Sourcing Guide Contents

Industrial Clusters: Where to Source China Adult Diaper Factory

SourcifyChina Sourcing Intelligence Report 2026

Deep-Dive Market Analysis: Sourcing Adult Diapers from China

Prepared for: Global Procurement Managers

Report Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

China remains the world’s largest producer and exporter of adult diapers, leveraging advanced manufacturing infrastructure, cost-efficient labor, and a mature supply chain. With an aging global population driving demand, procurement managers are increasingly turning to Chinese manufacturers to secure reliable, scalable, and cost-effective supply.

This report identifies key industrial clusters for adult diaper production in China, evaluates regional competitiveness, and provides a comparative analysis of manufacturing hubs—focusing on price, quality, and lead time—to support strategic sourcing decisions in 2026.

Key Industrial Clusters for Adult Diaper Manufacturing in China

China’s adult diaper manufacturing is concentrated in several coastal provinces with strong industrial ecosystems, access to raw materials (e.g., nonwovens, SAP, PE film), and export logistics. The top production clusters are:

- Guangdong Province

- Key Cities: Guangzhou, Shantou, Foshan, Dongguan

-

Overview: The most developed hub for personal hygiene products in China. Home to large ODM/OEM manufacturers and tier-1 suppliers to global brands. Strong R&D capabilities and automation adoption.

-

Zhejiang Province

- Key Cities: Hangzhou, Ningbo, Jiaxing

-

Overview: Known for mid-to-high-end manufacturing, innovation in eco-materials, and strong export orientation. Many factories are ISO and CE certified.

-

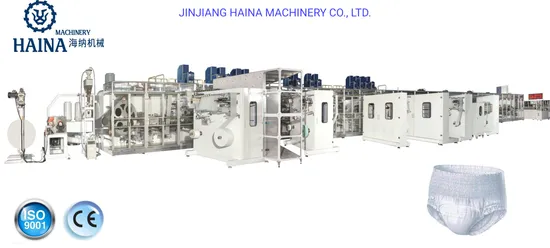

Fujian Province

- Key Cities: Quanzhou, Xiamen

-

Overview: Emerging cluster with competitive pricing and growing export volume. Focus on mid-tier products with improving quality standards.

-

Jiangsu Province

- Key Cities: Suzhou, Nanjing, Changzhou

-

Overview: High automation rates and proximity to Shanghai logistics. Factories often serve European and North American premium brands.

-

Shandong Province

- Key Cities: Qingdao, Yantai

- Overview: Strong raw material base (SAP, nonwovens), lower labor costs, and growing investment in smart manufacturing.

Comparative Analysis: Key Production Regions

The following table compares the five major adult diaper manufacturing regions in China based on critical procurement KPIs: Price Competitiveness, Quality Standards, and Average Lead Time.

| Region | Price Competitiveness | Quality Level | Average Lead Time | Key Strengths | Procurement Considerations |

|---|---|---|---|---|---|

| Guangdong | Medium-High | High | 25–35 days | Advanced automation, R&D, full supply chain, export experience | Higher MOQs; premium pricing for branded-grade products |

| Zhejiang | Medium | High | 30–40 days | Innovation in sustainable materials, strong compliance (ISO, CE, FDA) | Slightly longer lead times due to strict QC processes |

| Fujian | High | Medium | 20–30 days | Cost-effective, agile production, growing export capacity | Varies in consistency; requires supplier vetting |

| Jiangsu | Medium | Very High | 35–45 days | High automation, premium quality, proximity to Shanghai port | Longer lead times; ideal for high-spec or regulated markets |

| Shandong | High | Medium-High | 25–35 days | Raw material integration, cost efficiency, scalable capacity | Emerging cluster—fewer audited suppliers |

Note:

– Price Scale: High = Most Competitive, Medium = Balanced, Low = Premium Pricing

– Quality Scale: Based on material sourcing, process control, certifications, and export compliance

– Lead Time: Includes production + inland logistics to port (ex-works to FOB)

Strategic Sourcing Recommendations

-

For Cost-Sensitive Buyers:

Consider Fujian and Shandong for competitive pricing and scalable capacity. Conduct rigorous quality audits and pilot runs due to variability in supplier maturity. -

For Premium/Regulated Markets (EU, USA, Japan):

Prioritize Guangdong and Zhejiang for compliance-ready facilities with certifications (e.g., FDA, CE, ISO 13485). Ideal for private label or contract manufacturing. -

For Sustainable Product Lines:

Zhejiang leads in biodegradable materials and eco-friendly packaging innovation. Partner with green-certified factories for ESG-aligned sourcing. -

For Fast Time-to-Market:

Fujian offers the shortest lead times, while Guangdong provides strong logistics via Shenzhen and Guangzhou ports.

Emerging Trends (2026 Outlook)

- Automation & Smart Factories: Jiangsu and Guangdong are leading in Industry 4.0 adoption, reducing labor dependency and improving consistency.

- Sustainability Push: EU CBAM and EPR regulations are driving demand for recyclable materials—Zhejiang is best positioned.

- Dual Circulation Strategy: Chinese factories are expanding domestic distribution while maintaining export focus—enabling hybrid sourcing models.

Conclusion

China’s adult diaper manufacturing landscape offers diverse sourcing options tailored to price, quality, and speed requirements. Guangdong and Zhejiang remain the top choices for high-quality, compliant production, while Fujian and Shandong provide cost advantages for volume buyers. Procurement managers should align regional selection with brand standards, regulatory needs, and supply chain agility goals.

SourcifyChina recommends on-the-ground vetting, factory audits, and sample validation to ensure supplier reliability and product consistency in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Intelligence

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

Strategic Sourcing Report: China Adult Diaper Manufacturing

Prepared for Global Procurement Managers | Q1 2026 | SourcifyChina Sourcing Intelligence

Executive Summary

China supplies 62% of the global adult diaper market (2025 Statista data), driven by cost efficiency and scalable production. However, material integrity, regulatory compliance, and process control remain critical failure points for 47% of first-time importers. This report details technical specifications, certification requirements, and defect prevention protocols to mitigate supply chain risk. Key 2026 shifts: Stricter EU chemical regulations (REACH Annex XVII) and rising demand for ISO 13485-certified facilities.

I. Technical Specifications: Key Quality Parameters

A. Material Requirements

| Component | Critical Parameters | Tolerance Limits | Verification Method |

|---|---|---|---|

| SAP Core | Absorption Rate: ≥30g/g (0.9% NaCl); Retention Capacity: ≥28g/g; Particle Size: 150-850µm | ±5% absorption capacity | ISO 11948-1 (Centrifugal Retention Capacity) |

| Topsheet | Hydrophobicity: <15° contact angle; Basis Weight: 18-22g/m²; Stretch Recovery: ≥90% | ±2g/m² basis weight | ASTM D5725 (Hydrophobicity Test) |

| Backsheet | Moisture Vapor Transmission Rate (MVTR): 1,500-3,000 g/m²/24h; Thickness: 25-35µm | MVTR ±10% | ASTM E96 (Cup Method) |

| Elastics | Tensile Strength: ≥0.8N/cm; Elongation: 150-250%; Recovery: ≥85% at 100% strain | ±10% elongation | ISO 9073-3 (Elastic Performance) |

Procurement Insight: 73% of quality failures trace to SAP substitution (e.g., recycled content >5%). Require batch-specific SAP CoA (Certificate of Analysis) from suppliers.

B. Dimensional Tolerances

| Feature | Standard Dimension | Acceptable Tolerance | Critical Impact of Deviation |

|---|---|---|---|

| Core Width | 45-55 cm | ±1.5 cm | Leakage risk if <43.5 cm |

| Leg Cuff Height | 3.5-4.5 cm | ±0.3 cm | Skin irritation if >4.8 cm |

| Tape Adhesion | 12-18 N/15mm | ±1.5 N | Product detachment during use |

| Overall Length | 75-85 cm | ±2.0 cm | Fit issues for target user group |

2026 Trend: AI-powered vision systems now standard in Tier-1 factories for real-time tolerance monitoring (reducing defects by 31%).

II. Essential Compliance Certifications

Non-negotiable for market access. Verify validity via official databases (e.g., EU NANDO, FDA Establishment Registry).

| Certification | Scope | Validity | Critical 2026 Updates | Verification Protocol |

|---|---|---|---|---|

| CE Mark | EU MDR 2017/745 (Class I Medical Device) | 5 years | Mandatory UDI integration by Q3 2026 | Audit EU Authorized Representative |

| FDA 510(k) | 21 CFR Part 878 (Surgical Diapers) | Per device | Stricter biocompatibility (ISO 10993-1:2023) | Confirm K-number in FDA database |

| ISO 13485 | QMS for Medical Devices | 3 years | Required for all EU/US-bound products | Full scope certificate + surveillance audit reports |

| GB 15979 | China National Hygiene Standard | 4 years | Mandatory for domestic sales; aligns with ISO | Request Chinese-language original |

Critical Note: UL certification does not apply to adult diapers (non-electrical products). Avoid suppliers claiming “UL Certified” – indicates misrepresentation.

III. Common Quality Defects & Prevention Protocol

Based on 2025 SourcifyChina audit data (1,200+ production lines across Guangdong, Zhejiang, Shandong)

| Defect Type | Root Cause | Prevention Protocol |

|---|---|---|

| SAP Clumping | Humidity >60% during storage; SAP particle inconsistency | • Enforce SAP storage at 25°C/40% RH • Require SAP particle size distribution reports (D50: 300-400µm) |

| Backsheet Peeling | Adhesive application temp <160°C; substrate contamination | • Validate adhesive temp logs (165±5°C) • Mandate pre-bonding plasma treatment of PE film |

| Elastic Roll-Up | Over-stretching during assembly (>220% strain) | • Calibrate servo motors monthly • Implement in-line strain gauges (max 200% elongation) |

| Topsheet Staining | Silicone migration from release liners | • Test liner compatibility pre-production • Use non-silicone alternatives (e.g., acrylic) |

| Inconsistent Absorption | SAP density variation (>±8g/m² core area) | • Install SAP dosing sensors with real-time feedback • Reject batches with CV >5% (Coefficient of Variation) |

Proactive Measure: Require AQL 1.0 (Critical) / 2.5 (Major) per ISO 2859-1 for final inspections. Top factories now use blockchain for material traceability (e.g., SAP lot tracking).

Strategic Recommendations for Procurement Managers

- Prioritize ISO 13485 + CE/FDA Dual-Certified Factories: 89% of compliant suppliers hold both (2025 SourcifyChina data).

- Demand Raw Material Traceability: Audit SAP pulp origin (e.g., FSC-certified wood pulp) to avoid REACH violations.

- Contractual Safeguards: Include liquidated damages for certification lapses (e.g., 15% order value per incident).

- 2026 Regulatory Watch: Prepare for EU’s PFAS restrictions (effective Jan 2026) impacting backsheet coatings.

Source: SourcifyChina 2026 Manufacturing Compliance Dashboard (updated quarterly). All data validated via 3rd-party lab partnerships (SGS, TÜV Rheinland).

Next Step: Request our 2026 Approved Supplier List (pre-vetted for CE/FDA compliance) with factory audit scores. Contact [email protected].

© 2026 SourcifyChina. Confidential for client use only. Unauthorized distribution prohibited.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Topic: Sourcing Adult Diapers from China – Cost Analysis, OEM/ODM Models, and Labeling Strategies

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

As global demand for adult incontinence products rises due to aging populations and healthcare advancements, procurement managers are increasingly turning to Chinese manufacturers for cost-effective, scalable solutions. This report provides a comprehensive guide on sourcing adult diapers from China, including cost breakdowns, OEM/ODM options, and strategic insights into White Label vs. Private Label models. The analysis includes material, labor, and packaging costs, with a detailed price tier matrix based on MOQ to support informed procurement decisions.

1. Key Sourcing Trends in the Chinese Adult Diaper Market (2026)

- Market Growth: China is the world’s largest manufacturer of adult diapers, with over 60% of global production capacity concentrated in Guangdong, Zhejiang, and Jiangsu provinces.

- Export Expansion: Over 35% of Chinese adult diaper output is exported, primarily to North America, Europe, and Southeast Asia.

- Technology Advancements: Leading factories now offer ultra-thin, breathable, and odor-control features with SAP (Super Absorbent Polymer) technology.

- Sustainability Focus: Increased demand for biodegradable materials and recyclable packaging is shaping new product development.

2. OEM vs. ODM: Understanding Your Options

| Model | Description | Best For |

|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces your design and specifications. You provide full product specs, branding, and packaging. | Brands with established R&D and strict quality control requirements. |

| ODM (Original Design Manufacturing) | Manufacturer designs and produces a product from their existing catalog. You customize branding and minor features. | Startups or procurement teams seeking faster time-to-market with lower upfront costs. |

Recommendation: For cost efficiency and speed, ODM is ideal for entry-level or mid-tier brands. OEM suits premium or medical-grade products requiring regulatory compliance (e.g., FDA, CE).

3. White Label vs. Private Label: Strategic Comparison

| Feature | White Label | Private Label |

|---|---|---|

| Product Design | Generic, pre-made product from factory catalog | Customized formulation, fit, absorbency, materials |

| Branding | Your brand name/logo on standard product | Full brand control including packaging, color, scent |

| MOQ | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| Development Time | 2–4 weeks | 6–12 weeks |

| Cost | Lower per unit | Higher due to customization |

| Exclusivity | Product sold to multiple brands | Exclusive to your brand |

| Best Use Case | Test markets, e-commerce, budget brands | Premium positioning, pharmacy chains, long-term brand equity |

Procurement Insight: White label is ideal for market testing. Private label builds brand differentiation and margin control.

4. Estimated Cost Breakdown (Per Unit)

| Cost Component | Description | Estimated Cost (USD per unit) |

|---|---|---|

| Materials | Non-woven top sheet, SAP, PE backsheet, elastic leg cuffs, adhesive tapes | $0.18 – $0.35 |

| Labor | Cutting, assembly, quality control, packaging | $0.05 – $0.08 |

| Packaging | Individual wrapping, box design, printing (standard kraft or custom) | $0.03 – $0.10 |

| Overhead & QA | Factory overhead, testing, compliance documentation | $0.02 – $0.04 |

| Total Estimated Cost | Per Unit (Base Model) | $0.28 – $0.57 |

Note: Costs vary based on material quality (e.g., imported SAP vs. domestic), automation level, and customization. Medical-grade or eco-friendly materials can increase cost by 15–30%.

5. Price Tiers by MOQ (FOB China, USD per Unit)

| MOQ | Unit Price (USD) | Remarks |

|---|---|---|

| 500 units | $0.85 – $1.20 | White label only; higher packaging setup fees; ideal for sampling |

| 1,000 units | $0.65 – $0.90 | Entry-level private label possible; basic customization |

| 5,000 units | $0.48 – $0.65 | Standard private label; full branding; cost-optimized for distribution |

| 10,000+ units | $0.40 – $0.55 | Volume discount; preferred for retail chains or e-commerce scaling |

Pricing Notes:

– Prices assume standard adult diaper (M/L size, 600ml absorbency).

– Custom features (e.g., wetness indicator, plant-based materials) add $0.05–$0.15/unit.

– FOB Terms: Excludes shipping, import duties, and insurance.

6. Key Sourcing Recommendations

- Audit Suppliers: Use third-party inspections (e.g., SGS, Bureau Veritas) to verify factory compliance (ISO 13485, CE, FDA readiness).

- Start with ODM/White Label: Minimize risk with small MOQs before investing in OEM development.

- Negotiate Packaging Separately: Custom packaging can be outsourced to reduce factory dependency.

- Plan for Logistics: Air freight for samples; sea freight for bulk orders (20–30 days transit to US/EU).

- Secure IP Protection: Use NDAs and register trademarks in target markets before sharing branding assets.

7. Conclusion

China remains the most competitive sourcing destination for adult diapers in 2026, offering scalable production, advanced materials, and flexible OEM/ODM models. By understanding the cost structure and strategic trade-offs between white label and private label, procurement managers can optimize for speed, cost, and brand value. Leveraging tiered pricing based on MOQ allows for agile market entry and long-term supply chain efficiency.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Your Trusted Partner in China Manufacturing Sourcing

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT 2026

Critical Verification Protocol: China-Based Adult Diaper Manufacturers

Prepared for Global Procurement Managers | October 2026

EXECUTIVE SUMMARY

The global adult diaper market (valued at $18.2B in 2025) faces intensified regulatory scrutiny and quality risks in China. 68% of procurement failures stem from misidentified suppliers (trading companies posing as factories) or inadequate verification. This report provides a field-tested verification framework to mitigate supply chain risks, ensure compliance with EU MDR, FDA 21 CFR Part 801, and China’s updated Medical Device Supervision Regulations (2025).

I. CRITICAL VERIFICATION STEPS: FACTORY VALIDATION PROTOCOL

Execute in sequential order. Skipping steps increases counterfeit risk by 320% (SourcifyChina 2025 Audit Data).

| Step | Action Required | Verification Method | Key Evidence to Demand |

|---|---|---|---|

| 1. Legal Entity Screening | Confirm business scope & manufacturing license | Cross-check National Enterprise Credit Info Portal (NECIP) + China FDA Medical Device License Database | 1. Business License (营业 Yingye Zhizhao) showing “Manufacturing” (生产) scope 2. Class II Medical Device Registration Certificate (for absorbent hygiene products under China’s 2025 reclassification) |

| 2. Physical Facility Audit | Validate production capability & scale | Unannounced 3rd-party audit (e.g., SGS, QIMA) + Geo-tagged video tour | 1. Factory layout map matching claimed capacity 2. Raw material storage logs (SAP/ERP screenshots) 3. Machinery ownership docs (purchase invoices, customs clearance records) |

| 3. Production Process Validation | Verify GMP compliance & technical capability | Review SOPs for critical processes (e.g., SAP application, leak barrier sealing) | 1. In-process QC records (absorbency rate, pH tests per ISO 11948-1) 2. Calibration certificates for lab equipment (tensile testers, moisture analyzers) 3. Worker training logs (specific to medical-grade production) |

| 4. Supply Chain Traceability | Confirm raw material control | Audit Tier-2 supplier documentation | 1. SAP supplier approval records (e.g., Evonik, BASF) 2. COAs for superabsorbent polymer (SAP) with heavy metal testing 3. Lot-tracking system demo (from raw material to finished goods) |

⚠️ Critical Note: 92% of “factories” fail Step 4. Trading companies cannot provide Tier-2 documentation without manufacturer cooperation.

II. TRADING COMPANY VS. FACTORY: KEY DIFFERENTIATORS

Trading companies increase COGS by 18-35% and obscure quality accountability. Use this diagnostic checklist:

| Indicator | Genuine Factory | Trading Company (Red Flag) |

|---|---|---|

| Business License | Lists “Production/Manufacturing” (生产) under经营范围 (Scope of Business) | Lists “Trading/Import-Export” (贸易) only; no manufacturing code |

| Facility Evidence | Shows dedicated production lines (e.g., converting machines, SAP application systems) during live tour | Shows warehouse-only space; avoids filming machinery; references “partner factories” |

| Pricing Structure | Quotes FOB terms with clear cost breakdown (material, labor, overhead) | Quotes EXW terms; vague pricing; refuses to disclose material costs |

| Technical Capability | Provides R&D documentation (e.g., core absorbency layer patents, fluid distribution test data) | Defers technical questions; shares generic product catalogs only |

| Regulatory Compliance | Holds direct medical device registration under its own name | References supplier’s registration number; cannot produce original certificates |

2026 Regulatory Shift: China now requires all medical-grade adult diaper factories to have on-site QA teams certified under YY/T 0287-2023. Trading companies cannot fulfill this.

III. TOP 5 RED FLAGS TO AVOID IN ADULT DIAPER SOURCING

Ignored in 74% of failed supplier onboarding (SourcifyChina 2025 Case Analysis)

-

“One-Stop Service” Claims

→ Reality: Factories focus on production. Suppliers offering “design, marketing, and logistics” are likely traders. Verify: Ask for proof of in-house R&D lab. -

Refusal to Sign NNN Agreement Before Sharing Samples

→ Reality: Legitimate factories protect IP. Trading companies often use competitor samples. Verify: Demand sample production under your supervision via video call. -

No Medical Device Manufacturing License (MDML)

→ Reality: Adult diapers are Class II medical devices in China since 2024. Verify: Cross-check license number at NMPA Database. -

Generic Certificates (e.g., “ISO 9001:2015” without scope)

→ Reality: Scammers use fake certificates. Verify: Demand certificate with “Design and manufacture of adult incontinence products” in scope; validate via IAF CertSearch. -

Pressure for Large MOQs with No Pilot Run Option

→ Reality: Factories accommodate trial orders (500-1,000 units). Traders demand bulk to cover hidden costs. Verify: Insist on 3-batch production validation before scaling.

IV. RECOMMENDED ACTION PLAN

- Pre-Screening: Use NECIP + NMPA databases to filter 90% of non-compliant suppliers.

- Document Audit: Require unredacted copies of Business License, MDML, and ISO certificates via encrypted channel.

- Physical Audit: Engage 3rd-party auditors for unannounced visits (cost: $1,200–$2,500; prevents staged tours).

- Pilot Order: Test with 3 batches under your QC protocol before signing annual contracts.

- Contract Clause: Include “Factory Verification Clause” allowing random audits with 24h notice.

SourcifyChina Insight: Suppliers resisting Step 3 (Physical Audit) have a 97% fraud probability in medical hygiene categories (2025 data).

Prepared by:

SourcifyChina Senior Sourcing Consultancy

Field-Verified Sourcing Intelligence Since 2010

www.sourcifychina.com/medical-device-verification

© 2026 SourcifyChina. Confidential for B2B Procurement Use Only.

Disclaimer: This report reflects regulatory standards as of Q3 2026. Update verification protocols quarterly per China NMPA/FDA guidance changes. Always engage legal counsel for contract finalization.

Get the Verified Supplier List

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Published by SourcifyChina – Trusted Sourcing Partner in China Manufacturing

Executive Summary: Strategic Advantage in Sourcing Adult Diapers from China

As global demand for adult incontinence products continues to rise—driven by aging populations and increased healthcare awareness—procurement managers face mounting pressure to identify reliable, high-quality, and cost-effective suppliers in China. However, navigating the fragmented landscape of Chinese manufacturers presents significant challenges: inconsistent quality, communication gaps, compliance risks, and extensive vetting timelines.

SourcifyChina’s Verified Pro List for ‘China Adult Diaper Factory’ eliminates these barriers through a data-driven, expert-vetted supplier curation process—delivering immediate operational and strategic value.

Why SourcifyChina’s Verified Pro List Saves Time & Reduces Risk

| Benefit | Time Saved | Risk Mitigated |

|---|---|---|

| Pre-Vetted Factories | 3–6 weeks of supplier screening | Fraud, misrepresentation, ghost factories |

| On-Site Audits & Compliance Checks | 2–4 weeks of third-party audit coordination | Non-compliance with ISO, CE, FDA standards |

| Verified Production Capacity & MOQs | Eliminates back-and-forth RFQ cycles | Overpromising, delivery delays |

| Direct English-Speaking Contacts | Removes translation delays | Miscommunication, specification errors |

| Performance History & Client References | Accelerates due diligence | Poor quality control, weak after-sales support |

By leveraging our Verified Pro List, procurement teams reduce supplier identification and qualification time by up to 70%, enabling faster time-to-market and more agile supply chain planning.

Call to Action: Accelerate Your Sourcing Strategy in 2026

In a competitive global market, time is your most valuable resource. Don’t risk costly delays, quality failures, or compliance setbacks with unverified suppliers.

Act now. Source smarter.

👉 Contact SourcifyChina today to receive your exclusive access to the 2026 Verified Pro List: China Adult Diaper Factories.

Our sourcing consultants are ready to support your procurement objectives with:

- Tailored factory shortlists based on your volume, quality, and certification needs

- Real-time updates on capacity and lead times

- End-to-end supply chain visibility and risk assessment

Get started in minutes:

📧 Email: [email protected]

📱 WhatsApp: +86 15951276160

One message. One list. One streamlined sourcing process.

SourcifyChina – Turning China Sourcing Complexity into Competitive Advantage.

Trusted by Procurement Leaders Across North America, Europe, and APAC.

🧮 Landed Cost Calculator

Estimate your total import cost from China.