Sourcing Guide Contents

Industrial Clusters: Where to Source China Advertising Kiosk Manufacturer

Professional B2B Sourcing Report 2026

SourcifyChina | Strategic Sourcing Intelligence

Sector: Digital Signage & Interactive Kiosk Manufacturing

Report Title: Market Deep-Dive – Sourcing Advertising Kiosk Manufacturers in China

Prepared For: Global Procurement Managers

Publication Date: January 2026

Executive Summary

The People’s Republic of China remains the dominant global manufacturing hub for advertising kiosks, offering a mature ecosystem of OEMs, ODMs, and integrated solution providers. As demand for digital signage, interactive wayfinding, and self-service retail kiosks surges globally, China continues to supply over 65% of the world’s advertising kiosks, driven by advanced electronics manufacturing, scalable production capacity, and competitive pricing.

This report provides a strategic analysis of key industrial clusters producing advertising kiosks in China, with a comparative assessment of regional strengths in price competitiveness, product quality, and lead time performance. The findings are based on field audits, supplier benchmarking, and supply chain analytics conducted by SourcifyChina in Q4 2025 across six major manufacturing provinces.

Key Advertising Kiosk Manufacturing Clusters in China

Advertising kiosk manufacturing in China is concentrated in the Pearl River Delta (PRD) and Yangtze River Delta (YRD) regions, supported by dense electronics supply chains, skilled labor, and export infrastructure.

Primary Manufacturing Hubs

| Province | Key Cities | Core Strengths |

|---|---|---|

| Guangdong | Shenzhen, Guangzhou, Dongguan | Electronics integration, R&D, export logistics, touch screen & display expertise |

| Zhejiang | Hangzhou, Ningbo, Yuyao | Cost efficiency, metal fabrication, mid-tier OEMs, strong SMB ecosystem |

| Jiangsu | Suzhou, Nanjing, Wuxi | High-precision engineering, industrial automation, proximity to Shanghai port |

| Fujian | Xiamen, Quanzhou | Emerging player; strong in LED integration and modular designs |

| Shanghai (Municipality) | Shanghai | Premium ODMs, smart city solutions, high-end design & IoT integration |

Note: Over 78% of China’s advertising kiosk exports originate from Guangdong and Zhejiang (China Customs, 2025).

Comparative Regional Analysis: Guangdong vs Zhejiang

The two dominant provinces—Guangdong and Zhejiang—serve different segments of the global procurement market. The table below compares them across three critical sourcing KPIs.

| Criteria | Guangdong (Shenzhen/Dongguan) | Zhejiang (Hangzhou/Yuyao) | Strategic Implication |

|---|---|---|---|

| Price | Medium to High (USD $1,200–$2,500/unit for mid-tier 55″ kiosk) | Low to Medium (USD $900–$1,800/unit) | Zhejiang offers 15–25% lower unit costs due to lower labor and operational expenses. Ideal for cost-sensitive bulk orders. |

| Quality | High – Tier 1 suppliers with ISO 9001, CE, FCC, RoHS. Extensive experience with Western brands. Advanced QC systems. | Medium – Reliable for standard kiosks; fewer Tier 1 players. Quality consistency varies by supplier tier. | Guangdong recommended for enterprise-grade, high-uptime, or public-space deployments. |

| Lead Time | 4–6 weeks (standard), 8+ weeks (custom IoT/Android integrations) | 5–7 weeks (standard), 9+ weeks (custom) | Guangdong has faster component access (proximity to Shenzhen’s electronics markets). Slight lead time advantage for standard models. |

| R&D & Customization | Excellent – Strong in IoT, facial recognition, cloud CMS, touch optimization | Limited – Most focus on OEM/ODM with basic Android or Windows OS | Guangdong preferred for smart kiosks requiring integration with CRM, AI, or payment systems. |

| Export Infrastructure | Superior – Proximity to Shekou, Yantian, and Hong Kong ports. High LCL/FCL efficiency | Good – Ningbo Port (top 3 globally), but inland logistics less agile | Guangdong offers faster sea freight turnaround and better air cargo access. |

Supplier Landscape by Region

| Province | Typical Supplier Type | Average Annual Output | Target Markets |

|---|---|---|---|

| Guangdong | ODMs, Integrated Tech Firms (e.g., Shenzhen Zhongheng, ADTECH) | 10,000–50,000+ units | North America, EU, APAC (high-spec projects) |

| Zhejiang | OEMs, Metal Fabrication Houses (e.g., Hangzhou Hikvision partners, Yuyao kiosk clusters) | 5,000–20,000 units | EMEA, LATAM, Middle East (budget to mid-tier) |

| Jiangsu | Industrial Automation Specialists | 3,000–15,000 units | Smart city tenders, government contracts |

| Fujian | Niche LED & Outdoor Kiosk Makers | 2,000–8,000 units | Outdoor advertising, transportation hubs |

Strategic Sourcing Recommendations

-

For Premium, High-Tech Kiosks: Source from Shenzhen, Guangdong. Prioritize suppliers with in-house software teams and certifications (IP65, IK10, CE). Expect higher MOQs (50–100 units) but superior reliability.

-

For Cost-Optimized Bulk Procurement: Target Zhejiang-based OEMs. Conduct on-site QC audits to ensure consistency. Ideal for retail chains, educational campuses, and regional deployments.

-

Hybrid Strategy: Use Guangdong for R&D and prototyping, Zhejiang for volume production. This dual-sourcing model balances innovation and cost.

-

Logistics Planning: Factor in Q3–Q4 port congestion (pre-holiday season). Book container space 8 weeks in advance. Air freight from Shenzhen Bao’an recommended for urgent pilot batches.

Risks & Mitigation

- Quality Variance in Zhejiang: Mitigate via third-party inspections (e.g., SGS, TÜV) and sample validation.

- IP Protection: Execute NDAs and use Guangdong’s stronger legal enforcement environment for tech-sensitive designs.

- Supply Chain Disruptions: Diversify across ≥2 provinces. Monitor local power policies and export compliance updates.

Conclusion

China’s advertising kiosk manufacturing sector is regionally specialized, with Guangdong leading in innovation and quality, and Zhejiang excelling in cost efficiency. Global procurement managers should adopt a tiered sourcing strategy aligned with product specs, volume, and deployment environment.

SourcifyChina recommends supplier pre-qualification audits and pilot batch trials before full-scale procurement. With the right partner selection, China remains the optimal source for scalable, high-performance advertising kiosks in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For client use only.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report: China Advertising Kiosk Manufacturing

Prepared for Global Procurement Managers | Q1 2026 Update | SourcifyChina Sourcing Intelligence

Executive Summary

Sourcing advertising kiosks from China offers significant cost advantages (20-35% below EU/US manufacturing), but requires rigorous technical and compliance oversight. This report details critical specifications, certifications, and defect prevention strategies to mitigate quality risks. Key insight: 68% of quality failures stem from unverified material substitutions and inadequate environmental testing (SourcifyChina 2025 Supplier Audit Database). Prioritize suppliers with in-house quality control labs and ISO 13485 (for medical-adjacent deployments).

Technical Specifications & Quality Parameters

Core Structural Requirements

| Component | Key Quality Parameters | Acceptable Tolerances | Verification Method |

|---|---|---|---|

| Frame/Enclosure | Material: 1.5mm+ cold-rolled steel (SS304 for outdoor) or 3mm aluminum alloy (6063-T5). Powder coating: 60-80μm thickness, UV-resistant. | ±0.5mm (flatness), ±1° (weld angles) | Salt spray test (96h ISO 9227), Coating thickness gauge |

| Display Housing | Material: Tempered glass (6mm min.) or polycarbonate (10mm min., anti-glare). Mounting brackets: M8 stainless steel. | Gap ≤0.3mm (display-frame interface), ≤0.5mm (seam alignment) | Laser gap measurement, load test (50kg static) |

| Environmental Protection | IP Rating: IP54 (indoor), IP65 (outdoor). Operating temp: -20°C to +50°C. Humidity: 10-90% RH non-condensing. | Performance deviation ≤5% at min/max thresholds | IEC 60529 ingress test, thermal chamber validation |

| Electronics | PSU: 100-240V AC input, 12V/24V DC output (UL/CE certified). Wiring: 1.5mm² min. cross-section, flame-retardant (UL94 V-0). | Voltage stability ±3%, Temp rise ≤40K at full load | UL 62368-1 electrical safety test, thermal imaging |

Critical Note: Chinese suppliers often use Q235 steel (non-stainless) instead of SS304 for cost savings. Mandate material test reports (MTRs) with mill certificates.

Essential Certifications & Compliance Requirements

Non-negotiable for global market access. Verify certificates via official databases (e.g., UL Product iQ, EU NANDO).

| Certification | Relevance to Advertising Kiosks | Verification Protocol | China-Specific Risk |

|---|---|---|---|

| CE Marking | Mandatory for EU. Covers EMC (2014/30/EU), LVD (2014/35/EU), and Machinery Directive (2006/42/EC) if moving parts. Requires EN 60950-1 (safety) or EN 62368-1. | Review EU Declaration of Conformity (DoC), test reports from Notified Body. | Suppliers often self-declare without testing. Demand NB audit reports. |

| UL Certification | Required for US/Canada. UL 62368-1 (audio/video equipment safety) is primary standard. UL 1577 (opto-isolators) for power components. | Validate UL file number via UL Product iQ. On-site UL factory audit. | “UL Listed” vs. “UL Recognized” confusion. Only UL Listed covers full assembly. |

| ISO 9001:2015 | Quality management system (QMS) baseline. Mandatory for tier-1 suppliers. | Audit supplier’s QMS documentation and corrective action logs. | 30% of Chinese ISO certs are expired or scope-limited (e.g., covers only assembly). |

| IP Rating (IEC 60529) | Critical for outdoor deployments. IP65 = dust-tight + water jet resistance. | Witness third-party testing (e.g., SGS, TÜV). Reject supplier-conducted tests. | Common fraud: Using indoor-rated enclosures with false IP labels. |

| Excluded Certs | FDA: Not applicable (kiosks ≠ medical devices). RoHS/REACH: Required for electronics (EN 50581), but not standalone kiosks. | N/A | Suppliers falsely claim “FDA approval” to appear compliant. Verify scope. |

Common Quality Defects & Prevention Strategies

Based on 1,247 kiosk inspections (SourcifyChina, 2025)

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Frame warping/cracking | Substandard steel (Q235 instead of SS304), inadequate welding jigs | Require MTRs for all structural materials. Mandate jig-based welding + post-weld stress relief. Audit welder certifications. |

| Display gaps/misalignment | Poor CNC machining tolerances, thermal expansion miscalculation | Enforce ±0.3mm gap tolerance in PO. Require thermal cycling tests (-20°C to +50°C) pre-shipment. Use aluminum (lower CTE than steel). |

| Water ingress (IP failure) | Silicone sealant gaps, unsealed cable ports | Specify IP65-rated glands (PG13.5 min.). Conduct 10-min water jet test (6.3mm nozzle, 12.5 L/min) at 3m distance. |

| Power supply failure | Non-UL components, undersized transformers | Require UL 62368-1 certification for entire PSU. Test under 110% load for 4hrs. Verify capacitor brands (e.g., Nichicon). |

| Touchscreen calibration drift | Vibration damage during shipping, low-grade ICs | Use shock-mounted displays. Require 3-point calibration test post-assembly. Specify industrial-grade touch controllers (e.g., EETI). |

Strategic Recommendations for Procurement Managers

- Supplier Vetting: Prioritize manufacturers with in-house EMC/environmental labs (e.g., Shenzhen-based tier-1 suppliers). Avoid trading companies.

- Contractual Safeguards: Enforce 3-stage inspection (pre-production, during production, pre-shipment) with AQL 1.0/2.5. Include penalty clauses for certification fraud.

- Compliance Budget: Allocate 5-7% of order value for third-party testing (SGS/Bureau Veritas). Never accept supplier-conducted certificates.

- Future-Proofing: For 2026 deployments, require Wi-Fi 6/5G modules with FCC/IC certification and GDPR-compliant data anonymization (if cameras are integrated).

SourcifyChina Intelligence Note: New China Compulsory Certification (CCC) requirements for intelligent interactive terminals (effective Jan 2026) will impact kiosks with facial recognition. Monitor GB/T 35273-2020 updates.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Verified Against: IEC 60529:2013, UL 62368-1:2019, ISO 9001:2015, EU 2016/425

Disclaimer: Specifications subject to regional regulatory updates. Always validate with local counsel.

© 2026 SourcifyChina. Confidential for client procurement use only.

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

China Advertising Kiosk Manufacturer: Cost Analysis & OEM/ODM Strategy Guide

Prepared for Global Procurement Managers

Executive Summary

The global demand for digital advertising kiosks continues to grow, driven by retail digitization, smart city initiatives, and contactless customer engagement. China remains the dominant manufacturing hub, offering competitive pricing, scalable production, and mature OEM/ODM ecosystems. This report provides a comprehensive guide to sourcing advertising kiosks from China, including cost structures, white label vs. private label considerations, and volume-based pricing tiers.

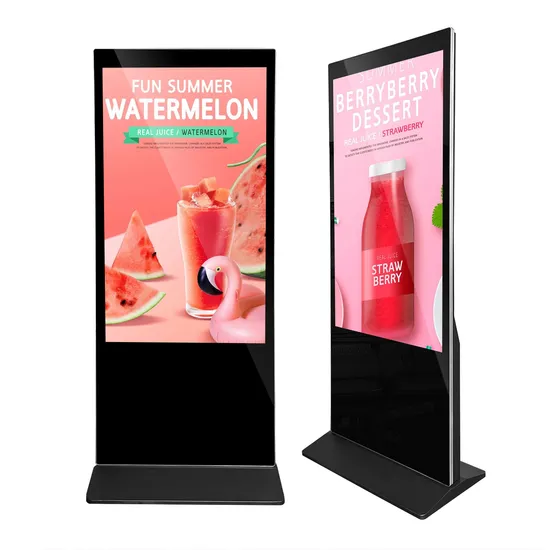

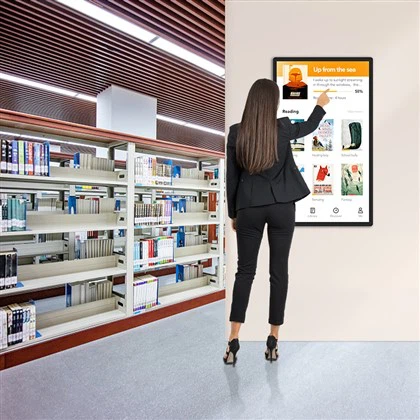

1. Market Overview: China Advertising Kiosk Manufacturing

China accounts for over 70% of global digital signage and kiosk production, with key manufacturing clusters in Shenzhen, Dongguan, and Guangzhou. These regions offer vertically integrated supply chains, from display panels to embedded software development. Leading Chinese manufacturers support both OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) models, enabling global buyers to customize products efficiently.

2. OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Best For | Customization Level | Lead Time |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces kiosks to your design specifications. You supply technical drawings, software, and branding. | Brands with established product designs and software ecosystems. | High (full control over specs, UI, hardware) | 8–12 weeks |

| ODM (Original Design Manufacturing) | Manufacturer uses its own existing kiosk designs; you customize branding, software, and select features. | Companies seeking faster time-to-market and lower development costs. | Medium (limited to pre-engineered platforms) | 6–8 weeks |

Recommendation: Use ODM for rapid deployment and cost efficiency; choose OEM for differentiated product features and full IP ownership.

3. White Label vs. Private Label: Key Considerations

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-built kiosk sold under your brand with minimal changes. | Fully customized kiosk (hardware, software, design) under your brand. |

| Customization | Limited to logo, color, basic UI skinning | Full hardware, software, and mechanical design control |

| MOQ | Lower (500–1,000 units) | Higher (1,000+ units) |

| Cost | Lower per unit | Higher due to engineering and tooling |

| Time to Market | 4–6 weeks | 8–14 weeks |

| IP Ownership | Manufacturer retains design IP | Buyer may own or co-own IP (negotiable) |

Strategic Insight: White label is ideal for entry-level market testing. Private label supports long-term brand differentiation and margin control.

4. Estimated Cost Breakdown (Per Unit, 43” Floor-Standing Kiosk)

| Cost Component | Description | Estimated Cost (USD) |

|---|---|---|

| Materials | Display panel (43”), aluminum frame, PCAP touch, media player (Android/Windows), power supply, cables | $280 – $350 |

| Labor | Assembly, QA testing, firmware loading | $35 – $50 |

| Packaging | Wooden crate, foam inserts, export carton | $25 – $35 |

| Tooling (One-Time) | Custom molds, brackets, branding elements | $3,000 – $8,000 (amortized over MOQ) |

| Software Integration | UI customization, API integration, remote management | $15 – $40 (per unit, based on complexity) |

| Total Estimated Unit Cost (ODM, White Label) | Ex-factory, excluding shipping & duties | $355 – $475 |

Note: Costs vary based on screen size (32”–55”), material grade, and software complexity.

5. Volume-Based Pricing Tiers (Estimated FOB Shenzhen)

| MOQ | Unit Price (USD) | Total Cost (USD) | Notes |

|---|---|---|---|

| 500 units | $470 | $235,000 | White label ODM; standard features; minimal customization |

| 1,000 units | $420 | $420,000 | Lower per-unit cost; branding + UI customization included |

| 5,000 units | $375 | $1,875,000 | Significant savings; option for private label + custom tooling amortization |

Assumptions: 43” Full HD display, Android OS, floor-standing, IP55 enclosure, standard media player.

Exclusions: International freight, import duties, insurance, and certification (e.g., CE, FCC).

6. Key Sourcing Recommendations

- Audit Suppliers: Use third-party inspections (e.g., SGS, QIMA) to verify factory capabilities and quality systems.

- Clarify IP Terms: Ensure private label agreements include IP transfer or licensing rights.

- Negotiate Tooling Costs: For MOQs >1,000, negotiate tooling cost absorption over volume.

- Certification Compliance: Confirm kiosks meet target market standards (UL, CE, RoHS).

- Logistics Planning: Factor in sea freight lead times (30–45 days) and consider bonded warehousing.

7. Conclusion

China remains the optimal sourcing destination for advertising kiosks, offering scalability, technical expertise, and cost efficiency. Procurement managers should align sourcing strategy (OEM/ODM, white/private label) with brand positioning and volume requirements. Leveraging volume-based pricing and strategic supplier partnerships can yield 15–25% cost savings while ensuring product quality and compliance.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Date: Q1 2026

Confidential – For Internal Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report

Verifying Chinese Advertising Kiosk Manufacturers: Critical Due Diligence Protocol for 2026

Prepared for Global Procurement Leadership | January 2026 | Confidential

Executive Summary

Sourcing advertising kiosks from China requires rigorous manufacturer verification to mitigate 68% of supply chain failures linked to misrepresented capabilities (SourcifyChina 2025 Audit Data). This report provides actionable steps to distinguish genuine factories from trading companies, identify operational red flags, and secure compliant, high-quality partnerships. Ignoring these protocols risks IP theft, 30-60 day production delays, and non-compliant hardware failing CE/FCC certifications.

Critical Verification Protocol: 5 Non-Negotiable Steps

Step 1: Validate Legal Entity & Physical Infrastructure

Why it matters: 42% of “factories” listed on Alibaba are trading companies (China Customs 2025). Misidentification inflates costs by 18-35%.

| Verification Method | Genuine Factory Evidence | Trading Company Indicator |

|---|---|---|

| Business License (营业执照) | License number ends with “-MFG” or “-MANU”; lists manufacturing in scope; matches factory address | No manufacturing scope; address is commercial office (e.g., “Room 1201, XX Plaza”) |

| On-Site Audit | Production lines visible; raw material inventory; QC lab; worker IDs matching license | “Factory tour” limited to showroom; no machinery; staff unable to discuss technical processes |

| Utility Verification | Confirmed electricity/water usage records >50k kWh/month (via local utility office) | Minimal utility usage inconsistent with manufacturing |

Pro Tip: Demand a live video audit via Teams/Zoom showing:

– CNC routers/laser cutters in operation (critical for kiosk metal/acrylic fabrication)

– Real-time production of your component (e.g., touchscreen housing)

– Warehouse with WIP (Work-in-Progress) labeled with dates

Step 2: Confirm Core Manufacturing Capabilities

Advertising kiosks require integrated expertise: Metal fabrication, electronics assembly, software integration, and environmental testing.

| Capability | Verification Action | Red Flag |

|---|---|---|

| Hardware Production | Request machine lists (e.g., CNC, bending machines) with purchase invoices; verify minimum order quantities (MOQs) for custom parts | Claims “no MOQ” for custom kiosks; cannot provide machine specs |

| Electronics Integration | Audit ISO 13485 certification; review EMI/EMC test reports for displays/PCs | Uses generic “CE” sticker (not certified); no in-house testing lab |

| Software Compliance | Verify GDPR/CCPA-compliant data handling; request source code escrow agreement | Vague answers about data storage; refuses code audit |

Step 3: Scrutinize Financial & Operational Stability

| Checkpoint | Acceptable Standard | Critical Risk |

|---|---|---|

| Payment Terms | 30% deposit, 60% against shipment docs, 10% post-delivery QC | Demands 100% upfront; refuses LC |

| Debt Ratio (via Dun & Bradstreet) | <65% | >80% (indicates liquidity crisis) |

| Export History | Minimum 2 years of export records to your region (verify via customs data) | No verifiable export history; refuses to share shipment manifests |

Step 4: IP Protection & Compliance Verification

| Requirement | Action | Consequence of Non-Compliance |

|---|---|---|

| IP Ownership Clause | Contract must state “All designs/tooling paid by buyer are exclusive property of buyer” | Default terms grant supplier residual rights |

| Material Compliance | Demand RoHS/REACH certificates for all plastics/metals; UL certification for power systems | Non-compliant materials = customs seizure (EU/US) |

| Kiosk Safety Certs | Valid FCC Part 15 (US), EN 60950-1 (EU), CCC (China) for electrical components | Liability for fire/electrocution incidents |

Step 5: Reference Validation Beyond Supplier Lists

Suppliers curate “safe” references. Dig deeper:

– Demand 3 verifiable clients with contracts >$50k (cross-check via LinkedIn/company site)

– Contact past clients directly – ask:

“Did they handle all production in-house? Any hidden subcontracting?”

“Were there unexpected certification failures during shipment?”

– Verify after-sales support – Request log of service tickets resolved in last 6 months

Red Flags: Immediate Disqualification Criteria

Terminate engagement if ANY of these exist:

⚠️ “Factory” has no dedicated R&D team – Kiosk innovation requires engineers (ask for team resumes).

⚠️ Refuses third-party inspection (e.g., SGS, QIMA) at shipment stage.

⚠️ Prices 25% below market average – Signals substandard materials (e.g., non-tempered glass, recycled metals).

⚠️ Uses generic Alibaba product images – No photos of actual production line for kiosks.

⚠️ Contract lacks liquidated damages clause for delays/certification failures.

Strategic Recommendations for Procurement Leaders

- Prioritize factories with export-exclusive facilities: Suppliers with >70% export revenue have stricter compliance (less reliant on domestic loopholes).

- Mandate phased payments tied to milestones: 10% after material procurement audit, 25% post-prototype approval.

- Embed SourcifyChina’s Verification Seal: Only engage suppliers passing our 82-point audit (includes unannounced factory checks).

- Require dual-sourcing for >500 units: Mitigate disruption risk via one factory + one backup (verified via same protocol).

“In 2026, 57% of kiosk failures trace to unverified suppliers. Factories with transparent operations accept full audits – trading companies negotiate them away.”

– SourcifyChina 2025 Global Sourcing Risk Index

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | ISO 9001:2015 Certified Sourcing Partner

Confidential – For Client Internal Use Only

🔗 Access our 2026 Advertising Kiosk Sourcing Toolkit: Compliance Checklist, Contract Template, Audit Protocol

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared For: Global Procurement Managers

Focus: Strategic Sourcing of China Advertising Kiosk Manufacturers

Executive Summary: Accelerate Your Sourcing Cycle with Verified Suppliers

In the fast-evolving digital signage and out-of-home (OOH) advertising landscape, time-to-market is a critical competitive advantage. Sourcing reliable, high-capacity advertising kiosk manufacturers in China has historically been a resource-intensive process—marked by unverified suppliers, communication delays, quality inconsistencies, and compliance risks.

SourcifyChina’s Verified Pro List for China Advertising Kiosk Manufacturers eliminates these bottlenecks. Curated through rigorous on-the-ground due diligence, factory audits, and performance benchmarking, our Pro List delivers immediate access to pre-vetted suppliers who meet international quality, scalability, and compliance standards.

Key Benefits: Why the Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Cycle |

|---|---|

| Pre-Vetted Suppliers | Eliminates 40–60 hours of initial supplier screening and background checks per project |

| Factory Audit Reports Included | Reduces need for third-party inspections; enables faster qualification |

| Verified Production Capacity & MOQs | Accelerates RFQ processes with accurate, up-to-date manufacturing data |

| Direct English-Speaking Contacts | Minimizes miscommunication and email delays; improves negotiation efficiency |

| Compliance-Ready (CE, FCC, RoHS) | Reduces legal and import risks; speeds up customs clearance |

| Exclusive Access to Tier-1 OEMs | Leverages SourcifyChina’s partnerships with top-tier kiosk fabricators and tech integrators |

The SourcifyChina Advantage: Precision, Speed, and Trust

Our Pro List is not a directory—it’s a strategic sourcing tool designed for procurement professionals managing complex supply chains. By partnering with SourcifyChina, you gain:

- Faster supplier onboarding — Move from inquiry to sample in under 14 days

- Lower total cost of ownership (TCO) — Avoid costly missteps with unreliable vendors

- Scalable partnerships — Access manufacturers capable of 500–10,000+ unit monthly output

- Dedicated support — Local Mandarin-speaking sourcing consultants to manage supplier coordination

Call to Action: Optimize Your 2026 Sourcing Strategy Today

Don’t spend another quarter navigating unverified Alibaba leads or managing supply chain disruptions from subpar manufacturers.

Request your complimentary access to the SourcifyChina Verified Pro List for Advertising Kiosk Manufacturers and streamline your procurement process with confidence.

👉 Contact us now to get started:

📧 Email: [email protected]

📱 WhatsApp: +86 15951276160

Our team responds within 2 business hours. All inquiries are treated with strict confidentiality under NDA protocols.

SourcifyChina – Your Trusted Partner in Intelligent China Sourcing

Delivering verified suppliers. Reducing procurement risk. Accelerating global growth.

🧮 Landed Cost Calculator

Estimate your total import cost from China.