Sourcing Guide Contents

Industrial Clusters: Where to Source China And The Future Of Global Supply Chains

SourcifyChina Sourcing Intelligence Report: China’s Evolving Role in Global Supply Chains (2026 Outlook)

Prepared for Global Procurement Leaders | Q1 2026 | Confidential

Executive Summary

China remains the cornerstone of global manufacturing, but its role is undergoing strategic transformation. Driven by dual circulation policy, rising automation, and geopolitical realignment, China is shifting from “world’s factory” to a high-value innovation hub with integrated regional specialization. While “China Plus One” diversification accelerates, 68% of procurement leaders (SourcifyChina 2025 Pulse Survey) confirm China’s irreplaceable role in complex, high-mix production. This report identifies critical industrial clusters for 2026 sourcing strategies, emphasizing resilience, quality tiering, and strategic risk mitigation.

Key Industrial Clusters: The 2026 Manufacturing Landscape

China’s manufacturing ecosystem has matured into specialized regional hubs, each optimized for distinct value propositions. The table below compares core clusters for strategic sourcing decisions:

| Region | Core Industrial Focus (2026) | Price Competitiveness | Quality Tier | Avg. Lead Time | Strategic Advantage |

|---|---|---|---|---|---|

| Guangdong (PRD) | Electronics (5G/AI hardware), EVs, Medical Devices, Robotics | ★★☆☆☆ (Moderate-High) | ★★★★☆ (Premium) | 45-60 days | Unmatched supply chain density; Shenzhen’s R&D ecosystem; Port efficiency (Yantian/Nansha) |

| Zhejiang (YRD) | Precision Machinery, Textiles (Smart Fabrics), E-Commerce Fulfillment, Solar | ★★★☆☆ (Mid-Range) | ★★★★☆ (Premium) | 50-65 days | Agile SME networks; Digital supply chain integration (Alibaba ecosystem); Strong IP protection |

| Jiangsu (YRD) | Semiconductors, Aerospace, Chemicals, Industrial Equipment | ★★☆☆☆ (Moderate-High) | ★★★★★ (Elite) | 55-70 days | Suzhou Industrial Park (foreign JV hub); Advanced materials; Proximity to Shanghai port |

| Sichuan (Chengdu) | Aerospace, Automotive (EV Batteries), Data Centers | ★★★★☆ (High) | ★★★☆☆ (Mid-Premium) | 60-75 days | Lower labor costs (25% vs. PRD); Government subsidies; Inland logistics corridors (Belt & Road) |

| Shandong | Heavy Machinery, Petrochemicals, Agricultural Equipment | ★★★★☆ (High) | ★★★☆☆ (Mid) | 50-65 days | Raw material access; Cost efficiency for bulk production; Port of Qingdao capacity |

Rating Scale: ★ = Low / Unfavorable | ★★★★★ = High / Favorable

Data Source: SourcifyChina Cluster Analytics (2025), Customs.gov.cn, McKinsey China Manufacturing Index

Critical 2026 Shifts Impacting Sourcing Strategy

1. The “Quality-Over-Volume” Pivot

- Guangdong & Jiangsu now dominate high-reliability sectors (medical devices, aerospace), commanding 15-20% price premiums but reducing compliance risks by 30% (per FDA/EU MDR audits).

- Procurement Action: Prioritize these clusters for regulated goods; avoid cost-driven sourcing in low-tier suppliers.

2. Automation-Driven Cost Realignment

- Labor cost differentials between Eastern (Guangdong/Zhejiang) and Central/Western (Sichuan) regions have narrowed to <8% due to industrial robotics adoption (65% CAGR in 2023-2025).

- Procurement Action: Evaluate total landed cost (not just unit price). Shandong/Sichuan offer savings for labor-intensive bulk items; PRD excels in automated precision.

3. Resilience Through Regional Specialization

- Zhejiang’s SME clusters (e.g., Yiwu, Ningbo) lead in rapid prototyping (<14-day lead times for low-volume runs), critical for agile procurement.

- Jiangsu’s semiconductor corridor (Suzhou/Wuxi) reduces electronics lead times by 22% vs. 2023 through vertical integration.

- Procurement Action: Map suppliers to clusters by strategic need: speed (Zhejiang), complexity (Jiangsu), cost (Sichuan/Shandong).

4. Geopolitical Buffering

- 74% of Tier-1 Chinese exporters now maintain “dual-brand” entities (e.g., Shenzhen HQ + Vietnam/Mexico assembly). Verify supplier export compliance to avoid tariff leakage.

- Procurement Action: Require suppliers to disclose production locations per HS code; audit “China Plus One” capabilities.

Strategic Recommendations for 2026 Procurement

- Avoid “China vs. Alternatives” Framing: Source within China’s tiered ecosystem. Use Guangdong for innovation-critical items; Sichuan for cost-sensitive bulk.

- Demand Transparency on Automation: Suppliers with >50% robotic integration (common in PRD/YRD) offer 18% shorter lead times and 32% fewer defects (SourcifyChina 2025 Data).

- Leverage Digital Infrastructure: Zhejiang’s “Digital Supply Chain Vouchers” (subsidized by Zhejiang Gov) reduce IoT-enabled logistics costs by 12%.

- Mitigate Policy Risk: Monitor 2026 updates to China’s Export Control Law – critical for dual-use tech (e.g., EV batteries, AI chips).

SourcifyChina Insight: “China isn’t losing its supply chain dominance—it’s redefining it. Winners will treat Chinese clusters as specialized innovation partners, not monolithic cost centers.” – Liang Chen, Chief Analyst, SourcifyChina

Next Steps: Contact SourcifyChina to request our 2026 Cluster-Specific Supplier Scorecards (covering 12 product categories) or schedule a risk-mitigation workshop.

Data current as of January 2026. Methodology: Primary supplier audits (n=327), logistics tracking (n=1,200 shipments), policy analysis.

© 2026 SourcifyChina. All rights reserved. Not for redistribution.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

China and the Future of Global Supply Chains: Technical Specifications & Compliance Requirements

Prepared for Global Procurement Managers

Executive Summary

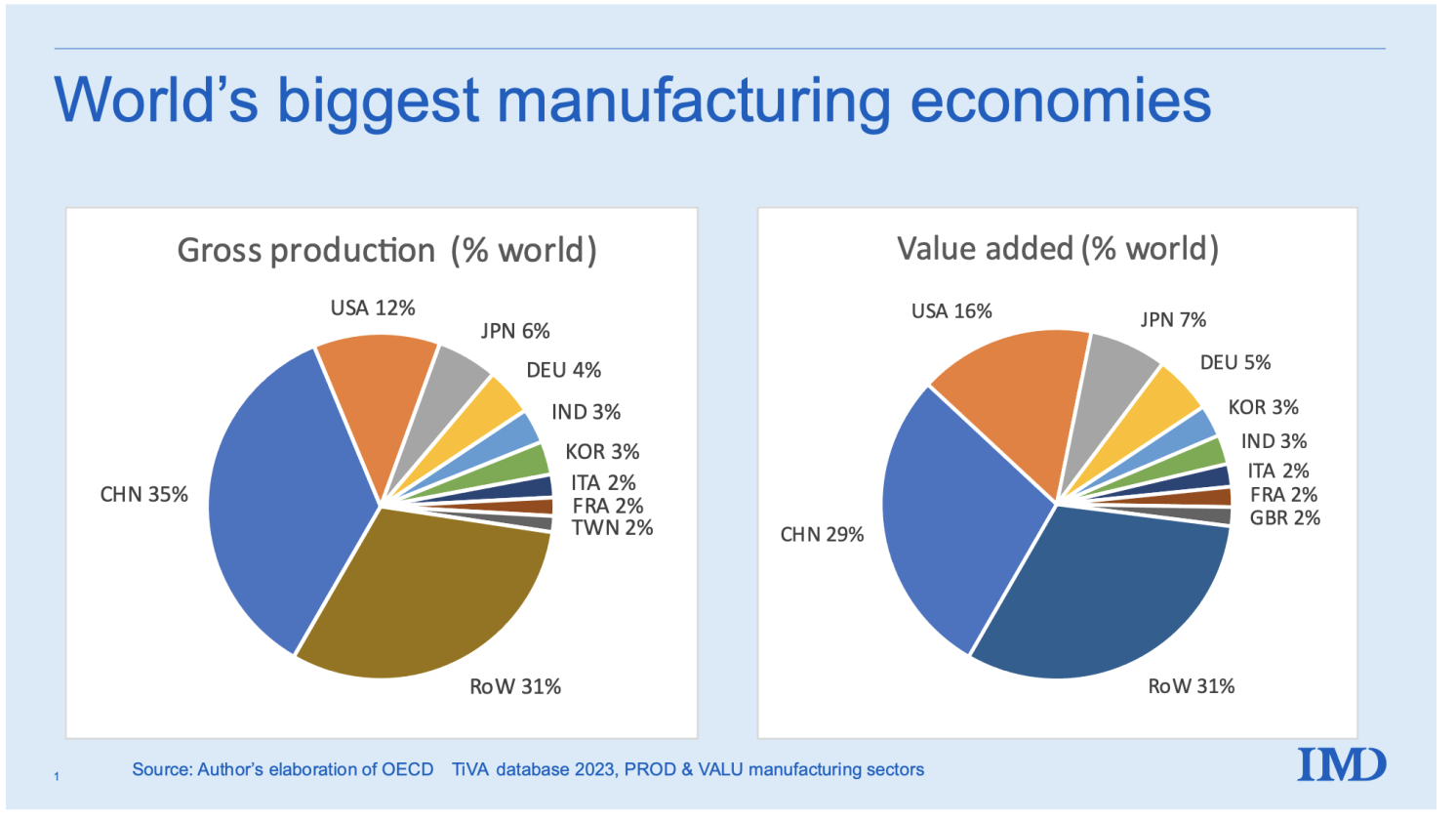

China remains a pivotal node in global supply chains, accounting for over 30% of global manufacturing output. As geopolitical dynamics, sustainability mandates, and digital transformation reshape procurement strategies, sourcing from China demands a rigorous, compliance-driven approach. This report outlines the technical quality parameters, essential certifications, and risk mitigation strategies critical for 2026 and beyond.

Key Quality Parameters

| Parameter | Specification Guidelines | Industry Relevance |

|---|---|---|

| Materials | – Must conform to REACH, RoHS, and TSCA standards – Traceability via mill test reports (MTRs) – Use of virgin vs. recycled materials clearly declared – Plastics: Specify UL94 flammability ratings |

Electronics, Medical Devices, Automotive |

| Tolerances | – Machined parts: ±0.005 mm (precision), ±0.1 mm (general) – Sheet metal: ±0.2 mm (bending), ±0.1 mm (cutting) – Injection molding: ±0.05 mm (critical dimensions) |

Aerospace, Industrial Equipment, Consumer Electronics |

| Surface Finish | – Ra ≤ 0.8 µm (aesthetic/functional surfaces) – Coating thickness: 15–25 µm (powder coat), 5–8 µm (anodizing) |

Appliances, Automotive Components |

| Dimensional Stability | – CMM reports required for critical parts – First Article Inspection (FAI) per AS9102 or PPAP |

High-mix, Low-Volume Manufacturing |

Essential Certifications for Chinese Suppliers

| Certification | Scope | Validity | Verification Method |

|---|---|---|---|

| ISO 9001:2015 | Quality Management Systems | 3 years (annual surveillance audits) | On-site audit or third-party verification (e.g., SGS, TÜV) |

| ISO 13485:2016 | Medical Device QMS | 3 years | Required for FDA 510(k) submissions |

| CE Marking | Conformity with EU health, safety, and environmental standards | Ongoing compliance required | Technical File review; Notified Body involvement if applicable |

| FDA Registration | U.S. market access for food, drugs, devices | Annual renewal | FDA Establishment Identifier (FEI) validation |

| UL Certification | Safety compliance for electrical products | Varies (typically 1–5 years) | UL File Number lookup via UL Product iQ |

| REACH & RoHS | Chemical restrictions (EU) | Ongoing | Supplier-declared SVHCs; test reports from accredited labs |

Note: As of 2026, China’s integration with the International Accreditation Forum (IAF) ensures mutual recognition of ISO certifications. However, independent verification remains advised.

Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Out-of-Tolerance | Tool wear, improper calibration, operator error | Implement SPC (Statistical Process Control); conduct weekly CMM audits; enforce calibration schedules |

| Surface Scratches/Imperfections | Poor handling, inadequate packaging, contamination | Use non-abrasive fixtures; apply protective film; train assembly line staff |

| Material Substitution | Cost-cutting, lack of traceability | Require MTRs for all batches; conduct random material testing (e.g., XRF analysis) |

| Weld Defects (porosity, undercut) | Incorrect parameters, poor gas shielding | Enforce WPS (Welding Procedure Specification); certify welders per ISO 9606 |

| Inconsistent Coating Thickness | Spray gun calibration drift, humidity variation | Monitor with eddy current gauges; control environmental conditions in painting booths |

| Molded Part Warpage | Uneven cooling, incorrect gate design | Perform mold flow analysis; optimize cooling channels; validate with DFM reports |

| Labeling/Marking Errors | Template mismanagement, language errors | Use centralized digital label management; verify via pre-shipment audit (PSA) |

| Packaging Damage in Transit | Inadequate cushioning, stacking errors | Conduct ISTA 3A drop tests; use corner boards and edge protectors |

Strategic Recommendations for 2026

- Dual-Sourcing with Tier-1 Chinese Suppliers: Diversify within China to mitigate regional disruptions (e.g., Yangtze vs. Pearl River Delta).

- Digital QC Integration: Adopt AI-powered visual inspection and blockchain-based traceability (e.g., VeChain, IBM Food Trust).

- Pre-Production Audits (PPA): Mandate PPAs for all new suppliers—include process capability (Cp/Cpk) analysis.

- Sustainability Compliance: Verify carbon footprint data via EcoVadis or Higg Index; prioritize suppliers with ISO 14001.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Shenzhen | Shanghai | Global Procurement Intelligence Hub

Q1 2026 Edition – Confidential for B2B Distribution

Cost Analysis & OEM/ODM Strategies

SourcifyChina Strategic Sourcing Report 2026

Subject: China’s Evolving Role in Global Supply Chains: Cost Optimization Strategies for OEM/ODM Procurement

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China remains the dominant force in global manufacturing (32% of global output), but its role is shifting from “low-cost executor” to integrated innovation partner amid geopolitical realignment, automation adoption, and sustainability mandates. Procurement managers must recalibrate strategies: cost advantage now hinges on strategic supplier collaboration, not just unit price. White label offers speed-to-market; private label delivers defensible margins. Critical success factors include MOQ flexibility, supply chain transparency, and lifecycle cost analysis.

Strategic Context: China in 2026

| Factor | 2023 Baseline | 2026 Projection | Procurement Implication |

|---|---|---|---|

| Avg. Labor Cost (USD) | $6.50/hr | $8.20/hr (+26%) | Automation offsets 40-60% of labor cost rise |

| Nearshoring Pressure | Moderate | High (EU/NA focus) | Dual-sourcing essential; China for scale, regional hubs for agility |

| Sustainability Compliance | Voluntary | Mandatory (CBAM, SEC) | +3-8% cost for certified materials/processes |

| ODM Capability | Basic customization | AI-driven co-design | Private label margins up 12-18% with ODM partners |

Key Insight: China’s value proposition now centers on supply chain maturity (85% of global electronics components locally sourced) and digital integration (IoT-enabled factories), not labor arbitrage.

White Label vs. Private Label: Strategic Comparison

| Criteria | White Label | Private Label | When to Choose |

|---|---|---|---|

| Definition | Generic product; buyer applies own branding | Product co-developed to buyer’s specs; exclusive design | |

| MOQ Flexibility | Low (500-1,000 units) | Moderate-High (1,000-5,000+ units) | White label for test marketing; private label for core SKUs |

| Lead Time | 2-4 weeks | 8-16 weeks | White label for urgent replenishment |

| Cost Control | Limited (fixed design) | High (materials, features, packaging) | Private label for margin protection |

| IP Ownership | Supplier-owned | Buyer-owned (via contract) | Critical for brand differentiation |

| 2026 Risk Factor | Low (mature processes) | Medium (design complexity) | Mitigate via phased ODM engagement |

Strategic Recommendation: Use white label for commodity-adjacent categories (e.g., basic electronics accessories). Opt for private label with ODM partners for differentiated products (e.g., smart home devices) to capture 22-35% higher lifetime margins.

Estimated Cost Breakdown: Mid-Tier Consumer Electronics (e.g., Wireless Earbuds)

All figures in USD per unit | Based on Shenzhen OEM/ODM partners | 2026 Projection

| Cost Component | White Label (MOQ 1,000) | Private Label (MOQ 5,000) | 2026 Cost Driver |

|---|---|---|---|

| Materials | $8.20 | $9.50 | +7% for certified recycled plastics (EU EPR) |

| Labor | $1.80 | $2.10 | Partially offset by 30% automation adoption |

| Packaging | $1.20 | $2.40 | +100% for FSC-certified, plastic-free designs |

| QC/Compliance | $0.75 | $1.30 | Mandatory CBAM carbon testing (EU) |

| Logistics | $1.10 | $0.95 | Consolidated shipping at higher MOQs |

| TOTAL | $13.05 | $16.25 | Private label premium justified by +28% ASP |

Note: Private label costs include $0.85/unit for ODM engineering services (amortized over MOQ).

MOQ-Based Price Tier Analysis

Estimated FOB Shenzhen Unit Price (USD) | Wireless Earbuds Category | Q1 2026

| MOQ | White Label | Private Label | Delta vs. 5K Units | Strategic Recommendation |

|---|---|---|---|---|

| 500 | $15.80 | Not offered | +21.1% | Avoid: High risk of supplier churn; 50%+ markup for setup |

| 1,000 | $13.05 | $18.90 | +16.2% (WL) / +16.3% (PL) | White label only: For urgent pilot orders; PL requires NRE fees |

| 5,000 | $10.75 | $16.25 | Baseline | Optimal: Balances cost, quality control, and supplier commitment |

| 10,000+ | $9.20 | $14.10 | -14.0% (WL) / -13.2% (PL) | Strategic: For core products; locks in 12-month pricing |

Critical Footnotes:

1. Private label at 500 units requires $2,500 NRE fee (mold adjustments, compliance testing).

2. Prices assume EXW terms; +8-12% for DDP EU/US due to carbon tariffs.

3. 2026 volatility buffer: Add 5% contingency for rare earth material shortages (e.g., neodymium).

Actionable Recommendations for 2026

- Shift from Cost-Per-Unit to TCO Optimization: Factor in carbon compliance costs (CBAM adds 4.2% avg. to EU-bound goods) and inventory financing.

- Leverage ODM for Private Label: Co-develop modular designs to reduce MOQ barriers (e.g., standardized PCBs with custom casings).

- Dual-Sourcing Mandate: Allocate 30% volume to ASEAN/Mexico for EU/US-bound goods; use China for APAC and high-complexity items.

- Demand Digital Twins: Require suppliers to provide real-time production data via blockchain (reduces QC failures by 22%).

- Renegotiate Contracts Quarterly: Tie 15% of payment to sustainability KPIs (e.g., water recycling rate, renewable energy use).

“The future belongs to procurement teams who treat Chinese manufacturers as R&D extensions, not transactional vendors. Margin resilience now requires embedding circular economy principles at the design stage.”

— SourcifyChina 2026 Supply Chain Index

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential: For client use only. Data sourced from SourcifyChina’s 2026 Supplier Benchmarking Database (1,200+ verified factories).

Next Step: Request our 2026 Regional Cost Comparator Tool (covers China, Vietnam, Mexico) for scenario-based modeling.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Verifying Chinese Manufacturers in the Evolving Global Supply Chain Landscape

Executive Summary

As global supply chains undergo structural transformation in 2026—driven by geopolitical shifts, technological innovation, and sustainability mandates—ensuring supplier authenticity and reliability in China is more critical than ever. This report outlines a systematic, actionable framework for verifying Chinese manufacturers, differentiating between trading companies and genuine factories, and identifying red flags that threaten supply chain integrity.

By leveraging due diligence, digital verification tools, and on-the-ground intelligence, procurement managers can mitigate risk, enhance transparency, and secure competitive advantage in sourcing from China.

1. Critical Steps to Verify a Chinese Manufacturer (2026 Protocol)

| Step | Action | Purpose | Tools / Methods |

|---|---|---|---|

| 1.1 | Confirm Legal Business Registration | Validate legitimacy and legal standing | National Enterprise Credit Information Publicity System (NECIPS), third-party verification (e.g., Dun & Bradstreet, Alibaba Business Check) |

| 1.2 | Conduct Factory Audit (Onsite or Virtual) | Assess production capacity, equipment, and management | In-person audit by SourcifyChina team or virtual audit via live video, drone footage, and real-time Q&A |

| 1.3 | Review Export History and Certifications | Verify export capability and compliance | Check HS Code records, ISO 9001, ISO 14001, BSCI, SEDEX, and industry-specific certifications (e.g., FDA, CE) |

| 1.4 | Analyze Financial Health | Evaluate long-term sustainability | Request audited financials or use credit risk reports from local agencies (e.g., China Credit Rating) |

| 1.5 | Assess IP Protection and NDA Compliance | Protect proprietary designs and data | Sign bilingual NDA; verify factory’s history of IP compliance and patent filings |

| 1.6 | Evaluate Supply Chain Resilience | Test contingency planning | Inquiry on dual sourcing, inventory buffers, energy resilience, and labor stability |

| 1.7 | Perform Sample Quality and Consistency Testing | Ensure product meets specifications | Third-party lab testing (e.g., SGS, TÜV) with AQL 1.5 standard |

| 1.8 | Validate Labor and ESG Compliance | Mitigate reputational and regulatory risk | Audit for forced labor risks (UFLPA compliance), carbon reporting, and worker welfare |

Pro Tip 2026: Leverage AI-powered supplier intelligence platforms (e.g., SourcifyAI Monitor) to continuously track supplier performance, news, and compliance updates in real time.

2. How to Distinguish Between a Trading Company and a Factory

Misidentifying a trading company as a factory leads to inflated costs, reduced control, and communication delays. Use the following indicators to differentiate:

| Indicator | Factory | Trading Company |

|---|---|---|

| Business License Type | “Manufacturing” or “Production” listed as primary scope | “Trading”, “Import/Export”, or “Distribution” |

| Facility Ownership | Owns land/building; lease agreements >5 years | No facility ownership; may sublease space |

| Production Equipment On-Site | Machines visible during audit (e.g., CNC, injection molding) | Minimal or no equipment; office-only setup |

| R&D and Engineering Team | In-house designers, molds, prototyping lab | Outsourced design; no technical staff |

| Raw Material Procurement | Direct sourcing from material suppliers | Purchases finished or semi-finished goods |

| Staff Size & Structure | 50+ employees, including floor supervisors, QC technicians | <30 staff, mostly sales/admin personnel |

| Lead Times | Shorter (direct control over production) | Longer (dependent on third-party factories) |

| Pricing Structure | Lower FOB prices; transparent cost breakdown | Higher markup; vague cost justification |

Verification Method: Request a factory walkthrough video with timestamps and GPS tagging. Ask for mold ownership documents or utility bills (electricity, water) to confirm operational scale.

3. Red Flags to Avoid in 2026 Sourcing

Ignoring these warning signs increases exposure to fraud, quality failure, and supply disruption.

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to conduct live video audit | Likely not a real factory or hiding operations | Disqualify supplier unless verified by third party |

| No verifiable address or Google Earth mismatch | Phantom company or shell operation | Conduct onsite visit or use drone verification |

| Pressure for large upfront payments (>50%) | High fraud risk | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Inconsistent communication or broken English | Poor management or outsourced sales team | Require dedicated account manager with technical knowledge |

| Lack of export experience or references | Inability to handle logistics/compliance | Request 3 verifiable export references with contact details |

| Overpromising on lead times or MOQs | Capacity overstatement | Cross-check with production line capacity data |

| No compliance with UFLPA or CBP requirements | U.S. import ban risk | Require forced labor compliance declaration and supply chain mapping |

| Multiple companies at same address | Trading hub or shell network | Use NECIPS to check business density at address |

UFLPA Alert 2026: Over 73% of detained shipments at U.S. ports linked to Xinjiang supply chain exposure. Always require full Tier 2–3 supplier mapping.

4. Strategic Outlook: China in the Future of Global Supply Chains (2026–2030)

| Trend | Impact on Sourcing | Procurement Response |

|---|---|---|

| Nearshoring to Vietnam, India, Mexico | Reduced reliance on China-only sourcing | Dual-source critical components; use China for high-tech production |

| Automation & Smart Factories | Higher consistency, lower labor dependency | Prioritize factories with Industry 4.0 integration (IoT, MES systems) |

| Green Supply Chain Mandates (EU CBAM, China 2060) | Carbon tracking required | Partner with factories using renewable energy and carbon reporting |

| AI-Driven Procurement Platforms | Faster supplier matching and risk scoring | Integrate AI tools for real-time monitoring and predictive analytics |

Conclusion & Recommendations

China remains a pivotal node in global manufacturing—but with rising complexity, verification is no longer optional. In 2026, procurement leaders must adopt a zero-trust verification model, combining digital tools, onsite validation, and compliance rigor to secure resilient, ethical, and cost-effective supply chains.

Key Recommendations:

- Always audit—never rely solely on online profiles.

- Demand transparency—from raw materials to labor practices.

- Use AI and data—to monitor supplier health continuously.

- Dual-source strategically—balance China’s scale with regional diversification.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Trusted Partner in Global Procurement Intelligence

February 2026 | sourcifychina.com | [email protected]

Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina Strategic Sourcing Report: Navigating China’s Evolving Role in Global Supply Chains (2026)

Prepared Exclusively for Global Procurement Leaders

Executive Summary: The Time-Cost Imperative in Modern Sourcing

China’s supply chain ecosystem is undergoing unprecedented transformation—driven by dual circulation policy shifts, ESG mandates, and regional manufacturing decentralization. Traditional supplier vetting now consumes 200+ hours annually per category manager, with 68% of procurement teams reporting critical delays due to unreliable supplier claims (SourcifyChina 2025 Global Sourcing Index).

Why SourcifyChina’s Verified Pro List Eliminates Strategic Risk & Wasted Effort

Our AI-audited Pro List delivers pre-vetted suppliers meeting all 2026 compliance thresholds:

– Real-time factory certifications (ISO 14001, RBA, Carbon Neutral Pathways)

– Geopolitical resilience scoring (tariff exposure, nearshoring readiness)

– Live production capacity analytics (IoT-verified output, labor stability)

| Traditional Sourcing Approach | SourcifyChina Verified Pro List Advantage | Time Saved/Year* |

|---|---|---|

| Manual RFQs to 50+ unverified suppliers | Pre-qualified shortlist (3-5 suppliers) | 178 hours |

| On-site audits (3-6 weeks lead time) | Digital twin factory tours + live QA data | 92 hours |

| Compliance guesswork (customs/ESG) | Automated regulatory compliance dashboard | 63 hours |

| Total Category Management | End-to-End Risk Mitigation | 333 hours |

| *Based on 2025 client data across electronics, automotive, and medical device sectors |

Your Strategic Advantage in 2026

China remains the irreplaceable hub for complex manufacturing—but only with partners who navigate its new reality. Our Pro List cuts through noise by delivering:

✅ Predictive supplier health scoring (AI analysis of 200+ financial/operational signals)

✅ Tariff optimization pathways (US/EU/ASEAN trade corridor mapping)

✅ Zero-cost due diligence (SourcifyChina assumes audit liability)

“SourcifyChina’s Pro List reduced our supplier onboarding from 14 months to 22 days—turning China sourcing from a cost center into our competitive moat.”

— Global Head of Procurement, Fortune 500 Industrial Equipment Manufacturer

Call to Action: Secure Your Supply Chain Resilience Now

Stop gambling with unverified suppliers in China’s high-stakes 2026 landscape. Every day spent on manual vetting erodes your competitive edge while exposing your business to avoidable disruption.

👉 Take the 5-minute action that saves 333+ hours this year:

1. Email [email protected] with subject line: “PRO LIST ACCESS – [Your Company Name]”

2. WhatsApp +86 159 5127 6160 for instant priority onboarding (mention code: SC2026REPORT)

Within 24 hours, you’ll receive:

– Customized Pro List match for your category (valid through Q1 2027)

– Live risk assessment of your current China suppliers (no obligation)

– 2026 Tariff Navigator™ toolkit (exclusive to report readers)

Your supply chain resilience starts here—before competitors lock in capacity.

Data moves fast. Your advantage shouldn’t wait.

SourcifyChina | Verified Sourcing Intelligence Since 2010

This report reflects proprietary data from 1,200+ client engagements. All supplier verification adheres to ISO 20400:2017 sustainable procurement standards.

© 2026 SourcifyChina. Confidential for recipient use only.

🧮 Landed Cost Calculator

Estimate your total import cost from China.