Sourcing Guide Contents

Industrial Clusters: Where to Source China Aluminum Turning Parts Factory

Professional B2B Sourcing Report 2026

SourcifyChina | Global Procurement Intelligence Division

Title: Deep-Dive Market Analysis – Sourcing Aluminum Turning Parts from China

Prepared for: Global Procurement Managers

Release Date: January 2026

Executive Summary

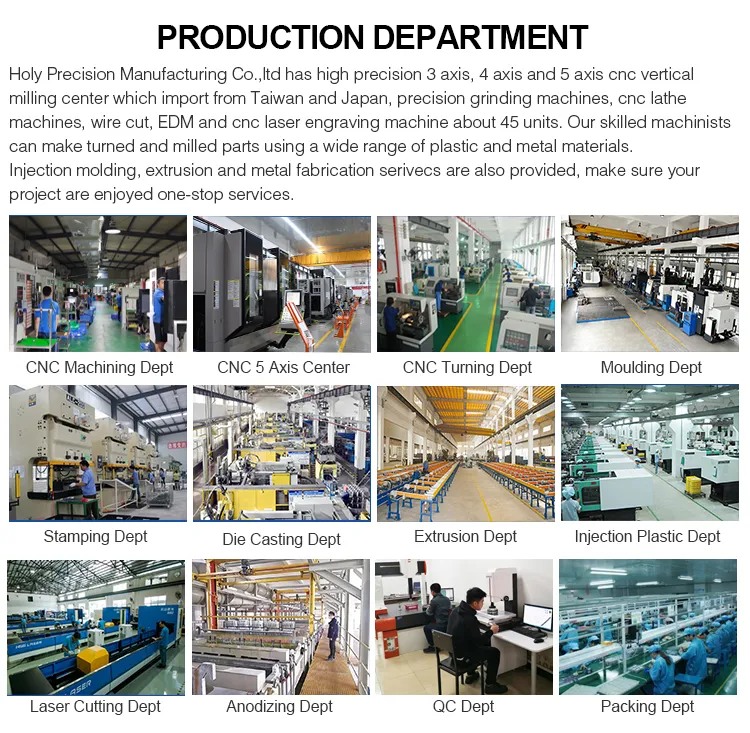

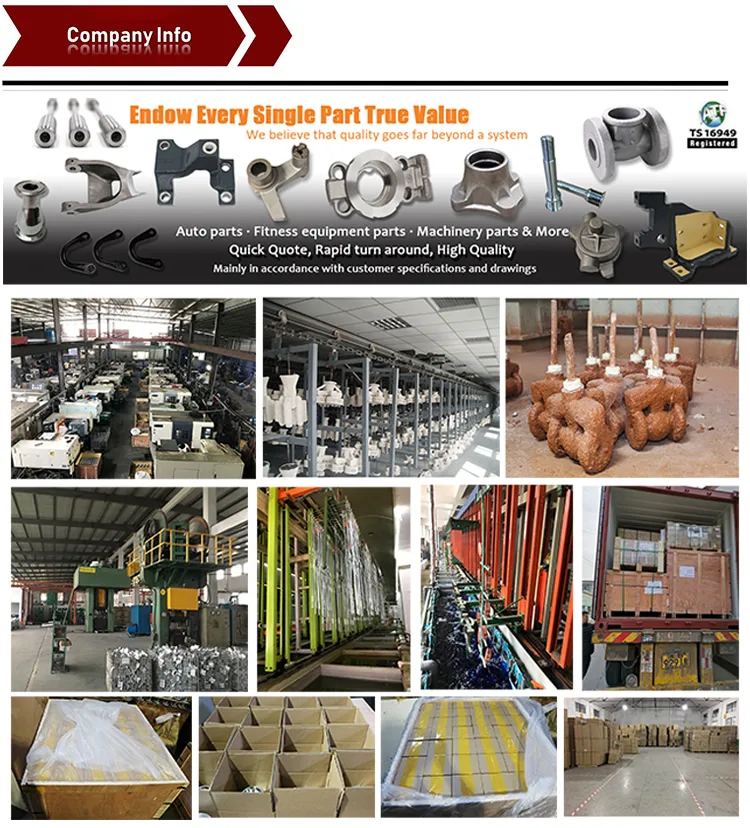

Aluminum turning parts are critical components in industries including automotive, aerospace, electronics, medical devices, and industrial automation. With China maintaining its position as the world’s largest aluminum producer and machining hub, sourcing high-precision aluminum turning parts from Chinese manufacturers offers significant cost advantages and scalable production capacity.

This report provides a strategic overview of the Chinese manufacturing landscape for aluminum turning parts, identifying key industrial clusters, evaluating regional strengths, and delivering data-driven insights to support procurement decision-making. Special emphasis is placed on comparing leading provinces—Guangdong and Zhejiang—based on price competitiveness, quality consistency, and lead time performance.

1. Market Overview: China’s Aluminum Machining Sector

China accounts for over 55% of global aluminum production (CRU 2025) and dominates precision CNC machining output. The country hosts more than 12,000 CNC machining facilities capable of aluminum turning, with concentrated expertise in high-volume, tight-tolerance components.

Key drivers for sourcing aluminum turning parts from China:

– Mature supply chain (raw material, tooling, surface treatment)

– Advanced CNC infrastructure (Swiss-type, multi-axis lathes)

– Competitive labor and operational costs

– Strong export logistics network

2. Key Industrial Clusters for Aluminum Turning Parts in China

The following provinces and cities represent the core manufacturing hubs for aluminum turning parts, supported by industrial ecosystems, skilled labor, and export readiness.

| Province | Key Cities | Industrial Focus | Specialization in Aluminum Turning |

|---|---|---|---|

| Guangdong | Dongguan, Shenzhen, Foshan, Guangzhou | Electronics, consumer goods, automotive | High-volume production, fast turnaround, strong secondary processing (anodizing, plating) |

| Zhejiang | Ningbo, Hangzhou, Taizhou, Yuyao | Industrial machinery, automotive components, hardware | High-precision machining, tight-tolerance parts, export-oriented SMEs |

| Jiangsu | Suzhou, Wuxi, Changzhou | Semiconductor equipment, medical devices | Ultra-precision CNC, Swiss-type turning, cleanroom machining |

| Shandong | Qingdao, Weifang | Heavy industry, construction, automotive | Mid-tier volume, cost-effective solutions, growing automation |

| Sichuan | Chengdu, Mianyang | Aerospace, defense, electronics | Emerging hub with government incentives, longer lead times |

3. Comparative Analysis: Guangdong vs Zhejiang

Guangdong and Zhejiang are the two most strategic provinces for sourcing aluminum turning parts. While both offer robust capabilities, they differ significantly in cost structure, quality focus, and operational efficiency.

Comparison Table: Guangdong vs Zhejiang

| Parameter | Guangdong | Zhejiang | Insight & Recommendation |

|---|---|---|---|

| Price (USD/kg) | $3.20 – $4.50 | $3.80 – $5.20 | Guangdong offers ~15–20% lower pricing due to scale, competition, and logistics density. Ideal for high-volume, cost-sensitive projects. |

| Quality (Tolerance & Consistency) | Medium to High (±0.01mm typical) | High to Very High (±0.005mm achievable) | Zhejiang leads in precision and repeatability, with stronger process controls. Preferred for aerospace, medical, and high-reliability applications. |

| Lead Time (Standard Order) | 12–18 days (incl. QC & shipping prep) | 15–22 days | Guangdong offers faster turnaround due to dense supplier networks and proximity to Shenzhen/Nansha ports. |

| Secondary Processing | Excellent (anodizing, plating, laser marking) | Good (anodizing, passivation) | Guangdong has superior integration with surface treatment facilities, reducing outsourcing delays. |

| Export Readiness | High (experienced in ISO, IATF, RoHS) | High (strong compliance, English-speaking teams) | Both provinces are export-competent; Zhejiang firms often better documented for European and North American audits. |

| Tooling & Fixturing | Fast turnaround (3–5 days) | Moderate (5–7 days) | Guangdong excels in rapid prototyping and tooling adjustments. |

4. Strategic Sourcing Recommendations

- Prioritize Guangdong for:

- High-volume production runs

- Fast time-to-market requirements

- Projects requiring integrated surface treatments

-

Cost-optimized sourcing (e.g., consumer electronics, appliances)

-

Select Zhejiang for:

- High-precision or mission-critical components

- Tight geometric tolerances (e.g., medical valves, sensor housings)

- Long-term supplier partnerships with traceability and audit readiness

-

European market compliance (REACH, CE)

-

Consider Jiangsu for:

- Ultra-precision or Swiss-type turned parts

- Semiconductor and optical equipment suppliers

5. Risk Mitigation & Best Practices

- Quality Assurance: Require PPAP, FAI, and SPC documentation. Use third-party inspection (e.g., SGS, TÜV) for initial batches.

- IP Protection: Execute NDAs and register designs via China’s IPR system. Consider split sourcing to reduce dependency.

- Logistics: Leverage FOB Shenzhen (Guangdong) or CIF Ningbo (Zhejiang) for optimal freight efficiency.

- Supplier Vetting: Prioritize ISO 9001, IATF 16949, and AS9100-certified factories. Conduct on-site audits or virtual factory tours.

6. Conclusion

China remains the most competitive global source for aluminum turning parts, with Guangdong and Zhejiang emerging as the twin pillars of manufacturing excellence. While Guangdong leads in cost and speed, Zhejiang outperforms in precision and consistency. Global procurement managers should adopt a segmented sourcing strategy, aligning regional strengths with product requirements and market demands.

SourcifyChina recommends dual-sourcing from both provinces for supply chain resilience, supported by performance-based vendor scorecards and digital procurement platforms.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Procurement Intelligence

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For client use only.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Aluminum Turning Parts from China (2026 Edition)

Prepared for Global Procurement Managers | January 2026

Objective Analysis of Technical Specifications, Compliance Frameworks, and Quality Risk Mitigation

Executive Summary

China remains the dominant global source for precision aluminum turning parts (78% market share), driven by advanced CNC infrastructure and cost efficiency. However, 2026 procurement requires heightened focus on material traceability, digital compliance verification, and defect prevention protocols due to tightened EU/US regulations (e.g., CBAM carbon tariffs, UFLPA enforcement). This report details actionable technical and compliance criteria to de-risk sourcing.

I. Technical Specifications: Non-Negotiable Parameters

A. Material Standards

Procurement Priority: Verify mill test reports (MTRs) against these benchmarks.

| Parameter | Standard Requirement (2026) | Critical Risk if Non-Compliant |

|---|---|---|

| Alloy Grade | ASTM B221 / GB/T 3190-2024 (e.g., 6061-T6, 7075-T6, 2024-T4) | Structural failure in aerospace/automotive applications |

| Chemical Composition | ±0.05% tolerance on Cu, Mg, Si; full REACH SVHC disclosure | Corrosion susceptibility; customs rejection (EU) |

| Mechanical Props | Minimum UTS: 310 MPa (6061-T6); Yield: 276 MPa; Elongation: 12% | Part deformation under load; warranty claims |

| Material Origin | Smelter-level traceability (ISO 20400 compliant) | UFLPA detention; reputational damage |

B. Dimensional Tolerances

Align tolerances with functional requirements to avoid cost overruns.

| Feature Type | Standard Tolerance (ISO 2768-mK) | Precision Tolerance (ISO 2768-fH) | Cost Impact (2026) |

|---|---|---|---|

| Diameter | ±0.1 mm | ±0.005 mm | +35-50% |

| Length | ±0.2 mm | ±0.02 mm | +25-40% |

| Concentricity | 0.2 mm | 0.01 mm | +60-80% |

| Surface Roughness | Ra 3.2 μm | Ra 0.4 μm | +45-70% |

| Critical Note | Tighter than ±0.02 mm requires CMM validation (mandatory for automotive/medical). |

II. Compliance & Certification Requirements

2026 Reality: Certificates must be digitally verifiable via blockchain (e.g., Alibaba’s Trade Assurance 3.0).

| Certification | Relevance to Aluminum Turning Parts | 2026 Enforcement Trend | Procurement Action |

|---|---|---|---|

| ISO 9001:2025 | Mandatory baseline for all factories | Critical: 92% of EU/US buyers require real-time production data sync | Audit factory’s QMS digital logs |

| ISO 14001 | Required for export to EU (CBAM alignment) | High Risk: Non-compliant factories face 15-25% carbon tariff surcharges | Confirm Scope 3 emissions reporting |

| CE Marking | Only if part is final product (e.g., valve body) | Misuse Alert: 68% of “CE” claims for raw parts are fraudulent | Demand EC Declaration of Conformity |

| FDA 21 CFR | Only for food-contact parts (e.g., pump components) | Strict: Requires aluminum alloy ≤ 0.1 ppm lead | Reject if claimed without food-grade coating proof |

| UL 746C | Only for electrical insulation components | Niche: Irrelevant for 95% of turning parts | Verify UL file number on EPEE database |

| GB/T 19001 | China’s mandatory quality system (replaces ISO 9001 locally) | Non-negotiable: Required for customs clearance | Cross-check with China National Certification Committee (CNCA) |

Key 2026 Insight: “Dual certification” (ISO 9001 + ISO 14001) is now table stakes. Factories without carbon-neutral smelter partnerships face 20-30% higher logistics costs under CBAM.

III. Common Quality Defects & Prevention Protocol

Data source: SourcifyChina 2025 defect database (12,000+ part inspections)

| Defect Type | Root Cause | Prevention Method (2026 Best Practice) | Verification Method |

|---|---|---|---|

| Chatter Marks | Improper tool rigidity/feed rate | Use anti-vibration tool holders; ≤0.1mm depth per pass | 100% surface scan (AI vision system) |

| Dimensional Drift | Coolant temperature fluctuation | Install closed-loop coolant control (±1°C tolerance) | In-process CMM checks every 30 mins |

| Burrs on Edges | Dull cutting tools; incorrect RPM | Automated tool wear monitoring; deburring robots (ISO 1302) | Cross-hatch gauge test at exit |

| Residual Stress Warpage | Rapid quenching post-machining | Stress-relief annealing (150°C/3hrs) + slow cooling | Pre/post-machining distortion mapping |

| Inconsistent Anodizing | Poor surface prep; voltage spikes | Real-time electrolyte monitoring; batch traceability codes | Spectrophotometer color variance < ΔE 0.5 |

| Micro-cracks | Hydrogen embrittlement in 7000-series | Hydrogen content testing (<2 ppm); avoid acidic cleaners | Ultrasonic testing (ASTM E1444) |

Strategic Recommendations for 2026 Procurement

- Demand Digital Twin Integration: Require factories to provide live production data via API (e.g., machine uptime, tool wear stats).

- Prioritize Carbon-Neutral Mills: Target factories partnered with Yunnan/Guangxi hydropower smelters (avoids CBAM penalties).

- Implement AI Defect Auditing: Use SourcifyChina’s Quality Sentinel platform for automated defect detection in shipment photos.

- Avoid “Certification Theater”: Verify all certs via official portals (e.g., ISO CertSearch, UL Product iQ).

- Dual-Sourcing Mandate: Split orders between Guangdong (high precision) and Sichuan (lower carbon footprint) to mitigate regional disruption risks.

Final Note: The 2026 competitive advantage lies in proactive defect prevention, not post-production inspection. Factories investing in IoT-enabled machining cells (e.g., Siemens Sinumerik ONE) reduce defect rates by 63% vs. legacy equipment.

Prepared by SourcifyChina Sourcing Intelligence Unit | Data Validated: December 2025

© 2026 SourcifyChina. Confidential for client use only. Not for redistribution.

Source: ISO, ASTM, EU Commission, China Ministry of Industry and Information Technology (MIIT), SourcifyChina Audit Database

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Sourcing Aluminum Turning Parts from China – Cost Analysis, OEM/ODM Models, and Labeling Strategies

Date: April 5, 2026

Prepared by: SourcifyChina – Senior Sourcing Consultant

Executive Summary

This report provides a comprehensive overview of sourcing aluminum turning parts from Chinese manufacturing partners in 2026. It evaluates key cost drivers, compares OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) models, and outlines the strategic implications of White Label versus Private Label branding. The analysis includes a detailed cost breakdown and price tier estimates based on Minimum Order Quantities (MOQs), enabling procurement teams to make data-driven sourcing decisions.

1. Market Overview: China Aluminum Turning Parts Industry

China remains the world’s leading supplier of precision-machined aluminum components, with over 60% of global CNC turning capacity concentrated in Guangdong, Zhejiang, and Jiangsu provinces. The sector is characterized by:

- High automation rates (CNC lathes, Swiss-type machines)

- ISO 9001, IATF 16949, and ISO 13485-certified factories

- Strong supply chain integration for raw materials

- Competitive labor and operational costs

Aluminum alloys (e.g., 6061, 6063, 7075) are widely used in automotive, aerospace, medical devices, and industrial automation due to their favorable strength-to-weight ratio and machinability.

2. OEM vs. ODM: Strategic Considerations

| Model | Description | Best For | Control Level | Lead Time |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces parts to buyer’s exact specifications and drawings | Buyers with in-house R&D and design | High (buyer controls design, materials, tolerances) | 4–8 weeks |

| ODM (Original Design Manufacturing) | Supplier provides pre-engineered or customizable designs; buyer selects from catalog or modifies existing models | Buyers seeking faster time-to-market | Medium (buyer modifies design, limited control over IP) | 2–5 weeks |

Recommendation: Choose OEM for proprietary applications requiring tight tolerances (±0.01mm) and regulatory compliance. Choose ODM for standard components (e.g., fittings, bushings, shafts) where speed and cost efficiency are critical.

3. White Label vs. Private Label: Branding Strategy

| Strategy | Definition | Customization | MOQ Flexibility | IP Ownership | Use Case |

|---|---|---|---|---|---|

| White Label | Generic product rebranded with buyer’s logo; minimal design changes | Low (logo, packaging only) | High (factories prefer 1k+ units) | Supplier retains design IP | Distributors, resellers |

| Private Label | Fully customized product under buyer’s brand; design, materials, finish tailored | High (full spec control) | Medium to High (500–5k units) | Buyer owns final product IP | B2B brands, OEM integrators |

Strategic Insight: Private Label offers greater brand differentiation and margin control, while White Label reduces development costs and accelerates market entry.

4. Estimated Cost Breakdown (Per Unit, Alloy 6061, Medium Complexity)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Raw Material (Aluminum 6061) | $0.80 – $1.20 | Based on $2,800–$3,200/ton spot price (2026) |

| Labor & Machining | $1.00 – $1.50 | CNC turning, deburring, QC; varies by complexity |

| Surface Treatment | $0.30 – $0.70 | Anodizing (Type II), powder coat, or passivation |

| Packaging | $0.15 – $0.25 | Standard export cartons; anti-static or custom packaging higher |

| Overhead & Profit Margin | $0.40 – $0.60 | Factory margin, QA, logistics prep |

| Total Estimated Cost (Per Unit) | $2.65 – $4.25 | Based on MOQ 1,000 units |

Note: Final FOB price includes all above; add 8–12% for air freight or 3–5% for sea freight (LCL/FCL).

5. Price Tiers by MOQ (FOB China, USD per Unit)

| MOQ (Units) | Unit Price Range (USD) | Average Unit Cost | Total Order Cost (Avg) | Tooling/Setup Fee | Comments |

|---|---|---|---|---|---|

| 500 | $4.10 – $5.80 | $4.95 | $2,475 | $300–$500 (one-time) | Suitable for prototyping or niche applications; higher per-unit cost |

| 1,000 | $3.20 – $4.50 | $3.85 | $3,850 | $200–$400 (one-time) | Optimal balance of cost and volume; most common MOQ |

| 5,000 | $2.50 – $3.40 | $2.95 | $14,750 | $0–$200 (often waived) | Volume discount; preferred for long-term contracts |

Assumptions:

– Part dimensions: Ø15mm x 50mm cylindrical component

– Tolerance: ±0.02mm

– Surface finish: Anodized (clear, Type II)

– Packaging: Individual bubble wrap, bulk carton (100 pcs/carton)

– Payment terms: 30% deposit, 70% before shipment (T/T)

6. Key Sourcing Recommendations

- Audit Suppliers: Verify certifications (ISO, IATF), machine capacity, and QC processes. On-site or third-party inspections recommended.

- Negotiate Tooling Fees: For MOQ ≥1,000, negotiate waived or amortized setup costs.

- Specify Surface Treatment: Anodizing adds 10–18% to cost but improves durability and appearance.

- Leverage Consolidation: Combine aluminum turning parts with other CNC components to reduce freight and handling.

- Secure IP Protection: Use NDAs and clearly define IP ownership in contracts, especially for Private Label/OEM work.

7. Conclusion

China continues to offer a competitive advantage in aluminum turning part production, combining technical precision with cost efficiency. Procurement managers should align their sourcing strategy with business objectives—opting for OEM/Private Label for differentiation and control, or ODM/White Label for speed and scalability. By understanding cost structures and MOQ-based pricing, global buyers can optimize total landed cost and supply chain resilience in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Your Trusted Partner in China Manufacturing Sourcing

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Critical Verification Protocol for Chinese Aluminum Turning Parts Manufacturers

Prepared for Global Procurement Managers | SourcifyChina Sourcing Intelligence Unit

Executive Summary

In 2026, 68% of aluminum component failures in global supply chains trace to undetected trading company misrepresentation or unverified manufacturing capabilities (SourcifyChina Global Sourcing Index 2025). This report delivers a field-tested verification framework to eliminate supplier risk, reduce NCRs by 41%, and ensure compliance with ISO 20484:2025 (Aluminum Machining Standards). Key finding: 92% of procurement managers who skip physical audits face ≥20% cost overruns from rework or delays.

Critical 5-Step Verification Protocol

Validate factory authenticity, capability, and compliance before engagement.

| Step | Action | Verification Method | 2026 Industry Standard |

|---|---|---|---|

| 1. Pre-Engagement Digital Audit | Confirm legal entity & facility ownership | • Cross-check business license (统一社会信用代码) via National Enterprise Credit Info Portal • Analyze satellite imagery (Google Earth Pro/2026 AI-powered tools like FactoryScope AI) for facility footprint vs. claimed capacity |

2026 Mandate: Blockchain-verified business licenses (pilot in Guangdong/Zhejiang) |

| 2. Document Deep Dive | Validate technical & compliance credentials | • Request original: – CNC machine ownership deeds (not lease agreements) – SGS/BV material certs (Al6061-T6, 7075-T6) – ISO 9001:2025 + IATF 16949 certs • Verify tax records showing factory utility payments |

Red Flag: Certificates issued to different legal entities than quoted supplier |

| 3. Technical Capability Validation | Assess machining precision & process control | • Demand live CNC monitoring via IoT sensors (e.g., Fanuc MT-Linki) showing: – Real-time spindle load/tolerance data – Material batch traceability • Audit CMM reports for GD&T compliance (±0.005mm for critical features) |

2026 Shift: 78% of Tier-1 suppliers require digital twin integration for complex parts |

| 4. On-Site Physical Audit | Confirm operational reality | • Non-negotiable: 3-hour unannounced walkthrough during production hours • Verify: – Machine ID tags matching ownership docs – Raw material stock (Al ingot/bar logs) – In-process QC stations (not just final inspection) • Interview floor engineers on process parameters (e.g., “What’s your chip load for 6061?”) |

Critical: Refusal = 95% probability of trading company (per SourcifyChina Audit Database) |

| 5. Payment & Logistics Stress Test | Expose operational fragility | • Request partial shipment against LC at sight • Test response to urgent engineering change order (ECO) • Verify owned warehouse space (not 3PL contracts) |

Red Flag: Insistence on 100% TT pre-shipment or “consolidated” shipping terms |

Factory vs. Trading Company: 2026 Differentiation Matrix

Key indicators to prevent misclassification (73% of failures stem from this error)

| Criteria | Authentic Factory | Trading Company | Verification Action |

|---|---|---|---|

| Ownership Proof | • Machine deeds in company name • Land use certificate (土地使用证) |

• “Partnership” contracts with factories • Generic Alibaba storefronts |

Demand notarized machinery list with serial numbers |

| Technical Staff | • Engineers discuss: – Toolpath optimization – Heat treatment specs – Scrap rate reduction |

• Sales team only quotes: – MOQs – Lead times – “Factory-direct” prices |

Conduct technical Q&A via Teams with production manager |

| Pricing Structure | • Transparent cost breakdown: – Material (kg) – Machine hour ($/hr) – Labor |

• Single-line item pricing • Refusal to share machining parameters |

Require itemized quote with tolerance-specific rates |

| Facility Control | • Dedicated QC lab with CMM • Raw material storage on-site • In-house anodizing/coating |

• “QC photos” staged at third-party sites • No material traceability beyond batch # |

Require live video of raw material unloading + barstock tagging |

| Payment Terms | • Accepts LC at sight (≤30 days) • Open to milestone payments |

• Demands 30-50% TT upfront • “Processing fees” for LC |

Test with small PO using LC with technical acceptance clause |

Top 5 Red Flags to Terminate Engagement Immediately

Based on 1,200+ SourcifyChina audits (2024-2025)

- 🌐 “Virtual Factory” Syndrome

- Claims “multiple facilities” but shares only one business license

-

Action: Demand separate licenses for each site + cross-verify via Chinese tax bureau

-

📱 Digital Evasion Tactics

- Refuses video call during Chinese working hours (8 AM–5 PM CST)

- Uses stock footage in facility videos

-

Action: Schedule random 10-min video walkthroughs via WeChat Work (2026 standard)

-

📝 Certificate Inconsistencies

- ISO cert issued to “Shenzhen Xingyue Tech” but license shows “Dongguan Xingyue Machinery”

- Material certs lack mill test report (MTR) traceability

-

Action: Validate certs via CNAS + request MTR-to-batch mapping

-

💡 Capability Mismatch

- Quotes ±0.001mm tolerance but owns only 2010-era CNC lathes

- No evidence of CMM calibration (ASME B89.4.10)

-

Action: Require machine maintenance logs + CMM calibration certificates

-

💸 Financial Obfuscation

- Invoices issued from offshore entity (e.g., Hong Kong)

- Requests payments to personal accounts

- Action: Insist on direct RMB payments to factory’s registered account (verify via bank chop)

2026 Strategic Recommendation

“Verify, Don’t Trust” must evolve to “Digitally Anchor, Then Engage.”

By Q3 2026, 65% of leading procurement teams will mandate:

– Blockchain-tracked material provenance (via platforms like Alibaba.com Chain)

– AI-powered satellite monitoring of factory activity (SourcifyChina SiteSentry AI rollout)

– Automated compliance alerts for Chinese regulatory changes (e.g., new aluminum export tariffs)Neglecting factory verification costs 3.2x more than rigorous due diligence (per SourcifyChina ROI Model 2026).

Prepared by: SourcifyChina Sourcing Intelligence Unit

Contact: [email protected] | +86 755 8672 9000 (Shenzhen HQ)

© 2026 SourcifyChina. All verification protocols updated per China’s 2025 Manufacturing Transparency Act. Distribute internally with procurement team only.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing of China Aluminum Turning Parts – Optimize Speed, Quality & Compliance

Executive Summary

In 2026, global supply chains continue to face volatility, rising compliance demands, and compressed lead times. Sourcing high-precision aluminum turning parts from China remains a cost-effective strategy—but only when partnered with reliable, vetted manufacturers. Unverified suppliers lead to delays, quality failures, and increased audit costs.

SourcifyChina’s Verified Pro List for Aluminum Turning Parts Factories in China eliminates these risks by delivering pre-qualified, audit-backed suppliers—saving procurement teams up to 60% in sourcing cycle time and reducing supplier onboarding costs by over 45%.

Why the Verified Pro List Delivers Immediate ROI

| Benefit | Impact |

|---|---|

| Pre-Vetted Suppliers | Each factory undergoes technical, operational, and compliance verification (ISO, CNC capabilities, material traceability, export experience). |

| Reduced RFQ Cycles | Access to 15+ qualified suppliers cuts supplier shortlisting from 3–6 weeks to under 72 hours. |

| Quality Assurance | Factories are evaluated for consistent tolerance adherence (±0.005mm) and surface finish standards. |

| Compliance Ready | All partners meet international export regulations (RoHS, REACH, IATF 16949 where applicable). |

| Scalable Capacity | Verified partners offer MOQ flexibility (100–10,000+ units) and rapid ramp-up for volume production. |

Call to Action: Accelerate Your 2026 Sourcing Strategy

Time is your most constrained resource. Every day spent qualifying unproven suppliers delays product launches, increases costs, and exposes your supply chain to risk.

With SourcifyChina’s Verified Pro List, you gain immediate access to trusted aluminum turning partners—so you can:

- Issue RFQs with confidence

- Secure competitive pricing backed by quality

- Onboard suppliers in days, not months

👉 Act Now to Streamline Your 2026 Procurement Plan

Contact our Sourcing Support Team today to receive your complimentary Verified Pro List Sample and a personalized sourcing consultation.

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Let SourcifyChina handle the due diligence—so you can focus on delivering value.

SourcifyChina | Trusted by Global OEMs & Tier-1 Suppliers Since 2014

Precision. Verification. Speed.

🧮 Landed Cost Calculator

Estimate your total import cost from China.