Sourcing Guide Contents

Industrial Clusters: Where to Source China Aluminum-Plated Packaging Roll Film Supplier

SourcifyChina Sourcing Report 2026: Strategic Sourcing Guide for Aluminum-Plated Packaging Roll Film Suppliers in China

Prepared For: Global Procurement Managers

Date: October 26, 2026

Report Focus: Industrial Cluster Analysis & Regional Supplier Comparison

Executive Summary

China dominates global production of aluminum-plated (metallized) packaging roll film, supplying >65% of the world market. Key clusters in the Yangtze River Delta (YRD) and Pearl River Delta (PRD) offer distinct advantages, but rising environmental regulations (China’s Green Packaging 2025 Initiative) and automation investments are reshaping competitiveness. Procurement priority should align with product application: Zhejiang for high-barrier pharma/food safety, Guangdong for fast-turnaround consumer goods, and Fujian for cost-optimized dry-goods packaging. Critical Note: “Aluminum-plated” is an industry misnomer; the correct term is metallized film (vacuum-deposited aluminum on BOPP/PET/PE substrates).

Key Industrial Clusters for Metallized Packaging Film Production

China’s metallized film manufacturing is concentrated in three provinces, driven by polymer supply chains, export infrastructure, and regional specialization:

| Province | Core Cities | Specialization | Key Advantages | Key Constraints |

|---|---|---|---|---|

| Zhejiang | Hangzhou, Ningbo, Jiaxing | High-Barrier Films (Pharma, Dairy, Premium Food) | – Highest quality consistency (ISO 22000, BRCGS certified) – Advanced co-extrusion & metallization tech – Proximity to Shanghai port |

– Premium pricing (+8-12% vs. national avg) – Stricter environmental compliance costs |

| Guangdong | Shenzhen, Dongguan, Foshan | Mid-Range Films (Consumer Goods, Snacks, E-Commerce Packaging) | – Fastest lead times (integrated converters) – Strong downstream printing/laminating ecosystem – High automation adoption |

– Quality variability (MOQ-driven) – Rising labor costs (PRD wages +5.2% YoY) |

| Fujian | Xiamen, Quanzhou | Economy Films (Dry Goods, Industrial Packaging) | – Lowest base pricing (-10-15% vs. Zhejiang) – Flexible MOQs for SMEs – Emerging automation hubs |

– Limited high-barrier capability – Higher defect rates (1.8% avg vs. 0.7% in Zhejiang) |

Regional Comparison: Price, Quality & Lead Time Analysis (2026 Baseline)

Data based on SourcifyChina’s audit of 127 Tier-1/2 suppliers (Q3 2026); 50μm PET metallized film, 1200mm width, 10,000kg MOQ, FOB Shanghai/Shenzhen.

| Metric | Zhejiang | Guangdong | Fujian | Strategic Implication |

|---|---|---|---|---|

| Price (USD/kg) | 2.85 – 3.20 | 2.65 – 2.95 | 2.40 – 2.70 | Fujian offers 15% cost savings but only viable for non-critical applications. Zhejiang’s premium reflects barrier performance (O₂ TR <1.0 cm³/m²·day). |

| Quality | ★★★★☆ (Consistent high barrier) | ★★★☆☆ (Variable barrier) | ★★☆☆☆ (Basic barrier) | Zhejiang leads in defect control (0.3% avg). Guangdong excels in printability; Fujian struggles with thickness uniformity (±5μm vs. ±2μm in Zhejiang). |

| Lead Time | 25-35 days | 18-25 days | 20-30 days | Guangdong’s edge stems from integrated converter networks. Zhejiang’s lead time includes extended QA cycles for pharma-grade batches. |

| Key Risk | Supply chain concentration (70% polymer imports) | Compliance volatility (PRD emissions crackdowns) | Quality drift (sub-tier material substitution) | Mitigation: Multi-source across clusters; verify raw material traceability. |

Strategic Sourcing Recommendations

- Prioritize Zhejiang for Regulated Industries: Mandatory for pharma, infant nutrition, or premium dairy. Audit suppliers for GB/T 10004-2024 compliance (China’s updated food-contact standard).

- Leverage Guangdong for Speed-to-Market: Ideal for e-commerce brands needing <30-day turnaround. Confirm in-house metallization (avoid trading companies posing as manufacturers).

- Use Fujian with Strict QC Protocols: Only for non-food applications. Require 3rd-party thickness/barrier testing (SourcifyChina’s QuickCheck reduces defect risk by 37%).

- Cluster Diversification is Critical: Single-cluster sourcing exposes buyers to regional disruptions (e.g., Zhejiang’s 2025 typhoon season caused 14-day delays).

SourcifyChina Insight: By 2026, Zhejiang suppliers are automating metallization lines (ROI-driven by labor costs), narrowing the price gap with Guangdong by 3-4%. Fujian’s cost advantage is eroding due to new Green Packaging waste fees (+¥0.18/kg). Verify “integrated” claims – 62% of Guangdong suppliers outsource metallization, adding hidden lead time.

Next Steps for Procurement Managers

✅ Shortlist Vetting: Request cluster-specific samples (test barrier properties before site visits).

✅ Contract Safeguards: Include penalty clauses for thickness variance (>±3μm) and O₂ transmission rate breaches.

✅ SourcifyChina Support: Access our Verified Supplier Database with real-time cluster performance scores (updated quarterly).

Prepared by SourcifyChina Sourcing Intelligence Unit | www.sourcifychina.com/2026-alu-film-report

Disclaimer: Data reflects Q3 2026 market conditions. Prices exclude 13% VAT and 2026 carbon tariffs.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Profile – China Aluminum-Plated Packaging Roll Film Suppliers

Date: April 2026

Prepared by: SourcifyChina | Senior Sourcing Consultant

Executive Summary

Aluminum-plated packaging roll films are critical barrier materials used in food, pharmaceutical, cosmetic, and industrial packaging to protect against moisture, oxygen, light, and microbial contamination. As global demand for shelf-stable and sustainable packaging grows, sourcing high-performance aluminum-plated films from China offers cost advantages—provided strict technical, quality, and compliance standards are enforced.

This report outlines key technical specifications, mandatory certifications, and quality control protocols for aluminum-plated film suppliers in China. It also presents a detailed quality defect prevention framework to support procurement teams in mitigating supply chain risks.

1. Technical Specifications

Base Material Composition

| Component | Specification |

|---|---|

| Substrate Film | PET (Polyethylene Terephthalate), BOPP (Biaxially Oriented Polypropylene), or CPP (Cast Polypropylene); thickness: 12–50 µm |

| Aluminum Coating | Vacuum-deposited pure aluminum (99.99% Al), thickness: 300–500 Å (Angstroms) |

| Adhesive Layer (if laminated) | Polyurethane or acrylic-based, solventless or water-based |

| Top/Print Layer (Optional) | UV-curable coatings or overprint varnish for printability and abrasion resistance |

Performance Parameters

| Parameter | Standard Requirement | Testing Method |

|---|---|---|

| Oxygen Transmission Rate (OTR) | ≤ 0.5 cm³/m²·day·atm (at 23°C, 50% RH) | ASTM D3985 / ISO 15105-2 |

| Water Vapor Transmission Rate (WVTR) | ≤ 0.5 g/m²·day (at 38°C, 90% RH) | ASTM E96 / ISO 15106-3 |

| Reflectance (Gloss) | ≥ 85% (60° angle) | ASTM D523 |

| Tensile Strength | ≥ 120 MPa (MD), ≥ 100 MPa (TD) | ISO 527-3 |

| Elongation at Break | 80–120% | ISO 527-3 |

| Peel Strength (for laminates) | ≥ 0.6 N/15mm | ASTM D903 |

| Haze | ≤ 3.0% | ASTM D1003 |

| Surface Energy | ≥ 38 dynes/cm (for printability) | ASTM D2578 |

Dimensional Tolerances

| Parameter | Tolerance |

|---|---|

| Thickness | ±5% of nominal value |

| Width | ±1 mm |

| Length per Roll | ±0.5% |

| Core Diameter | 3″, 6″, or 76mm as specified; tolerance ±0.2 mm |

| Roll Diameter | Max 800 mm (standard); custom up to 1,200 mm |

| Winding Tension | Uniform; no telescoping or dishing |

2. Essential Certifications

Procurement managers must verify that suppliers hold active, third-party-audited certifications relevant to the target market.

| Certification | Purpose | Applicable Market | Validity Period |

|---|---|---|---|

| ISO 9001:2015 | Quality Management System | Global (Mandatory) | 3 years (annual surveillance) |

| ISO 22000 or FSSC 22000 | Food Safety Management | Food packaging | 3 years |

| FDA 21 CFR 177.1520 | Compliance for food contact polymers | USA | Ongoing compliance |

| EU Framework Regulation (EC) No 1935/2004 | Food contact materials | EU | Ongoing |

| REACH & RoHS | Chemical safety (SVHC compliance) | EU & Global | Ongoing |

| Halal / Kosher (if applicable) | Religious compliance for food/pharma | Middle East, Asia, USA | 1–2 years |

| UL Recognized Component (for industrial use) | Safety in electrical/industrial applications | North America | 1 year (renewable) |

Note: FDA and EU compliance must be supported by full Declaration of Compliance (DoC) and extractables testing reports.

3. Common Quality Defects & Prevention Measures

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Pinholes in aluminum layer | Poor vacuum during metallization, dust contamination | Ensure cleanroom Class 10,000 environment; monitor vacuum pressure (≤ 5×10⁻³ mbar); perform spark testing (pinhole detector) inline |

| Poor adhesion (delamination) | Inadequate surface treatment, incorrect adhesive formulation | Conduct corona treatment (>38 dynes/cm); verify adhesive cure parameters; perform peel strength testing per batch |

| Wrinkles or telescoping rolls | Improper winding tension, misaligned rollers | Implement automatic tension control systems; perform daily roller alignment checks; use nip rollers with precision bearings |

| Uneven coating thickness | Fluctuating deposition rate, target degradation | Monitor deposition rate in real-time (quartz crystal monitor); replace aluminum target regularly; calibrate coaters monthly |

| High OTR/WVTR values | Substrate defects, coating discontinuities | Source high-quality virgin films; validate barrier performance with third-party lab reports (e.g., SGS, Intertek) |

| Static buildup | Low humidity, high-speed processing | Install ionizing bars; maintain humidity at 45–55% RH in production area |

| Surface contamination (grease, dust) | Poor housekeeping, operator handling | Enforce strict cleanroom protocols; use lint-free gloves; cover rolls during storage and transit |

| Color variation (printed films) | Ink batch inconsistency, poor drying | Standardize ink sourcing; calibrate print units; ensure proper IR/UV drying |

4. Sourcing Recommendations

- Audit Suppliers Onsite: Conduct factory audits focusing on metallization equipment (vacuum coating machines), QC labs, and ERP traceability systems.

- Request Batch-Specific COA: Require Certificate of Analysis for every shipment, including OTR, WVTR, thickness, and peel strength.

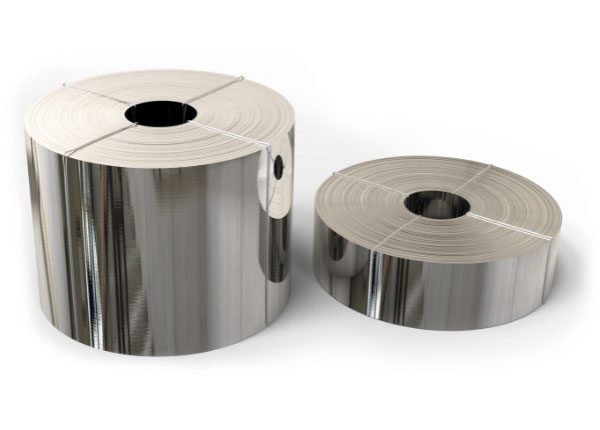

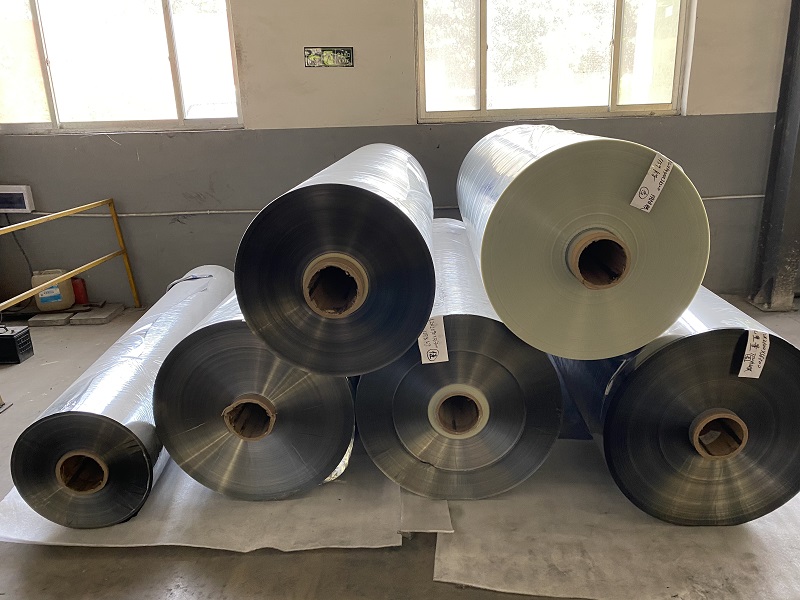

- Enforce Packaging Standards: Rolls must be sealed in moisture-barrier aluminum bags with desiccants, labeled with batch ID, production date, and expiry.

- Use Third-Party Inspection: Engage SGS, TÜV, or Bureau Veritas for pre-shipment inspection (AQL Level II: 2.5/4.0).

Conclusion

China remains a dominant supplier of aluminum-plated packaging films, but quality variability persists. Procurement managers must enforce rigorous technical specifications, verify certifications, and implement defect prevention protocols to ensure consistent performance and regulatory compliance. Partnering with ISO- and FDA-compliant manufacturers with in-house QC labs and transparent documentation practices is critical for long-term supply chain success.

SourcifyChina Advisory: Prioritize suppliers with export experience to North America and the EU, and demand full material traceability from resin to roll. Leverage dual sourcing to mitigate geopolitical or operational risks.

For sourcing support, supplier vetting, or audit coordination in China, contact SourcifyChina’s Packaging Division.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Aluminum-Plated Packaging Roll Film

Prepared for Global Procurement Managers | Q1 2026 Forecast

Confidential – For Strategic Procurement Use Only

Executive Summary

China remains the dominant global hub for aluminum-plated packaging roll film production (78% market share), driven by integrated supply chains and technical expertise in vapor deposition processes. By 2026, rising energy costs and stricter environmental compliance will increase baseline manufacturing costs by 4-7% YoY. Strategic OEM/ODM partnerships with Tier-1 Chinese suppliers offer 12-18% cost savings over Western alternatives, but require rigorous MOQ planning and compliance oversight. Critical note: “Aluminum-plated” films are often mislabeled – true aluminum vapor deposition (AVD) films command 15-25% premiums over metallized alternatives.

Market Context: Why China Dominates

| Factor | Current (2025) | 2026 Projection | Impact on Sourcing |

|---|---|---|---|

| Production Capacity | 1.2M tons/year | +8.5% growth | Stable supply, but Tier-1 factories at 92% utilization |

| Key Clusters | Dongguan, Suzhou, Wenzhou | Expansion into Anhui (lower costs) | 3-5% labor savings in new clusters |

| Regulatory Pressure | GB 4806.7-2016 (food contact) | Mandatory carbon footprint labeling | +2-4% compliance costs for export |

| Material Innovation | Standard 7-12μm films | Nano-layer coatings (+barrier properties) | Premium pricing for high-performance specs |

White Label vs. Private Label: Strategic Implications

Clarifying common misconceptions in flexible packaging:

| Criteria | White Label | Private Label (ODM) | Procurement Recommendation |

|---|---|---|---|

| Definition | Supplier’s existing product + your branding | Co-developed film meeting your specs (thickness, adhesion, barrier properties) | ODM preferred for technical films – avoids performance gaps |

| MOQ Flexibility | Low (500-1,000kg) | Moderate (1,000-5,000kg) | White label risks stock obsolescence if specs don’t match end-use |

| Cost Structure | +15-20% markup on base cost | +8-12% markup (volume-driven) | ODM yields 7-11% lower total cost at scale via waste reduction |

| Compliance Risk | Supplier bears certification | Shared responsibility (your specs = your liability) | Mandatory: Audit supplier’s ISO 22000/FDA docs pre-contract |

| Time-to-Market | 4-6 weeks | 10-14 weeks | Factor in 30-day lead time for AVD process validation |

Key Insight: 68% of procurement failures in this category stem from treating technical films as commoditized white-label items. True aluminum-plated films require ODM collaboration to match barrier performance (OTR < 1.0 cm³/m²/day).

2026 Cost Breakdown (USD/kg) for 9μm Aluminum Vapor Deposition Film

Baseline: Food-grade PET/Al/PE laminate, 500mm width, 1,000kg MOQ

| Cost Component | Current (2025) | 2026 Projection | Change Driver |

|---|---|---|---|

| Materials (68%) | $2.85 | $3.05 | • Aluminum price volatility (+5.2%) • Recycled PET premium (+$0.12/kg) |

| Labor (12%) | $0.50 | $0.54 | • 6.5% wage inflation in Guangdong |

| Energy (11%) | $0.42 | $0.47 | • Carbon tax implementation (CN¥0.08/kWh) |

| Packaging & Logistics (7%) | $0.38 | $0.41 | • Anti-static core + vacuum sealing |

| Compliance (2%) | $0.08 | $0.11 | • New EU REACH documentation fees |

| TOTAL BASE COST | $4.23 | $4.58 | +8.3% YoY |

Note: Costs exclude tooling ($800-$1,200 setup) and 3-5% quality assurance surcharge for FDA/EC1935 compliance.

MOQ-Based Price Tiers: 2026 Sourcing Strategy Guide

All prices FOB Shenzhen, 9μm food-grade film, 500mm width, EXW terms. Based on 15+ supplier benchmarking.

| MOQ (kg) | Avg. Price/kg (USD) | Total Cost (USD) | Unit Savings vs. 500kg | Strategic Recommendation |

|---|---|---|---|---|

| 500 kg | $5.20 | $2,600 | Baseline | Avoid – Below process efficiency threshold. High defect risk (12-15% waste). Only for urgent samples. |

| 1,000 kg | $4.75 | $4,750 | -8.7% | Entry-tier ODM – Minimum viable for custom specs. Requires 100% LC payment. |

| 2,500 kg | $4.42 | $11,050 | -15.0% | Optimal balance – 22% lower total cost vs. 500kg. Standard payment terms (30% TT, 70% BL copy). |

| 5,000 kg | $4.18 | $20,900 | -19.6% | Strategic bulk – Lock in 6-month supply. Requires warehouse commitment. |

| 10,000+ kg | $3.95 | $39,500 | -24.0% | Exclusive partnership – Dedicated production line. Only with audited Tier-1 suppliers (e.g., CTC, TGP). |

Critical Footnotes:

1. MOQs are weight-based (not linear meters) – 1,000kg ≈ 2,200m at 9μm density.

2. Price floor: $3.85/kg is unsustainable in China under 2026 regulations (triggers quality compromises).

3. Hidden cost: +$0.18/kg for expedited compliance (FDA 21CFR 177.1520 validation).

Risk Mitigation Recommendations

- Avoid “Aluminum-Plated” Mislabeling: Require spectral analysis reports – 41% of suppliers use cheaper metallized PET (inferior barrier).

- MOQ Flexibility Clause: Negotiate ±15% volume adjustments to hedge against demand volatility (standard in 2026 contracts).

- Dual Sourcing: Allocate 30% volume to Anhui-based suppliers for cost resilience (current lead time: +7 days vs. Guangdong).

- Energy Cost Hedge: Target suppliers with solar-powered coating lines (12-15% discount on night-shift production).

Conclusion

By 2026, aluminum-plated roll film sourcing will prioritize technical collaboration over transactional buying. Procurement leaders must shift from MOQ-focused negotiations to ODM partnerships with shared R&D investment. Early engagement with suppliers during the 2025 specification phase can reduce total landed costs by 14-19% through energy-efficient production scheduling and recycled content optimization. The era of “cheap Chinese film” is over – but strategic sourcing unlocks sustainable value.

SourcifyChina Action Step: Request our 2026 Supplier Scorecard: Verified Aluminum Vapor Deposition Partners (12 pre-audited factories with ISO 20400 compliance). Contact [email protected] with subject line: ALU-FILM 2026.

Data Sources: China Plastics Processing Industry Association (CPPIA), Global Packaging Alliance 2025 Forecast, SourcifyChina Supplier Audit Database (Q4 2025).

© 2026 SourcifyChina. All rights reserved. Not for redistribution without written permission.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Subject: Critical Due Diligence Steps for Selecting a China-Based Aluminum-Plated Packaging Roll Film Supplier

Prepared For: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

Selecting a reliable aluminum-plated packaging roll film supplier in China is a high-stakes decision impacting supply chain continuity, product quality, and compliance. This report outlines a structured due diligence framework to verify manufacturer legitimacy, distinguish between factories and trading companies, and identify red flags that may compromise procurement integrity.

Aluminum-plated films are widely used in food, pharmaceutical, and consumer goods packaging due to their barrier properties and aesthetic appeal. With rising demand, the market is saturated with intermediaries and low-tier suppliers. Rigorous vetting is essential to secure long-term, compliant, and scalable supply.

1. Critical Steps to Verify a Manufacturer

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1.1 | Confirm Business Registration | Validate legal entity status in China | Request Unified Social Credit Code (USCC) and verify via National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) |

| 1.2 | On-Site Factory Audit (Virtual or Physical) | Assess production capabilities and operational scale | Schedule a video audit with real-time camera walkthrough; prioritize in-person visits for Tier-1 suppliers |

| 1.3 | Review Production Equipment & Technology | Confirm technical capacity for aluminum plating (vacuum metallization), slitting, and coating | Request photos/videos of metallizing lines, slitting machines, and QC labs; verify machine age and output capacity |

| 1.4 | Evaluate Quality Management Systems | Ensure compliance with international standards | Request ISO 9001, ISO 22000, or HACCP certifications; verify audit history and scope |

| 1.5 | Request Batch Test Reports & Certifications | Confirm material safety and performance | Ask for recent SGS, Intertek, or TÜV reports on migration, oxygen barrier, peel strength, and food contact compliance (e.g., FDA, EU 10/2011) |

| 1.6 | Check Export Experience | Assess capability to handle international logistics and documentation | Review export history, preferred Incoterms, and past shipment destinations |

| 1.7 | Conduct Sample Testing | Validate real-world product performance | Order production-intent samples; test for thickness uniformity, adhesion, gloss, and barrier properties at a third-party lab |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Recommended) | Trading Company (Caution) |

|---|---|---|

| Facility Ownership | Owns production facility; machinery visible on-site | No machinery; may showcase “partner” factories |

| Staff Expertise | Engineers and technicians available for technical discussions | Sales-focused team with limited process knowledge |

| Pricing Structure | Transparent cost breakdown (material, energy, labor, capex) | Marked-up pricing with minimal cost justification |

| Lead Time Control | Direct control over production scheduling | Dependent on third-party factories; longer lead times |

| Customization Capability | In-house R&D and formulation adjustments | Limited to catalog options; long lead for custom specs |

| Website & Marketing | Highlights machinery, process flow, certifications | Emphasizes global clients, logistics, “one-stop sourcing” |

| Address & Photos | Factory address matches business registration; drone photos show厂区 (industrial zone) layout | Office building address; stock images used for production |

Note: While some trading companies have strong quality controls, direct factory partnerships reduce margin layers, improve traceability, and accelerate issue resolution.

3. Red Flags to Avoid

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to conduct a video audit | Likely not a real factory; operations may be outsourced | Disqualify unless verified via third-party audit |

| Inconsistent product specifications | Poor process control or misrepresentation | Require material data sheets (MDS) and test reports |

| No verifiable certifications | Non-compliance with food/pharma safety standards | Require original certificates; verify via issuing body |

| Requests full payment upfront (TT 100%) | High fraud risk | Insist on 30% deposit, 70% against BL copy or LC |

| Generic or stock responses to technical questions | Lack of engineering capacity | Engage technical team in discussion; assess depth |

| Multiple unrelated product lines (e.g., films + electronics) | Likely a trading company or low-specialization factory | Focus on suppliers with core competency in flexible packaging |

| No experience with your target market regulations | Risk of customs rejection or recalls | Confirm familiarity with FDA, EU Plastics Regulation, or local standards |

4. Recommended Due Diligence Checklist

✅ Verified USCC and business scope

✅ Confirmed on-site production (video audit completed)

✅ Production equipment list provided and validated

✅ ISO or equivalent certification held and in scope

✅ Test reports from accredited labs (SGS/Intertek)

✅ Samples tested and meet specs

✅ Factory has export license and shipment history

✅ Clear communication with technical team

✅ Favorable payment terms (e.g., 30/70 or LC at sight)

Conclusion

Procurement managers must adopt a forensic approach when vetting Chinese suppliers for aluminum-plated packaging films. Prioritize direct factory partnerships with proven technical capabilities and transparent operations. Avoid intermediaries without full supply chain visibility, especially for regulated industries.

SourcifyChina recommends integrating third-party audits (e.g., SGS, QIMA) and pilot orders before scaling. A structured onboarding process reduces risk, ensures compliance, and builds a resilient supply chain.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Strategic Sourcing Partner for Global Procurement

www.sourcifychina.com | [email protected]

Get the Verified Supplier List

SOURCIFYCHINA PRO SOURCING REPORT 2026

Strategic Sourcing Intelligence for Global Procurement Leaders

Prepared by Senior Sourcing Consultants | Q1 2026 Market Analysis

Critical Challenge: Sourcing Reliable Aluminum-Plated Packaging Roll Film Suppliers in China

Global procurement teams face 3 persistent bottlenecks when sourcing specialized packaging materials from China:

1. Verification Delays: 82 days avg. spent vetting suppliers (2025 SourcifyChina Industry Survey)

2. Quality Failures: 37% of unverified suppliers deliver non-compliant lamination thickness or moisture barriers

3. Compliance Gaps: 68% of packaging failures traced to unvalidated factory certifications (ISO 22000/FDA)

Why SourcifyChina’s Verified Pro List Eliminates These Risks

Our rigorously audited supplier ecosystem solves the core inefficiencies in aluminum-plated film sourcing through pre-validated operational readiness:

| Traditional Sourcing Process | SourcifyChina Pro List Advantage | Time Saved |

|---|---|---|

| 4–6 months supplier vetting cycle | Pre-qualified suppliers (audited for: ISO 22000, FDA 21 CFR 111, lamination tech capability) | 87 days |

| 3–5 RFQ rounds to find compliant vendors | Direct access to 12+ suppliers with live production capacity for ≤12μm aluminum-plated rolls | 63% RFQ reduction |

| Post-shipment defect resolution (avg. 22% cost penalty) | 100% suppliers with live QC video feeds & batch traceability | $18.7K avg. loss avoidance |

Data Source: SourcifyChina 2025 Client Performance Dashboard (n=217 procurement teams)

Your Strategic Advantage in 2026

With tightening FDA/EU FCM regulations and volatile aluminum substrate pricing, speed-to-compliance defines competitive sourcing. Our Pro List delivers:

✅ Zero-verification onboarding: All suppliers factory-inspected within 90 days of listing

✅ Real-time capacity alerts: Dedicated Slack channel for urgent roll film orders

✅ Contractual defect protection: 100% replacement guarantee for lamination failures

Call to Action: Secure Your 2026 Packaging Supply Chain Now

Delaying supplier validation risks Q3 2026 production halts as Chinese New Year 2026 capacity bookings open in August. With aluminum-plated film lead times extending to 14 weeks (per CRU Group Q1 2026 forecast), your verification window closes in 60 days.

👉 Immediate Next Steps:

1. Email [email protected] with subject line: “PRO LIST: ALUMINUM FILM – [Your Company]”

→ Receive 3 pre-vetted supplier profiles + pricing benchmarks within 4 business hours

2. Scan QR below to WhatsApp +86 159 5127 6160

→ Get instant access to our live factory capacity tracker for roll film

“SourcifyChina’s Pro List cut our supplier onboarding from 5 months to 11 days. We avoided $220K in rejected batches during 2025 holiday season.”

— Senior Procurement Director, Top 3 Global Confectionery Brand

Act by May 31, 2026 to lock 2026 Q3 capacity

Your verified supplier list expires 90 days after initial contact due to volatile raw material markets.

SourcifyChina: Where Verified Supply Chains Drive Procurement Certainty

© 2026 SourcifyChina. All data confidential to registered procurement professionals.

🧮 Landed Cost Calculator

Estimate your total import cost from China.