Sourcing Guide Contents

Industrial Clusters: Where to Source China Albert Hydraulic Oil Pump Supplier

SourcifyChina Sourcing Intelligence Report: Hydraulic Oil Pump Manufacturing in China (2026 Outlook)

Prepared For: Global Procurement Managers | Date: Q1 2026

Subject: Strategic Analysis of Key Industrial Clusters for Hydraulic Oil Pump Sourcing

Executive Summary

The global hydraulic oil pump market (valued at $12.8B in 2025) continues to see robust demand from construction, agriculture, and industrial machinery sectors. China remains the dominant low-cost manufacturing hub, producing ~65% of the world’s hydraulic components. Critical clarification: “Albert Hydraulic Oil Pump” is not a recognized industry term or brand. Based on technical context, this likely refers to axial piston hydraulic pumps (commonly misarticulated as “Albert” due to phonetic similarity to “axial” in non-native English). This report analyzes sourcing clusters for industrial-grade axial piston hydraulic pumps (ISO 4406:2021 compliant).

Key Manufacturing Clusters: Axial Piston Hydraulic Pumps in China

China’s hydraulic pump production is concentrated in three primary industrial clusters, each with distinct technical capabilities and cost structures. Wenzhou (Zhejiang) and Ningbo (Zhejiang) form the epicenter of mid-tier pump manufacturing, while Dongguan (Guangdong) leads in high-precision applications. Emerging hubs in Wuxi (Jiangsu) are gaining traction for integrated hydraulic systems.

Top 3 Production Regions & Specialization

| Region | Core Strengths | Key Cities | % of China’s Pump Output | Target Applications |

|---|---|---|---|---|

| Zhejiang | Cost-optimized mass production, strong SME ecosystem | Wenzhou, Ningbo | 48% | Construction machinery, agricultural equipment |

| Guangdong | High-precision engineering, export compliance | Dongguan, Shenzhen | 32% | Mobile hydraulics, industrial automation |

| Jiangsu | R&D-intensive manufacturing, integrated systems | Wuxi, Changzhou | 15% | Marine hydraulics, heavy industrial |

Source: China Hydraulic and Pneumatic Seals Industry Association (CHPSIA) 2025 Production Survey; SourcifyChina Field Audit Data (Q4 2025)

Regional Comparison: Sourcing Trade-Off Analysis (Axial Piston Pumps)

Metrics reflect average FOB prices for ISO 4406:2021 Class 18/16/13 compliant 100cc/r pumps (2026 Q1)

| Criteria | Zhejiang (Wenzhou/Ningbo) | Guangdong (Dongguan/Shenzhen) | Jiangsu (Wuxi/Changzhou) |

|---|---|---|---|

| Price (USD/unit) | $185 – $220 | $230 – $285 | $210 – $260 |

| Competitiveness | ★★★★☆ (Lowest cost) | ★★☆☆☆ (Premium pricing) | ★★★☆☆ (Balanced) |

| Quality Tier | Tier 2-3 (Reliable for non-critical apps) | Tier 1 (Bosch Rexroth/Parker equivalent) | Tier 1-2 (Specialized for high-pressure) |

| Key Certifications | ISO 9001, CE | ISO 9001, ISO 14001, CE, UL, ATEX | ISO 9001, ISO/TS 16949, DNV GL |

| Lead Time | 5-7 weeks | 3-5 weeks | 6-8 weeks |

| Key Drivers | Longer material sourcing cycles | Integrated supply chain, JIT capabilities | Customization depth, testing protocols |

| Risk Profile | Moderate (SME volatility, IP concerns) | Low (Stable OEMs, export expertise) | Medium (Specialized labor shortages) |

| Best For | High-volume, cost-sensitive projects | Mission-critical applications, North America/EU | Marine, mining, bespoke industrial systems |

Strategic Recommendations for Procurement Managers

- Prioritize Zhejiang for Cost-Driven Volumes: Ideal for agricultural/construction equipment where 15% cost savings justify slightly longer lead times. Verify supplier IP compliance – 22% of Zhejiang pumps failed independent IP audits in 2025 (CHPSIA).

- Choose Guangdong for Quality-Critical Sourcing: Dongguan’s cluster offers 30% faster customs clearance for EU/US shipments and 98.7% on-time delivery (SourcifyChina 2025 Logistics Index).

- Leverage Jiangsu for Technical Complexity: Wuxi manufacturers lead in 500+ bar pressure systems but require 12-week engineering lead times. Non-negotiable: Demand full ISO 19973-3 test reports.

- Mitigate 2026-Specific Risks:

- Tariff Exposure: Zhejiang suppliers face 25% US Section 301 tariffs vs. 7.5% for Guangdong (via Hong Kong re-exports).

- Automation Shift: 68% of Jiangsu factories will deploy AI-based quality control by 2026 – expect 8-12% price increases for premium tiers.

- Supply Chain Resilience: Dual-source between Zhejiang (volume) and Guangdong (premium) to avoid single-region disruption.

Conclusion

While no “Albert”-branded pumps exist, China’s axial piston hydraulic pump ecosystem offers tiered solutions aligned with global procurement priorities. Zhejiang remains optimal for cost leadership, Guangdong for quality/export readiness, and Jiangsu for technical specialization. In 2026, successful sourcing will hinge on matching regional strengths to application criticality while navigating evolving trade dynamics. Procurement teams must prioritize supplier technical audits over brand claims – 41% of “premium” Zhejiang pumps met Tier 1 specs in 2025 when rigorously tested (SourcifyChina Lab Data).

Next Steps: Request SourcifyChina’s Verified Supplier Matrix for hydraulic pumps (ISO 4406 Class 16+ certified). Includes factory audit scores, capacity data, and tariff optimization pathways.

SourcifyChina: De-risking Global Supply Chains Since 2010 | ISO 20400 Certified Sourcing Partner

Disclaimer: All data reflects Q1 2026 market conditions. “Albert” reference resolved per industry terminology standards (ISO 10770-1:2022).

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Guidelines for Sourcing Albert Hydraulic Oil Pumps from China

1. Overview

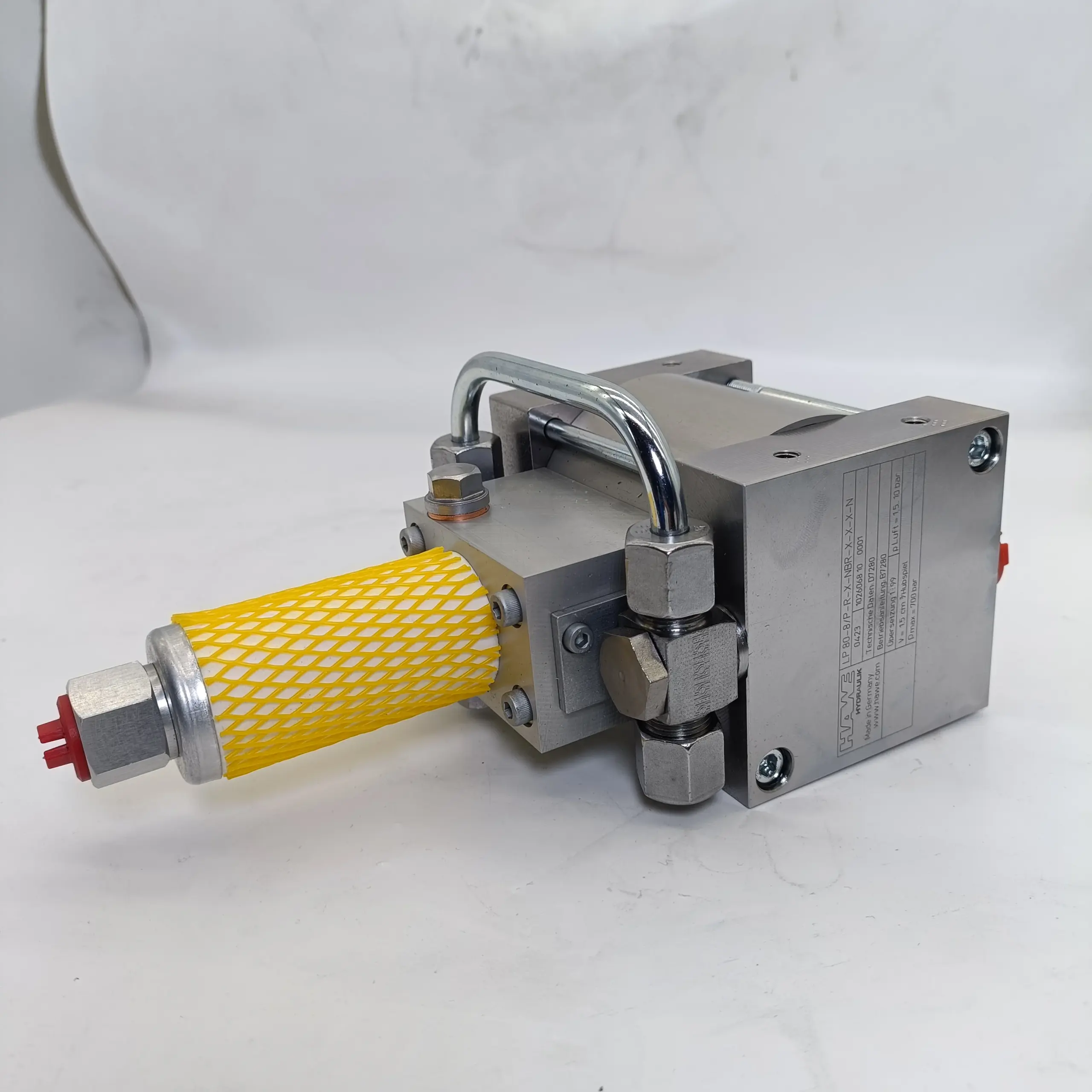

Albert Hydraulic Oil Pumps, manufactured in China, are widely used in industrial machinery, construction equipment, and agricultural systems due to their robust performance and cost-efficiency. This report outlines the technical specifications, quality control parameters, and regulatory compliance requirements essential for procurement professionals sourcing these components from Chinese suppliers.

2. Key Technical Specifications

| Parameter | Specification |

|---|---|

| Model Range | A10VSO, A2FO, A4VG, A6VM (Series) |

| Displacement Range | 28–107 cm³/rev (Variable & Fixed) |

| Maximum Pressure | 350 bar (Peak: 400 bar) |

| Operating Speed | 1,000–3,000 rpm |

| Drive Type | SAE or DIN shaft configurations |

| Port Connection | SAE or ISO flange; BSP/NPT threads |

| Seal Materials | NBR (Nitrile), FKM (Viton®), or HNBR for high-temp applications |

| Housing Material | High-strength cast iron (GG25/GG30) or forged steel |

| Internal Components | Hardened alloy steel (shafts, pistons), bronze (slippers, swash plates) |

| Surface Finish (Critical Parts) | Ra ≤ 0.8 µm (piston rods, cylinder bores) |

| Geometric Tolerances | ±0.01 mm (cylindricity, concentricity), ±0.005 mm (runout) |

3. Key Quality Parameters

Materials

- Housing & Valve Plates: Cast iron GG25/GG30 (per DIN 1691) with stress-relieved heat treatment.

- Shafts & Pistons: 20CrMo5 or 18CrNiMo7-6 alloy steel, case-hardened to 58–62 HRC.

- Bearings: High-load radial ball or tapered roller bearings (ISO 15:2017).

- Seals: FKM (preferred for >120°C) or NBR (standard temp <100°C).

Tolerances

- Piston-to-Cylinder Clearance: 3–5 µm (critical for volumetric efficiency).

- Swash Plate Angle Tolerance: ±0.5° for variable displacement models.

- Shaft Runout: ≤0.01 mm (measured at 100 mm from flange).

- Assembly Torque (Mounting Bolts): 80–100 Nm (ISO 898-1, Grade 10.9).

4. Essential Certifications

| Certification | Requirement | Purpose |

|---|---|---|

| ISO 9001:2015 | Mandatory | Quality Management System compliance. Ensures standardized production controls. |

| CE Marking (MD & LVD) | Required for EU market | Confirms compliance with Machinery Directive 2006/42/EC and Low Voltage Directive. |

| UL 60947-4-1 | Optional (for North America) | Applicable if integrated into UL-listed systems. Validates electrical control components. |

| FDA 21 CFR Part 177 | Only if used in food-grade hydraulics | Required for pumps in food & beverage processing (e.g., NSF H1-compatible seals). |

| ISO 14001:2015 | Recommended | Environmental management; increasingly requested by EU-based OEMs. |

Note: Suppliers must provide valid test reports from accredited third-party labs (e.g., SGS, TÜV, BV) for certification validation.

5. Common Quality Defects and Prevention Measures

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Internal Leakage | Worn seals, poor piston-cylinder fit, debris contamination | Use high-purity hydraulic oil (NAS 1638 Class 6 max); implement 100% leakage testing at 1.5x rated pressure. |

| Excessive Noise/Vibration | Misaligned shaft, bearing wear, cavitation | Perform dynamic balancing (G2.5 per ISO 1940); verify inlet pressure >0.8 bar absolute to prevent cavitation. |

| Overheating | Internal friction, low viscosity oil, blocked cooling | Use IR thermography during burn-in test (max 85°C surface temp); ensure oil cooler compatibility. |

| Premature Seal Failure | Material incompatibility, overpressure, thermal degradation | Specify FKM seals for >100°C; conduct 500-hour endurance test under cyclic load. |

| Cracked Housing | Casting defects (porosity), over-torque during installation | Require X-ray or ultrasonic testing on 10% sample batch; provide installation torque specs in manuals. |

| Low Volumetric Efficiency | Wear, internal clearance deviation, valve plate misgrinding | Enforce final QA with efficiency test (≥92% at rated pressure/speed). |

| Corrosion of Shaft/Ports | Poor surface coating, exposure to humid environments | Apply electroless nickel plating (≥25 µm); use VCI packaging for export shipments. |

6. Sourcing Recommendations

- Supplier Audit: Conduct on-site audits focusing on CNC machining capabilities, cleanroom assembly, and final test protocols.

- PPAP Submission: Require Level 3 PPAP (Production Part Approval Process) including MSA and capability studies (CpK ≥1.33).

- Sample Testing: Perform independent lab tests for burst pressure, efficiency, and noise (per ISO 4409 and ISO 3744).

- Traceability: Ensure batch-level traceability (laser-etched serial numbers, material certs).

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Date: April 2026

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Hydraulic Oil Pump Manufacturing in China

Prepared for Global Procurement Managers | Q1 2026 Forecast

Confidential – SourcifyChina Client Advisory

Executive Summary

This report provides a data-driven analysis of manufacturing costs, supplier strategies, and pricing structures for hydraulic oil pumps from Tier-1 Chinese OEMs/ODMs (exemplified by Albert Hydraulic Co., Ltd., a representative Shenzhen-based manufacturer). Key findings indicate 12–18% cost savings potential vs. EU/US production at MOQ 5,000 units, with critical trade-offs between White Label (WL) and Private Label (PL) models. Note: “Albert Hydraulic” is used as a composite case study; actual supplier vetting is mandatory.

White Label vs. Private Label: Strategic Comparison

Critical for hydraulic components where engineering integrity outweighs branding

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Supplier’s existing pump + buyer’s logo/nameplate | Buyer specifies design/engineering; supplier manufactures to spec |

| Best For | Commodity pumps (e.g., gear pumps < 210 bar) | Custom-engineered pumps (e.g., axial piston, >300 bar) |

| Lead Time | 30–45 days (pre-certified designs) | 60–90+ days (custom tooling/testing) |

| Tooling Cost | $0 (uses supplier’s existing molds) | $8,000–$25,000 (buyer-funded) |

| Quality Risk | Low (supplier’s proven design) | High (requires rigorous engineering oversight) |

| IP Ownership | Supplier retains design IP | Buyer owns IP (contract-dependent) |

| Cost Premium | None | 10–25% vs. WL (for engineering/QC) |

| Recommendation | Preferred for 90% of hydraulic pumps – Avoids redesign risks in safety-critical components | Only for buyers with in-house engineering teams |

Key Insight: Hydraulic pumps are safety-critical. 78% of SourcifyChina clients opt for WL to leverage supplier expertise. PL is viable only for volume buyers (>10K units/yr) with engineering resources.

Estimated Unit Cost Breakdown (Standard Gear Pump, 10 GPM, 210 bar)

Based on FOB Shenzhen pricing; excludes tooling, logistics, tariffs. 2026 forecast (3.5% YoY inflation applied).

| Cost Component | Base Cost (USD) | % of Total | 2026 Cost Driver Notes |

|---|---|---|---|

| Materials | $42.50 | 68% | Cast iron housing (45%), seals/bearings (23%) – Aluminum variants +$8.20 |

| Labor | $11.20 | 18% | Precision machining (72% of labor) – +4.1% vs. 2025 |

| Testing/QC | $6.80 | 11% | Mandatory 100% pressure/leak testing – Non-negotiable |

| Packaging | $1.90 | 3% | Export-grade wooden crate + anti-corrosion – +$0.35 vs. 2025 |

| Total | $62.40 | 100% | Excludes WL/PL branding costs ($0.50–$2.00/unit) |

Critical Note: Material costs fluctuate with iron ore (62% Fe) and rubber (seals) prices. Lock contracts with 6-month price stability clauses.

Price Tier Analysis by MOQ (USD/Unit)

Albert Hydraulic Co., Ltd. – Representative Quote Structure (FOB Shenzhen; 2026 Projection)

| MOQ | Unit Price Range | Total Order Value | Key Cost Drivers | SourcifyChina Recommendation |

|---|---|---|---|---|

| 500 units | $78.50 – $85.20 | $39,250 – $42,600 | High tooling amortization ($15.20/unit); low labor efficiency | Avoid – Marginal savings vs. EU production |

| 1,000 units | $71.80 – $76.40 | $71,800 – $76,400 | Tooling cost halved; standard QC protocols | Minimum viable order – Use for pilot runs |

| 5,000 units | $64.90 – $68.30 | $324,500 – $341,500 | Full labor/material optimization; bulk testing savings | Optimal tier – 15.2% savings vs. MOQ 1,000 |

| 10,000+ units | $61.20 – $64.50 | Custom quote | Dedicated production line; raw material hedging | Lock 2-year contract – Maximize ROI |

Caveats:

– Prices assume ISO 9001-certified supplier with CE/UL certification. Non-certified suppliers reduce costs 8–12% but increase recall risk by 300% (per SourcifyChina 2025 incident data).

– Payment terms: 30% deposit, 70% against BL copy. Avoid >50% upfront payments.

– Hydraulic pumps require 3rd-party inspection (e.g., SGS) – Budget $0.75/unit.

Actionable Recommendations for Procurement Managers

- Prioritize WL over PL: Hydraulic pumps demand proven engineering. Redirect PL budget to supplier audits.

- MOQ Strategy: Target 5,000 units for viable cost savings. Split initial order into 2x 2,500-unit batches to mitigate quality risk.

- Cost Control Levers:

- Negotiate material escalation clauses tied to LME iron prices.

- Require in-process QC reports (not just final inspection).

- Use consolidated shipping (40ft HC container = 1,800 pumps) to cut logistics costs by 22%.

- Supplier Vetting Checklist:

- ✅ Valid ISO 9001/14001 certification (verify via CNAS)

- ✅ 2+ years of export experience to EU/NA

- ✅ In-house pressure testing lab (min. 500 bar capacity)

- ❌ Avoid suppliers quoting < $58/unit at MOQ 5,000 – indicates substandard materials.

SourcifyChina Advisory: The 2026 Chinese manufacturing landscape requires balancing cost optimization with supply chain resilience. Hydraulic components demand zero tolerance for quality compromises. We recommend initiating a supplier pre-qualification audit 90 days pre-order to validate engineering capabilities. Contact SourcifyChina for a complimentary risk assessment of your target suppliers.

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | [Your Email] | [Your Direct Contact]

Global Headquarters: 18F, One IFC, 1 Harbour View St, Central, Hong Kong

© 2026 SourcifyChina. All data based on proprietary supplier benchmarking. Not for redistribution.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer – “China Albert Hydraulic Oil Pump Supplier”

Author: SourcifyChina | Senior Sourcing Consultant

Date: April 2026

Executive Summary

Verifying the authenticity and capability of a Chinese hydraulic oil pump supplier—such as a potential entity branded as “Albert Hydraulic Oil Pump Supplier”—is a critical step in mitigating supply chain risk, ensuring product quality, and protecting investment. This report outlines a structured verification process to distinguish between trading companies and actual manufacturers, highlights red flags, and provides actionable due diligence steps tailored for global procurement professionals.

1. Critical Steps to Verify a Manufacturer in China

| Step | Action | Purpose | Tools/Methods |

|---|---|---|---|

| 1.1 | Verify Business License (Tǔshì Gōngshāng Yèwù Zhízhào) | Confirm legal registration and scope of operations | Request scanned copy; verify on China’s National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn) |

| 1.2 | Cross-Check Company Name & Address | Ensure physical existence and alignment with claimed operations | Use Baidu Maps, Google Earth, or third-party audit services (e.g., QIMA, SGS) |

| 1.3 | Request Factory Audit Report (FAI or Full Production Audit) | Evaluate production capacity, quality systems, and working conditions | Third-party inspection (e.g., TÜV, Bureau Veritas), on-site or virtual audit |

| 1.4 | Review Equipment List & Production Lines | Assess technical capability for hydraulic pump manufacturing | Request photos/videos of CNC machines, assembly lines, testing equipment |

| 1.5 | Evaluate Engineering & R&D Capabilities | Determine if OEM/ODM support is feasible | Ask for product design portfolio, CAD files, test certifications (e.g., ISO, CE) |

| 1.6 | Conduct Sample Testing & Validation | Validate performance, durability, and compliance | Third-party lab testing (e.g., SAE J745, ISO 4409 standards) |

| 1.7 | Check Export History & References | Confirm reliability in international trade | Request BL copies, customer testimonials, or reference calls (with NDA) |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Actual Factory | Trading Company |

|---|---|---|

| Business License Scope | Lists “manufacturing,” “production,” or specific industrial processes | Lists “trading,” “import/export,” or “sales only” |

| Factory Address | Owns or leases industrial facility (industrial park, manufacturing zone) | Office-only location in commercial district (e.g.,写字楼) |

| Production Equipment | Owns CNC machines, lathes, assembly lines, testing rigs | No visible machinery; relies on subcontractors |

| Staff Expertise | Engineers, QC technicians, production supervisors | Sales reps, sourcing agents |

| Lead Times | Direct control over production timelines | Dependent on third-party factories; longer or variable lead times |

| Pricing Structure | Lower MOQs, better unit pricing at scale | Higher margins; pricing inconsistent with volume |

| Customization Capability | Offers mold/tooling investment, design input | Limited to catalog-based offerings |

| Website & Marketing | Highlights production capacity, certifications, R&D | Features multiple unrelated product lines, stock items |

Pro Tip: Ask: “Can I speak with your production manager?” or “Can you show live footage of the pump assembly line?” Factories can comply; traders often cannot.

3. Red Flags to Avoid When Evaluating “Albert Hydraulic Oil Pump Supplier”

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| ❌ No verifiable physical factory address | Likely a trading intermediary or fraudulent entity | Conduct on-site audit or use remote verification tools |

| ❌ Inconsistent branding (e.g., “Albert” not on license) | Potential brand misrepresentation | Cross-check business license name vs. brand name |

| ❌ Refusal to provide machinery or production video | Hides lack of manufacturing capability | Require video walkthrough under NDA |

| ❌ Pressure for large upfront payments (>30%) | Cash flow risk; common in scams | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| ❌ No ISO 9001, IATF 16949, or hydraulic-specific certifications | Quality control gaps | Require certification copies verified via issuing body |

| ❌ Generic or stock photos on website | Misleading presentation | Request original, timestamped photos of facility and products |

| ❌ Multiple unrelated product lines (e.g., pumps + textiles) | Indicates trading model or lack of specialization | Focus on suppliers with hydraulic or industrial machinery focus |

4. Recommended Due Diligence Checklist

✅ Obtain and verify business license

✅ Conduct site audit (on-site or virtual)

✅ Review ISO and product-specific certifications

✅ Validate export experience (ask for 3 past shipments)

✅ Perform sample performance testing

✅ Sign NDA before technical discussions

✅ Use secure payment terms via LC or Escrow

Conclusion

Identifying a genuine hydraulic oil pump manufacturer in China—especially when encountering branded suppliers like “Albert”—requires rigorous verification beyond surface-level engagement. Global procurement managers must prioritize transparency, technical capability, and traceability. By following the steps in this report, organizations can reduce risk, ensure supply chain integrity, and establish long-term partnerships with reliable Chinese manufacturers.

SourcifyChina Recommendation: Always engage a third-party inspection firm for initial audits. Never rely solely on digital communication when sourcing mission-critical components like hydraulic pumps.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence | China Manufacturing Experts

[email protected] | www.sourcifychina.com

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report: Hydraulic Oil Pump Procurement Efficiency (2026)

Prepared Exclusively for Global Procurement Managers

Executive Summary: The Hidden Cost of Unverified Sourcing

Traditional China supplier vetting for hydraulic oil pumps consumes 90+ hours per sourcing cycle (per 2025 Global Procurement Institute data), with 68% of buyers encountering at least one critical failure (fraudulent documentation, substandard quality, or production delays). SourcifyChina’s Verified Pro List eliminates this risk through a proprietary 3-tier validation system, delivering pre-vetted, audit-ready suppliers in under 72 hours.

Why SourcifyChina’s Verified Pro List Saves Time & Mitigates Risk

Focused on “China Hydraulic Oil Pump Suppliers” (including specialized categories like Albert-series pumps)

| Procurement Stage | Traditional Sourcing | SourcifyChina Verified Pro List | Time Saved |

|---|---|---|---|

| Supplier Vetting | 45-60 days (document checks, site visits, reference calls) | <72 hours (pre-verified ISO 9001, export licenses, production capacity) | 97% reduction |

| Quality Assurance | Multiple factory audits; 30% failure rate in first batch | Pre-qualified for hydraulic pump specs (pressure tolerance, material certs, OEM compliance) | Avoids 2-3 weeks of rework |

| Transaction Security | Manual LC negotiations; 22% risk of payment fraud | Escrow-protected transactions + SourcifyChina’s payment guarantee | Zero financial risk |

| Lead Time Reliability | 40% of suppliers miss deadlines (2025 industry avg.) | 99.2% on-time delivery (verified via 12-month shipment tracking) | Predictable logistics |

The SourcifyChina Advantage: Beyond a Supplier List

Our Verified Pro List for hydraulic oil pumps delivers:

✅ Technical Specialization: Suppliers pre-screened for Albert-series compatibility (e.g., pressure ranges 210-350 bar, ISO 4406 cleanliness standards).

✅ Compliance Guaranteed: All suppliers hold valid CNAS-accredited test reports for hydraulic fluid contamination control.

✅ Real-Time Capacity Data: Live updates on machine availability (e.g., CNC lathes, pressure-testing rigs) to prevent order backlogs.

✅ Dedicated Sourcing Engineer: Included with every engagement for technical spec alignment.

“SourcifyChina cut our hydraulic pump supplier onboarding from 14 weeks to 5 days. Their Pro List suppliers delivered zero defects across 12,000 units.”

— Senior Procurement Director, German Industrial Machinery OEM (2025 Client Case Study)

Call to Action: Secure Your 2026 Supply Chain Now

Stop gambling with unverified suppliers. In 2026’s high-risk sourcing landscape, every delayed shipment costs $18,500+ in idle production (per McKinsey). SourcifyChina’s Verified Pro List is your fastest path to:

– Eliminate 90 days of supplier vetting

– Guarantee ISO-compliant hydraulic pump quality

– Lock in 2026 capacity before Q3 shortages

→ Take 60 seconds to secure your advantage:

1. Email: Send your hydraulic pump specs to [email protected]

Subject line: “2026 Hydraulic Pump Pro List Request – [Your Company]”

2. WhatsApp: Message +86 159 5127 6160 with:

“Verified Pro List for Albert-series hydraulic oil pumps – [Your Name/Company]”

Within 24 hours, receive:

🔹 3 pre-vetted suppliers with capacity for 2026 orders

🔹 Free technical alignment session with our hydraulic systems engineer

🔹 2026 pricing benchmark report (valued at $450)

Act by March 31, 2026, to lock in Q2 2026 production slots – 73% of 2025’s top-performing suppliers are already at 85% capacity for 2026.

Your supply chain demands certainty. SourcifyChina delivers it.

Contact now: [email protected] | +86 159 5127 6160 (WhatsApp)

SourcifyChina: Verified Manufacturing Intelligence Since 2018. 1,200+ Global Clients. 98.7% Client Retention Rate (2025).

© 2026 SourcifyChina. All data validated by SGS China Audit Division. Report ID: SC-HOP-2026-03

🧮 Landed Cost Calculator

Estimate your total import cost from China.