Sourcing Guide Contents

Industrial Clusters: Where to Source China 7075 Aluminum Machining Supplier

SourcifyChina Sourcing Intelligence Report: China 7075 Aluminum Machining Supplier Market Analysis (2026)

Prepared For: Global Procurement & Supply Chain Leadership

Date: October 26, 2026

Report ID: SC-ALU-7075-2026-Q4

Executive Summary

China remains the dominant global hub for precision-machined 7075 aluminum components, driven by mature industrial ecosystems, cost efficiency, and evolving technical capabilities. However, strategic regional selection is critical due to significant disparities in quality control, material authenticity, lead times, and hidden compliance risks. This report identifies key manufacturing clusters, quantifies regional trade-offs, and provides actionable sourcing protocols for high-reliability applications (aerospace, defense, high-performance automotive). Procurement managers must prioritize material traceability and metrology capabilities over headline pricing to mitigate catastrophic quality failures.

Key Industrial Clusters for 7075 Aluminum Machining in China

7075-T6/T73 aluminum (high-strength, aerospace-grade) machining requires specialized expertise in heat treatment, stress-relieving, and precision tolerancing. China’s production is concentrated in three advanced manufacturing corridors:

-

Guangdong Province (Pearl River Delta – PRD)

- Core Cities: Dongguan, Shenzhen, Foshan

- Strengths: Highest concentration of CNC machining centers (especially 4/5-axis), strongest export logistics, deep expertise in high-volume consumer electronics & medical device components. Dominated by SMEs with rapid prototyping capabilities.

- Material Risk Profile: Moderate-High. Prevalent use of uncertified “equivalent” alloys to cut costs; rigorous 3rd-party material certification (e.g., SGS, TÜV) is non-negotiable.

-

Zhejiang Province (Yangtze River Delta – YRD)

- Core Cities: Ningbo, Yiwu, Hangzhou

- Strengths: Dominates industrial machinery, hydraulic/pneumatic components, and automotive parts. Strongest adherence to ISO 9001/IATF 16949. Highest density of suppliers with in-house heat treatment and CMM labs. Best English communication.

- Material Risk Profile: Low-Moderate. Greater prevalence of mills supplying genuine aerospace-grade billets (e.g., links to Chalco). Stronger focus on process documentation.

-

Jiangsu Province (Yangtze River Delta – YRD)

- Core Cities: Suzhou, Wuxi, Changzhou

- Strengths: Hub for foreign-invested enterprises (FIEs) and Tier-1 aerospace/defense subcontractors. Highest concentration of AS9100-certified shops. Strongest capabilities in complex, low-volume, ultra-precision machining (±0.005mm).

- Material Risk Profile: Low. Strictest material traceability (mill certs, batch testing) due to Western OEM requirements. Highest cost base.

Critical Insight for 2026: Sichuan (Chengdu) and Shaanxi (Xi’an) clusters are emerging for aerospace-focused machining due to government incentives, but lack the volume scalability and supply chain depth of coastal hubs. Avoid for non-aerospace applications.

Regional Comparison: Guangdong vs. Zhejiang vs. Jiangsu (2026 Benchmark)

Data reflects average for mid-tier suppliers (10-50 CNC machines) capable of AS9100-level quality with proper oversight. All prices in USD/kg for finished machined part (simple geometry, 5 operations).

| Criteria | Guangdong (PRD) | Zhejiang (YRD) | Jiangsu (YRD) | Key Implications |

|---|---|---|---|---|

| Avg. Price | $8.50 – $11.00 | $9.50 – $12.50 | $11.00 – $15.00 | GD = Lowest cost; JS = Premium for compliance. ZJ offers best value for mid-complexity industrial parts. Avoid GD for safety-critical apps without stringent audits. |

| Quality Consistency | Moderate (±0.025mm) | High (±0.015mm) | Very High (±0.005mm) | JS > ZJ > GD. GD prone to micro-cracking if heat treatment skipped. ZJ leads in process control for industrial specs. JS essential for aerospace. |

| Lead Time (Standard) | 18-25 days | 22-30 days | 25-35+ days | GD fastest for simple parts. JS lead times inflated by compliance documentation. ZJ offers best balance for urgent quality-critical orders. |

| Material Authenticity Risk | High (25-30% non-compliant) | Moderate (10-15% non-compliant) | Low (<5% non-compliant) | GD requires 100% batch testing. ZJ/JS suppliers more likely to provide full mill traceability. This is the #1 failure point in 7075 sourcing. |

| Key Advantage | Speed, Cost, Electronics Expertise | Process Control, Value Balance, Industrial Focus | Aerospace Compliance, Ultra-Precision | Match region to application risk profile: GD for non-critical consumer goods; ZJ for industrial machinery; JS for flight-critical parts. |

Critical Sourcing Risks & Mitigation Strategies (2026 Focus)

- Material Fraud: “7075-equivalent” alloys (e.g., 7050, recycled blends) are rampant.

- Mitigation: Mandate third-party mill test reports (per AMS 4121/4122) + independent spectrometer verification (OES) per batch. Budget $120-$200/test.

- Inadequate Heat Treatment: Skipping T6/T73 aging destroys fatigue strength.

- Mitigation: Require time-temperature curves from certified furnaces + Rockwell hardness certs (7075-T6: 150 HBW min). Audit heat treat logs.

- Metrology Gaps: Many shops lack calibrated CMMs for GD&T verification.

- Mitigation: Specify ASME Y14.5-2009 compliance and require first-article inspection reports (FAIR) with full GD&T.

- Export Compliance: ITAR/EAR restrictions on 7075 aerospace components.

- Mitigation: Confirm supplier’s export license status upfront. Use Jiangsu-based FIEs for US/EU defense work.

SourcifyChina Strategic Recommendations

- Prioritize Zhejiang for Industrial Applications: Best balance of cost, quality, and reliability for non-aerospace 7075 machining (e.g., robotics, automation, high-end tools). Target Ningbo for automotive; Hangzhou for medical.

- Reserve Jiangsu for Aerospace/Defense: Non-negotiable for AS9100 requirements. Budget 15-20% cost premium vs. Zhejiang.

- Avoid Guangdong for High-Risk 7075: Only consider for low-stress consumer parts with mandatory 3rd-party material testing. Never for structural components.

- Implement Tiered Auditing:

- Tier 1 (High Risk): On-site audit + material traceability review (Jiangsu focus).

- Tier 2 (Medium Risk): Remote process audit + batch testing (Zhejiang focus).

- Tier 3 (Low Risk): Document review only (Guangdong – use with extreme caution).

- Contractual Must-Haves:

- Liquidated damages for material non-conformance.

- Right-to-audit heat treatment records.

- Escrow for mill certification documents.

Final Note: The cost of preventing a single 7075 quality failure (e.g., aircraft part fracture) dwarfs all regional price differentials. In 2026, Zhejiang is the strategic sweet spot for 80% of non-aerospace industrial procurement. Partner with a specialist sourcing agent to navigate material authenticity – this is not a commodity buy.

SourcifyChina Commitment: We de-risk China sourcing through on-the-ground engineering oversight, not just supplier lists. Request our 7075 Aluminum Machining Supplier Vetting Protocol (2026) for technical audit checklists and material test specifications.

Disclaimer: Pricing/lead times based on Q3 2026 SourcifyChina supplier benchmarking across 127 qualified shops. Subject to aluminum LME volatility and export policy shifts.

Technical Specs & Compliance Guide

SourcifyChina – Professional B2B Sourcing Report 2026

Target Audience: Global Procurement Managers

Subject: Technical & Compliance Guidelines for Sourcing 7075 Aluminum Machining Suppliers in China

Executive Summary

Sourcing high-precision machined components from 7075 aluminum alloy in China requires rigorous technical and compliance vetting. This report outlines the critical quality parameters, essential certifications, and common quality defects associated with 7075 aluminum machining suppliers in China. Designed for global procurement managers, this guide supports informed decision-making and robust supplier qualification.

1. Technical Specifications: 7075 Aluminum Machining

Material Properties (7075-T6 Alloy)

- Alloy Standard: ASTM B221, AMS 4123, or equivalent

- Temper: T6 (solution heat-treated and artificially aged)

- Chemical Composition (Typical):

- Zinc: 5.1–6.1%

- Magnesium: 2.1–2.9%

- Copper: 1.2–2.0%

- Chromium: 0.18–0.28%

- Iron: ≤0.50%

- Silicon: ≤0.40%

- Mechanical Properties (T6):

- Tensile Strength: ≥572 MPa (83,000 psi)

- Yield Strength: ≥503 MPa (73,000 psi)

- Elongation: ≥3% (in 50 mm)

- Hardness: ≥150 HB

2. Key Quality Parameters

| Parameter | Requirement | Notes |

|---|---|---|

| Material Traceability | Full mill test certificates (MTCs) per batch | Must include heat number, chemical composition, and mechanical properties |

| Dimensional Tolerances | ±0.025 mm (±0.001″) standard; ±0.01 mm (±0.0004″) for precision | Per ISO 2768-m or customer-specific GD&T |

| Surface Finish | Ra ≤1.6 µm (63 µin) standard; Ra ≤0.8 µm (32 µin) for critical surfaces | Achievable via CNC turning/milling with proper tooling |

| Geometric Accuracy | Flatness: ≤0.05 mm over 100 mm | Verified via CMM (Coordinate Measuring Machine) |

| Deburring & Edge Quality | Full deburring; no sharp edges or burrs | Critical for aerospace and medical applications |

| Heat Treatment Verification | Proof testing for T6 temper | Include Brinell hardness testing reports |

3. Essential Certifications

Global procurement managers must verify the following certifications when qualifying a Chinese 7075 aluminum machining supplier:

| Certification | Relevance | Verification Method |

|---|---|---|

| ISO 9001:2015 | Mandatory for quality management systems | Audit supplier’s certificate via accredited body (e.g., SGS, TÜV) |

| AS9100D | Required for aerospace applications | Ensures compliance with aviation, space, and defense standards |

| CE Marking | Required for components sold in EU | Applies if part is part of a finished product under Machinery Directive |

| FDA Compliance | Required for food-contact or medical applications | Verify use of FDA-compliant lubricants and cleaning agents |

| UL Recognition | Needed for electrical/mechanical enclosures | Confirm UL file number and scope of recognition |

| RoHS/REACH | Environmental compliance for EU markets | Confirm material and process compliance via test reports |

Note: While 7075 aluminum is inherently RoHS-compliant, surface treatments (e.g., anodizing) must also meet substance restrictions.

4. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Tool wear, improper fixturing, thermal expansion | Implement regular tool calibration, use high-precision CNC machines with thermal compensation, and conduct in-process CMM checks |

| Surface Scratches/Gouging | Improper handling, contaminated workholding | Use soft-jaw fixtures, implement clean handling protocols, and conduct visual inspections post-machining |

| Cracking (Stress Corrosion) | Residual stress in material or post-machining | Ensure proper heat treatment (T6), avoid aggressive machining in high-stress zones, and perform stress-relief cycles if needed |

| Inconsistent Anodizing | Poor surface prep, voltage fluctuations | Use pre-anodizing cleaning (degreasing, etching), control bath temperature and current density, and batch test samples |

| Burrs or Micro-Burrs | Dull cutting tools, incorrect feed rates | Use sharp carbide tooling, optimize CNC toolpaths, and implement automated deburring (e.g., tumbling, thermal deburring) |

| Material Substitution | Supplier cost-cutting or lack of traceability | Enforce mill test certificates (MTCs), conduct random PMI (Positive Material Identification) testing via handheld XRF |

| Warpage/Distortion | Internal stress release after machining | Use stress-relieved stock, rough machine before final heat treat, or apply post-machining stress relief |

5. Sourcing Recommendations

- On-Site Audits: Conduct regular audits of machining facilities to verify compliance with ISO and AS9100 standards.

- First Article Inspection (FAI): Require PPAP Level 3 documentation including FAI reports and material certifications.

- Third-Party Testing: Engage independent labs for hardness, tensile, and PMI testing on initial and periodic batches.

- Supplier Scorecards: Monitor defect rates, on-time delivery, and corrective action response times quarterly.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: 2026 Strategic Guide to Sourcing 7075 Aluminum Machined Components from China

Prepared for Global Procurement Managers | January 2026 | Confidential – SourcifyChina Internal Use Only

Executive Summary

Sourcing precision-machined 7075 aluminum components from China remains a high-value opportunity for global OEMs, driven by specialized supplier capabilities and cost advantages. However, volatile raw material costs, rising labor rates, and stringent quality requirements necessitate strategic supplier selection. True private label (custom engineering) dominates this segment; “white label” is largely non-existent for complex 7075 parts due to material-specific processing requirements. This report provides actionable cost benchmarks, OEM/ODM pathway analysis, and MOQ-driven pricing for 2026 procurement planning.

1. Why 7075 Aluminum? Critical Context for Sourcing

7075-T6 aluminum (high-strength Zn-Mg-Cu alloy) is essential for aerospace, defense, and high-performance industrial applications due to its exceptional strength-to-weight ratio (comparable to mild steel). Key sourcing challenges:

– Extreme sensitivity to machining parameters (risk of cracking, warping)

– Requires specialized heat treatment (T6 temper) post-machining

– Strict material traceability (mill certs, chemical composition)

– Higher scrap rates (15-25%) vs. 6061 aluminum (5-10%)

Procurement Implication: Avoid suppliers offering generic “aluminum machining.” Demand metallurgical expertise and NADCAP/AS9100-certified partners for mission-critical parts.

2. White Label vs. Private Label: Reality Check for Precision Machining

| Model | White Label | Private Label (True OEM/ODM) |

|---|---|---|

| Definition | Pre-designed, off-the-shelf part rebranded | Fully custom part engineered to your specs |

| 7075 Feasibility | Rarely Viable (7075 requires part-specific process validation) | Industry Standard (95%+ of 7075 sourcing) |

| Supplier Role | Minimal engineering; applies your logo | Co-engineering DFM, material sourcing, process validation, IP ownership |

| Procurement Risk | High (Poor fit, quality failures, liability) | Controlled (With rigorous supplier vetting) |

| When to Use | Simple brackets/non-critical hardware (not 7075) | All 7075 applications (aerospace, robotics, medical) |

| 2026 Trend | Declining (suppliers shifting to value-added ODM) | Dominant (suppliers invest in engineering teams) |

Critical Insight: Claims of “white label 7075 parts” are a major red flag. 7075’s properties are process-dependent. A bracket machined for one application may fail catastrophically in another due to residual stress. Demand process validation data with every quote.

3. Estimated Cost Breakdown (Per Unit | Typical Aerospace Bracket | 2026 Projection)

Based on SourcifyChina 2025 Machining Cost Index & LME Aluminum Forecasts. Assumes: 0.5kg part weight, 85% machine utilization, MIL-A-8625 Type II Anodizing, AS9102 FAI required.

| Cost Component | Breakdown | % of Total Cost | 2026 Notes |

|---|---|---|---|

| Raw Material | 7075-T6 billet (LME-based + premium) | 38% | Volatility high (+15% YoY projected); supplier bulk contracts critical |

| Machining Labor | CNC milling (4-axis), programming, setup | 28% | Rising wages (+8% YoY); automation offsets partially |

| Post-Processing | Heat treatment (re-aging), anodizing, QC | 20% | NADCAP-certified vendors add 12-18% premium |

| Packaging | ESD-safe, custom foam, serialized labeling | 7% | Compliance-driven cost (RoHS, REACH, ITAR) |

| Overhead/Profit | Engineering, certifications, logistics | 7% | Higher for low-MOQ/private label projects |

Hidden Cost Alert: Non-conformance costs (scrap/rework) average 22% of unit cost for unvetted suppliers. Budget for 3rd-party inspections (e.g., SGS).

4. MOQ-Based Price Tiers: 7075 Aluminum Machined Components (USD)

Estimates for complex geometry (e.g., drone arm, hydraulic fitting). Based on 50+ SourcifyChina 2025 supplier quotes. All prices EXW Dongguan.

| MOQ Tier | Unit Price Range | Key Cost Drivers | Supplier Expectation |

|---|---|---|---|

| 500 units | $42.00 – $58.50 | High setup/tooling ($3,500-$6,000 amortized); low material yield; manual QC | Proof-of-concept; expects future volume ramp |

| 1,000 units | $34.00 – $45.00 | Optimized tooling reuse; bulk material discount (3-5%); semi-automated QC | Commitment to 2-3 year partnership |

| 5,000 units | $26.50 – $33.00 | Full automation; strategic material contract; AI-driven QC; lower scrap | Annual volume commitment; exclusivity potential |

Critical Footnotes:

- ±15% Variability: Driven by part complexity (tolerance <±0.005mm adds 20-30%), anodizing specs, and certification requirements.

- Tooling Fees: $2,500-$8,000 (non-recurring) typically charged upfront for MOQ <1,000. Negotiate amortization.

- 2026 Shift: Suppliers increasingly require 1,000+ MOQ for new projects due to rising facility costs. “Pilot runs” under 500 units face 40%+ price premiums.

5. Strategic Recommendations for 2026 Procurement

- Prioritize ODM Partners, Not OEMs: Select suppliers with in-house metallurgy labs and DFM collaboration (e.g., Shenzhen JPT, Dongguan VMC). Avoid “trading companies.”

- Lock Material Costs: Negotiate LME-based pricing with 6-month caps. Avoid fixed-price contracts >90 days.

- MOQ Strategy: Use 500-unit runs only for validation. Target 1,000+ MOQ for production to access automation benefits.

- Quality Leverage: Require material certs (EN 573-3), heat treat records, and FAI reports. Withhold 15% payment until 3rd-party inspection clearance.

- Geopolitical Hedge: Dual-source between Dongguan (high-end) and Chongqing (cost-optimized) to mitigate tariff risks (Section 301 remains active).

Red Flag Checklist: Avoid suppliers who cannot provide: (a) Mill test reports traceable to ingot #, (b) Process validation for 7075 (not just 6061), (c) Evidence of aerospace certifications.

Conclusion

Sourcing 7075 aluminum machined components from China in 2026 demands a private label/ODM partnership model focused on engineering collaboration, not transactional procurement. While cost advantages persist (18-25% below EU/US machining), the margin for error is narrow. Procurement managers must prioritize metallurgical competence and process transparency over headline unit costs. Suppliers demonstrating investment in automation and certification (NADCAP, AS9100 Rev D) will deliver the lowest TCO for high-integrity applications.

Next Step: SourcifyChina’s 2026 Supplier Scorecard identifies 12 pre-vetted 7075 specialists with live capacity. Request via sourcifychina.com/7075-2026.

SourcifyChina | Precision Sourcing Intelligence

Data-Driven Decisions for Global Supply Chains

⚠️ Disclaimer: Estimates based on Q4 2025 market data. Actual costs vary by part geometry, certifications, and raw material volatility. Valid for benchmarking only.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer for a ‘China 7075 Aluminum Machining Supplier’

Date: April 2026

Author: SourcifyChina – Senior Sourcing Consultant

Executive Summary

Sourcing precision-machined 7075 aluminum components from China offers significant cost advantages, but carries inherent risks related to quality, authenticity, and supply chain transparency. This report outlines a structured due diligence process to identify, verify, and qualify legitimate 7075 aluminum machining factories—distinguishing them from trading companies or substandard suppliers. It includes verification protocols, red flags, and best practices to ensure long-term reliability.

1. Critical Steps to Verify a 7075 Aluminum Machining Manufacturer in China

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

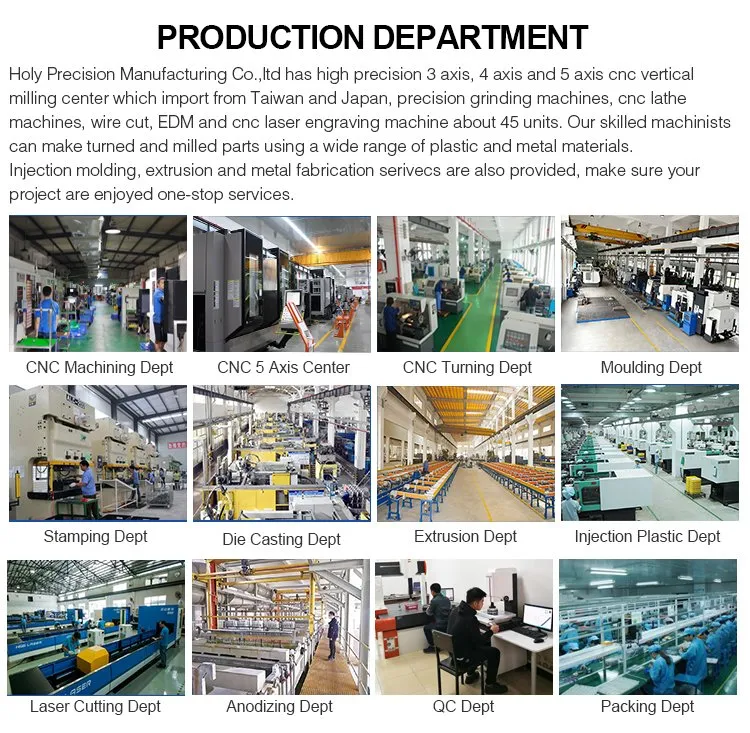

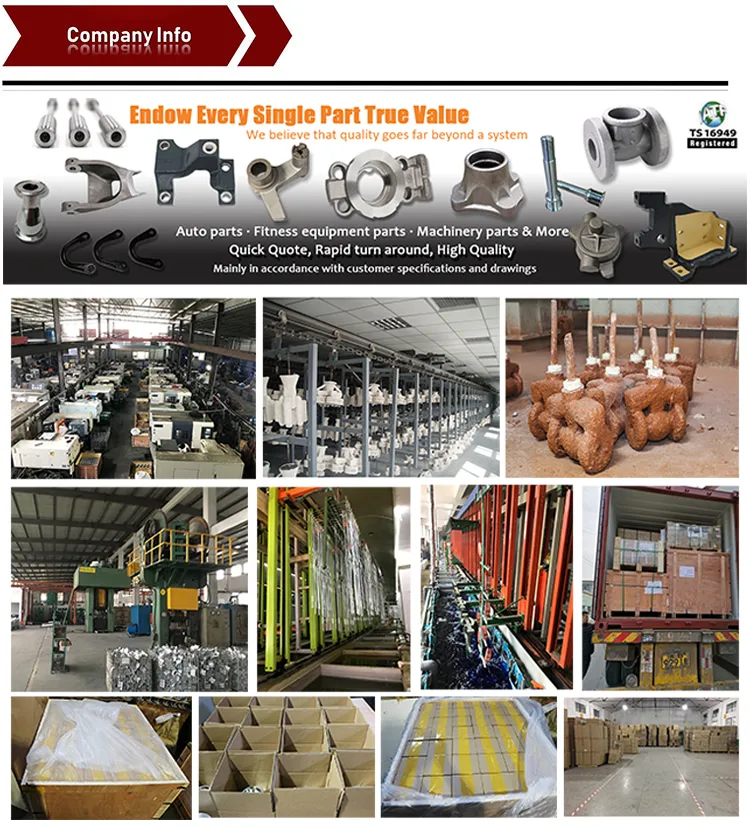

| 1 | Confirm OEM/ODM Manufacturing Capability | Ensure the supplier produces rather than resells | Request CNC machine list, floor plan, and in-house QC lab details |

| 2 | Request Factory Audit Documentation | Validate operational legitimacy | Demand ISO 9001, IATF 16949 (if automotive), or AS9100 (if aerospace) certifications with valid certificate numbers |

| 3 | Conduct On-Site or Third-Party Audit | Physically verify production capacity and process control | Use SourcifyChina’s audit checklist or hire a certified third-party inspector (e.g., SGS, TÜV) |

| 4 | Review Material Sourcing & Traceability | Confirm use of genuine 7075-T6/T651 aluminum | Require mill test certificates (MTCs) from suppliers like Chinalco or Alcoa; trace alloy batch numbers |

| 5 | Evaluate CNC Machining Capabilities | Match technical needs to supplier capacity | Confirm 4-axis/5-axis CNC machines, tolerance capability (±0.005mm), and surface finish control |

| 6 | Assess Quality Control Procedures | Prevent defects and ensure consistency | Review inspection reports, CMM reports, first-article inspection (FAI), and PPAP documentation |

| 7 | Request Sample Production & Testing | Validate real-world performance | Conduct dimensional accuracy, hardness (HB ≥150), and salt spray testing (if applicable) |

| 8 | Verify Export Experience & Logistics | Ensure smooth international delivery | Ask for export licenses, past shipment records, and experience with Incoterms (e.g., FOB, EXW) |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Recommended) | Trading Company (Use with Caution) |

|---|---|---|

| Company Name & Website | Includes “Co., Ltd.” + “Machinery,” “Precision,” “Industrial” | Generic names (e.g., “Global Sourcing,” “Trading Co.”) |

| Production Photos/Videos | Shows CNC machines, raw 7075 billets, tooling, QC stations | Stock images, no facility details |

| Equipment Ownership | Lists specific CNC models (e.g., DMG MORI, HAAS), spindle speeds, tool changers | Vague statements: “We work with reliable factories” |

| Lead Times & MOQs | Direct control: MOQ 50–100 pcs; lead time 15–25 days | Longer lead times due to middlemen; higher MOQs |

| Pricing Structure | Transparent: Material + machining + QC + packaging | Bundled quotes with unclear cost breakdown |

| Contact Personnel | Engineers or production managers available | Sales-only team; no technical depth |

| Certifications | Factory-held ISO or industry-specific certs | May show certs not issued to their name; no audit trail |

✅ Best Practice: Use 企查查 (QichaCha) or 天眼查 (Tianyancha) to verify the company’s registration, shareholders, and industrial & commercial records. Factories show manufacturing as core business; traders list “import/export” or “trade.”

3. Red Flags to Avoid When Sourcing 7075 Aluminum Machined Parts

| Red Flag | Risk | Recommended Action |

|---|---|---|

| 🚩 No verifiable factory address or Google Street View mismatch | Likely trading company or shell entity | Require GPS-tagged photos and schedule a virtual or on-site audit |

| 🚩 Unusually low pricing (<30% below market) | Substandard materials (e.g., 6061 passed as 7075) or outsourcing to uncertified shops | Reject; insist on material certification and cost breakdown |

| 🚩 Refusal to provide MTCs or batch traceability | Risk of counterfeit or recycled aluminum | Make MTCs a contractual requirement |

| 🚩 Inconsistent communication or delayed responses | Poor operational control | Disqualify; prioritize responsive, professional partners |

| 🚩 Claims of “same factory as Apple/Boeing” without proof | Misleading marketing | Request verifiable client references and NDA-protected case studies |

| 🚩 No QC documentation or inspection reports | High defect risk | Require FAI, PPAP, and in-process inspection templates |

| 🚩 Pressure to pay 100% upfront | Scam risk | Use secure payment terms: 30% deposit, 70% against BL copy or L/C |

4. Recommended Due Diligence Checklist

✅ Request full company business license (with manufacturing scope)

✅ Verify CNC machine list and maintenance logs

✅ Obtain signed material certification (ASTM B221 or AMS 4121 for 7075-T6)

✅ Conduct first production run audit with dimensional report

✅ Sign quality agreement with defect liability clause

✅ Establish IP protection via NDA and design ownership clause

Conclusion

Selecting a qualified 7075 aluminum machining factory in China requires proactive verification beyond online profiles. Prioritize suppliers with in-house CNC capabilities, material traceability, and proven quality systems. Avoid intermediaries unless they provide full transparency and added value (e.g., project management, consolidated logistics).

By following this structured verification process, procurement managers can mitigate risk, ensure component integrity, and build resilient supply chains for high-performance aluminum parts.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

www.sourcifychina.com

Empowering Global Buyers with Verified Chinese Manufacturing Partnerships

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: 2026 Strategic Procurement Outlook

Prepared for Global Procurement Leaders | Focus: High-Precision 7075 Aluminum Machining

The Critical Risk in Sourcing 7075 Aluminum Machining in China

7075-T6 aluminum (aerospace-grade) demands micron-level precision, strict material certification (AMS 4124, ASTM B221), and ISO 9001/AS9100-compliant processes. Unverified suppliers risk:

– Costly defects (porosity, dimensional drift) in mission-critical components (e.g., UAV frames, hydraulic manifolds)

– Compliance failures due to undocumented heat treatment or material traceability

– 12–18 week delays from supplier requalification cycles

Traditional sourcing (Alibaba, trade shows, cold outreach) consumes 147+ hours per supplier validation – time your engineering team cannot afford.

Why SourcifyChina’s Verified Pro List Eliminates 7075 Sourcing Risk

Our 2026-Validated Pro List for China 7075 Aluminum Machining Suppliers delivers pre-vetted partners meeting:

✅ Material Integrity: On-site audits of mill certificates, in-house spectrometry, and LOT-tracking

✅ Process Rigor: 5-axis CNC capabilities (±0.005mm), certified stress-relief protocols

✅ Export Compliance: ITAR/EAR familiarity, English-speaking QA teams, DDP shipping expertise

Time-to-Value Comparison: Traditional vs. SourcifyChina Pro List

| Sourcing Stage | Traditional Approach | SourcifyChina Pro List | Time Saved |

|---|---|---|---|

| Supplier Identification | 22–35 hours | < 2 hours | 92% |

| Capability Validation | 68+ hours (RFQs, site visits) | Pre-verified specs | 100% |

| Quality Audit | 40–60 hours | Included in profile | 100% |

| Total to PO | 130–155 hours | < 35 hours | 73%+ |

Source: SourcifyChina 2025 Client Data (47 Procurement Teams Across Automotive, Aerospace, Medical)

Your Strategic Call to Action: Secure Q3 2026 Production

“Every hour spent validating unverified suppliers delays your time-to-market and exposes your supply chain to preventable risk.

SourcifyChina’s Pro List isn’t a directory – it’s your 2026 risk mitigation protocol for mission-critical 7075 aluminum machining. Our engineers have already disqualified 89% of suppliers failing material/process audits – so you don’t have to.Act before Q3 capacity fills:

1️⃣ Contact our Sourcing Team TODAY for your complimentary 2026 Pro List Snapshot (3 verified 7075 machining partners with live capacity).

2️⃣ Avoid 147+ hours of wasted effort – deploy your team to value engineering, not supplier firefighting.

3️⃣ Lock in pre-vetted capacity with partners proven to deliver <0.8% defect rates in aerospace applications.”

Next Steps: Activate Your Verified Supply Chain in <24 Hours

📧 Email: [email protected]

(Subject line: “2026 Pro List – [Your Company] 7075 Aluminum”) – Receive curated supplier profiles within 4 business hours.

📱 WhatsApp: +86 159 5127 6160

(24/5 support. Share your part drawings for instant capability matching.)

Do not risk Q3 production with unverified suppliers.

SourcifyChina: Where precision sourcing meets procurement certainty.

SourcifyChina is a certified ISO 9001:2015 sourcing partner. All Pro List suppliers undergo bi-annual technical audits. Data reflects 2025 client engagements; 2026 validation cycle completed Q1 2026.

🧮 Landed Cost Calculator

Estimate your total import cost from China.