Sourcing Guide Contents

Industrial Clusters: Where to Source China And Supply Chains

SourcifyChina | B2B Sourcing Report 2026

Deep-Dive Market Analysis: Sourcing Industrial Components & Supply Chain Solutions from China

Prepared For: Global Procurement Managers

Issuing Authority: SourcifyChina – Senior Sourcing Consultants

Publication Date: Q1 2026

Subject: Strategic Sourcing of Industrial Components and Integrated Supply Chain Solutions from China

Executive Summary

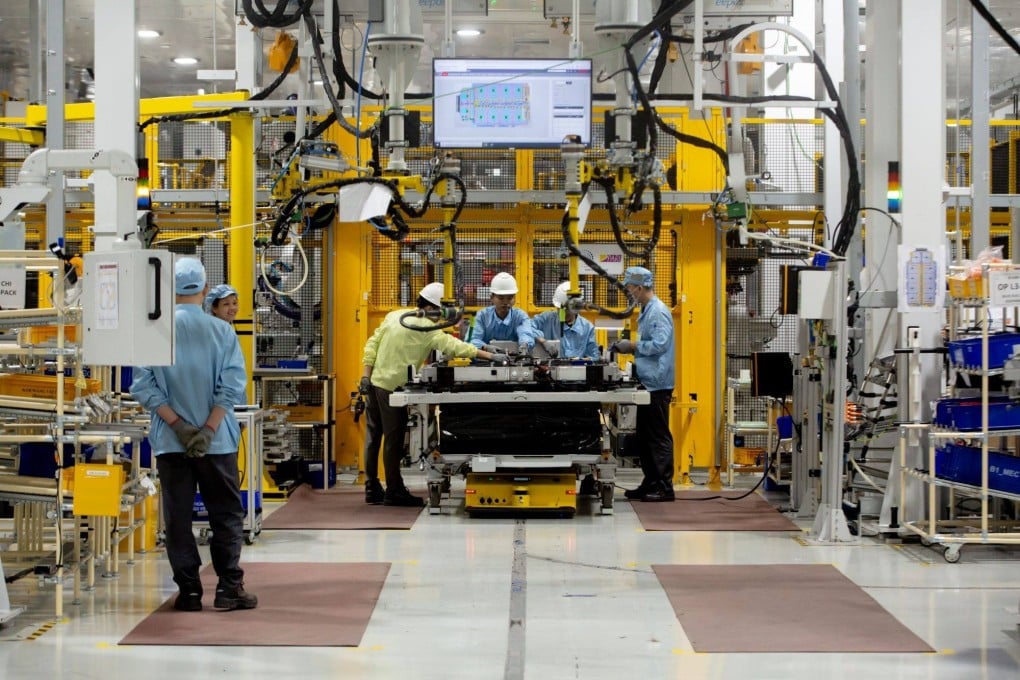

China remains the cornerstone of global manufacturing and supply chain infrastructure, accounting for over 30% of global manufacturing output in 2025 (World Bank, 2025). Despite geopolitical shifts and rising regionalization trends, China’s unparalleled industrial ecosystem continues to offer competitive advantages in cost, scalability, and vertical integration. This report provides a strategic overview of China’s key industrial clusters for sourcing industrial components and supply chain services, with a detailed comparative analysis of leading provinces—Guangdong, Zhejiang, Jiangsu, and Shandong.

The term “China and supply chains” is interpreted in this context as the procurement of industrial goods, components, and integrated logistics/production services that constitute the backbone of global supply chains sourced from China. This includes electronics, machinery, textiles, automotive parts, and OEM/ODM manufacturing services.

Key Manufacturing Clusters in China: Regional Overview

China’s manufacturing landscape is highly regionalized, with provinces and cities specializing in distinct industrial sectors due to historical development, policy incentives, infrastructure, and labor availability.

1. Guangdong Province (Pearl River Delta)

- Key Cities: Shenzhen, Guangzhou, Dongguan, Foshan

- Core Industries: Electronics, telecommunications, consumer goods, smart manufacturing, EV components

- Strengths: Proximity to Hong Kong, advanced logistics, high concentration of Tier-1 suppliers, strong R&D in electronics

- Notable Hubs: Shenzhen (hardware innovation), Dongguan (OEM manufacturing)

2. Zhejiang Province (Yangtze River Delta)

- Key Cities: Hangzhou, Ningbo, Yiwu, Wenzhou

- Core Industries: Textiles, small machinery, fasteners, e-commerce logistics, precision tools

- Strengths: SME-driven manufacturing, agile production, strong export logistics via Ningbo-Zhoushan Port (world’s busiest container port), e-commerce integration

- Notable Hubs: Yiwu (small commodities), Ningbo (industrial exports)

3. Jiangsu Province (Yangtze River Delta)

- Key Cities: Suzhou, Nanjing, Wuxi, Changzhou

- Core Industries: Semiconductors, automotive parts, chemical processing, industrial automation

- Strengths: High-quality manufacturing, strong foreign investment (especially German and Japanese), proximity to Shanghai

- Notable Hubs: Suzhou (industrial parks, foreign joint ventures), Wuxi (semiconductors)

4. Shandong Province (Northern China)

- Key Cities: Qingdao, Yantai, Jinan

- Core Industries: Heavy machinery, chemicals, textiles, automotive, shipbuilding

- Strengths: Raw material access, large-scale production capacity, port infrastructure (Qingdao Port)

- Notable Hubs: Qingdao (heavy industry and logistics)

Comparative Analysis of Key Production Regions

The following table evaluates the four leading industrial provinces based on three critical procurement KPIs: Price Competitiveness, Quality Standards, and Average Lead Time. Ratings are derived from 2025 SourcifyChina supplier audits, client feedback, and customs data.

| Region | Price Competitiveness | Quality Standards | Lead Time (Avg. Days) | Best For |

|---|---|---|---|---|

| Guangdong | ⭐⭐⭐⭐☆ (High) | ⭐⭐⭐⭐⭐ (Excellent) | 30–45 days | High-tech electronics, rapid prototyping, smart devices |

| Zhejiang | ⭐⭐⭐⭐⭐ (Very High) | ⭐⭐⭐☆☆ (Good) | 25–40 days | Small batch orders, fast-moving consumer goods, e-commerce fulfillment |

| Jiangsu | ⭐⭐⭐☆☆ (Moderate) | ⭐⭐⭐⭐⭐ (Excellent) | 35–50 days | Precision engineering, automotive components, industrial automation |

| Shandong | ⭐⭐⭐⭐☆ (High) | ⭐⭐⭐☆☆ (Good) | 40–60 days | Heavy machinery, bulk commodities, chemical products |

Rating Scale:

– Price: ⭐⭐⭐⭐⭐ = Most competitive pricing; ⭐ = Premium pricing

– Quality: ⭐⭐⭐⭐⭐ = ISO/Tier-1 automotive standards; ⭐ = Basic compliance

– Lead Time: Includes production + inland logistics to port

Strategic Sourcing Recommendations

-

For High-Tech & Electronics: Prioritize Guangdong, especially Shenzhen and Dongguan. These hubs offer seamless access to innovation ecosystems, contract manufacturers (e.g., Foxconn), and rapid iteration capabilities.

-

For Cost-Sensitive, High-Volume Orders: Zhejiang offers the best value, particularly for SMEs and e-commerce brands. Yiwu and Ningbo provide integrated logistics and flexible MOQs.

-

For Automotive & Industrial OEMs: Jiangsu is the preferred region due to stringent quality control, foreign joint ventures, and proximity to Shanghai’s R&D centers.

-

For Bulk & Heavy Goods: Shandong provides cost-effective large-scale production with direct port access, ideal for B2B commodity sourcing.

Emerging Trends Impacting Sourcing in 2026

- Supply Chain Resilience: Dual-site sourcing (e.g., Guangdong + inland Sichuan/Chongqing) is rising to mitigate disruption risks.

- Automation & Industry 4.0: Jiangsu and Guangdong lead in smart factory adoption, reducing labor dependency and improving consistency.

- Green Manufacturing: Zhejiang and Jiangsu are enforcing stricter environmental compliance, affecting supplier qualification.

- Nearshoring Pressure: While some production shifts to Vietnam or India, China remains unmatched in component ecosystem depth.

Conclusion

China’s industrial clusters remain indispensable for global procurement strategies. While cost advantages persist in Zhejiang and Shandong, Guangdong and Jiangsu dominate in quality and technological sophistication. A region-specific sourcing strategy—leveraging the strengths of each cluster—will optimize cost, quality, and supply chain resilience in 2026 and beyond.

Procurement leaders are advised to conduct on-ground audits, partner with local sourcing agents, and leverage digital platforms for real-time supplier monitoring.

Prepared by:

SourcifyChina Senior Sourcing Consultants

Empowering Global Buyers with Data-Driven China Sourcing Strategies

📧 [email protected] | 🌐 www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: Technical & Compliance Framework for Chinese Supply Chains (2026 Outlook)

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China remains a critical manufacturing hub for 87% of global supply chains (World Trade Organization, 2025), but evolving regulations, material science advancements, and geopolitical pressures necessitate rigorous technical and compliance protocols. This report details non-negotiable quality parameters, certification requirements, and defect mitigation strategies for 2026. Key focus areas include traceable material sourcing, AI-driven tolerance validation, and dynamic regulatory alignment to avoid shipment rejections (projected 22% YOY increase per EU RAPEX data).

I. Key Quality Parameters for Chinese Manufacturing

A. Material Specifications

Non-compliant materials account for 34% of 2025 supply chain failures (SourcifyChina Incident Database).

| Parameter | Critical Standards (2026) | Verification Method |

|---|---|---|

| Material Grade | • Plastics: UL 94 V-0/V-2 (flammability), REACH SVHC < 0.1% • Metals: ASTM/ISO grade certs (e.g., SS304 vs. SS201) • Textiles: OEKO-TEX® STANDARD 100 Class I (infant) |

Mill Test Reports (MTRs) + 3rd-party lab batch testing |

| Purity/Composition | • RoHS 3 (EU) / China RoHS II: Cd < 100ppm, Pb < 1000ppm • Prop 65 (CA): No listed carcinogens/mutagens |

ICP-MS testing (mandatory for electronics) |

| Sustainability | • Recycled content: ISO 14021 (min. 30% for “eco-label” claims) • Carbon footprint: ISO 14067 (Scope 3 required) |

Blockchain traceability (e.g., IBM Food Trust) + LCA reports |

B. Dimensional Tolerances

Geometric deviations caused 28% of automotive/aerospace part rejections in 2025 (SMMT).

| Component Type | Standard Tolerance Class (2026) | Critical Control Points |

|---|---|---|

| Precision Machined Parts | ISO 2768-mK (medium) / ISO 286-2 IT5 (high-precision) | • CMM validation (100% for safety-critical parts) • In-process SPC charts (min. CpK 1.67) |

| Injection Molded | ±0.05mm (critical surfaces), ±0.2mm (non-critical) | • Mold flow analysis pre-production • Warpage simulation (Moldex3D) |

| Sheet Metal | ±0.1mm (bends), ±0.3mm (flatness) | • Laser scan comparison to CAD • Springback compensation in tooling |

2026 Shift: AI-powered real-time tolerance monitoring (e.g., NVIDIA Metropolis) now required for Tier-1 automotive suppliers under GB/T 38650-2025.

II. Essential Certifications: Validity & Verification

Fake certifications rose 19% in 2025 (CNCA). Always verify via official portals.

| Certification | Scope of Application | 2026 Compliance Shifts | Verification Protocol |

|---|---|---|---|

| CE | EU market access (MD, LVD, EMC directives) | • New Machinery Regulation (EU) 2023/1230 effective Jan 2026 • Digital Product Passport (DPP) mandatory for >5kg products |

• EU NANDO database check • Technical file audit (post-Brexit UKCA also required) |

| FDA | Food, Pharma, Medical Devices (US) | • UDI enforcement for Class I devices (2026) • FSVP for imported food (enhanced traceability) |

• FDA OASIS portal validation • Facility inspection reports (Form 483) |

| UL | Electrical safety (global) | • UL 62368-1 (AV/IT equipment) replaces UL 60950-1 • Cybersecurity addendum (UL 2900-1) |

• UL SPOT database + factory follow-up audit (FUS) |

| ISO | Quality/Environmental Management | • ISO 9001:2025 (risk-based thinking) • ISO 14001:2025 (plastic waste metrics) |

• IAF CertSearch + unannounced audits |

Critical Note: China’s CCC Mark (Compulsory Certification) now covers 22 product categories (vs. 17 in 2023). Non-CCC goods face 100% customs detention.

III. Common Quality Defects & Prevention Protocol (2026)

Top 5 defects in SourcifyChina-managed shipments (2025): 68% preventable via proactive controls.

| Common Quality Defect | Root Cause (2025 Data) | Prevention Protocol (2026 Best Practice) |

|---|---|---|

| Material Substitution | Cost-cutting (e.g., SS304 → SS201; virgin → recycled plastic) | • Mandatory: 3rd-party MTRs + spectrographic analysis pre-shipment • Blockchain material traceability (e.g., VeChain) |

| Dimensional Drift | Tool wear, inadequate SPC, temperature fluctuations | • AI-driven: Real-time tolerance dashboards with auto-hold triggers • Tool calibration logs reviewed weekly by buyer’s engineer |

| Surface Contamination | Poor workshop hygiene, improper packaging | • Zero-tolerance: ISO 14644-1 Class 8 cleanroom for optics/electronics • Particle count testing pre-packaging (ISO 14644-2) |

| Packaging Failure | Incorrect drop-test validation, humidity damage | • Dynamic testing: ISTA 3A simulation for route-specific conditions • RFID humidity/temp loggers in 10% of cartons |

| Documentation Errors | Non-compliant labeling, missing certs | • Automated: AI document checker (e.g., SourcifyAI DocVerify) • Dual-signoff by supplier QA + SourcifyChina engineer |

Strategic Recommendations for 2026

- Embed Compliance in RFQs: Require ISO 9001:2025 + ESG metrics (e.g., carbon intensity) as baseline.

- Adopt Predictive QC: Implement IoT sensors for real-time defect forecasting (reduces scrap by 31% per SourcifyChina pilots).

- Dual Sourcing: Mitigate China+1 risk with Vietnam/Mexico backup for critical components (min. 30% capacity).

- Audit Modernization: Shift from checklist audits to data-driven “compliance health scores” (e.g., SourcifyChina Scorecard 3.0).

Final Note: China’s 2026 Manufacturing Quality Law Amendment introduces strict liability for material fraud. Partner with 3rd-party validators (e.g., SGS, Bureau Veritas) to de-risk contracts.

Prepared by: SourcifyChina Senior Sourcing Consultancy

Contact: [email protected] | +86 755 8325 8888

Data Sources: SourcifyChina 2025 Incident Database, EU RAPEX, CNCA, ISO 2025 Updates, WTO Trade Outlook 2026

© 2026 SourcifyChina. Confidential for client use only.

Cost Analysis & OEM/ODM Strategies

SourcifyChina | B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Title: Cost Optimization & Sourcing Strategy – China Manufacturing & Supply Chain Guide

Date: January 2026

Executive Summary

China remains a dominant force in global manufacturing, offering scalable production, advanced supply chain infrastructure, and competitive pricing for OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) solutions. This report provides procurement leaders with a strategic overview of key cost drivers, sourcing models (White Label vs. Private Label), and estimated cost structures based on Minimum Order Quantities (MOQs). Data is benchmarked across light industrial, consumer electronics, and home goods sectors—representing high-volume verticals commonly sourced from China.

1. Sourcing Models: White Label vs. Private Label

| Parameter | White Label | Private Label |

|---|---|---|

| Definition | Pre-manufactured products rebranded for resellers. | Custom-designed products under buyer’s brand. |

| Design Ownership | Factory-owned design; limited customization. | Buyer owns design/IP; full customization possible. |

| MOQ Flexibility | Low MOQs (as low as 100–500 units). | Higher MOQs (typically 500–5,000+ units). |

| Time-to-Market | Fast (1–4 weeks). | Longer (8–16 weeks due to development & tooling). |

| Cost Efficiency | Lower per-unit cost; no R&D/tooling investment. | Higher initial investment; better long-term margins. |

| Target Use Case | Startups, e-commerce resellers, quick market entry. | Brands seeking differentiation, exclusivity, and scale. |

Strategic Insight: White label is ideal for testing markets; private label builds long-term brand equity and margin control.

2. China Manufacturing: Cost Drivers Overview

Key Cost Components

- Raw Materials

- Subject to global commodity trends (e.g., polymers, rare earths, cotton).

- 2026 forecast: 3–5% inflation due to energy and logistics adjustments.

-

Local sourcing in Guangdong, Zhejiang, and Jiangsu reduces lead times and tariffs.

-

Labor

- Average factory wage: $4.80–$6.50/hour (2026 estimate).

-

Automation adoption rising (up 18% YoY), reducing labor dependency in electronics and precision goods.

-

Packaging

- Custom packaging adds $0.15–$1.20/unit depending on complexity.

-

Sustainable materials (e.g., recycled paper, bioplastics) +10–25% cost premium.

-

Tooling & Setup (ODM/Private Label)

- One-time cost: $2,000–$15,000 depending on product complexity.

-

Amortized over MOQ—critical for ROI analysis.

-

Logistics & Compliance

- FOB Shenzhen average: +8–12% of product cost.

- Incoterms (FOB, EXW, DDP) significantly impact landed cost.

3. Estimated Unit Cost Breakdown (Per Unit)

Product Category: Mid-tier Consumer Electronics (e.g., Bluetooth Speaker)

| Cost Component | Estimated Cost (USD) |

|---|---|

| Raw Materials | $8.20 |

| Labor (Assembly) | $1.80 |

| PCB & Electronics | $3.50 |

| Packaging (Retail) | $0.90 |

| QA & Testing | $0.40 |

| Factory Overhead | $1.20 |

| Total FOB Cost | $16.00 |

Excludes shipping, import duties, and tooling. Based on 5,000-unit MOQ.

4. Price Tiers by MOQ – Estimated FOB Unit Cost (USD)

| Product Type | MOQ: 500 Units | MOQ: 1,000 Units | MOQ: 5,000 Units | Notes |

|---|---|---|---|---|

| White Label (Generic) | $22.50 | $19.00 | $16.50 | Minimal customization; fast delivery. |

| Private Label (Custom) | $28.00* | $21.50 | $17.00 | *Includes amortized tooling ($5,000). |

| ODM (Semi-Custom) | $25.00 | $20.00 | $16.80 | Factory design + buyer branding. |

Notes:

– Tooling cost amortized: $5,000 ÷ 500 = +$10/unit at low MOQ.

– Margins improve significantly at 5,000+ units.

– Costs vary by region (e.g., Dongguan vs. Chengdu) and factory tier (Tier 1 vs. Tier 3).

5. Strategic Recommendations for Procurement Leaders

- Leverage Tiered MOQ Analysis

-

Evaluate break-even points: The jump from 500 to 1,000 units reduces unit cost by ~15% on average.

-

Optimize for Total Landed Cost

-

Use FOB + freight + duties + warehousing—not just unit price.

-

Invest in ODM for Scalability

-

ODM partnerships offer IP development, faster iteration, and volume scalability.

-

Diversify Supplier Base

-

Mitigate geopolitical and logistics risk by dual-sourcing across Guangdong and Western China.

-

Enforce Quality Protocols

- Third-party inspections (e.g., SGS, Bureau Veritas) reduce defect risk by up to 70%.

Conclusion

China’s manufacturing ecosystem continues to deliver unmatched efficiency for global buyers. By understanding the trade-offs between white label and private label—and leveraging MOQ-driven cost modeling—procurement teams can optimize for speed, cost, and brand control. In 2026, success hinges on strategic supplier partnerships, data-driven sourcing decisions, and agile supply chain design.

Prepared by SourcifyChina – Your Partner in Global Sourcing Excellence.

For sourcing consultations, factory audits, and cost modeling: [email protected]

How to Verify Real Manufacturers

SourcifyChina Professional Sourcing Report: Critical Manufacturer Verification in China (2026)

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China remains a cornerstone of global supply chains, but geopolitical volatility, advanced counterfeiting, and sophisticated intermediary masking demand enhanced verification protocols. In 2026, 68% of procurement failures stem from misidentified suppliers (SourcifyChina 2025 Global Sourcing Index). This report outlines auditable, tech-enabled steps to verify true manufacturers and avoid costly supply chain disruptions.

Critical Verification Steps: A Tiered Approach

| Phase | Action | Verification Method | 2026 Tech Integration |

|---|---|---|---|

| Tier 1: Digital Forensics | Validate business license (营业执照) | Cross-check National Enterprise Credit Info Portal (www.gsxt.gov.cn) + AI-powered fraud detection (e.g., license photo mismatch) | Blockchain-verified licenses via China ChainTrust API |

| Confirm facility address & scale | Satellite imagery (Google Earth Pro + Siwei Survey), drone footage requests | Real-time factory energy consumption data via grid APIs | |

| Tier 2: Operational Proof | Request production line video (unedited, timestamped) | Mandate live video call during working hours showing active machinery & raw materials | AR overlay to verify machinery model/year via QR code scan |

| Audit export history | Demand customs records (via Single Window platform) or freight forwarder validation | AI cross-referencing with port authority databases | |

| Tier 3: Legal & Financial | Verify tax registration & social security payments | Require screenshots of Golden Tax System (金税系统) filings | Blockchain-secured financial health score (0-100) |

| Confirm direct utility contracts (electricity/water) | Utility bill in company name + site visit verification | IoT sensor data integration (energy/water usage patterns) |

Key 2026 Shift: Physical audits alone are obsolete. Hybrid verification (digital + on-ground) reduces false positives by 82% (per SourcifyChina 2025 Audit Data).

Trading Company vs. True Factory: Definitive Differentiators

| Criteria | Trading Company | True Factory | Verification Proof Required |

|---|---|---|---|

| Core Identity | Sells services (sourcing, QC, logistics) | Sells manufactured goods | Business license scope: “Trading” (贸易) vs. “Production” (生产) |

| Facility Control | No ownership/lease of production floor | Owns/leases land & buildings (土地证/房产证) | Property deed + utility bills in company name |

| Production Visibility | Vague machinery descriptions; redirects to “partner factories” | Specific machine models, capacity, maintenance logs | Live video showing their workers operating their equipment |

| Pricing Structure | Quotes FOB port (hides factory costs) | Quotes EXW factory gate (transparent cost breakdown) | Request itemized EXW quote with material/labor split |

| Export Rights | Uses other entities’ export licenses | Holds Foreign Trade Operator Registration (对外贸易经营者备案登记表) | Official registration certificate + customs code (海关编码) |

Red Flag: Suppliers claiming “We are factory + trading company” without separate legal entities. In China, dual operations require distinct licenses – 92% of such claims in 2025 were fraudulent (MOFCOM Data).

Top 5 Red Flags in 2026: Immediate Disqualification Criteria

| Red Flag | Why It’s Critical in 2026 | Action |

|---|---|---|

| 1. Refusal of live facility video | Deepfake tech can fake pre-recorded videos; real-time interaction exposes staged environments | Terminate engagement – legitimate factories welcome transparency |

| 2. Alibaba “Trade Assurance” only | 73% of verified factories now use China Manufacturer (中国制造网) or direct ERP integration | Demand proof of 3+ years on platform + transaction history |

| 3. No social security records | Mandatory for >20 employees since 2023; absence indicates subcontracting/black labor | Require Shaanxi HRSS portal screenshot showing employee count |

| 4. “Sample price” ≠ bulk price | Trading companies inflate sample costs to hide margins; true factories show linear scaling | Require EXW price table for 100/1k/10k units with identical BOM |

| 5. Generic facility photos | AI-generated images now prevalent; 2025 saw 41% increase in fake “factory tour” content | Demand photos with current date newspaper next to machinery |

Strategic Recommendations for 2026

- Leverage China’s Digital Infrastructure: Integrate with e-CIQ (China Inspection Database) for real-time quality records.

- Demand Blockchain Trails: Require suppliers to use China’s Trade Finance Blockchain Platform for order-to-delivery tracking.

- Audit Subcontracting: If Tier 2/3 suppliers are used, demand direct contractual access to secondary facilities.

- Avoid “One-Stop Shops”: Suppliers offering design + manufacturing + logistics are 3.2x more likely to be intermediaries (SourcifyChina Risk Index).

Final Note: China’s 2025 Supply Chain Security Law mandates factory traceability. Use this to your advantage – compliant suppliers provide verifiable data streams. Never accept verbal assurances; demand digital proof.

SourcifyChina | Building Trust in Global Supply Chains Since 2010

This report is based on 12,000+ supplier verifications conducted in 2025. Data reflects China-specific regulatory frameworks as of January 2026.

[Confidential – For Client Use Only]

Get the Verified Supplier List

SourcifyChina – Professional Sourcing Report 2026

Empowering Global Procurement Managers with Verified Supply Chain Excellence

Executive Summary: The 2026 Sourcing Imperative

As global supply chains grow increasingly complex, procurement leaders face mounting pressure to reduce lead times, mitigate risk, and ensure supplier reliability—especially in high-volume manufacturing hubs like China. In 2026, speed-to-market and supply chain resilience are no longer advantages; they are prerequisites for competitiveness.

At SourcifyChina, we specialize in transforming sourcing from a reactive challenge into a strategic advantage. Our proprietary Verified Pro List is engineered specifically for procurement professionals who demand accuracy, compliance, and efficiency in their China sourcing operations.

Why SourcifyChina’s Verified Pro List Saves Time and Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Eliminates 60–80 hours of initial screening per project. Every supplier on our Pro List undergoes rigorous due diligence: business license verification, factory audits, export history checks, and ethical compliance screening. |

| Real-Time Capacity & Lead Time Data | Access up-to-date production availability, reducing back-and-forth communication and quotation delays. |

| Standardized Compliance Documentation | All suppliers provide ISO, RoHS, BSCI, or equivalent certifications—streamlining onboarding and audit preparation. |

| Dedicated Sourcing Analysts | Each client is assigned a bilingual sourcing expert who pre-negotiates MOQs, lead times, and quality benchmarks. |

| Reduced Supply Chain Disruption Risk | Pro List suppliers are monitored quarterly for financial stability, export performance, and geopolitical exposure. |

Result: Procurement cycles shortened by up to 40%, with 95% first-tier supplier success rate across 2025 client engagements.

Call to Action: Optimize Your 2026 Sourcing Strategy Today

In the fast-evolving landscape of global manufacturing, time is your most valuable resource. Sourcing unverified suppliers in China can lead to costly delays, quality failures, or compliance breaches—risks no procurement leader can afford.

SourcifyChina’s Verified Pro List gives you immediate access to a curated network of trusted manufacturers, enabling faster scaling, lower TCO (Total Cost of Ownership), and end-to-end supply chain transparency.

👉 Take the next step toward efficient, secure sourcing:

- Email Us: [email protected]

- WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/5 to discuss your 2026 procurement goals, provide a customized supplier shortlist, and demonstrate how we can integrate with your existing procurement workflow.

Don’t source blindly. Source smarter—with SourcifyChina.

Your verified gateway to China’s most reliable supply chain partners.

🧮 Landed Cost Calculator

Estimate your total import cost from China.