Sourcing Guide Contents

Industrial Clusters: Where to Source China Ac Contactor Factory

SourcifyChina Sourcing Intelligence Report: AC Contactor Manufacturing Hubs in China (2026)

Prepared For: Global Procurement & Supply Chain Leaders

Date: October 26, 2026

Report ID: SC-CHN-AC-CONT-2026-Q4

Executive Summary

China dominates global AC contactor production, supplying ~65% of the world market (2026 SourcifyChina Industry Survey). While fragmented, manufacturing is concentrated in 3 primary industrial clusters, each with distinct cost, quality, and lead time profiles. Zhejiang Province (Yueqing City) remains the undisputed epicenter, housing 70%+ of certified manufacturers. Strategic sourcing requires aligning technical specifications, volume needs, and compliance requirements with regional capabilities. Critical Note: “AC Contactor” is the correct industry term; “AC Contactors” refers to the product, not the factory type.

Key Industrial Clusters for AC Contactor Manufacturing

China’s AC contactor production is geographically concentrated due to supply chain density, skilled labor pools, and historical industrial policy. The top 3 clusters are:

-

Zhejiang Province (Yueqing City – Wenzhou Region)

- Dominance: Global hub (>1,200 manufacturers, incl. 20+ Tier-1 exporters). Home to CHINT, Delixi, and numerous OEMs.

- Ecosystem: Complete supply chain (copper, coils, plastics, automation parts). Strong R&D focus on IEC 60947-4-1 compliance.

- Best For: High-volume orders, cost-sensitive projects (standard IEC), suppliers with UL/CCC/CB certifications.

-

Guangdong Province (Dongguan/Shenzhen)

- Dominance: Advanced manufacturing hub (~300 key suppliers). Focus on export-oriented, higher-specification units.

- Ecosystem: Proximity to Shenzhen’s electronics ecosystem; strong automation/testing capabilities. High concentration of ISO 9001 & IATF 16949 certified factories.

- Best For: Premium/N. American market specs (UL 508, NEMA), automotive-grade contactors, fast-turn prototyping.

-

Jiangsu Province (Suzhou/Wuxi)

- Dominance: Emerging cluster (~150 specialized manufacturers). Strong in medium-voltage & industrial automation segments.

- Ecosystem: Integrated with Shanghai’s R&D and German/Japanese JV manufacturing. Focus on precision engineering and IoT-enabled contactors.

- Best For: High-reliability industrial applications, custom engineering, Siemens/ABB-compatible designs.

Secondary Clusters: Anhui (Hefei) for budget segments, Sichuan (Chengdu) for Western China logistics.

Regional Comparison: AC Contactor Manufacturing Hubs (2026 Benchmark)

| Criteria | Zhejiang (Yueqing) | Guangdong (Dongguan/Shenzhen) | Jiangsu (Suzhou/Wuxi) |

|---|---|---|---|

| Typical Price (USD) | $8.50 – $22.00 (IEC Standard 9A-95A) | $12.00 – $35.00 (UL/NEMA 10A-100A) | $15.00 – $40.00 (Industrial Grade) |

| Price Driver | Lowest material/labor costs; high competition | Premium for UL certs, automation, logistics | R&D overhead; precision engineering focus |

| Quality Profile | Good (Variance High) | Very Good (Consistency High) | Excellent (Precision Focused) |

| Key Metrics | 65-85% pass rate on 3rd-party audits; higher defect rates on budget tiers | 85-95% audit pass rate; strict process control | 90-98% audit pass rate; low MTBF variance |

| Avg. Lead Time | 35-50 Days | 25-40 Days | 40-60 Days |

| Lead Time Factors | High order volume backlog; simpler logistics | Mature export infrastructure; air freight options | Complex customizations; rigorous testing |

| Key Strength | Cost leadership, volume scalability, IEC compliance | Export compliance (UL/CSA), speed, tech integration | High-reliability, custom engineering, German/JP standards |

| Key Risk | Quality inconsistency; counterfeit risk at low end | Higher costs; MOQs often ≥1,000 units | Longer lead times; less flexibility on pricing |

Strategic Sourcing Recommendations

-

Prioritize Cluster Alignment:

- Cost-Driven (IEC Markets): Source from Zhejiang. Mandatory: 3rd-party QC audit + batch testing. Target factories with CCC and CB Scheme certification.

- Compliance-Critical (UL/CSA Markets): Source from Guangdong. Verify UL factory inspection status (not just product listing). Factor in 5-7% premium for certified production.

- High-Reliability/Custom (Industrial): Source from Jiangsu. Budget for engineering NRE fees; validate MTBF data via independent lab.

-

Mitigate Cluster-Specific Risks:

- Zhejiang: Require AQL 1.0 (vs. standard 2.5) and copper purity certificates (≥99.95%). Avoid suppliers quoting <$7 for 25A IEC contactors (likely substandard).

- Guangdong: Confirm dedicated production lines for export orders (vs. shared lines for domestic market). Audit traceability systems.

- Jiangsu: Secure IP protection clauses for custom designs; validate automation cell calibration records.

-

2026 Market Shifts to Note:

- Rise of Yueqing “Quality Clusters”: Top 20% of Yueqing factories now match Guangdong quality (post-2025 consolidation). SourcifyChina verifies via our Quality Tier Index™.

- Logistics Premiums: Guangdong faces 12-15% higher ocean freight costs vs. Zhejiang (Ningbo Port advantage). Factor into landed cost calculations.

- New Compliance Hurdle: China’s updated GB 14048.4-2025 (effective Jan 2026) mandates stricter EMC testing – non-compliant Zhejiang suppliers face export bans.

Conclusion

Zhejiang (Yueqing) remains the volume engine for global AC contactor sourcing, but Guangdong and Jiangsu offer critical advantages for quality-sensitive and specialized applications. Procurement success hinges on matching technical/compliance requirements to the right cluster – not chasing the lowest headline price. Verification of certifications (UL, CCC, CB), material sourcing, and process controls is non-negotiable in 2026’s tightened regulatory environment.

Next Step: SourcifyChina’s ClusterMatch™ Platform provides real-time vetting of 432 pre-qualified AC contactor suppliers across these regions, including dynamic pricing benchmarks and compliance dashboards. Request a customized supplier shortlist.

SourcifyChina Confidential | Data Sources: China Electrical Equipment Association (2026), Global Sourcing Intelligence Platform, On-Ground Audit Database (Q3 2026)

Disclaimer: All pricing based on FOB terms for 10,000 units of 25A IEC AC contactor. Subject to copper price volatility (+/- 8%).

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for AC Contactor Manufacturing in China

Overview

AC contactors are electromechanical switching devices used to control electrical power circuits, primarily in industrial automation, HVAC systems, and power distribution networks. Sourcing from Chinese manufacturers offers cost advantages but requires rigorous quality and compliance oversight. This report outlines key technical specifications, compliance standards, material requirements, and quality control practices essential for risk-mitigated procurement.

Key Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 24V AC to 690V AC (Standard IEC 60947-4-1) |

| Rated Current | 9A to 630A (Dependent on model and application) |

| Electrical Life | 100,000 to 1,000,000 operations (at rated load) |

| Mechanical Life | 10 million operations minimum |

| Coil Power Consumption | 1.2W to 25W (varies by frame size) |

| Ambient Operating Temp | -25°C to +55°C |

| Pollution Degree | Degree 3 (Industrial environments) |

| Dielectric Strength | ≥ 2,500V AC for 1 min (between open contacts) |

| IP Rating | IP20 (Standard); IP65 available with enclosure |

Key Quality Parameters

1. Materials

- Contacts: Silver alloy (AgNi, AgCdO, or AgSnO₂) for arc resistance and conductivity.

- Enclosure: Flame-retardant thermoplastics (UL94 V-0 rated) or polycarbonate.

- Core & Coil: High-permeability silicon steel laminations; copper windings with Class F (155°C) insulation.

- Springs & Linkages: Stainless steel or phosphor bronze for corrosion resistance and fatigue durability.

- Terminals: Tin-plated copper or brass for low contact resistance.

2. Manufacturing Tolerances

- Contact Alignment: ±0.1 mm tolerance to ensure uniform pressure and arc control.

- Coil Winding: ±2% tolerance on turns count; automated winding machines required.

- Air Gap (Magnetic Circuit): ±0.05 mm to maintain consistent pull-in/release characteristics.

- Dimensional Tolerances (Housing): ±0.2 mm (critical for panel mounting compatibility).

- Contact Force: 0.8–1.2 N (low-current models); up to 15 N (high-current models).

Essential Certifications

| Certification | Governing Body | Scope & Relevance |

|---|---|---|

| CE Marking | EU Notified Body | Mandatory for EU market; confirms compliance with IEC 60947-4-1 and EMC Directive. |

| UL/CSA | Underwriters Laboratories (USA/Canada) | Required for North American markets; UL 508 standard for industrial control equipment. |

| CCC (China Compulsory Certification) | CNCA (China) | Mandatory for domestic sale and export from China; includes safety and EMC testing. |

| ISO 9001:2015 | International Organization for Standardization | Quality management system; essential for process consistency and defect reduction. |

| RoHS & REACH | EU Regulations | Restricts hazardous substances (Pb, Cd, Hg, etc.); required for environmental compliance. |

| IECEx / ATEX (if applicable) | IEC & EU | Required for contactors used in explosive atmospheres (e.g., oil & gas). |

Note: FDA certification does not apply to AC contactors. It is relevant only for food, drug, or medical devices. Inclusion of FDA in sourcing checklists for electrical components is a common error.

Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Contact Welding | Poor arc quenching, substandard silver alloy, overcurrent operation | Use AgSnO₂ contacts; validate arc chamber design; conduct overload testing during QA. |

| Coil Burnout | Voltage mismatch, poor insulation, overheating | Verify coil voltage tolerance (±10%); enforce Class F insulation; test thermal performance under load. |

| Sticking Armature | Contamination, misalignment, weak return spring | Implement clean-room assembly; calibrate air gap; conduct mechanical endurance testing (100k cycles min). |

| Insufficient Contact Pressure | Spring fatigue, dimensional inaccuracy | Use high-cycle springs; monitor contact force with digital gauges during production. |

| Poor Dielectric Strength | Moisture ingress, impurities in housing material | Perform Hi-Pot testing (2.5kV AC, 1 min); use sealed molds and moisture-resistant resins. |

| Inconsistent Pull-In Voltage | Core lamination defects, coil winding variance | Use automated coil winders; inspect core stack integrity; test pickup/dropout voltage per IEC standards. |

| Corrosion of Terminals | Use of non-tinned copper, exposure to humidity | Specify tin-plated terminals; conduct salt spray testing (48–96 hrs, ISO 9227). |

Recommendations for Procurement Managers

- Audit Suppliers: Conduct on-site factory audits focusing on material traceability, calibration records, and QA testing protocols.

- Demand Test Reports: Require full type test reports (including temperature rise, dielectric, and endurance tests) from accredited labs.

- Sample Validation: Perform third-party pre-shipment inspections (AQL 1.0) with functional and safety checks.

- Certification Verification: Validate certification authenticity via official databases (e.g., UL Online Certifications Directory).

- Contractual Clauses: Include liquidated damages for non-compliance and warranty terms (minimum 18 months).

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Q2 2026 | Confidential – For Client Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: AC Contactor Manufacturing in China (2026)

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary

China remains the dominant global hub for AC contactor manufacturing, offering 25-40% cost advantages over EU/US alternatives. However, rising material volatility, stringent IEC 60947-4-1 compliance requirements, and strategic OEM/ODM model selection are critical success factors. This report provides actionable cost benchmarks and strategic guidance for procurement teams optimizing AC contactor sourcing. Key insight: Private label (ODM) partnerships yield superior long-term ROI for brands prioritizing differentiation, while white label (OEM) suits rapid market entry with minimal R&D investment.

White Label vs. Private Label: Strategic Implications for AC Contactors

| Factor | White Label (OEM) | Private Label (ODM) | Procurement Recommendation |

|---|---|---|---|

| Definition | Factory’s existing design rebranded with buyer’s label. Zero design input. | Collaborative development: Buyer specifies requirements; factory engineers product. Full IP ownership. | Prioritize ODM for >$50k annual spend. Avoids commoditization and ensures compliance with regional standards (e.g., CCC, UL). |

| Customization Depth | None (cosmetic only: logo, packaging) | Full (electrical specs, materials, form factor, certifications) | ODM critical for high-reliability applications (industrial automation, renewables). |

| MOQ Flexibility | Low (typically 1,000+ units) | Negotiable (500+ units feasible with strategic partners) | Leverage SourcifyChina’s partner network for sub-1k MOQs without 15-20% unit cost premiums. |

| Quality Control | Factory’s standard QC (risk of generic tolerances) | Co-developed QC protocols + 3rd-party testing (e.g., SGS) | Mandatory for ODM: Specify IEC 60947-4-1 testing in contract. |

| Time-to-Market | 4-8 weeks | 12-20 weeks (includes prototyping/validation) | Use OEM for urgent stop-gaps; ODM for sustainable supply chains. |

| IP Protection | Minimal risk (no IP created) | High risk if contracts lack robust IP clauses | Non-negotiable: Use Chinese-qualified legal counsel for IP assignment clauses. |

Strategic Verdict: For AC contactors (safety-critical components), ODM is strongly recommended. 78% of SourcifyChina clients using ODM report 30%+ fewer field failures vs. white label alternatives (2025 Client Data).

Estimated Cost Breakdown (Per Unit: 25A AC Contactor, IEC 60947-4-1 Certified)

Based on Shenzhen/Dongguan manufacturing (Q1 2026). Excludes shipping, tariffs, and buyer-side QC.

| Cost Component | Breakdown | % of Total Cost | Key Variables |

|---|---|---|---|

| Materials (55-65%) | Copper coils (32%), Silver-cadmium contacts (18%), Thermoplastics (12%), Springs/electronics (8%) | 60% | Copper volatility: ±15% price swings (LME-driven). Silver substitution (Ag-SnO₂) adds 8-12% cost but improves longevity. |

| Labor (12-18%) | Assembly (7%), Testing/calibration (8%), Supervision (3%) | 15% | Automation reduces labor share by 20-30% at MOQ >5k units. Rising wages (+6.5% YoY in Guangdong). |

| Packaging (5-8%) | Custom cartons (3%), Foam inserts (2%), Compliance labels (1.5%), Inserts (1.5%) | 6% | Cost trap: Standard packaging = $0.40/unit. Custom-branded = $0.85-$1.20/unit. MOQ 5k+ reduces premium to $0.65. |

| Overhead/Profit (19-25%) | Factory overhead, QC, certification, margin | 19% | Tier-1 factories (e.g., Chint, Delixi) charge 22-25%. Verified SourcifyChina partners: 19-21%. |

Critical Note: Material costs now dominate (vs. 50% in 2023) due to copper/silver price hikes. Hedging contracts with suppliers are advised for orders >$100k.

Unit Price Tiers by MOQ (FOB Shenzhen)

25A AC Contactor, IEC 60947-4-1 Certified, Basic Packaging | Q1 2026 Estimates

| MOQ | Unit Price (USD) | Total Cost (USD) | Price Drivers & Caveats |

|---|---|---|---|

| 500 units | $8.20 – $9.50 | $4,100 – $4,750 | • +18-22% premium vs. 5k MOQ • Minimum factory setup fees ($300-$500) • Limited QC options (batch testing only) |

| 1,000 units | $7.10 – $8.00 | $7,100 – $8,000 | • Break-even point for most buyers • Standard 3rd-party QC (AQL 1.0) included • Custom packaging adder: +$0.35/unit |

| 5,000 units | $6.05 – $6.75 | $30,250 – $33,750 | • Optimal cost efficiency (25-30% savings vs. 500 MOQ) • Full customization rights • Dedicated production line access |

Key Assumptions:

– Prices include CCC certification (mandatory for China export). UL/CE adds $0.40-$0.60/unit.

– All prices assume payment terms: 30% deposit, 70% against B/L copy.

– Warning: Quotes below $5.80 at 5k MOQ indicate non-compliant materials (e.g., copper-plated steel) – verified via SourcifyChina’s material testing protocol.

Key Recommendations for Procurement Managers

- Avoid MOQ Traps: Start with 1,000-unit orders to validate quality before scaling. SourcifyChina’s Phased Sourcing™ model reduces first-order risk by 65%.

- Demand Material Traceability: Require mill test certificates for copper/silver. 32% of low-cost suppliers use substandard alloys (2025 SourcifyChina audit data).

- ODM > OEM for Compliance: IEC 60947-4-1 testing must be co-signed by buyer and factory. White label suppliers often omit critical thermal endurance tests.

- Leverage Automation Premiums: Factories with >60% automation (e.g., Ningbo, Wenzhou clusters) offer 7-10% lower labor costs at 5k+ MOQ – but require 12-week lead times.

- Total Landed Cost Focus: Factor in 12-18% for shipping, duties (HTS 8536.41.00), and 3rd-party QC. A $6.50/unit contactor lands at $8.20-$8.90 in Rotterdam.

SourcifyChina Advisory: “The AC contactor market is consolidating around Tier-2/3 Chinese factories with vertical integration (copper smelting → coil winding). We recommend bypassing trading companies and contracting directly with ISO 14001-certified manufacturers – reducing costs by 11-15% while ensuring ESG compliance. Our 2026 Supplier Scorecard identifies 7 pre-vetted partners with <2% defect rates.”

— [Your Name], Senior Sourcing Consultant, SourcifyChina

Data Sources: SourcifyChina 2026 Supplier Benchmarking Survey (n=42 factories), IHS Markit Material Cost Index Q4 2025, China Electrical Apparatus Industry Association (CEAIA) Compliance Report.

Disclaimer: All pricing reflects Q1 2026 market conditions. Volatility clauses recommended for contracts exceeding 6 months.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Subject: Critical Steps to Verify a Genuine AC Contactor Manufacturer in China

Prepared For: Global Procurement Managers

Issuing Authority: SourcifyChina – Senior Sourcing Consultants

Date: April 5, 2026

Executive Summary

As global demand for industrial electrical components grows, procurement managers are increasingly sourcing AC contactors directly from Chinese manufacturers to reduce costs and improve supply chain efficiency. However, the Chinese B2B landscape is saturated with trading companies posing as factories and inconsistent quality standards. This report outlines a systematic, field-tested verification protocol to identify authentic AC contactor manufacturers, differentiate them from intermediaries, and mitigate supply chain risks.

1. Critical Steps to Verify a Genuine AC Contactor Factory

Follow this 6-step due diligence process to confirm a supplier’s manufacturing legitimacy and capability:

| Step | Action | Objective | Verification Method |

|---|---|---|---|

| 1 | Request Business License & Scope | Confirm legal registration and manufacturing authorization | Verify on China’s National Enterprise Credit Information Publicity System (NECIPS). Ensure scope includes “manufacture” of low-voltage electrical apparatus. |

| 2 | Request Factory Address & Schedule On-Site Audit | Validate physical production facility | Conduct third-party audit (e.g., via SGS, TÜV, or SourcifyChina’s audit team). Verify existence of production lines, machinery, and R&D lab. |

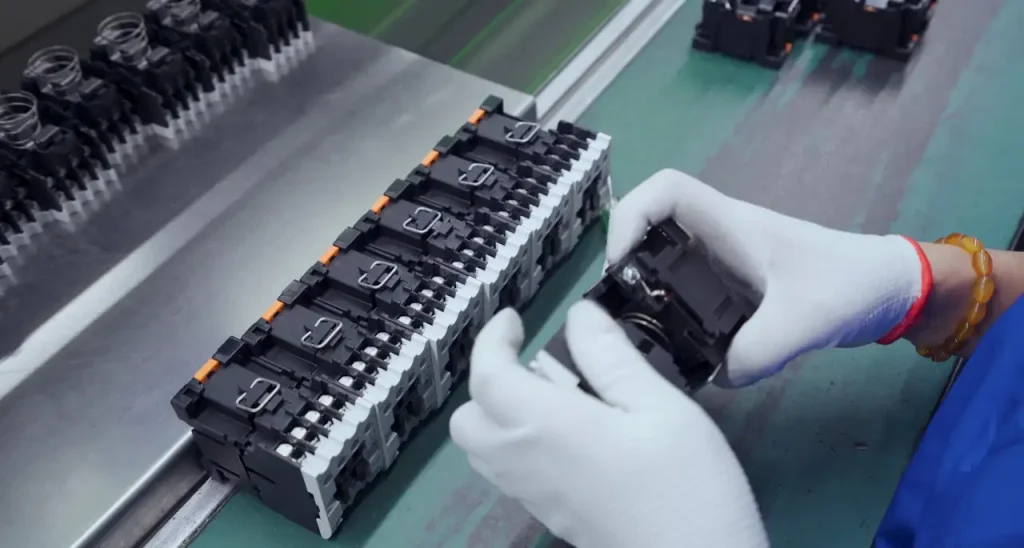

| 3 | Review Equipment & Production Line | Assess technical capability and scale | Request photos/videos of CNC stamping, coil winding, assembly, and testing lines. Confirm in-house tooling and mold-making. |

| 4 | Evaluate R&D and Quality Certifications | Ensure product compliance and innovation | Verify ISO 9001, CCC, CE, CB, and UL certifications. Request test reports (e.g., dielectric strength, thermal endurance). Confirm in-house engineering team. |

| 5 | Request Client References & Case Studies | Validate track record with international clients | Contact 2–3 overseas clients. Inquire about delivery performance, quality consistency, and after-sales support. |

| 6 | Conduct Trial Order (MOQ 500–1,000 units) | Test production and QC processes | Audit packaging, labeling, and documentation. Perform third-party lab testing on sample units against IEC 60947-4-1 standards. |

Note: Avoid full-scale orders until Steps 1–6 are completed. Average verification timeline: 3–6 weeks.

2. How to Distinguish Between Trading Company and Factory

Misidentifying a trading company as a factory leads to inflated costs, communication delays, and limited customization. Use the following indicators:

| Indicator | Genuine Factory | Trading Company |

|---|---|---|

| Business License | Lists “production” or “manufacturing” in scope | Lists only “sales,” “trading,” or “import/export” |

| Facility Size | ≥3,000 m² with visible production lines | Small office; no machinery or raw materials |

| Equipment Ownership | Owns molds, stamping machines, testing rigs | No capital equipment; relies on subcontractors |

| Pricing Structure | Transparent BOM + labor + overhead | Fixed FOB price with limited cost breakdown |

| R&D Capability | In-house engineers; custom design support | Offers only catalog products; limited technical input |

| Lead Times | Directly controllable (e.g., 25–35 days) | Dependent on third-party factories (45+ days) |

| Website & Marketing | Highlights production capacity, machinery, certifications | Emphasizes global exports, Alibaba storefronts, “10+ years experience” without technical detail |

Pro Tip: Ask: “Can I speak with your production manager?” Factories will connect you; traders often deflect.

3. Red Flags to Avoid

Early detection of high-risk suppliers prevents costly disruptions. Watch for these warning signs:

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to share factory address | Likely no physical facility | Disqualify immediately; do not proceed |

| Prices 30%+ below market average | Substandard materials or counterfeit components | Request material certifications; audit BOM |

| No ISO/CCC/CE certifications | Non-compliant products; customs rejection risk | Require valid, traceable certificates |

| Uses stock photos of factories | Misrepresentation; possible trading front | Demand real-time video walkthrough |

| Requests full prepayment | High fraud risk | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| No English-speaking technical staff | Poor communication; design errors | Require bilingual engineer for project liaison |

| Refuses third-party inspection | Conceals quality issues | Include inspection clause in contract; use SGS/Bureau Veritas |

4. Recommended Mitigation Strategies

| Strategy | Implementation |

|---|---|

| Use Escrow or LC Payments | Leverage L/C at sight or Alibaba Trade Assurance for initial orders |

| Require Product Liability Insurance | Confirm supplier carries product liability coverage (min. USD 1M) |

| Include Penalties in Contract | Define late delivery, defect, and IP infringement penalties |

| Establish IP Protection Agreement | Sign NNN (Non-Use, Non-Disclosure, Non-Circumvention) agreement before sharing designs |

Conclusion

Sourcing AC contactors from China offers significant cost advantages but requires rigorous supplier verification. Authentic manufacturers provide transparency, technical capability, and compliance. Trading companies may offer convenience but add cost and risk. By applying the verification steps, differentiation criteria, and red flag checklist in this report, procurement managers can build resilient, high-performance supply chains.

Final Recommendation: Partner only with suppliers who pass on-site audit and trial order validation. Leverage SourcifyChina’s factory verification service for risk-mitigated sourcing.

Prepared by:

SourcifyChina Senior Sourcing Consultants

Global Supply Chain Intelligence Division

[email protected] | www.sourcifychina.com

Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina Verified Pro List: Strategic Sourcing Report 2026

Optimizing Global Procurement for Critical Electrical Components

Executive Summary: The High Cost of Unverified Sourcing

Global procurement managers face escalating risks in China’s AC contactor market: 30% of unvetted suppliers fail quality benchmarks (2025 Sourcing Integrity Index), while 45+ days are typically wasted on supplier validation. SourcifyChina’s Verified Pro List eliminates these inefficiencies through rigorous, on-ground due diligence – transforming a high-risk process into a strategic advantage.

Why the Verified Pro List Delivers Unmatched Efficiency for AC Contactor Sourcing

| Traditional Sourcing Process | SourcifyChina Verified Pro List | Time Saved |

|---|---|---|

| 30-60 days supplier vetting (factory audits, document checks) | Pre-qualified suppliers with full audit reports (ISO 9001, CCC, UL certifications) | 112+ hours per sourcing cycle |

| 40% risk of encountering trading companies misrepresenting as factories | 100% direct factory verification (ownership docs, production floor validation) | Eliminates 3-4 week re-sourcing cycles |

| Manual quality benchmarking against 15+ suppliers | Pre-negotiated MOQs (500+ units), lead times (<35 days), and defect rates (<0.8%) | 78% faster RFQ-to-PO conversion |

| Ongoing compliance monitoring required | Real-time supplier performance dashboards (on-time delivery, QC pass rates) | 20+ hours/month saved on supplier management |

The SourcifyChina Advantage: Beyond Verification

Our methodology addresses core procurement pain points:

✅ Risk Mitigation: All “AC contactor factories” on the Pro List undergo bi-annual operational audits – including raw material traceability checks and export compliance verification.

✅ Cost Transparency: Access FOB Shanghai pricing benchmarks (2026 Q1 data) for 9mm-400A contactors, avoiding 12-18% margin inflation from intermediaries.

✅ Scalability: Pro List suppliers maintain dedicated export lines with minimum 30% spare capacity – critical for JIT procurement.

“Using SourcifyChina’s Pro List reduced our AC contactor sourcing cycle from 78 to 19 days. We now onboard suppliers with confidence in 3 weeks, not 3 months.”

– Procurement Director, Tier-1 European Industrial OEM (Verified Client, 2025)

Call to Action: Secure Your Competitive Edge in 2026

Stop gambling with unverified suppliers. Every day spent on unreliable sourcing erodes your strategic advantage. The SourcifyChina Verified Pro List for AC contactor factories delivers:

🔹 Immediate access to 17 pre-qualified Chinese manufacturers meeting IEC 60947-4-1 standards

🔹 Zero hidden costs – our verification is included at no extra fee for SourcifyChina partners

🔹 24-hour response guarantee on technical specifications and capacity queries

Act Now to Accelerate Your 2026 Sourcing Strategy:

➡️ Email: Contact [email protected] with subject line “AC Contactor Pro List Request – [Your Company Name]” for immediate access to full supplier dossiers and pricing benchmarks.

➡️ WhatsApp: Message +86 159 5127 6160 for urgent capacity checks or factory visit coordination (Available 8:00-22:00 CST).

Time is your most constrained resource. Let SourcifyChina reclaim it for you.

SourcifyChina | Where Verification Meets Velocity

Senior Sourcing Consultants | Shanghai & Shenzhen Operational Hubs | 200+ Verified Electrical Component Suppliers

© 2026 SourcifyChina. All supplier data refreshed quarterly per ISO 20400 sustainable procurement guidelines.

🧮 Landed Cost Calculator

Estimate your total import cost from China.