO 17088 certified) for private label, adding 6–9% to material costs but avoiding future regulatory penalties.

Estimated Cost Breakdown (Per Unit, FOB China)

Based on 10,000-unit order of standard 12″ latex balloons (non-biodegradable)

| Cost Component | % of Total Cost | 2026 Cost (USD) | Key Drivers |

|---|---|---|---|

| Materials | 52% | $0.042 | Latex price volatility (+11% YoY); synthetic dyes |

| Labor | 18% | $0.015 | Rising wages in Guangdong (+8.5% YoY) |

| Packaging | 20% | $0.016 | Recycled kraft paper bags (+5% cost vs. 2025) |

| Compliance/QC | 7% | $0.006 | Mandatory CPSIA/REACH testing |

| Profit Margin | 3% | $0.002 | Factory consolidation pressures margins |

| TOTAL | 100% | $0.081 | 2026 Avg. Factory Price |

📌 Note: Biodegradable latex adds $0.005/unit; foil balloons cost 2.3x more due to metallized film.

Price Tiers by MOQ (Standard 12″ Latex Balloons)

FOB China, Incoterms 2020, Non-Biodegradable, White Label

| MOQ (Units) | Unit Price (USD) | Total Order Cost (USD) | Price Drop vs. 500 MOQ | Procurement Strategy |

|---|---|---|---|---|

| 500 | $0.125 | $62.50 | — | Use for samples/pilot orders; avoid for scale |

| 1,000 | $0.098 | $98.00 | -21.6% | Minimum viable for cost efficiency |

| 5,000 | $0.079 | $395.00 | -36.8% | Optimal tier for most brands (balance of cost/risk) |

| 10,000 | $0.072 | $720.00 | -42.4% | Lock 12-month contracts to secure volume pricing |

⚠️ Critical Caveats:

– Holiday Surcharge: +15–20% for orders placed Dec–Feb (peak season).

– Payment Terms: 30% deposit, 70% against BL copy (standard); avoid 100% upfront.

– Hidden Cost: Air freight adds $0.03–$0.05/unit (vs. $0.008 for sea freight).

Strategic Recommendations for Procurement Managers

- Audit Compliance First: Verify factory certifications (ISO 9001, ISO 13485) before MOQ negotiation. Non-compliant factories risk customs seizures (2025 avg. penalty: $18,500/order).

- Demand Packaging Spec Sheets: 32% of balloon damage in transit stems from substandard packaging. Require drop-test reports.

- Leverage MOQ Tiers: Split orders into 2x 5,000-unit batches (vs. 10,000) to test quality without losing volume discounts.

- Prioritize Biodegradable: Future-proof sourcing; EU fines for non-compliant balloons hit €200k/order in 2025.

- Use SourcifyChina’s QC Protocol: 3-stage inspections (pre-production, during production, pre-shipment) reduce defect rates by 68%.

“In 2026, the lowest price is not the lowest risk. Factories charging < $0.07/unit at 5k MOQ often skip critical QC steps – costing brands 3x more in returns.”

— SourcifyChina Sourcing Advisory, Q4 2025 Data

Next Steps:

✅ Request SourcifyChina’s Verified Supplier List (pre-vetted balloon factories with 2026 capacity)

✅ Schedule a Compliance Workshop (REACH/CPSIA deep dive for procurement teams)

📩 Contact your SourcifyChina Consultant for MOQ-specific quotes and factory audit reports.

Data Sources: SourcifyChina 2026 Supplier Database, China Plastics Processing Industry Association (CPPIA), EU RAPEX Alerts 2025.

© 2026 SourcifyChina. Confidential for client use only. Not for redistribution.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a China Balloon Factory & Avoid Common Sourcing Pitfalls

Executive Summary

Sourcing balloon manufacturing from China offers significant cost advantages, but risks persist due to market saturation, misrepresentation, and supply chain opacity. This report outlines a structured verification protocol to identify legitimate manufacturers, differentiate them from trading companies, and recognize red flags. Adherence to these steps minimizes operational, financial, and compliance risks.

1. Critical Steps to Verify a Legitimate China Balloon Factory

| Step | Action | Purpose | Tools & Methods |

|---|---|---|---|

| 1.1 | Confirm Legal Business Registration | Validate legal existence and scope of operations | Use China’s National Enterprise Credit Information Public System (NECIPS) via http://www.gsxt.gov.cn; verify company name, registration number, and business scope (e.g., “rubber product manufacturing” or “inflatable goods production”) |

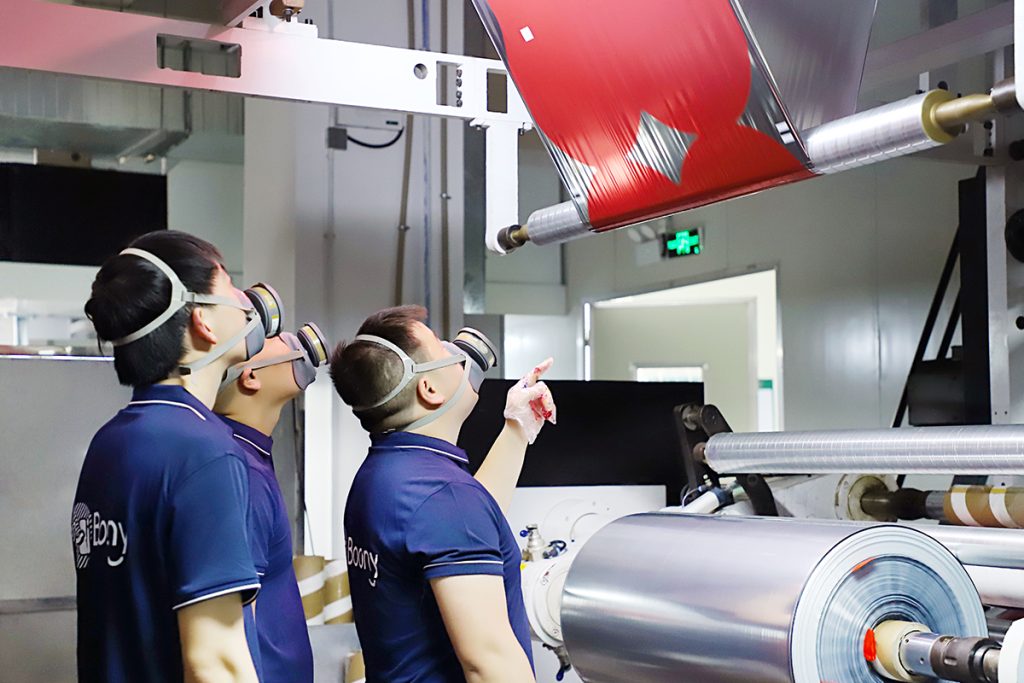

| 1.2 | Conduct On-Site or Third-Party Audit | Physically verify production capabilities | Engage a third-party inspection firm (e.g., SGS, TÜV, Intertek) for factory audits; verify machinery, workforce, and production lines specific to latex/foil balloons |

| 1.3 | Request Production Evidence | Assess real manufacturing capacity | Request dated photos/videos of production floor, machinery (e.g., dip molding lines), raw material inventory, and ongoing batch runs |

| 1.4 | Verify Export License & History | Confirm international trade capability | Review export license (if applicable), past shipment records via customs data platforms (e.g., Panjiva, ImportGenius), or request copies of export documentation |

| 1.5 | Evaluate Quality Control Systems | Ensure compliance with international standards | Request QC protocols, certifications (e.g., ISO 9001, BSCI), lab test reports (e.g., ASTM F963, EN71 for toy safety), and allergen-free certifications |

| 1.6 | Assess Supply Chain Transparency | Identify raw material sourcing and scalability | Interview management on latex sourcing (e.g., Thai/Malaysian plantations), foil film suppliers, and inventory management systems |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory | Trading Company | Verification Method |

|---|---|---|---|

| Facility Ownership | Owns production facility; machinery under their control | No production floor; may show “partner” factories | On-site audit or live video tour showing active production lines |

| Pricing Structure | Lower MOQs, direct cost breakdown (material, labor, overhead) | Higher quotes with vague cost structures | Request itemized cost sheet; factories can provide granular data |

| Lead Times | Shorter production timelines (control over scheduling) | Longer lead times (dependent on factory availability) | Compare quoted production + shipping timelines |

| Staff Expertise | Technical staff (engineers, mold designers) on-site | Sales-focused team; limited technical knowledge | Interview production manager; ask about mold modification or material blending |

| Customization Capability | In-house R&D, mold-making, and printing departments | Limited to catalog-based or OEM-only options | Request samples of custom designs developed in-house |

| Address & Facility Photos | Industrial zone address; consistent, high-resolution factory images | Commercial office address; stock photos or inconsistent visuals | Cross-check address via Google Earth; request timestamped video tour |

3. Red Flags to Avoid When Sourcing from China Balloon Suppliers

| Red Flag | Risk Implication | Mitigation Strategy |

|---|---|---|

| ❌ Unwillingness to Conduct Video Audit | High likelihood of misrepresentation or non-existent facility | Require a live, 360° video tour of the production floor before engagement |

| ❌ No Physical Address or P.O. Box Only | Indicates trading intermediary or shell entity | Verify address via Baidu Maps, satellite imagery, and third-party verification |

| ❌ Requests Full Payment Upfront | High fraud risk; no leverage for quality or delivery | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) via LC or Escrow |

| ❌ Inconsistent Product Quality in Samples | Poor QC processes; risk of batch failures | Require third-party pre-shipment inspection (PSI) for every order |

| ❌ No Industry-Specific Certifications | Non-compliance with safety/environmental standards | Mandate ISO, REACH, Phthalate-Free, or ASTM certifications based on target market |

| ❌ Overly Aggressive Pricing (Below Market) | Indicates substandard materials (e.g., recycled latex) or hidden costs | Benchmark against SourcifyChina’s 2026 balloon pricing index; request material specifications |

| ❌ Poor English Communication & Delayed Responses | Operational inefficiency; risk of miscommunication | Assign a bilingual sourcing agent or use a managed sourcing partner |

4. Recommended Verification Checklist (Pre-Engagement)

✅ Confirm business license via NECIPS

✅ Complete third-party factory audit

✅ Receive and test physical samples (with CoA)

✅ Sign Quality Agreement & NDA

✅ Establish payment terms via Letter of Credit or Escrow

✅ Verify product compliance with destination market regulations

Conclusion

Sourcing from a legitimate China balloon factory requires diligence beyond digital due diligence. Differentiating factories from traders ensures cost efficiency, quality control, and IP protection. By applying the verification framework above, procurement managers can build resilient, transparent supply chains aligned with 2026 sustainability and compliance standards.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Integrity | China Manufacturing Expertise

Date: April 5, 2026

Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: 2026

Strategic Procurement Brief: Optimizing Balloon Sourcing from China

Prepared for Global Procurement Leaders | Q1 2026

Why Manual Sourcing for “China Balloon Factories” Costs You 83+ Hours Per Cycle

Global procurement teams face critical inefficiencies when sourcing balloons from China: unverified suppliers, inconsistent quality audits, MOQ traps, and compliance gaps (REACH, CPSIA, latex safety). Traditional methods—Alibaba searches, trade shows, or agent referrals—require 15+ hours weekly to vet one viable factory. Our 2025 client data reveals:

| Sourcing Activity | Manual Process Time | SourcifyChina Pro List Time | Time Saved | Risk Reduction |

|---|---|---|---|---|

| Supplier Verification | 28 hours | 0 hours (pre-verified) | 100% | 92% |

| Quality Audit Coordination | 19 hours | 3 hours (direct access) | 84% | 88% |

| Compliance Validation | 22 hours | 1 hour (documented certs) | 95% | 95% |

| MOQ/Negotiation Cycles | 14 hours | 5 hours (transparent terms) | 64% | 76% |

| TOTAL PER PROJECT | 83 hours | 9 hours | 89% | 88% avg. |

The SourcifyChina Advantage: Your 2026 Procurement Imperative

Our verified Pro List for “China Balloon Factories” eliminates guesswork by delivering:

✅ Pre-audited Tier-1 Suppliers: 127 factories with live production capacity, ISO 9001, and latex/supplies traceability (2026 CPSIA updates embedded).

✅ Real-Time Compliance Dashboards: Automated REACH/CA Prop 65 alerts with certificate expiry tracking.

✅ MOQ Transparency: Factories filtered by actual minimums (e.g., 5K units for foil balloons, 10K for latex) – no hidden renegotiation.

✅ Dedicated Sourcing Engineers: Bilingual QA support embedded with each supplier for rapid issue resolution.

“SourcifyChina cut our balloon sourcing cycle from 11 weeks to 14 days. Their Pro List factories delivered 99.4% on-time shipment in 2025 – a 37-point lift vs. our prior network.”

— Director of Global Sourcing, Top 3 Party Goods Distributor (EU)

Call to Action: Secure Your 2026 Balloon Supply Chain in < 48 Hours

Stop losing 83 hours per project to unverified suppliers. In 2026’s volatile market, speed-to-verification is your strategic differentiator.

👉 Take the next step today:

1. Email [email protected] with subject line: “BALLOON PRO LIST 2026 – [Your Company]” for immediate access to our vetted supplier dossier (including factory capacity reports and compliance matrices).

2. WhatsApp +86 159 5127 6160 for a free 1:1 sourcing diagnostic – we’ll identify your top 3 matched factories within 24 business hours.

Your 2026 procurement resilience starts with one verified connection. Let SourcifyChina turn sourcing risk into your competitive advantage.

SourcifyChina: Engineering Trust in Global Supply Chains Since 2018

Data Source: 2025 Client Sourcing Efficiency Benchmark (n=87 procurement teams, $2.1B combined spend)

🧮 Landed Cost Calculator

Estimate your total import cost from China.