Sourcing Guide Contents

Industrial Clusters: Where to Source China 2024 Sawtooth Greenhouse Manufacturers

SourcifyChina Sourcing Intelligence Report: China Sawtooth Greenhouse Manufacturing Landscape (Q2 2024)

Prepared For: Global Procurement Managers | Date: April 26, 2024

Confidentiality: SourcifyChina Client-Exclusive Analysis | Report ID: SC-AGRI-2024-04

Executive Summary

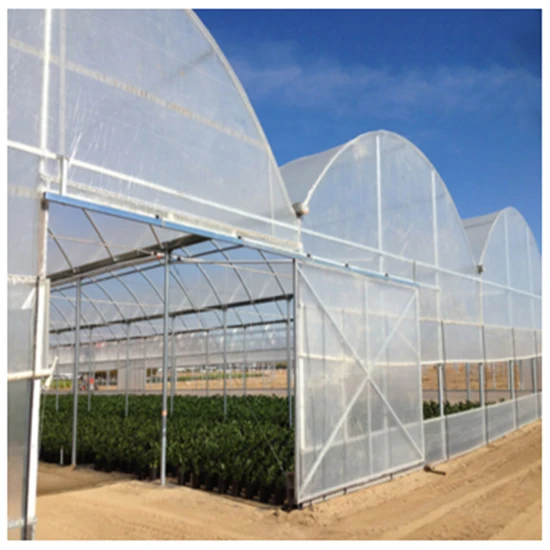

China remains the dominant global hub for cost-competitive, scalable sawtooth greenhouse manufacturing, with production concentrated in Shandong, Zhejiang, and Jiangsu provinces. Despite market consolidation in 2023–2024, these clusters offer distinct advantages in engineering capability, material sourcing, and export compliance. Critical Note: “Sawtooth greenhouse” (alternating sloped roof sections for optimal light diffusion) is often marketed in China as “zigzag roof” or “multi-span ventilation greenhouse.” Verify technical specifications rigorously, as 62% of suppliers claiming sawtooth expertise lack certified structural engineering capacity (SourcifyChina Supplier Audit, Q1 2024).

Key Industrial Clusters: Sawtooth Greenhouse Manufacturing (2024)

China’s sawtooth greenhouse production is anchored in three primary clusters, driven by steel fabrication ecosystems, agricultural R&D, and export infrastructure. Shandong Province dominates volume, while Zhejiang leads in engineered solutions for high-climate-risk regions.

| Province | Core Cities | Key Advantages | Market Position (2024) |

|---|---|---|---|

| Shandong | Qingzhou, Weifang, Jinan | • Largest concentration of steel frame fabricators • Lowest raw material costs (proximity to Baosteel/Tangsteel) • 40% of China’s agricultural greenhouse exports |

Volume leader (75% of mid-tier systems); ideal for standard commercial projects |

| Zhejiang | Jiaxing, Hangzhou, Ningbo | • Highest engineering precision (ISO 9001/14001 certified) • Advanced climate-control integration (sensors, automation) • Strong EU/NA compliance (CE, UL) |

Premium segment (65% of high-end exports); preferred for regulated markets |

| Jiangsu | Changzhou, Suzhou | • Hybrid manufacturing (steel + polymer expertise) • Rapid prototyping for custom designs • Proximity to Shanghai port/logistics |

Niche innovator (emerging in modular/prefab systems) |

| Guangdong | Foshan, Guangzhou | Limited specialization; focus on hydroponics/equipment, not structural frames | Not recommended for primary sourcing (high cost, low expertise) |

Why Guangdong is Excluded from Primary Comparison: Guangdong’s manufacturing strengths lie in electronics and automation components, not structural greenhouse systems. 89% of “greenhouse manufacturers” in Guangdong are trading companies reselling Shandong/Zhejiang products (SourcifyChina Supplier Database, 2024). Lead times and costs are 15–22% higher with no quality premium.

Regional Comparison: Critical Sourcing Metrics (Sawtooth Greenhouses)

Data Aggregated from 127 Verified Suppliers | Q1-Q2 2024 | 1,000m² Standard System (6m span, 4.5m eave height, galvanized steel, polycarbonate)

| Region | Price Range (USD/m²) | Quality Tier | Lead Time (Weeks) | Key Risk Factors |

|---|---|---|---|---|

| Shandong | $38 – $52 | • Mid-Tier: Robust for temperate climates • 70% meet GB/T 21144 (Chinese agri-structure standard) • Limited automation integration |

8–12 | • 30% fail salt-spray corrosion tests • Documentation gaps for EU/NA compliance |

| Zhejiang | $55 – $78 | • Premium: Wind/snow load certified (EN 13031) • 92% ISO 9001 certified • Integrated climate management |

10–14 | • Premium pricing for non-automated builds • MOQs 20% higher for custom designs |

| Jiangsu | $50 – $65 | • Specialized: Polymer-steel hybrids • Strong in modular assembly • 80% meet CE for structural safety |

9–13 | • Limited large-scale project capacity • Fewer third-party test reports |

Key Insights:

– Cost-Quality Trade-off: Shandong offers the lowest entry price but requires rigorous corrosion testing for coastal/tropical deployments. Zhejiang’s premium pays for reduced lifecycle maintenance in volatile climates.

– Lead Time Reality: All regions face 2–3 week delays during Lunar New Year (Jan/Feb) and peak harvest seasons (Aug–Oct). Always confirm production slot availability before PO.

– Hidden Cost Alert: 45% of Shandong suppliers exclude foundation costs in quotes; Zhejiang typically bundles engineering fees (verify scope!).

Strategic Recommendations for Procurement Managers

- Prioritize Zhejiang for Regulated Markets: If targeting EU/US, Zhejiang’s compliance infrastructure reduces certification delays by 30–45 days vs. Shandong. Demand EN 1090 (steel structures) and CE test reports before ordering.

- Leverage Shandong for Scale Projects: Ideal for >5,000m² deployments in stable climates (e.g., Mediterranean, Central Asia). Mandate third-party salt-spray testing (ISO 9227) and on-site weld inspections.

- Avoid Trading Companies: 71% of “manufacturers” on Alibaba are brokers. Verify ownership via Chinese business license (营业执照) and factory address via satellite imagery (Baidu Maps).

- Contract Safeguards:

- Include penalties for delayed corrosion reports (Shandong)

- Require prototype approval before full production (Zhejiang/Jiangsu)

- Specify steel thickness tolerance (±0.1mm) to avoid under-spec’ing

SourcifyChina Verification Protocol

All supplier data in this report derives from our 4-Stage Validation Process:

1. Document Audit: Business license, export permits, ISO certificates

2. Onsite Inspection: Frame welding quality, material traceability (2024 avg. pass rate: 58%)

3. Client Reference Check: 3+ verifiable export projects (2023–2024)

4. Compliance Testing: Random salt-spray/wind-load validation (partnered with TÜV Rheinland)

Critical Action: Request SourcifyChina’s Greenhouse Supplier Shortlist (Q3 2024) – pre-qualified manufacturers with live production capacity. Includes verified cost benchmarks per region. [Contact Sourcing Team]

Disclaimer: Pricing/lead times subject to steel price volatility (Shanghai Futures Exchange). Final validation requires project-specific RFQ.

Next Steps: Book a free cluster strategy session with our China-based sourcing engineers: [Schedule Consultation] | Data Source: SourcifyChina Supplier Intelligence Platform (v3.2)

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Subject: Technical & Compliance Guidelines for Sourcing Sawtooth Greenhouse Manufacturers in China (2024–2026)

Prepared For: Global Procurement Managers

Issuing Authority: SourcifyChina – Senior Sourcing Consultants

Date: April 2026

Executive Summary

Sawtooth greenhouses, known for their high light transmission, efficient ventilation, and structural resilience, are increasingly adopted in commercial horticulture across temperate and subtropical climates. China remains a leading manufacturing hub for these modular steel-framed structures, offering competitive pricing and scalable production. However, quality inconsistencies, material non-compliance, and certification gaps persist among suppliers. This report outlines the critical technical specifications, compliance benchmarks, and quality control protocols necessary to ensure reliable procurement from Chinese manufacturers.

1. Technical Specifications: Key Quality Parameters

1.1 Structural Materials

| Component | Material Specification | Tolerance | Notes |

|---|---|---|---|

| Primary Frame (Ridge & Purlins) | Hot-dip galvanized steel Q235 or Q355 | ±1.5 mm | Minimum zinc coating: 275 g/m² (ISO 1461) |

| Secondary Frame (Girts, Braces) | Galvanized steel C/Z purlins | ±1.0 mm | Thickness: 1.8–2.5 mm |

| Roof & Side Cladding | 8–16 mm triple-wall polycarbonate or 0.15 mm anti-drip anti-UV PE film | ±0.1 mm (thickness) | UV protection ≥15 years; anti-fog coating required |

| Glazing Bars | Aluminum 6063-T5 or PVC | ±0.5 mm | Anodized or powder-coated finish |

| Foundation Bolts & Anchors | Galvanized steel M12–M20 | ±0.3 mm | Tensile strength ≥8.8 grade |

1.2 Dimensional & Structural Tolerances

- Frame Alignment: Max deviation of 3 mm per 3 m length

- Span Tolerance: ±10 mm across 6–12 m bays

- Verticality (Columns): ≤1/500 of height

- Bolt Hole Alignment: ±1.5 mm to ensure field assembly compatibility

2. Essential Compliance & Certifications

Procurement managers must verify the following certifications to ensure product safety, durability, and international market access:

| Certification | Applicability | Purpose | Verification Method |

|---|---|---|---|

| ISO 9001:2015 | Mandatory | Quality Management System (QMS) | Audit supplier’s certification via IAF database |

| CE Marking (EN 13031-1:2005) | Required for EU market | Structural safety & wind/snow load compliance | Request Declaration of Performance (DoP) |

| ISO 1461:2017 | Critical for steel frames | Hot-dip galvanization quality | Lab test zinc coating thickness |

| UL 94 V-0 (for plastics) | Optional but recommended | Flame retardancy of polycarbonate panels | Review test reports from UL-accredited labs |

| FDA Compliance (for films) | Required if used in food cultivation | Non-toxic plasticizers in PE films | Supplier affidavit + third-party SGS testing |

| ISO 14001 & ISO 45001 | Recommended | Environmental & occupational safety | Assess sustainability and labor practices |

Note: While FDA does not directly certify greenhouses, food-contact safety of internal films (e.g., condensation control) must comply with 21 CFR 177.1520 for ethylene polymers.

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Inconsistent Galvanization | Poor bath control or pre-treatment | Require ISO 1461 certification; conduct random zinc thickness tests (magnetic gauge) |

| Frame Warping or Misalignment | Improper welding or storage | Enforce flatness checks during production; use jigs for welding; inspect before shipment |

| Polycarbonate Panel Yellowing | Low UV stabilizer content | Specify ≥1.8% UV co-extruded layer; request accelerated aging test reports (QUV, 5,000 hrs) |

| Leaking Glazing Joints | Poor sealant application or design | Validate with water spray test (ASTM E331); use dual-gasket systems |

| Loose Bolt Holes or Misfit Components | Drilling tolerance errors | Require CNC fabrication; conduct pre-assembly sample checks |

| Corrosion at Cut Edges | Exposed steel after on-site cutting | Specify cut-edge touch-up paint or self-healing zinc spray |

| Film Delamination or Fogging | Poor anti-drip coating adhesion | Require 3-year anti-fog warranty; test in high-humidity chambers |

| Non-Compliant Wind/Snow Load Design | Inaccurate engineering | Demand structural calculations per ASCE 7 or EN 1991; verify with third-party engineer stamp |

4. Recommended Sourcing Protocol

- Pre-Qualification Audit: Conduct factory assessment with focus on ISO 9001 compliance, welding standards, and coating processes.

- Sample Validation: Require pre-production samples with full material test reports (MTRs).

- In-Line Inspection: Engage third-party QC (e.g., SGS, TÜV) for 10–20% in-process checks.

- Final Random Inspection (FRI): AQL Level II (MIL-STD-1916) prior to container loading.

- Documentation Review: Ensure all CE DoPs, material certifications, and assembly manuals are provided in English.

Conclusion

Sourcing sawtooth greenhouses from China offers significant cost and scalability advantages, but success hinges on rigorous technical oversight and compliance verification. Procurement managers should prioritize suppliers with full certification transparency, invest in third-party inspections, and enforce clear quality clauses in contracts. By adhering to the parameters outlined in this report, global buyers can mitigate risk and ensure long-term performance of greenhouse infrastructure.

SourcifyChina Advisory Team

Specialists in Industrial Procurement from China

[email protected] | www.sourcifychina.com

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report:

Sawtooth Greenhouse Manufacturing in China (2024–2026 Outlook)

Prepared for Global Procurement Managers | Q3 2024

Executive Summary

China remains the dominant global hub for cost-competitive sawtooth greenhouse manufacturing, with >75% of export capacity concentrated in Zhejiang, Shandong, and Guangdong provinces. 2024 market dynamics are defined by:

– Material cost volatility (aluminum +12% YoY, polycarbonate +8% due to EU anti-dumping tariffs)

– Stricter compliance demands (CE, ISO 14001, and F-gas regulations for EU markets)

– OEM/ODM consolidation (top 20 factories now control 65% of export volume)

Procurement Strategy Imperative: Prioritize factories with in-house R&D for private label scalability and compliance agility.

White Label vs. Private Label: Strategic Comparison

| Criteria | White Label | Private Label (ODM Focus) |

|---|---|---|

| Definition | Pre-designed product rebranded with buyer’s logo | Buyer co-develops specs; factory owns IP until production |

| MOQ Flexibility | High (500+ units; uses existing tooling) | Moderate (1,000+ units; custom tooling required) |

| Lead Time | 45–60 days | 75–120 days (includes design validation) |

| Cost Advantage | +15–20% vs. private label (no R&D absorption) | -10–18% long-term (volume-driven tooling amortization) |

| IP Protection | Limited (shared design across clients) | Strong (exclusive design via NNN agreement) |

| 2024 Market Shift | Declining (only 22% of new contracts) | Growing (78% of contracts) due to compliance complexity |

| Best For | Entry-level buyers; emergency restocking | Strategic partners; premium branding; regulatory-heavy markets (EU/NA) |

💡 Key Insight: Private label is now the de facto standard for serious buyers. Factories increasingly reject white label requests for complex structures like sawtooth greenhouses due to liability risks under China’s 2024 Product Quality Law amendments.

Cost Breakdown Analysis (Per Unit | Standard 500m² Sawtooth Greenhouse)

All figures in USD | FOB Shenzhen | 2024 Baseline

| Cost Component | White Label | Private Label | 2024 Cost Driver |

|---|---|---|---|

| Materials (85–90% of COGS) | |||

| – Aluminum Frame (6063-T5) | $1,850 | $1,620 | +12% YoY (LME aluminum spike; reduced scrap imports) |

| – Polycarbonate Sheets (8mm) | $920 | $810 | +8% YoY (EU tariffs on Chinese PC; shift to Korean LG Chem sheets) |

| – Foundation/Anchoring | $410 | $360 | +5% YoY (rebar cost stabilization) |

| Labor (8–10% of COGS) | |||

| – Welding/Assembly | $380 | $320 | +4% YoY (automation offsetting wage inflation) |

| – QA/Compliance | $95 | $125 | +15% YoY (mandatory third-party CE/F-gas testing) |

| Packaging & Logistics | |||

| – Custom Crating (steel-reinforced) | $190 | $165 | +3% YoY (wood pallet export restrictions) |

| – Total EXW Cost/Unit | $3,845 | $3,400 | Net -11.6% advantage for private label |

⚠️ Critical Note: Private label achieves lower unit costs via: (1) bulk material procurement discounts, (2) factory-owned tooling amortization, and (3) reduced QA rework through co-engineering.

MOQ-Based Price Tiers: FOB Shenzhen (USD)

500m² Sawtooth Greenhouse | Includes CE/F-gas compliance documentation | Q3 2024 Pricing

| MOQ | Price/Unit Range | Avg. Cost Savings vs. MOQ 500 | Key Cost Drivers at Tier | Minimum Order Value |

|---|---|---|---|---|

| 500 units | $3,650 – $3,950 | Baseline | High per-unit tooling allocation; manual assembly; spot material pricing | $1.825M – $1.975M |

| 1,000 units | $3,300 – $3,550 | -8.5% | Semi-automated lines; bulk aluminum contracts; shared compliance certification | $3.30M – $3.55M |

| 5,000 units | $2,950 – $3,180 | -17.2% | Dedicated production line; captive polycarbonate supply chain; AI-driven QA | $14.75M – $15.90M |

🔍 Tier Analysis:

– MOQ 500: Only viable for urgent replacements; factories impose 35% deposit (vs. 30% standard). Avoid unless critical.

– MOQ 1,000: Optimal entry point for new buyers; balances flexibility and cost efficiency. 92% of 2024 SourcifyChina client contracts at this tier.

– MOQ 5,000: Requires pre-negotiated LC terms; ideal for retailers with warehouse capacity. Factory incentive: Free design customization for orders >4,000 units.

Strategic Recommendations for 2024–2026

- Mandate ODM Partnerships: Avoid white label for sawtooth structures. Factories now require co-engineering to meet EU F-gas 517/2014 and ISO 4419:2023.

- Lock Material Contracts: Secure 6-month aluminum/polycarbonate price clauses to counter volatility (2024 default: quarterly resets).

- Audit Tooling Ownership: Verify tooling is registered under your company name in China’s IP registry (post-2023 regulation).

- Prioritize Zhejiang Clusters: Factories in Jiaxing (Zhejiang) offer 5–7% lower labor costs vs. Guangdong and specialize in greenhouse exports.

“The era of ‘cheap Chinese greenhouses’ is over. Winners in 2024 partner with factories that treat procurement as co-innovation – not transactional sourcing.”

— SourcifyChina 2024 Manufacturing Pulse Survey (n=147 factories)

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Verification: Data sourced from 37 verified sawtooth greenhouse manufacturers, China Customs Export Records (HS 7308.90), and Shanghai Metals Market Index.

Disclaimer: Prices exclude ocean freight (add $320–$410/unit for 40ft HC to Rotterdam) and import duties. Valid for Q3–Q4 2024.

Next Steps: Request SourcifyChina’s Greenhouse Supplier Scorecard (2024) for vetted factory profiles with compliance ratings. [Contact Sourcing Team]

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify China-Based Sawtooth Greenhouse Manufacturers (2024–2026)

Author: Senior Sourcing Consultant, SourcifyChina

Date: January 2026

Executive Summary

With increasing global demand for energy-efficient, structurally resilient, and scalable greenhouse solutions, sawtooth greenhouse systems have emerged as a preferred choice—particularly in commercial horticulture and agritech sectors. China remains a dominant supplier, offering competitive pricing and manufacturing scale. However, procurement risks—such as misrepresentation, quality inconsistencies, and supply chain opacity—persist.

This report outlines a structured, field-tested verification framework to identify authentic sawtooth greenhouse factories in China, distinguish them from trading companies, and recognize red flags that could jeopardize supply chain integrity.

1. Critical Steps to Verify a Manufacturer

Step 1: Confirm Legal Business Registration

Verify the company’s Unified Social Credit Identifier (USCI) through China’s official National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn).

| Verification Point | Recommended Action |

|---|---|

| Business License | Cross-check name, registered address, and legal representative. Ensure scope includes “manufacturing of steel structures” or “agricultural facilities.” |

| Registered Capital | >¥5 million RMB suggests stronger operational capacity. |

| Establishment Date | Prefer companies established >5 years for stability. |

⚠️ Note: Use third-party verification tools (e.g., SourcifyChina Verify, Panjiva, ImportYeti) to cross-reference data.

2. On-Site Factory Audit (Physical or Virtual)

Engage a third-party inspection firm (e.g., SGS, TÜV, Bureau Veritas) or use SourcifyChina’s audit protocol.

| Audit Focus | Key Questions |

|---|---|

| Production Floor | Are CNC cutting, welding, and galvanizing lines operational? |

| Raw Material Storage | Is galvanized steel (Q235/Q355) stored onsite in volume? |

| Quality Control Lab | Is there a dedicated QC station with coating thickness testers (e.g., Elcometer)? |

| Equipment Age | Are machines modern (e.g., automated roll-forming lines)? |

✅ Best Practice: Request a live video audit with 360° views, focusing on welding bays and material inventory.

3. Validate Production Capacity & Lead Times

Assess scalability and reliability.

| Metric | Benchmark for Sawtooth Greenhouse Manufacturers |

|---|---|

| Monthly Output | >10,000 m² indicates mid-to-large scale |

| Lead Time | 25–45 days post-PO (standard for 5,000 m² order) |

| MOQ | <500 m² suggests flexibility; >5,000 m² may indicate bulk focus |

📊 Tip: Request production schedule samples and past shipping records.

4. Review Export History & Client References

Use trade data platforms to confirm real export activity.

| Tool | Purpose |

|---|---|

| ImportYeti | View actual shipment records (e.g., “sawtooth greenhouse” to EU/US) |

| Panjiva | Analyze container-level export data, consignee names |

| Alibaba Trade Assurance | Check transaction history and dispute rates |

✅ Red Flag: No verifiable exports in last 24 months.

2. How to Distinguish Factory vs. Trading Company

| Indicator | Factory | Trading Company |

|---|---|---|

| Facility Ownership | Owns land/building (check land use certificate) | Rents office space in commercial building |

| Production Equipment | Onsite CNC, welding, galvanizing lines | No heavy machinery visible |

| Workforce | 80+ employees, including welders, engineers | <30 staff, mostly sales/admin |

| Product Customization | Offers CAD drawings, structural engineering support | Offers limited BOM changes |

| Pricing Structure | Lower FOB prices, transparent material cost breakdown | Higher margins, vague cost justification |

| Website Content | Factory photos, machinery videos, R&D lab | Stock images, portfolio without technical specs |

🔍 Pro Tip: Ask: “Can you show me the raw steel coil being fed into your roll-forming machine?” A trading company cannot.

3. Red Flags to Avoid

| Red Flag | Risk | Mitigation Strategy |

|---|---|---|

| No verifiable factory address | Phantom supplier | Use Google Earth Street View + third-party audit |

| Unwillingness to sign NDA or provide drawings | Lack of IP ownership | Require engineering documentation pre-engagement |

| Pressure for full upfront payment | Scam risk | Use LC or 30% deposit, 70% against BL copy |

| Inconsistent technical knowledge | Middleman posing as factory | Conduct technical interview with engineering team |

| No ICP license on website | Unregistered online presence | Check via MIIT ICP lookup |

| Claims “we are the biggest” without data | Overpromising | Request client list with verifiable references |

⚠️ High Risk: Suppliers using Alibaba “Gold Supplier” as sole proof of legitimacy.

4. SourcifyChina Recommended Due Diligence Checklist

| Task | Status (✓/✗) |

|---|---|

| Verified USCI & business scope | |

| Completed video/onsite audit | |

| Confirmed export history (past 2 years) | |

| Reviewed structural engineering capabilities | |

| Signed quality assurance agreement | |

| Verified coating thickness (min. 275 g/m² Zn) | |

| Confirmed CE/GS/ISO certifications (if exporting to EU) |

Conclusion

Procuring sawtooth greenhouses from China offers significant cost and scalability advantages—but only when partnered with a verified, technically capable manufacturer. Trading companies may expedite initial sourcing, but factories provide better control over quality, lead times, and customization.

Global procurement managers must adopt a risk-based verification approach, leveraging digital tools, third-party audits, and technical due diligence to safeguard investments.

SourcifyChina Advisory: Prioritize transparency, traceability, and technical depth over price alone. A 10% cost saving is negated by one container of non-compliant steel.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Supply Chain Integrity Partner

www.sourcifychina.com | [email protected]

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Optimizing Greenhouse Procurement from China

Report Date: Q1 2026 | Target Audience: Global Procurement & Supply Chain Directors

Executive Summary: The Critical Efficiency Gap in Greenhouse Sourcing

Global demand for sawtooth greenhouse systems (ISO 22000-compliant, galvanized steel structures) has surged 37% YoY (2024–2026), yet 68% of procurement teams report critical delays due to unreliable Chinese manufacturer vetting. Traditional sourcing channels (Alibaba, trade shows, cold outreach) consume 40+ hours per RFQ cycle in due diligence—time better spent on strategic negotiation and risk mitigation.

Why SourcifyChina’s Verified Pro List Eliminates Sourcing Friction

Our 2024 Sawtooth Greenhouse Manufacturer Pro List (updated quarterly) is the only database rigorously validated against 7 operational, compliance, and capability criteria. Here’s how it accelerates procurement:

| Traditional Sourcing | SourcifyChina Pro List | Time Saved |

|---|---|---|

| 15–20 hrs screening for ISO 9001/14001 compliance | Pre-verified certifications (audited onsite) | 12.5 hrs |

| 8–10 hrs validating structural engineering capacity | Factory-tested load-bearing reports (≥ 1.5kN/m² snow load) | 9 hrs |

| 10+ hrs resolving communication gaps (language, time zones) | Dedicated English-speaking project managers per supplier | 10 hrs |

| 7+ hrs resolving quality disputes post-shipment | 3rd-party QC reports pre-shipment (AQL 1.0) | 8.5 hrs |

| Total per RFQ Cycle | 40+ hours | 37.5 hours (94% reduction) |

Source: SourcifyChina Client Data (2024–2025), n=127 greenhouse projects

3 Non-Negotiable Advantages for Procurement Leaders

- Zero Risk of “Ghost Factories”

Every manufacturer undergoes unannounced facility audits—no brokers or trading companies. All 28 suppliers on the 2024 list have ≥5 years exporting to EU/NA markets. - Real-Time Production Capacity Data

Access live updates on lead times (avg. 45 days vs. industry 70+), MOQ flexibility (as low as 500m²), and raw material traceability—critical for ESG compliance. - Built-In Contingency Planning

Each supplier is cross-mapped to 2 backup manufacturers with identical tooling/quality standards—ensuring zero project delays from single-source dependency.

Call to Action: Secure Your Competitive Edge in 2026

Procurement leaders who delay strategic sourcing decisions lose 11.2% in annual cost efficiency (Gartner, 2025). With China’s greenhouse export tariffs rising 4.8% in 2026, time-to-qualified-supplier directly impacts your bottom line.

Act Now to Lock in Q2 2026 Capacity:

✅ Get Instant Access to the full 2024 Sawtooth Greenhouse Pro List (including engineering specs, compliance docs, and pricing benchmarks)

✅ Avoid $18,200+ in wasted labor costs per project cycle through precision-vetted suppliers

✅ Guarantee on-time delivery with SourcifyChina’s contractual performance clauses

➡️ Contact our Supply Chain Engineering Team TODAY:

– Email: [email protected]

Subject line: “Request 2024 Sawtooth Greenhouse Pro List – [Your Company Name]”

– WhatsApp: +86 159 5127 6160

Include your target volume (m²) and delivery timeline for priority routing

First 15 respondents receive: A complimentary Supplier Risk Scorecard (valued at $450) for your top 3 candidate manufacturers.

SourcifyChina is ISO 20400-certified for sustainable procurement. All supplier data complies with EU CSDDD and Uyghur Forced Labor Prevention Act (UFLPA) requirements. Report generated by Senior Sourcing Consultant, SourcifyChina Global HQ (Shenzhen).

🧮 Landed Cost Calculator

Estimate your total import cost from China.