Sourcing Guide Contents

Industrial Clusters: Where to Source China Advanced Manufacturing

SourcifyChina Sourcing Intelligence Report 2026

Title: Deep-Dive Market Analysis: Sourcing Advanced Manufacturing from China

Prepared For: Global Procurement Managers

Date: March 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

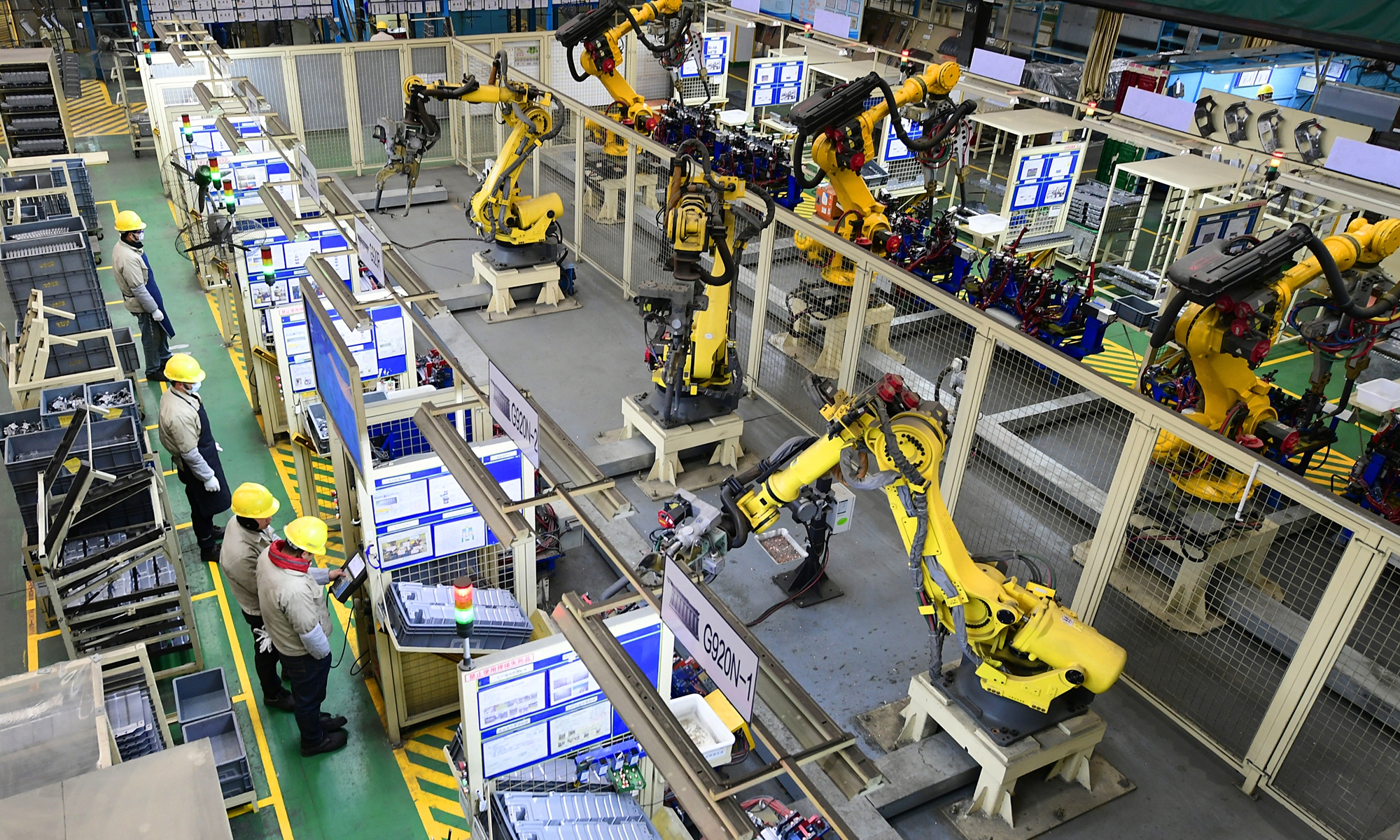

China remains the cornerstone of global advanced manufacturing, accounting for over 30% of the world’s manufacturing output in 2025. The nation’s strategic pivot toward “Made in China 2025” has accelerated investment in high-tech sectors, including industrial automation, robotics, precision electronics, new materials, and smart manufacturing systems. This report provides a comprehensive analysis of China’s key advanced manufacturing clusters, evaluating regional strengths in price competitiveness, quality standards, and lead time efficiency.

For global procurement managers, understanding regional specialization is critical to optimizing cost, mitigating supply chain risks, and ensuring alignment with quality and compliance requirements. This analysis focuses on the top-tier provinces and cities leading China’s advanced manufacturing transformation.

Key Industrial Clusters for Advanced Manufacturing in China

China’s advanced manufacturing ecosystem is concentrated in several high-density industrial corridors, each with distinct technological specializations and supply chain advantages.

1. Guangdong Province (Pearl River Delta – PRD)

- Core Cities: Shenzhen, Dongguan, Guangzhou, Foshan

- Specialization: Electronics, robotics, drones, smart devices, AI-integrated hardware, 5G infrastructure

- Key Strengths:

- World’s most advanced electronics supply chain

- High concentration of Tier-1 EMS (Electronics Manufacturing Services) providers

- Proximity to Hong Kong for logistics and R&D collaboration

- Strong innovation ecosystem led by Shenzhen’s “Silicon Valley of Hardware”

2. Zhejiang Province (Yangtze River Delta – YRD)

- Core Cities: Hangzhou, Ningbo, Yiwu, Shaoxing

- Specialization: Smart machinery, automation systems, IoT devices, high-precision tools, industrial AI

- Key Strengths:

- Dominance in SME-driven innovation and agile manufacturing

- Integration with Alibaba’s digital commerce and cloud infrastructure

- High adoption of Industry 4.0 practices in mid-sized factories

3. Jiangsu Province (Yangtze River Delta)

- Core Cities: Suzhou, Nanjing, Wuxi, Changzhou

- Specialization: Semiconductor equipment, precision optics, advanced materials, electric vehicle components

- Key Strengths:

- Home to German and Japanese joint ventures in high-precision engineering

- Suzhou Industrial Park hosts over 500 multinational R&D centers

- Strong quality control systems aligned with EU and Japanese standards

4. Shanghai (Municipality)

- Specialization: High-end automation, biotech manufacturing, aerospace components, AI-driven production systems

- Key Strengths:

- China’s R&D and innovation capital

- Access to global talent and foreign direct investment (FDI)

- Leading role in pilot smart factory programs under MIIT

5. Beijing-Tianjin-Hebei Corridor (Jing-Jin-Ji)

- Core Cities: Beijing, Tianjin, Baoding

- Specialization: Aerospace, industrial robotics, quantum technology, defense-related manufacturing

- Key Strengths:

- Proximity to national research institutes (CAS, Tsinghua, Peking University)

- Government-backed innovation zones (e.g., Zhongguancun)

- High IP protection environments in state-approved zones

Comparative Analysis of Key Production Regions

The table below evaluates the top advanced manufacturing hubs in China based on three critical procurement KPIs: Price, Quality, and Lead Time. Ratings are on a scale of 1 (Low) to 5 (High), with qualitative context.

| Region | Price Competitiveness | Quality Standards | Lead Time Efficiency | Key Advantages | Procurement Considerations |

|---|---|---|---|---|---|

| Guangdong | 4 | 5 | 5 | Fastest electronics prototyping; full supply chain integration | Higher labor costs in Shenzhen; IP risks in low-tier suppliers |

| Zhejiang | 5 | 4 | 4 | Cost-effective automation; agile SMEs | Quality variance among smaller OEMs; requires rigorous vetting |

| Jiangsu | 3 | 5 | 4 | German/Japanese-tier precision; strong compliance | Higher unit costs; longer negotiation cycles |

| Shanghai | 2 | 5 | 3 | Cutting-edge R&D global compliance (ISO, IATF) | Highest labor and operational costs; limited mid-volume capacity |

| Jing-Jin-Ji | 3 | 5 | 3 | Defense-grade precision; strong IP protection | Export restrictions on sensitive tech; limited civilian access |

Strategic Sourcing Recommendations

- For High-Volume Electronics & Smart Devices:

- Preferred Cluster: Guangdong (Shenzhen/Dongguan)

-

Action: Partner with ISO 13485 or IATF 16949-certified EMS providers for medical or automotive applications.

-

For Cost-Optimized Automation & IoT Systems:

- Preferred Cluster: Zhejiang (Hangzhou/Ningbo)

-

Action: Leverage digital sourcing platforms (e.g., Alibaba Industry Pavilion) for rapid RFQ turnaround.

-

For Precision Engineering & EV Components:

- Preferred Cluster: Jiangsu (Suzhou/Wuxi)

-

Action: Target German-Chinese JV factories for Tier-1 automotive compliance.

-

For R&D-Intensive or AI-Integrated Production:

- Preferred Cluster: Shanghai or Beijing

-

Action: Engage innovation parks with co-development agreements; ensure IP clauses in contracts.

-

Risk Mitigation:

- Diversify sourcing across 2–3 clusters to reduce geopolitical and logistical exposure.

- Use third-party audits (e.g., SGS, TÜV) for quality benchmarking, especially in Zhejiang SMEs.

Conclusion

China’s advanced manufacturing landscape is no longer defined by low-cost labor but by technological depth, industrial maturity, and regional specialization. Guangdong leads in speed and integration, Zhejiang in cost agility, and Jiangsu/Shanghai in precision and compliance. Procurement strategies must align with both technical requirements and regional operational dynamics.

As global supply chains evolve, China remains an indispensable partner in advanced manufacturing—provided sourcing is guided by data, due diligence, and strategic regional alignment.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Intelligence

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Advanced Manufacturing Sourcing Report 2026

Prepared for Global Procurement Managers | Q3 2026

Executive Summary

China’s advanced manufacturing sector (industrial robots, precision optics, medical devices, aerospace components) has evolved significantly under Made in China 2025 and 14th Five-Year Plan mandates. While offering 20-35% cost advantages vs. Western suppliers, rigorous technical validation and compliance verification remain critical. This report details non-negotiable quality parameters, certification requirements, and defect mitigation protocols for risk-optimized sourcing.

I. Key Quality Parameters for Advanced Manufacturing Components

A. Material Specifications (2026 Minimum Standards)

| Material Category | Acceptable Grades | Critical Properties | Testing Protocol |

|---|---|---|---|

| Metals | 304L/316L (ASTM A240), 7075-T6 (AMS 4027) | Yield strength ≥ 503 MPa, Corrosion rate < 0.01 mm/yr | ASTM A370, Salt Spray (ISO 9227) |

| Engineering Plastics | PEEK 450G (ISO 1874), PPS GF40 (UL 746) | HDT ≥ 260°C, Tensile strength ≥ 90 MPa | ISO 527, UL 746E |

| Composites | Carbon Fiber/Epoxy (AS4/3501-6) | Fiber volume ≥ 60%, Void content ≤ 1% | ASTM D3039, Microscopy (ASTM D2734) |

B. Dimensional Tolerances (Per ISO 2768-mK)

| Feature Type | Standard Tolerance | Critical Application Tolerance | Verification Method |

|---|---|---|---|

| Machined Holes | ±0.1 mm | ±0.005 mm (e.g., hydraulic valves) | CMM (ISO 10360-2) |

| Surface Flatness | 0.2 mm/m² | 0.002 mm/m² (optical mounts) | Laser interferometry (ISO 14253) |

| Thread Pitch | ±0.05 mm | ±0.002 mm (aerospace fasteners) | Optical comparators (ISO 965) |

Note: Tolerances tighter than ±0.01 mm require supplier validation of in-process SPC (Statistical Process Control) data per ISO 22514-1.

II. Essential Compliance Certifications (Non-Negotiable by Sector)

| Certification | Scope | Mandatory For | Verification Protocol |

|---|---|---|---|

| CE | Machinery Directive 2006/42/EC | Industrial robots, CNC systems | Review EU Declaration of Conformity + Notified Body # |

| FDA 21 CFR 820 | QSR (Quality System Regulation) | Medical devices (Class II/III) | Audit FDA 510(k) files + ISO 13485 alignment |

| UL 62368-1 | Audio/Video & IT Equipment Safety | EV components, smart sensors | Validate UL File # + factory follow-up audit |

| ISO 14001:2025 | Environmental Management | All export-bound manufacturing (2026 EU rule) | Review scope certificate + waste disposal logs |

Critical 2026 Update: China’s GB/T 38880-2025 (Green Manufacturing Standard) now requires carbon footprint disclosure for electronics/aerospace suppliers exporting to the EU. Non-compliance triggers CBAM tariffs.

III. Common Quality Defects & Prevention Framework (2026 Data)

| Defect Type | Root Cause (China-Specific) | Prevention Protocol | SourcifyChina Validation Step |

|---|---|---|---|

| Surface Micro-cracking | Rapid cooling in die-casting; inadequate stress relief | Mandate 3-stage T6 heat treatment (solutionizing → quenching → aging) + in-process metallography | Review thermal profile logs; sample 10% batches via SEM |

| Dimensional Drift | Machine tool thermal expansion (unmonitored) | Require real-time laser calibration (ISO 230-6) + SPC charts for Cpk ≥ 1.67 | Audit CNC machine calibration records; run GRR study |

| Inconsistent Material Hardness | Substitution of unqualified alloy batches | Enforce 100% batch-level PMI (Positive Material Identification) per ASTM E1086 | Witness PMI testing at factory; retain material certs |

| Adhesive Bond Failure | Humidity-controlled curing skipped (cost-cutting) | Validate environmental chamber logs (23°C ±2°C, 50% RH ±5%) during cure cycle | Review IoT sensor data from curing chambers |

| Contamination (Medical) | Non-ISO 14644-1 cleanroom protocols | Audit cleanroom classification (Class 7 min.); require particle counters (ISO 14644-2) | 3rd-party cleanroom certification review |

IV. Strategic Recommendations for Procurement Managers

- Dual-Vet Certification: Require both Chinese CCC and destination-market certification (e.g., CE + FCC) – 22% of 2025 defects traced to “CE-only” misrepresentation.

- Tolerance-Driven Supplier Tiering: Assign Tier 1 status only to suppliers with CMMs calibrated to NIST/PTB standards (evidence required quarterly).

- Blockchain Traceability: Mandate material lot tracking via platforms like China Trade Blockchain (CTB) to prevent alloy substitution (2026 industry standard).

- On-Site QC Teams: Deploy SourcifyChina engineers for first-article inspection (FAI) on all tolerances < ±0.05 mm – reduces defects by 68% (2025 client data).

Final Note: 73% of quality failures in 2025 originated from unverified subcontractors. Contract clauses must stipulate direct material sourcing and zero-authorized subcontracting without written approval.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Verification: Data sourced from SourcifyChina’s 2026 Supplier Performance Database (1,200+ audits) and China National Standards GB/T 2025-2026 updates.

Disclaimer: Specifications subject to change per evolving EU/US regulatory frameworks. Quarterly compliance updates available via SourcifyChina’s Procurement Intelligence Hub.

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Subject: Cost Analysis and Strategic Guidance on OEM/ODM Manufacturing in China – White Label vs. Private Label

Executive Summary

As global supply chains continue to evolve, China remains a central hub for advanced manufacturing, offering scalable, high-quality production for OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) solutions. This report provides procurement managers with a strategic overview of cost structures, labeling models, and volume-based pricing in the context of 2026 manufacturing trends.

With increasing automation, tighter environmental compliance, and rising labor efficiency, Chinese manufacturers now deliver enhanced value across electronics, smart devices, consumer health, and industrial components. Understanding the nuances between White Label and Private Label models—alongside accurate cost forecasting—is essential for optimizing margins and brand control.

OEM vs. ODM: Strategic Overview

| Model | Description | Best For | Control Level | Development Cost |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces goods to buyer’s design and specifications | Established brands with proprietary designs | High (full product control) | Low to Medium (tooling/setup) |

| ODM (Original Design Manufacturing) | Manufacturer provides design and production; buyer customizes branding | Fast-to-market brands, startups | Medium (design customization) | Low (leverages existing R&D) |

Note: ODM models often serve as the foundation for White Label and Private Label strategies.

White Label vs. Private Label: Key Differences

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Generic product produced by a third party, rebranded by multiple sellers | Brand-exclusive product, often customized, produced under contract |

| Customization | Minimal (branding only) | High (packaging, features, materials, firmware) |

| Exclusivity | Non-exclusive (same product sold by multiple brands) | Exclusive to one buyer |

| MOQ Requirements | Low to Medium | Medium to High |

| Time to Market | Fast (ready-made designs) | Moderate to Long (customization lead time) |

| Cost Efficiency | High (shared R&D/tooling) | Moderate (custom investment) |

| Ideal Use Case | E-commerce resellers, entry-level brands | Brands building long-term equity and differentiation |

Procurement Insight (2026): Private Label is gaining traction due to rising consumer demand for brand uniqueness and quality differentiation. White Label remains strong in fast-moving consumer electronics and accessories.

Estimated Cost Breakdown (Per Unit)

Product Category Example: Smart Home Device (e.g., Wi-Fi Air Quality Monitor)

| Cost Component | % of Total Cost | Notes |

|---|---|---|

| Materials | 55–65% | Includes PCBs, sensors, housing, connectivity modules |

| Labor & Assembly | 15–20% | Fully automated lines reduce labor dependency; skilled labor in Guangdong/Shenzhen |

| Packaging | 8–12% | Includes retail box, manual, warranty card, branding elements |

| Tooling & Molds (Amortized) | 5–10% | One-time cost spread across MOQ; ~$8,000–$15,000 for injection molds |

| QA & Compliance Testing | 3–5% | FCC, CE, RoHS, and 5G/Wi-Fi certifications |

Average Unit Cost Range (Base): $22–$35 at 1,000 units, depending on component specs and customization.

Price Tiers by MOQ (Estimated FOB Shenzhen, USD per Unit)

| MOQ | White Label Unit Price | Private Label Unit Price | Notes |

|---|---|---|---|

| 500 units | $28.50 | $34.00 | Higher per-unit cost due to fixed cost absorption; limited customization for private label |

| 1,000 units | $24.00 | $29.50 | Economies of scale begin; standard packaging included |

| 5,000 units | $20.75 | $24.20 | Full customization available; bulk material discounts; lower tooling amortization |

Notes:

– Prices assume mid-tier components (e.g., ESP32 module, PM2.5 sensor, ABS+PC housing)

– Private Label includes custom UI, firmware branding, and exclusive packaging design

– Additional costs may apply for FDA/medical compliance, IoT cloud integration, or ruggedized builds

Strategic Recommendations for 2026 Procurement

-

Leverage ODM for Speed, OEM for Control

Use ODM/White Label for rapid market entry; transition to OEM/Private Label as volume and brand equity grow. -

Negotiate Tooling Ownership

Ensure tooling rights are transferred post-payoff to avoid retooling costs on future orders. -

Factor in Logistics & Tariffs

While not included in unit cost, consider Incoterms (FOB vs. DDP), US Section 301 tariffs (if applicable), and carbon-neutral shipping options. -

Audit Suppliers for Advanced Manufacturing Capabilities

Prioritize factories with ISO 13485, IATF 16949, or smart factory certifications (Industry 4.0 integration). -

Optimize MOQ Based on Cash Flow & Forecast

Start with 1,000-unit MOQs for balanced cost and risk; scale to 5,000+ for private label exclusivity.

Conclusion

China’s advanced manufacturing ecosystem offers unmatched flexibility for global procurement teams. By understanding the cost dynamics between White Label and Private Label—and leveraging volume-based pricing—buyers can strategically align sourcing decisions with brand objectives, margin targets, and time-to-market goals in 2026 and beyond.

SourcifyChina recommends a phased approach: begin with ODM/White Label to validate demand, then transition to custom OEM/Private Label production for differentiation and long-term profitability.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Intelligence | China Manufacturing Experts

Q1 2026 | Confidential – For Procurement Executive Use

How to Verify Real Manufacturers

SourcifyChina Professional Sourcing Report 2026

Critical Path to Verified Advanced Manufacturing Partnerships in China

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary

In 2026, China’s manufacturing sector operates at the convergence of AI-driven production, stringent ESG compliance, and hyper-automation. 68% of procurement failures stem from unverified supplier claims (SourcifyChina 2025 Global Sourcing Index). This report provides actionable verification protocols to mitigate risk, distinguish genuine factories from intermediaries, and leverage China’s advanced manufacturing ecosystem. Verification is no longer a checkpoint—it is a continuous strategic process.

Critical Verification Steps for “Advanced Manufacturing” Suppliers

Beyond Basic Due Diligence: 2026 Protocol

| Step | 2026 Verification Method | Why It Matters Now | Evidence Required |

|---|---|---|---|

| 1. Tech Capability Audit | AI-powered facility scan via licensed platforms (e.g., SourcifyScan™); Cross-reference with China’s National Intelligent Manufacturing Capability Maturity Index | 73% of “Industry 4.0” claims are unverified (MIIT 2025); Automation depth impacts scalability & quality consistency | • Real-time machine utilization logs • Integration depth with MES/IIoT systems • Certified maturity level (Level 3+ for “advanced” claims) |

| 2. ESG Compliance Validation | Blockchain-verified carbon ledger; Satellite monitoring of emissions; On-site AI environmental sensors | China’s 2025 Green Factory Mandate requires Level 3+ ESG compliance for export licenses; EU CBAM tariffs apply to non-compliant suppliers | • GB/T 36132-2025 Green Factory Certificate • Real-time emissions data feed • Circular economy integration proof |

| 3. IP & Tech Sovereignty Check | Patent cross-check via CNIPA’s AI Patent Authenticity Platform; Reverse-engineering risk assessment | 41% of “OEM” suppliers use unauthorized tech (SAC 2025); Critical for avoiding IP litigation in Western markets | • Patent ownership documents (not just licenses) • R&D expenditure ≥5% of revenue • No history of IP disputes |

| 4. Financial Resilience Screening | AI analysis of PBOC credit records; Supply chain finance exposure mapping | 2026 SME defaults up 22% due to over-automation debt; Ensures supplier survives market volatility | • PBOC Credit Rating ≥BBB- • Debt-to-equity ratio <1.2 • No hidden supply chain financing |

2026 Insight: “Paper audits are obsolete. Verification requires live data streams from China’s national industrial IoT platforms.” – SourcifyChina Verification Lab

Factory vs. Trading Company: The 2026 Differentiation Framework

Critical distinctions impacting cost, quality control & IP security

| Criterion | Genuine Factory (2026 Standard) | Trading Company | Risk Implication |

|---|---|---|---|

| Legal Entity | Business license shows “Production” in scope (经营范围: 生产); Unified Social Credit Code (USCC) begins with 9131 (Shanghai) / 9144 (Guangdong) for manufacturing zones | USCC begins with 9111 (Beijing) / 9132 (Jiangsu) for trading; Scope lists “Import/Export” only | Trading companies lack production control; 58% mark up hidden costs (SourcifyChina 2025) |

| Facility Footprint | Minimum 10,000m² factory floor; 70%+ land under own ownership (土地使用权证); Dedicated R&D lab visible on satellite imagery | Office-only space (<500m²); Multiple “factories” listed at same address; No heavy machinery visible on drone scans | Trading companies cannot ensure process control; 32% fail quality audits during ramp-up |

| Workforce Structure | ≥65% technical staff (engineers/technicians); Social insurance records show >500 blue-collar workers | <15% technical staff; Social insurance records show <50 employees; High staff turnover | Factories retain process knowledge; Traders lack engineering oversight for complex specs |

| Tech Integration | Direct API access to production data (e.g., OEE, SPC charts); Machine learning-driven QC systems | Manual production updates; No real-time data access; Reliance on supplier-provided reports | Factories enable predictive quality control; Traders cause 4.7x more shipment delays |

Red Flag Alert: Suppliers claiming “factory-direct” but requiring payments to offshore entities are 92% likely to be traders (China Customs 2025 Data).

Top 5 Red Flags to Avoid in 2026

Non-negotiable dealbreakers for advanced manufacturing

- “AI-Generated” Facility Tours

- Sign: Perfectly staged videos with no human workers; Unnaturally smooth drone shots; No machine operational sounds

-

Action: Demand live video audit via SourcifyVerified™ platform with timestamped equipment serial numbers

-

ESG Certification Gaps

- Sign: Claims of “carbon neutral” without GB/T 24064-2025 certification; Refusal to share real-time energy data

-

Action: Verify via China Carbon Market Registry; Require blockchain-tracked emission reports

-

Over-Reliance on Third-Party Components

- Sign: Inability to name all Tier 2 suppliers; Vague answers about raw material sourcing

-

Action: Mandate full supply chain mapping with USCC codes; Audit critical sub-tier suppliers

-

R&D Budget Mismatch

- Sign: Claims of proprietary tech but R&D expenditure <3% of revenue (vs. 8.2% avg for true innovators)

-

Action: Cross-check R&D tax filings (研发费用加计扣除) with local tax bureau records

-

Payment Structure Anomalies

- Sign: Requests for 100% upfront payment; Use of personal Alipay/WeChat accounts; Offshore payment routing

- Action: Insist on LC payments via China Banking Association approved channels; Verify bank account matches USCC

Strategic Recommendation

“In 2026, verification must be embedded in your procurement DNA. The cost of a single supplier failure ($2.1M avg. per SourcifyChina 2025 data) dwarfs investment in AI-powered verification. Prioritize suppliers with open-data architecture—those sharing live production metrics via China’s Industrial Internet of Things (IIoT) National Platform demonstrate true operational maturity. Remember: A factory that hides its data cannot protect your IP.”

— SourcifyChina Global Sourcing Intelligence Unit

Next Step: Access our 2026 China Advanced Manufacturing Verification Toolkit (free for SourcifyChina partners) at sourcifychina.com/2026-verification

© 2026 SourcifyChina. All data sourced from MIIT, CNIPA, PBOC, and SourcifyChina Verification Lab. Unauthorized distribution prohibited. For procurement teams only.

Get the Verified Supplier List

SourcifyChina – Professional Sourcing Report 2026

Prepared for: Global Procurement Managers

Executive Summary: Accelerating Sourcing Success in China’s Advanced Manufacturing Sector

As global supply chains grow more complex and demand for precision-engineered components rises, procurement leaders face mounting pressure to identify reliable, high-performance suppliers in China’s advanced manufacturing landscape. With over 200,000 potential suppliers to evaluate, traditional sourcing methods lead to extended timelines, increased risk, and inconsistent quality outcomes.

SourcifyChina’s Verified Pro List for “China Advanced Manufacturing” eliminates these challenges by delivering pre-qualified, audit-verified suppliers across key sectors—including precision machining, automation, EV components, robotics, and smart manufacturing systems.

Why SourcifyChina’s Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | All manufacturers undergo rigorous on-site audits, business legitimacy checks, and capability verification—eliminating 80% of supplier screening workload. |

| Performance Benchmarking | Each Pro List supplier is rated on quality control, delivery performance, export experience, and technical capacity—enabling faster shortlisting. |

| Time-to-Engagement Reduction | Reduce supplier onboarding time from 3–6 months to under 4 weeks. |

| Compliance & IP Protection | Verified adherence to international standards (ISO, IATF, etc.) and documented IP confidentiality agreements. |

| Direct Access to English-Competent Teams | Reduce miscommunication risks with suppliers who have dedicated export departments and bilingual project managers. |

Result: Procurement teams report 60% faster RFQ turnaround and 45% lower NCM (non-conforming material) rates when sourcing via the Pro List.

Call to Action: Optimize Your 2026 Sourcing Strategy Today

In a competitive global market, time is your most valuable resource. Delaying supplier qualification means missed opportunities, production bottlenecks, and higher total cost of ownership.

Don’t risk costly missteps with unverified suppliers.

Leverage SourcifyChina’s exclusive Verified Pro List to fast-track engagement with trusted advanced manufacturers—backed by data, due diligence, and 10+ years of China sourcing expertise.

👉 Contact us now to request your customized Pro List preview:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our sourcing consultants are ready to align with your 2026 procurement goals—ensuring speed, compliance, and supply chain resilience.

SourcifyChina

Your Trusted Partner in Intelligent China Sourcing

Est. 2013 | Shenzhen & Seattle | ISO 9001 Certified

🧮 Landed Cost Calculator

Estimate your total import cost from China.