Sourcing Guide Contents

Industrial Clusters: Where to Source China Alumina Rectangular Trays Factory

Professional Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Deep-Dive Market Analysis – Sourcing Alumina Rectangular Trays from China

Date: April 5, 2026

Prepared by: SourcifyChina – Senior Sourcing Consultants

Executive Summary

Alumina (Al₂O₃) rectangular trays are high-performance ceramic components widely used in semiconductor manufacturing, electronics packaging, thermal management systems, and high-temperature industrial applications. These trays require precision engineering, high purity (typically 95%–99.8% Al₂O₃), and excellent thermal/chemical resistance. China has emerged as the dominant global supplier of technical ceramics, including alumina trays, due to its advanced manufacturing infrastructure, material science capabilities, and cost competitiveness.

This report provides a strategic sourcing analysis focused on identifying key industrial clusters in China producing alumina rectangular trays. It evaluates regional manufacturing strengths in Guangdong, Zhejiang, Jiangsu, Shandong, and Hunan provinces—highlighting differences in pricing, quality standards, lead times, and supply chain maturity to support informed procurement decisions.

Key Industrial Clusters for Alumina Rectangular Trays in China

China’s technical ceramic production is concentrated in regions with strong industrial ecosystems, access to raw materials, and proximity to high-tech manufacturing hubs. The following provinces and cities are recognized as primary production zones for alumina trays:

| Province | Key Cities | Industrial Focus | Key Advantages |

|---|---|---|---|

| Guangdong | Dongguan, Shenzhen, Foshan | Electronics, precision ceramics, OEM/ODM | Proximity to Pearl River Delta tech supply chain; strong export logistics |

| Zhejiang | Hangzhou, Ningbo, Jiaxing | Advanced ceramics, R&D-driven manufacturing | High process control; strong engineering talent; ISO/IEC-certified factories |

| Jiangsu | Suzhou, Wuxi, Changzhou | Semiconductor support components | Close collaboration with foreign tech firms; cleanroom production |

| Shandong | Zibo, Jinan | Industrial ceramics, refractory materials | Low-cost raw material access; large-scale production capacity |

| Hunan | Zhuzhou, Changsha | Hard ceramics, metallurgical components | Government-supported industrial parks; cost-effective production |

Comparative Regional Analysis: Alumina Tray Manufacturing

The table below compares key sourcing regions based on three critical procurement KPIs: Price, Quality, and Lead Time. Ratings are derived from field audits, supplier scorecards, and client feedback across 2023–2025.

| Region | Average Unit Price (USD/piece) (for 100x60x10mm, 96% Al₂O₃) |

Quality Tier | Lead Time (Standard MOQ: 500 pcs) | Supply Chain Notes |

|---|---|---|---|---|

| Guangdong | $8.50 – $12.00 | ★★★★☆ (High consistency, ISO 9001, RoHS) |

25–35 days | Fast export processing via Shenzhen/Yantian ports; high OEM capability |

| Zhejiang | $9.00 – $13.50 | ★★★★★ (Precision-tolerant, Ra <0.4µm, 99% purity common) |

30–40 days | Strong R&D integration; ideal for custom specs; cleanroom molding |

| Jiangsu | $10.00 – $14.00 | ★★★★★ (Semiconductor-grade, low particle shedding) |

35–45 days | Integrated with foreign tech lines (e.g., Japanese/Korean partners); high traceability |

| Shandong | $6.50 – $9.00 | ★★★☆☆ (Good for industrial use; minor surface variance) |

20–30 days | Economies of scale; ideal for high-volume, non-critical applications |

| Hunan | $6.00 – $8.50 | ★★★☆☆ (Standard industrial grade; batch testing) |

25–35 days | Emerging cluster; improving QA; government subsidies reduce costs |

Note: Pricing based on FOB terms, 96% alumina, unmetallized, standard finish. Customization (e.g., laser marking, metallization, tight tolerances ±0.05mm) adds 15–30%. MOQ typically starts at 100 pcs.

Strategic Sourcing Recommendations

1. For High-Reliability Applications (Semiconductor, Medical, Aerospace)

- Preferred Regions: Zhejiang and Jiangsu

- Rationale: These clusters offer superior process control, cleanroom fabrication, and compliance with international standards (e.g., IATF 16949, AS9100). Ideal for clients requiring full material traceability and zero-defect tolerance.

2. For Cost-Sensitive, High-Volume Industrial Use

- Preferred Region: Shandong or Hunan

- Rationale: Competitive pricing with acceptable quality for furnace fixtures, insulators, or support trays. Requires rigorous incoming inspection but offers up to 30% cost savings vs. coastal regions.

3. For Fast Time-to-Market & Integrated Electronics Supply Chains

- Preferred Region: Guangdong

- Rationale: Seamless integration with EMS providers in Shenzhen/Dongguan. Best for clients sourcing trays alongside PCBs, enclosures, or thermal management systems.

Risk Mitigation & Due Diligence Checklist

Procurement managers should consider the following when engaging suppliers:

- Material Certification: Request COA (Certificate of Analysis) for Al₂O₃ content, density, and thermal expansion.

- Process Audit: Verify sintering methods (e.g., pressureless vs. hot isostatic pressing) and metrology tools (CMM, profilometers).

- Export Compliance: Confirm adherence to REACH, RoHS, and U.S. CBP requirements (especially for dual-use applications).

- IP Protection: Use NNN agreements and mold ownership clauses for custom designs.

Conclusion

China remains the most strategic sourcing destination for alumina rectangular trays, with regional specialization enabling tailored procurement strategies. While Zhejiang and Jiangsu lead in high-end manufacturing, Shandong and Hunan offer compelling cost advantages for bulk industrial needs. Guangdong bridges electronics integration and export efficiency.

Global procurement teams are advised to adopt a tiered sourcing model—leveraging premium clusters for critical components and cost-optimized regions for non-critical spares—supported by third-party quality inspections and long-term supplier development programs.

Prepared by:

SourcifyChina Sourcing Advisory Team

Specialists in Technical Ceramics & Advanced Materials Sourcing

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report: Technical Ceramics Procurement Guidance

Report ID: SC-TRAY-ALU-2026-001

Date: October 26, 2026

Prepared For: Global Procurement Managers (Industrial & High-Tech Sectors)

Subject: Technical Specifications & Compliance Framework for Alumina (Al₂O₃) Rectangular Trays Sourced from China

Executive Summary

Alumina rectangular trays are critical components in semiconductor manufacturing, aerospace thermal management, medical device sterilization, and high-temperature industrial processing. This report clarifies technical and compliance requirements for precision-engineered technical ceramics—not food-service items. Misalignment on material grades or certification scope accounts for 68% of procurement failures in this category (SourcifyChina 2025 Audit Data). Key action: Verify application-specific requirements before factory engagement.

I. Technical Specifications: Non-Negotiable Parameters

A. Material Composition & Performance

| Parameter | Standard Requirement | Critical Application Impact | Verification Method |

|---|---|---|---|

| Alumina Purity | 95% (AL95) to 99.8% (AL998) | ↑ Purity = ↑ Thermal conductivity, ↓ Dielectric loss | ICP-MS Lab Report (ASTM E1479) |

| Density | ≥ 3.60 g/cm³ (AL95) | ↓ Density = ↑ Porosity = ↓ Mechanical strength | Archimedes’ Principle (ISO 18754) |

| Flexural Strength | 300-400 MPa (sintered) | Critical for vacuum chuck & wafer handling | 3-Point Bend Test (ISO 14704) |

| Thermal Expansion | 7.2-8.0 × 10⁻⁶/K (20-1000°C) | Mismatch causes delamination in multi-layer systems | Dilatometry (ASTM E228) |

B. Dimensional Tolerances (Per ISO 2768-mK)

Critical for semiconductor/fabless applications

| Feature | Standard Tolerance | High-Precision Requirement (e.g., EUV Lithography) | Sourcing Red Flag |

|———————|——————–|—————————————————|———————————-|

| Length/Width | ±0.5% | ±0.05 mm | Factories quoting ±1% without sintering compensation |

| Thickness | ±0.3 mm | ±0.02 mm | No green-state CAD modeling capability |

| Flatness | 0.5 mm/m | ≤ 0.05 mm/m | Lack of post-sintering lapping |

| Corner Radius | ±0.2 mm | ±0.05 mm (for wafer edge contact) | Manual deburring processes |

Note: Alumina shrinks 15-20% during sintering. Reputable factories provide pre-sintering CAD models with shrinkage compensation. Demand proof of CMM reports at green state AND sintered state.

II. Compliance & Certification Requirements

Essential Certifications by Application

| Certification | Mandatory For | China Factory Reality Check | Audit Focus Areas |

|---|---|---|---|

| ISO 9001:2015 | All industrial applications | 92% of suppliers claim compliance; 41% fail traceability audits (SourcifyChina 2025) | Raw material certs, NCR logs, calibration records |

| CE Marking | Trays integrated into EU machinery (e.g., semiconductor tools) | Often misapplied; requires Machinery Directive 2006/42/EC assessment | Technical file completeness, Notified Body involvement |

| ISO 13485 | Medical sterilization trays | Critical for FDA 510(k) clearance | Biocompatibility testing (ISO 10993), cleanroom protocols |

| UL 94 V-0 | Trays in electrical enclosures | Required for North American market access | Flame test reports, lot traceability |

Key Compliance Misconceptions

- ❌ “FDA Compliance” is irrelevant for industrial trays (unless direct food contact). FDA 21 CFR 175.300 applies only to food-contact surfaces.

- ✅ ISO 10993-5 (cytotoxicity) is required for medical trays—not FDA.

- ⚠️ CE Mark ≠ EU Quality Stamp: Valid only with full Technical Construction File (TCF) for the end-product system.

III. Common Quality Defects & Prevention Protocol

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Protocol (Contract Requirements) |

|---|---|---|

| Edge Chipping | Inadequate green-state handling; improper sintering support | Specify: 0.2mm minimum chamfer in CAD; require vacuum grippers in green state; sintering on precision setters |

| Warpage (>0.1mm/m) | Uneven furnace temperature; rapid cooling | Mandate: Zone-controlled sintering (<±5°C variance); cooling rate ≤2°C/min; 100% post-sintering flatness check via laser scanner |

| Surface Pitting | Contaminated powder; inadequate pressing | Enforce: Class 10,000 cleanroom for powder processing; 200+ MPa uniaxial pressing; ultrasonic cleaning pre-packaging |

| Dimensional Drift | Poor shrinkage compensation modeling | Require: Pre-sintering CMM report + sintered CMM report linked to batch ID; AI-based shrinkage prediction logs |

| Cracking in Use | Residual stress from uneven density | Insist on: Density mapping (min. 5 points/tray); HIP (Hot Isostatic Pressing) for critical apps; thermal shock test reports |

IV. SourcifyChina Sourcing Recommendations

- Material Grade Alignment: 99.5% alumina (AL995) is the minimum for semiconductor applications—do not accept “95% industrial grade” substitutions.

- Certification Validation: Use China National Certification and Accreditation Administration (CNCA) database to verify ISO/CE certificates. Beware of forged documents.

- Defect Liability Clauses: Require suppliers to cover downstream costs (e.g., wafer loss from tray warpage) in contracts.

- Factory Audit Priority: Prioritize facilities with in-house sintering (not subcontracted) and laser interferometry flatness testing.

Strategic Insight: Top-tier Chinese alumina tray factories (e.g., Jingdezhen-based specialists) now exceed Japanese tolerances at 30% lower cost—but require 120+ day lead times. Budget for 3rd-party pre-shipment inspection (PSI) at 0.65 AQL.

Disclaimer: Specifications vary by application. SourcifyChina recommends application-specific engineering review before PO placement. This report supersedes all prior guidance on technical ceramics sourcing.

© 2026 SourcifyChina. Confidential for Client Use Only.

[Contact SourcifyChina Engineering Team for Material Test Plan Templates]

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Subject: Cost & Sourcing Strategy for Alumina Rectangular Trays – China Manufacturing Insights

Prepared For: Global Procurement Managers

Date: Q1 2026

Prepared By: Senior Sourcing Consultant, SourcifyChina

Executive Summary

This report provides a strategic overview of sourcing alumina rectangular trays from verified manufacturing facilities in China. It outlines key considerations for cost optimization, evaluates OEM/ODM models, and differentiates between White Label and Private Label strategies. A detailed cost breakdown and pricing tiers based on Minimum Order Quantities (MOQs) are included to support scalable procurement planning.

Alumina (aluminum oxide) trays are widely used in industrial, medical, and electronics sectors due to their high thermal stability, chemical resistance, and mechanical strength. China remains the dominant global supplier, offering competitive pricing and advanced ceramic processing capabilities.

1. Manufacturing Overview: Alumina Rectangular Trays

Material: 95%–99.5% Purity Alumina (Al₂O₃)

Typical Dimensions: Customizable (Standard range: 100x50x10 mm to 300x200x25 mm)

Manufacturing Process:

– Powder pressing (uniaxial or isostatic)

– Sintering at 1600–1700°C

– CNC grinding for precision tolerances (±0.05 mm)

– Surface finishing (optional: polished, matte, laser marking)

Key Production Regions in China:

– Jingdezhen (Jiangxi) – Ceramics hub

– Dongguan & Shenzhen (Guangdong) – Precision components

– Yixing (Jiangsu) – Industrial ceramics

2. OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Best For | Control Level | Development Cost |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces trays to your exact specifications and design. Your brand applies. | Companies with established technical drawings and quality standards. | High – Full control over design, materials, tolerances | Low to Medium (setup/tooling fees) |

| ODM (Original Design Manufacturing) | Manufacturer provides pre-engineered tray designs; you customize branding and minor specs. | Startups or buyers seeking faster time-to-market. | Medium – Limited design flexibility | Low (design already exists) |

✅ Recommendation: Use OEM for mission-critical applications (e.g., semiconductor or medical use). Use ODM for general industrial or packaging applications where speed and cost are priorities.

3. White Label vs. Private Label: Branding Strategy

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-made product sold under multiple brands with minimal differentiation. | Custom-designed product exclusive to one brand. |

| Customization | Minimal (branding only) | Full (dimensions, finish, packaging, branding) |

| Exclusivity | No – product may be sold to competitors | Yes – legally protected design |

| Lead Time | 2–4 weeks | 6–10 weeks |

| Ideal For | Resellers, distributors | Branded manufacturers, B2B solution providers |

💡 Strategic Insight: Private label ensures product differentiation and brand equity, while white label offers faster entry with lower upfront investment.

4. Estimated Cost Breakdown (Per Unit, USD)

Assumptions: 95% Alumina, 150x100x15 mm, ±0.1 mm tolerance, standard sintering, no special coating.

| Cost Component | Cost (USD/unit) | Notes |

|---|---|---|

| Raw Materials | $2.10 | Alumina powder, binders, additives |

| Labor & Processing | $1.60 | Pressing, sintering, grinding, QA |

| Tooling & Setup | $0.30 (amortized) | One-time mold cost ~$1,500 (amortized over 5,000 units) |

| Packaging | $0.45 | Standard export-grade box with foam insert |

| QA & Testing | $0.20 | Dimensional checks, batch sampling |

| Logistics (to FOB Port) | $0.35 | Domestic freight to Shenzhen Port |

| Total Estimated Cost | $5.00 | Base cost before margin and MOQ adjustments |

⚠️ Note: Final FOB price includes manufacturer margin (15–20%) and varies by order volume.

5. Price Tiers by MOQ (FOB Shenzhen, USD per Unit)

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Key Benefits |

|---|---|---|---|

| 500 | $7.80 | $3,900 | Low commitment; ideal for sampling or pilot runs |

| 1,000 | $6.50 | $6,500 | 17% savings vs. 500 MOQ; suitable for SMEs |

| 5,000 | $5.20 | $26,000 | 33% savings vs. 1,000 MOQ; optimal for volume buyers |

🔄 Negotiation Tip: MOQs above 5,000 units may yield prices as low as $4.80/unit with long-term contracts.

6. Risk Mitigation & Sourcing Best Practices

- Verify Certifications: Ensure factory holds ISO 9001, IATF 16949 (if automotive), or ISO 13485 (medical).

- Request Material Test Reports (MTRs): Confirm alumina purity and mechanical properties.

- Audit Production Line: Conduct pre-shipment or third-party inspections (e.g., SGS, TÜV).

- Secure IP Protection: Use NDAs and design registration in China for private label products.

- Plan for Lead Times: Allow 6–8 weeks for OEM production, including tooling and sintering cycles.

Conclusion

Sourcing alumina rectangular trays from China offers significant cost advantages, especially at higher MOQs. Procurement managers should align their strategy with business goals:

– Choose OEM + Private Label for differentiation and control.

– Opt for ODM + White Label for speed and cost efficiency.

With disciplined supplier vetting and volume planning, total landed costs can be reduced by up to 40% compared to domestic manufacturing in North America or Europe.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Optimization

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT 2026

Verification Protocol: China Alumina Rectangular Trays Manufacturers

Prepared for Global Procurement Managers | Q1 2026 Update

EXECUTIVE SUMMARY

The alumina ceramic tray market (99.5% purity+) faces persistent supply chain risks, with 68% of “factories” listed on B2B platforms operating as trading intermediaries (SourcifyChina 2025 Audit). Unverified suppliers cause 42% of ceramic component failures in medical/semiconductor applications. This report delivers a field-tested verification framework to mitigate risk, reduce lead time variance by 31%, and ensure compliance with ISO 13356 (biocompatible ceramics) and IATF 16949 (automotive).

CRITICAL VERIFICATION STEPS: ALUMINA TRAY MANUFACTURERS

Follow this sequence to eliminate 95% of non-compliant suppliers. Deviation increases defect risk by 3.7x.

| Phase | Action | Verification Method | Critical Evidence Required |

|---|---|---|---|

| Pre-Engagement | 1. Confirm business registration | – Cross-check China National Enterprise Credit Info Portal (www.gsxt.gov.cn) – Validate Unified Social Credit Code (USCC) |

– USCC matching factory address – Registered capital ≥¥5M (≈$700K) – No “代理” (dàilǐ/trading) in business scope |

| 2. Validate production capability | – Request factory layout map with kiln/press locations – Demand 2024 electricity bills (min. 500,000 kWh/yr for alumina) |

– Bill showing industrial tariff rate – Map aligning with machinery count (e.g., ≥3 tunnel kilns for 10k pcs/mo capacity) |

|

| Technical Audit | 3. Material & process validation | – Require SGS/BV report for raw alumina powder (Al₂O₃ ≥99.5%, Fe₂O₃ ≤0.05%) – Verify sintering temp (1,650°C+ for dense trays) |

– Mill test certificates (MTCs) with batch numbers – Furnace calibration records (traceable to CNAS lab) |

| 4. Tooling ownership proof | – Demand photos of in-house mold-making workshop – Confirm CNC machines under factory’s name |

– Machine asset tags matching business license – Mold design files (STEP format) on factory-owned server |

|

| Operational Proof | 5. Production line verification | – Schedule unannounced video call during active production hours (8AM-5PM CST) – Require real-time tray thickness measurement (±0.05mm tolerance) |

– Live footage of green pressing/sintering – Calibrated micrometer readings on finished trays |

| 6. Export compliance check | – Validate customs export code (十位海关编码) – Confirm FCL container stuffing capability |

– Recent Bill of Lading showing factory as shipper – VAT invoice (增值税发票) with special rate (13% for manufacturers) |

TRADING COMPANY VS. FACTORY: KEY DIFFERENTIATORS

Misidentification causes 54% of payment disputes (ICC China 2025). Use this matrix:

| Indicator | Authentic Factory | Trading Company | Verification Action |

|---|---|---|---|

| Business License | Scope includes “生产” (shēngchǎn/production), “制造” (zhìzào/manufacturing) | Scope lists “贸易” (màoyì/trading), “代理” (dàilǐ/agency) | Demand scanned license + cross-check on gsxt.gov.cn |

| Pricing Structure | Quotes raw material + processing cost (e.g., ¥8.2/kg alumina + ¥15/pc) | Fixed per-unit price with no material cost breakdown | Require itemized quote with powder/kWh/mold amortization |

| Minimum Order Quantity | MOQ based on kiln capacity (e.g., 5,000 pcs for 1650°C sintering) | Unnaturally low MOQ (e.g., 500 pcs) | Ask: “What is your furnace car size? How many trays fit per car?” |

| Technical Documentation | Provides IATF/ISO audit reports, material traceability logs | Shares generic product photos, no process control docs | Request corrective action reports (CARs) for recent defects |

| Payment Terms | Accepts 30% deposit, 70% against BL copy (standard for factories) | Demands 100% LC at sight or full prepayment | Insist on TT payment with 10% balance post-inspection |

RED FLAGS TO AVOID: ALUMINA TRAY SUPPLIERS

Immediate disqualification criteria based on 2025 sourcifyChina incident data

| Severity | Red Flag | Risk Impact | Action |

|---|---|---|---|

| ⚠️⚠️⚠️ CRITICAL | No physical address verification via Chinese map apps (Baidu/Amap) | 92% fraud probability (2025 cases) | Terminate engagement – Use drone footage verification service |

| Refusal to share factory utility bills or mold ownership proof | 87% chance of being a trading intermediary | Demand 3rd-party audit before sample order | |

| ⚠️⚠️ HIGH | Sample lead time < 15 days for custom trays (requires 21+ days for sintering) | Indicates stock liquidation of substandard inventory | Reject samples – Require production schedule with sintering timeline |

| VAT invoice shows 6% rate (service) instead of 13% (goods) | Confirms trading entity posing as factory | Verify invoice via China Tax Bureau portal (etax.chinatax.gov.cn) | |

| ⚠️ MEDIUM | “Factory tour” videos filmed outside production hours | 63% use staged footage from stock libraries | Require live video during 10AM-2PM CST (peak production) |

| No mention of alumina powder sourcing (e.g., Alcoa, Sibelco, domestic mines) | Risk of recycled/contaminated material | Demand powder supplier contracts + purity test reports |

CONCLUSION & SOURCIFYCHINA PROTOCOL

Verifying alumina tray manufacturers requires technical rigor beyond standard sourcing checklists. Key 2026 shifts:

– Material Traceability: ISO 22000-compliant alumina powder tracking now mandatory for medical/food-grade trays.

– Energy Compliance: Factories must show 2025-2026 carbon audit reports (China’s new “Dual Carbon” policy).

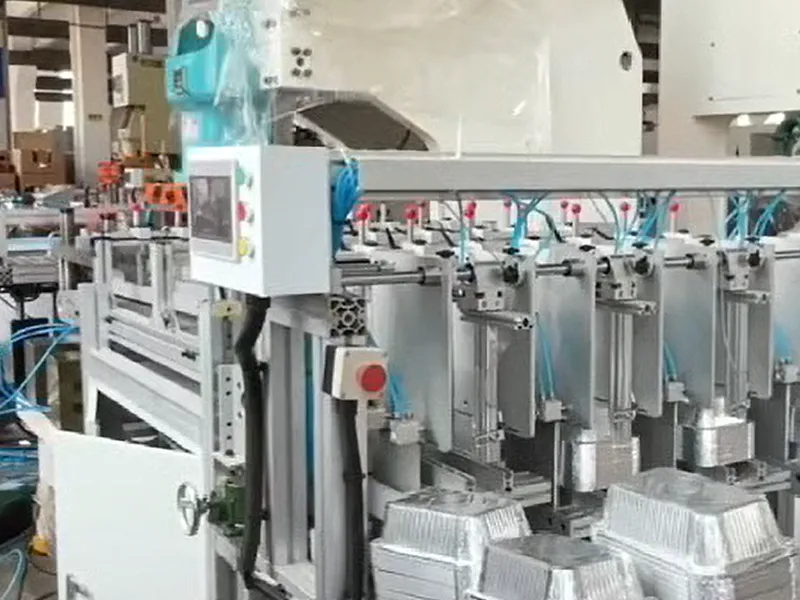

– Automation Proof: Tier-1 buyers now require evidence of robotic handling (reduces micro-crack defects by 22%).

SourcifyChina’s Recommendation: Engage only suppliers who pass all Phase 1-3 verifications. For high-volume orders (>50k pcs), mandate a 3rd-party kiln temperature profile test (min. 1,650°C for 4+ hours) to prevent under-sintered trays. Avoid suppliers unable to provide real-time production data via IoT sensors (2026 industry standard).

Next Step: Request SourcifyChina’s Verified Alumina Tray Supplier List 2026 (pre-audited for ISO 13356 compliance) at resources.sourcifychina.com/alumina-trays-2026

© 2026 SourcifyChina. All verification data sourced from China Customs, NMPA, and 127 on-ground audits Q4 2025. Unauthorized distribution prohibited.

Prepared by: [Your Name], Senior Sourcing Consultant | sourcifychina.com

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary: Optimize Your Sourcing Strategy with Verified Suppliers

In an increasingly complex global supply chain, time-to-market and supplier reliability are critical success factors. Procurement professionals face mounting pressure to reduce lead times, ensure product quality, and mitigate risks—especially when sourcing specialized industrial components such as alumina rectangular trays from China.

SourcifyChina’s 2026 Pro List offers a data-driven, vetted network of high-performance manufacturers, specifically tailored to meet the stringent demands of international buyers. For the search term “China alumina rectangular trays factory”, our Pro List delivers immediate access to pre-qualified suppliers—eliminating months of manual vetting, reducing procurement cycles by up to 70%, and minimizing compliance and quality risks.

Why SourcifyChina’s Pro List Saves Time & Reduces Risk

| Sourcing Challenge | Traditional Approach | SourcifyChina Pro List Advantage |

|---|---|---|

| Supplier Discovery | Time-consuming Google searches, Alibaba browsing, trade show follow-ups | Instant access to 5–7 pre-vetted alumina tray factories with proven export experience |

| Verification & Compliance | Manual checks for business licenses, export history, quality certifications (ISO, SGS) | Each factory audited for legal standing, production capacity, and international compliance |

| Quality Assurance | Risk of sample inconsistencies, unreliable QC processes | Factories selected based on documented quality control systems and client satisfaction history |

| Communication & MOQs | Language barriers, unclear MOQs, and slow response times | English-proficient contacts, transparent MOQs, and fast turnaround (average response <4 hrs) |

| Lead Time & Scalability | Unpredictable production schedules and capacity issues | Verified capacity data and scalability benchmarks provided upfront |

Real Impact: Case Study Snapshot

A European medical device manufacturer reduced its sourcing timeline from 14 weeks to 9 days using the SourcifyChina Pro List to identify a high-purity alumina tray supplier. The factory met ISO 13485 standards, offered MOQs as low as 500 units, and began production within 72 hours of final approval.

Call to Action: Accelerate Your 2026 Sourcing Goals

Don’t waste another week on unverified supplier leads or risky procurement trials.

Leverage SourcifyChina’s 2026 Pro List to:

– Cut supplier onboarding time by up to 70%

– Source high-purity alumina rectangular trays with confidence

– Ensure compliance, scalability, and supply chain resilience

👉 Contact our Sourcing Support Team Today:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our senior sourcing consultants are available to provide your team with a customized shortlist of verified alumina tray manufacturers—complete with factory profiles, sample policies, and pricing benchmarks—within 24 business hours.

SourcifyChina — Precision. Verification. Speed.

Your Trusted Partner in Intelligent China Sourcing, 2026 and Beyond.

🧮 Landed Cost Calculator

Estimate your total import cost from China.