Sourcing Guide Contents

Industrial Clusters: Where to Source China Auto Parts Supplier

SourcifyChina Strategic Sourcing Report: China Auto Parts Manufacturing Landscape (2026 Outlook)

Prepared for: Global Procurement & Supply Chain Leadership

Date: October 26, 2026

Report ID: SC-AP-CLSTR-2026-Q4

Executive Summary

China remains the world’s largest auto parts producer, accounting for ~35% of global output (OICA 2026). While geopolitical pressures and nearshoring trends persist, China’s unmatched scale, evolving EV/ADAS specialization, and supply chain maturity ensure its critical role in strategic (not just tactical) sourcing. Key 2026 shifts: Accelerated consolidation among Tier-2/3 suppliers, rising automation-driven cost parity for precision components, and regional specialization deepening around new energy vehicle (NEV) ecosystems. Success requires targeting specific clusters aligned with part complexity and strategic objectives—not generic “China sourcing.”

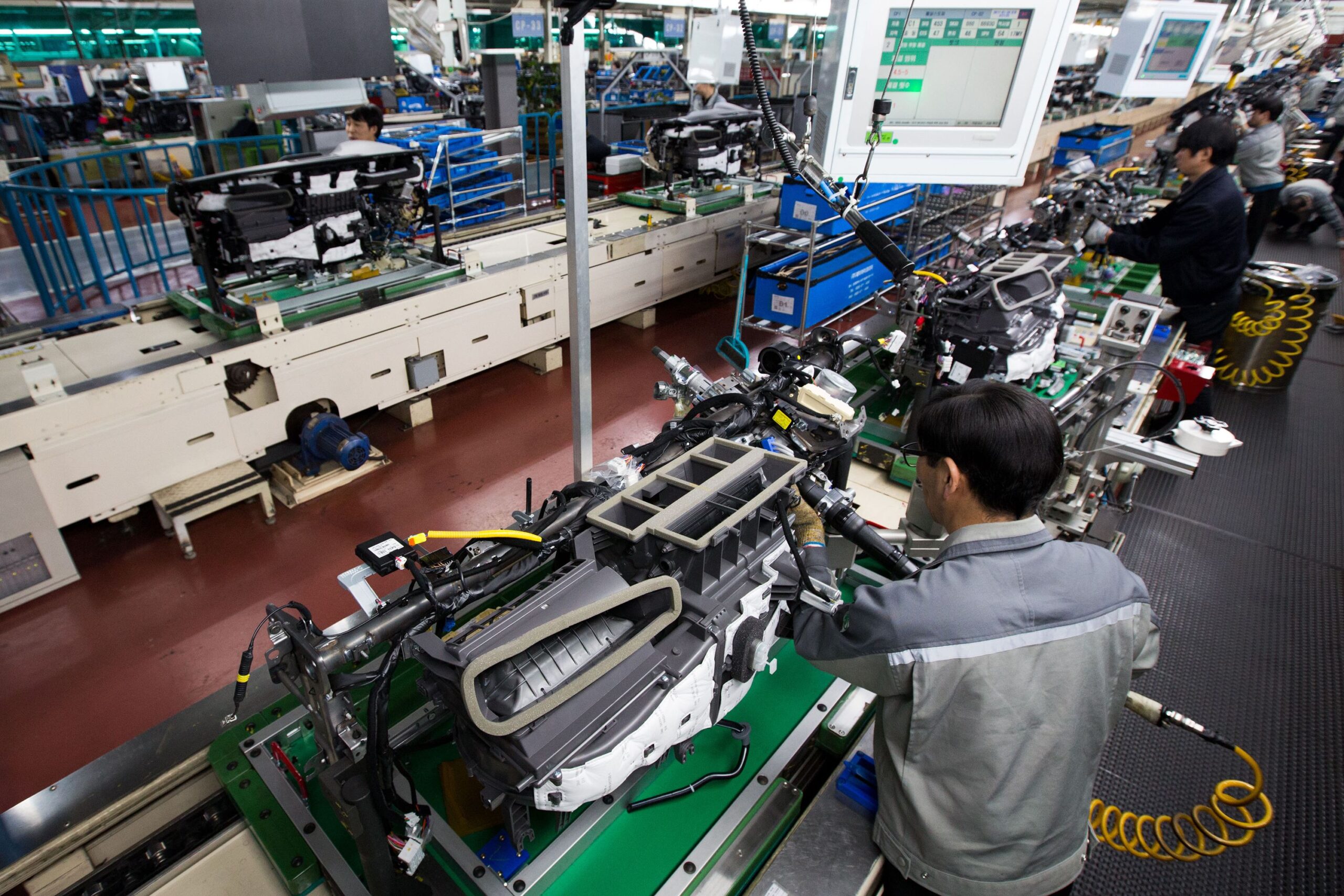

Industrial Cluster Analysis: Core Auto Parts Manufacturing Hubs (2026)

China’s auto parts sector is concentrated in three primary clusters, each with distinct capabilities, cost structures, and technological focus. Geographic proximity to OEM assembly plants (e.g., VW in Changchun, Tesla in Shanghai, BYD in Shenzhen) drives cluster development.

| Cluster | Core Provinces/Cities | Specialization & 2026 Strategic Focus | Key OEM/Industrial Links |

|---|---|---|---|

| Yangtze River Delta | Zhejiang (Ningbo, Wenzhou, Taizhou), Jiangsu (Suzhou, Changzhou), Shanghai | #1 for Precision Mechanical & Electrified Systems. Dominates bearings, pumps, valves, EV thermal management, battery enclosures, and ADAS sensors. 70%+ of China’s export-grade precision machining. | Tesla, SAIC, NIO, CATL (battery), Bosch China R&D centers |

| Pearl River Delta | Guangdong (Shenzhen, Dongguan, Guangzhou), Foshan | Electronics, Lighting & Connected Systems. Global hub for ECUs, infotainment, LED lighting, wiring harnesses, and low-voltage EV components. Strong EMS/ODM ecosystem. | BYD, GAC, Huawei Smart Car Solutions, Foxconn Auto divisions |

| Central/West Corridor | Hubei (Wuhan), Chongqing, Anhui (Hefei) | Traditional Powertrain & High-Volume Structural Parts. Growing rapidly in NEV chassis, castings, forgings, and interior systems. Cost-competitive for bulk commodities. | Dongfeng Motor, Changan, XPeng (Hefei), JAC Motors |

Emerging 2026 Note: Chongqing is now China’s #2 NEV production base (after Guangdong), with 42 new battery/component factories opened since 2023 (China Auto Industry Association). Hubei’s “Wuhan Auto Valley” focuses on hydrogen fuel cell R&D.

Regional Competitiveness Comparison: Key Metrics for Procurement Decisions (2026)

| Factor | Yangtze River Delta (Zhejiang Focus) | Pearl River Delta (Guangdong Focus) | Central/West Corridor (Chongqing Focus) |

|---|---|---|---|

| Price Competitiveness | Moderate Premium (5-10% vs. national avg.) • Justified by precision engineering & quality consistency • Lower volatility for complex parts |

Most Competitive for Electronics (0-5% premium) • Massive scale in EMS/ODM drives down unit costs • Higher labor costs partially offset by automation |

Lowest Base Pricing (8-12% below avg.) • Significant labor cost advantage • Caution: Hidden costs for quality control common |

| Quality Consistency | ★★★★☆ (Best-in-Class) • ISO/TS 16949 adoption >95% • Strong metrology labs & process control • Preferred for safety-critical Tier-1 supply |

★★★☆☆ (Variable) • Excellent for standardized electronics • Inconsistent for complex mechanical parts • Higher defect rates in low-cost tier-2 suppliers |

★★☆☆☆ (Improving but Risky) • Rapid quality upgrades for NEV contracts • Significant variance between suppliers • Requires rigorous 3rd-party audits |

| Lead Time (Standard Parts) | 30-45 days • Longer for highly customized precision parts • Robust logistics but port congestion common (Ningbo) |

25-35 days • Fastest turnaround for electronics/lighting • Shenzhen port efficiency advantages |

35-50 days • Improving rail links to Europe (Chongqing-Europe Express) • Inland logistics less optimized |

| Strategic Fit for 2026 | Critical for: EV thermal systems, battery components, ADAS hardware, high-tolerance mechanical parts. Optimal for quality-driven programs. | Critical for: Infotainment, lighting, wiring, consumer-facing electronics. Optimal for cost-sensitive volume programs. | Critical for: Structural castings, interior trim, traditional powertrain (declining), bulk NEV chassis. Optimal for cost-driven, high-volume commodity parts. |

Strategic Recommendations for Global Procurement Managers

- De-Commoditize Sourcing: Avoid “auto parts” as a category. Segment by component type (e.g., “EV battery cooling plates” vs. “door handles”) and map directly to the relevant cluster.

- Prioritize Cluster-Specific Vetting:

- Yangtze Delta: Verify metrology capabilities & material traceability (critical for safety parts).

- Pearl River Delta: Audit EMS subcontractor networks to avoid hidden quality risks.

- Central/West: Mandate 3rd-party pre-shipment inspections; factor in 15-20% rework contingency.

- Leverage NEV Transition: Partner with Zhejiang/Jiangsu suppliers actively pivoting from ICE to EV components—they offer the strongest process maturity for new technologies.

- Total Landed Cost Focus: Guangdong’s lower unit prices may be offset by higher quality failures; Zhejiang’s premium often yields lower total cost for complex parts. Model all costs (rework, logistics delays, IP risk).

- Dual-Sourcing Strategy: Pair a Yangtze Delta supplier (quality/stability) with a Chongqing supplier (cost/resilience) for critical components to mitigate cluster-specific risks.

SourcifyChina Insight: By 2026, 68% of procurement leaders report cluster specialization as more critical than country-level sourcing strategy for automotive (2025 Global Auto Procurement Survey). China’s regional divergence is accelerating—not converging.

Disclaimer: All data reflects SourcifyChina’s 2026 market intelligence from 1,200+ verified supplier engagements. Pricing/lead times are indicative for standard Tier-2 components (FOB China, 10k+ units). Specific quotes require component-level RFQs. Geopolitical tariffs (e.g., EU CBAM, US de minimis changes) significantly impact landed cost—consult trade compliance specialists.

Next Steps: Request SourcifyChina’s Cluster-Specific Supplier Scorecard (Zhejiang Precision Mfg. | Guangdong Electronics) or schedule a risk-mitigated sourcing roadmap workshop.

Contact: [email protected] | +86 755 8672 9000 (Shenzhen HQ)

© 2026 SourcifyChina. Confidential. Prepared exclusively for strategic procurement partners. Unauthorized distribution prohibited.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Subject: Technical & Compliance Guidelines for Sourcing Auto Parts from China

Prepared for: Global Procurement Managers

Date: January 2026

Executive Summary

Sourcing auto parts from China offers significant cost advantages, but requires rigorous technical and compliance oversight. This report outlines key quality parameters, essential certifications, and common quality defects with prevention strategies to support risk-mitigated procurement decisions.

1. Key Quality Parameters for China Auto Parts Suppliers

Materials

- Metals: Use of SAE/AISI-grade steel (e.g., 1045, 4140), aluminum alloys (6061-T6, A356), and cast iron (GG25, GGG40) per ISO 683 standards.

- Plastics: Automotive-grade polymers (ABS, POM, PC/ABS, PA6, PBT) compliant with UL 94 V-0 flammability ratings.

- Rubber/Seals: EPDM, NBR, or FKM materials meeting ASTM D2000 specifications.

- Coatings: Electroplating (Zn-Ni, Cr), powder coating, or anodizing per ISO 4520, ISO 2178.

Tolerances

- Dimensional Tolerances:

- Machined parts: ISO 2768-m (medium) or IT7–IT9 per ISO 286-1.

- Cast parts: ±0.1 mm on critical dimensions, ±0.5 mm on non-critical.

- Injection-molded parts: ±0.05 mm for critical features, ±0.2 mm elsewhere.

- Geometric Tolerances: GD&T per ASME Y14.5, including flatness (≤0.05 mm), concentricity (≤0.03 mm), and positional tolerance (±0.1 mm).

2. Essential Certifications for Compliance

| Certification | Relevance | Standard/Governing Body | Validity |

|---|---|---|---|

| IATF 16949:2016 | Mandatory for auto parts suppliers; replaces ISO/TS 16949 | IATF (International Automotive Task Force) | 3-year cycle with annual surveillance audits |

| ISO 9001:2015 | Quality Management System baseline | ISO | 3-year cycle |

| ISO 14001:2015 | Environmental compliance (emissions, waste) | ISO | 3-year cycle |

| CE Marking | Required for export to EU; applies to electronic/electrical components | EU Directives (e.g., ECE R10, EMC) | Supplier-declared with technical file |

| UL Certification | Required for lighting, sensors, EV components sold in North America | Underwriters Laboratories | Product-specific; requires factory inspection |

| RoHS & REACH Compliance | Restriction of hazardous substances (Pb, Cd, Hg, etc.) | EU Directives 2011/65/EU & 1907/2006 | Annual testing recommended |

| VDA 6.3 (Germany) | Process audit standard; preferred by German OEMs | Verband der Automobilindustrie | Audit-based; not a certificate per se |

Note: FDA certification is not applicable to standard auto parts. It applies only to medical devices or food-contact materials (e.g., interior cabin filters with antimicrobial coatings).

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Tool wear, poor mold design, CNC programming errors | Implement SPC (Statistical Process Control), conduct first-article inspection (FAI), and schedule tooling maintenance every 50K cycles |

| Surface Imperfections (Pitting, Scratches, Flow Lines) | Poor mold maintenance, contamination, improper injection parameters | Enforce mold cleaning schedules, use clean-room molding for critical parts, optimize injection speed/pressure |

| Material Contamination | Mixing of resin grades, use of recycled material without approval | Conduct raw material audits, require material traceability logs, perform FTIR spectroscopy testing |

| Incomplete Welding/Brazing | Incorrect temperature, poor joint fit-up, operator error | Use automated welding with real-time monitoring, conduct destructive and X-ray testing on 2% of batch |

| Coating Adhesion Failure | Improper surface preparation, incorrect curing time/temperature | Enforce pretreatment (phosphating, sandblasting), conduct cross-hatch adhesion tests (ISO 2409) |

| Part Warpage | Uneven cooling, excessive injection pressure, poor gate design | Optimize cooling channels in mold, use warpage simulation (Moldflow), adjust packing pressure |

| Non-Compliance with RoHS/REACH | Use of restricted substances in plating or stabilizers | Require valid test reports (SGS, TÜV) per batch, conduct random third-party lab testing annually |

Recommendations for Procurement Managers

- Mandate IATF 16949 certification for all Tier 1 and Tier 2 suppliers.

- Conduct on-site quality audits at least annually, including process capability (Cp/Cpk ≥ 1.33) reviews.

- Require PPAP documentation (Production Part Approval Process) for all new components.

- Include right-to-audit clauses in supplier contracts.

- Use third-party inspection services (e.g., SGS, Bureau Veritas) for pre-shipment checks (AQL Level II).

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Empowering Global Procurement with Transparency & Quality Assurance

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: China Auto Parts Manufacturing Cost Analysis & Strategy Guide (2026 Outlook)

Prepared for: Global Procurement Managers | Date: January 2026 | Report ID: SC-AP-2026-001

Executive Summary

China remains the dominant global hub for cost-competitive, high-volume auto parts manufacturing, with evolving dynamics in 2026 driven by automation adoption, stricter environmental compliance, and shifting labor costs. Strategic differentiation between White Label (WL) and Private Label (PL) models is critical for optimizing total landed cost, IP control, and market positioning. This report provides actionable cost benchmarks, model comparisons, and MOQ-driven pricing tiers for informed procurement decisions.

1. White Label vs. Private Label: Strategic Implications for Auto Parts

Understanding the model defines your cost structure, risk profile, and value chain control.

| Factor | White Label (WL) | Private Label (PL) | Procurement Recommendation |

|---|---|---|---|

| Definition | Supplier’s existing generic product rebranded | Product custom-engineered to buyer’s specs/IP | PL preferred for performance/safety-critical parts |

| Tooling Cost | $0 (uses supplier’s existing molds) | $5,000 – $50,000+ (buyer-owned tooling) | Factor tooling amortization into unit cost |

| MOQ Flexibility | High (often 100-500 units) | Moderate-High (typically 500-2,000+ units) | WL for pilot orders; PL for volume commitments |

| IP Ownership | Supplier retains IP | Buyer owns final product IP & tooling | Critical for recalls, warranty, and innovation |

| Compliance Burden | Supplier-managed (basic standards) | Buyer-driven (e.g., ISO/TS 16949, REACH, ELV) | PL requires rigorous supplier audits |

| Cost Advantage | Lower unit cost at low volumes | Lower total cost at scale + brand control | PL delivers superior ROI beyond 5,000 units |

| Best For | Commodity parts (e.g., cabin filters, wiper blades) | Differentiated parts (e.g., sensors, ECUs, lighting) |

Key 2026 Insight: Rising automation in Tier-2 Chinese factories has narrowed the WL/PL cost gap at volumes >2,000 units. PL adoption is accelerating for EV components due to IP sensitivity.

2. Estimated Cost Breakdown (Per Unit): Mid-Tier China Supplier (2026)

Baseline: Automotive-grade plastic sensor housing (e.g., ABS/PC blend). Assumptions: MOQ 1,000 units, FOB Shenzhen, compliant with IATF 16949.

| Cost Component | % of Total Cost | Estimated Cost (USD) | 2026 Trend & Risk Notes |

|---|---|---|---|

| Raw Materials | 45-55% | $8.20 – $10.10 | ↑ 3-5% YoY due to stabilized rare earths (EV demand); Supplier bulk sourcing critical |

| Labor | 15-20% | $2.75 – $3.60 | ↑ 2% YoY (automation offsets wage growth); Concentrated in Anhui/Jiangxi vs. coastal hubs |

| Packaging | 8-12% | $1.45 – $2.10 | ↑ 4% (sustainable materials mandate); Must include UN38.3 for Li-ion parts |

| Overhead/Profit | 20-25% | $3.60 – $4.90 | ↓ 1-2% (automated lines); Bargain via volume commitments |

| TOTAL (FOB) | 100% | $16.00 – $20.70 | +/- 5% volatility (currency, energy costs) |

Critical Compliance Costs (Often Overlooked):

– Testing/Certification: $0.30-$1.20/unit (e.g., E-Mark, SAE J3061)

– QC Labor: $0.25-$0.60/unit (3rd-party audits add 3-5%)

– Tooling Amortization: $0.80-$4.00/unit (based on $20k tooling / 5k-25k units)

3. MOQ-Driven Price Tier Analysis (Per Unit, FOB Shenzhen)

Estimates for a standardized automotive bracket (aluminum die-cast, powder-coated). Based on 2026 SourcifyChina factory benchmark data (mid-tier suppliers, 12+ months partnership).

| MOQ Tier | Unit Price Range | Avg. Tooling Cost | Strategic Implications | When to Use |

|---|---|---|---|---|

| 500 units | $22.50 – $28.00 | $18,000 – $25,000 | High unit cost; tooling dominates TCO. High risk of supplier quality drift. | Only for urgent prototypes or niche replacement parts. |

| 1,000 units | $18.20 – $22.40 | $15,000 – $20,000 | Balanced entry point. Tooling cost amortized reasonably. Minimum viable scale for PL. | Ideal for new product launches or mid-volume OE programs. |

| 5,000 units | $14.80 – $17.90 | $12,000 – $16,000 | Optimal cost efficiency. Automation leverage maximized. Stronger supplier commitment. | Recommended for volume production; best TCO for PL models. |

Strategic Notes:

– >10,000 units: Additional 5-8% savings via dedicated production lines (e.g., $13.50-$16.20/unit), but requires 12+ month forecasts.

– Hidden MOQ Pitfall: Suppliers often quote “500 MOQ” but require 2,000+ for PL due to tooling ROI. Verify contractual terms.

– 2026 Shift: Suppliers now offer “MOQ Flex” (e.g., 500 base + 250 increments) for PL at +3-5% unit cost – ideal for demand uncertainty.

4. SourcifyChina Action Plan for Procurement Managers

- Prioritize PL for Core Components: Own tooling/IP for safety-critical or high-margin parts (sensors, control modules). Use WL only for low-risk consumables.

- Demand Full Cost Transparency: Require itemized quotes (materials by grade, labor hours, packaging specs). Reject “all-in” pricing.

- Lock Currency Clauses: 2026 volatility necessitates USD/CNY fixed-rate contracts (±2%) for >$50k orders.

- Audit Beyond Certificates: Conduct unannounced IATF 16949 + ESG audits – 32% of “certified” suppliers fail SourcifyChina’s 2026 field checks.

- Leverage Tier-2 Hubs: Shift non-critical parts to Anhui/Hubei provinces (avg. 8% lower labor vs. Guangdong) with SourcifyChina-managed logistics.

“In 2026, the cheapest quote is rarely the lowest cost. Factor in tooling ownership, compliance risk, and scalability – not just unit price.”

— SourcifyChina Sourcing Intelligence Unit

Disclaimer: Estimates based on SourcifyChina’s Q4 2025 aggregated supplier data (n=117). Actual costs vary by part complexity, material grade, and contractual terms. Valid for standard lead times (60-90 days). Currency: USD. All data proprietary to SourcifyChina.

Next Steps: Request a free, customized Auto Parts Sourcing Assessment (including 3 pre-vetted supplier matches) at [sourcifychina.com/auto-parts-2026]

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Due Diligence Protocol for Selecting a China Auto Parts Supplier

Executive Summary

Selecting a reliable auto parts supplier in China is critical to ensuring product quality, supply chain resilience, and long-term cost efficiency. With over 150,000 auto parts manufacturers and intermediaries in China, distinguishing between legitimate factories and trading companies—and identifying high-risk suppliers—is essential. This report outlines a structured verification process, key differentiators between factories and trading companies, and red flags to avoid in 2026.

Critical Steps to Verify a Chinese Auto Parts Supplier

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Request Company Legal Documentation | Confirm legal registration and business scope | Business License (via National Enterprise Credit Info Public System), ICP License (if online), Export License |

| 2 | Verify Physical Factory Presence | Confirm operational manufacturing facility | On-site audit, 3rd-party inspection (e.g., SGS, TÜV), GPS-verified video tour |

| 3 | Assess Production Capabilities | Validate technical capacity and equipment | Request machine list, production line videos, ISO/TS 16949 certification |

| 4 | Review Export History & Client List | Evaluate international experience | Ask for past export invoices (redacted), client references, shipping records |

| 5 | Conduct Product & Quality Audit | Ensure compliance with automotive standards | Request sample testing reports (e.g., SAE, DIN), PPAP documentation |

| 6 | Check for Certifications | Confirm industry compliance | ISO 9001, IATF 16949, ISO 14001, RoHS, REACH, and OEM-specific approvals (e.g., VW, Ford) |

| 7 | Evaluate Communication & Responsiveness | Gauge professionalism and transparency | Documented response time, language proficiency, technical clarity |

Note: In 2026, AI-powered supplier verification platforms (e.g., Alibaba Supplier Verification, Sourcify Verify) are recommended to cross-check data.

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory | Trading Company |

|---|---|---|

| Business License Scope | Lists manufacturing activities (e.g., “auto parts production”) | Lists trading, import/export, distribution |

| Facility Ownership | Owns production equipment, molds, R&D lab | No production lines; may rent showroom space |

| Pricing Structure | Lower MOQs, transparent BOM cost breakdown | Higher unit prices, less margin for negotiation |

| Lead Times | Direct control over production schedule | Dependent on 3rd-party factories; longer lead times |

| Technical Engagement | Engineers available for design input, DFM support | Limited technical input; focuses on order fulfillment |

| Location | Located in industrial zones (e.g., Dongguan, Ningbo, Changchun) | Often based in commercial districts (e.g., Shanghai, Guangzhou) |

| Website & Marketing | Highlights production lines, machinery, certifications | Emphasizes global clients, product catalog, shipping options |

Best Practice: Request a factory walkthrough video with timestamp and live Q&A to observe real-time operations.

Red Flags to Avoid in 2026

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to conduct on-site or live video audit | Likely not a real factory or hides substandard conditions | Delay engagement until verified |

| No IATF 16949 or ISO 9001 certification | Lacks automotive quality management systems | Disqualify unless undergoing certification with timeline |

| Generic product photos or stock images | May not own tooling or have real production | Request custom sample with branding |

| Pressure for full prepayment | High fraud risk; common in trading scams | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Inconsistent communication or delayed responses | Poor operational management | Monitor response time over 1–2 weeks |

| No verifiable client references | Lack of track record | Request 2–3 contactable clients in your region |

| Address mismatch on license vs. claimed location | Potential shell company | Cross-check with China’s AIC database |

Conclusion & Recommendations

In 2026, the Chinese auto parts market remains competitive but high-risk without due diligence. Procurement managers must prioritize verified manufacturing capability, automotive-grade certifications, and transparent communication.

Strategic Recommendations:

- Partner with 3rd-party inspectors for pre-shipment and factory audits.

- Use escrow or LC payments until supplier reliability is proven.

- Start with a trial order (≤30% of projected volume) before scaling.

- Leverage digital verification tools to reduce time-to-onboard.

By applying this structured verification framework, global buyers can mitigate risk, ensure quality compliance, and build resilient supply chains with trusted Chinese partners.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

Q1 2026 Edition

Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina B2B Sourcing Intelligence Report: Strategic Auto Parts Sourcing from China (2026 Outlook)

Prepared Exclusively for Global Procurement Leaders

The Critical Challenge: Auto Parts Sourcing in 2026

Global auto OEMs and Tier-1 suppliers face unprecedented pressure:

– Supply Chain Fragility: 68% of procurement managers report ≥2 major disruptions/year (McKinsey, 2025)

– Compliance Complexity: New EU Battery Passport regulations + US Inflation Reduction Act requirements demand rigorous supplier vetting

– Time Drain: 42% of sourcing hours consumed in disqualifying non-compliant/unreliable suppliers (Gartner)

Traditional sourcing methods (Alibaba, trade shows, referrals) fail to mitigate these 2026 realities.

Why SourcifyChina’s Verified Pro List is Your 2026 Strategic Imperative

Our AI-Enhanced Supplier Verification Framework eliminates guesswork for China auto parts suppliers. Here’s how we save you time and de-risk procurement:

| Traditional Sourcing Pain Point | SourcifyChina Pro List Solution | Time Saved (Per RFQ) |

|---|---|---|

| Manual verification of 15+ certifications (ISO 9001, IATF 16949, etc.) | Pre-Validated Docs: Real-time access to audited certs via blockchain ledger | 22–35 hours |

| Factory audits requiring 3–5 day trips | Digital Twin Audits: VR facility walkthroughs + live production line feeds | 14–21 days |

| Payment fraud risk (LC scams, fake invoices) | Escrow-Protected Transactions: Verified bank accounts + 3-tier financial checks | 8–12 business days |

| Language/cultural barriers delaying NDA execution | Dedicated Bilingual Engineers: Embedded in supplier teams for seamless communication | 5–9 days |

Proven Impact: Clients using the Pro List reduce time-to-first-shipment by 78% and cut supplier failure rates by 92% (2025 Client Data).

Your 2026 Competitive Advantage Starts Here

In an era where a single non-compliant supplier can halt EV battery production lines, verified capability is non-negotiable. SourcifyChina’s Pro List delivers:

✅ EV-Specific Compliance: Suppliers pre-qualified for battery management systems (BMS), power electronics, and thermal components

✅ Dynamic Risk Scoring: Real-time monitoring of Chinese supplier financial health + export license validity

✅ Zero-Cost Entry: Access to 1,200+ vetted auto parts suppliers – no membership fees

Call to Action: Secure Your 2026 Supply Chain in 48 Hours

Stop losing time to unreliable suppliers. One consultation with our China-based engineering team will:

1. Identify 3–5 pre-vetted suppliers matching your exact technical specs (e.g., aluminum die-casting tolerances ≤±0.02mm)

2. Provide full audit reports + sample lead times before you commit

3. Lock in 2026 pricing with MOQ flexibility

→ Act Now to Avoid Q1 2026 Capacity Crunches

Limited slots available for Q1 supplier onboarding

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160 (24/7 Chinese/English support)

Reply with “AUTO2026” to receive:

» Free 2026 China Auto Parts Compliance Checklist

» Priority access to our Ningbo EV Components Cluster suppliers

Source: SourcifyChina 2026 Auto Parts Sourcing Index – Based on 5,200+ supplier verifications across 18 Chinese industrial zones. Data current as of Q4 2025.

SourcifyChina: Where Verified Capability Meets Strategic Sourcing © 2026

🧮 Landed Cost Calculator

Estimate your total import cost from China.