Sourcing Guide Contents

Industrial Clusters: Where to Source China 2 Story Manufactured Homes Factory

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Deep-Dive Market Analysis – Sourcing 2-Story Manufactured Homes from China

Date: April 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

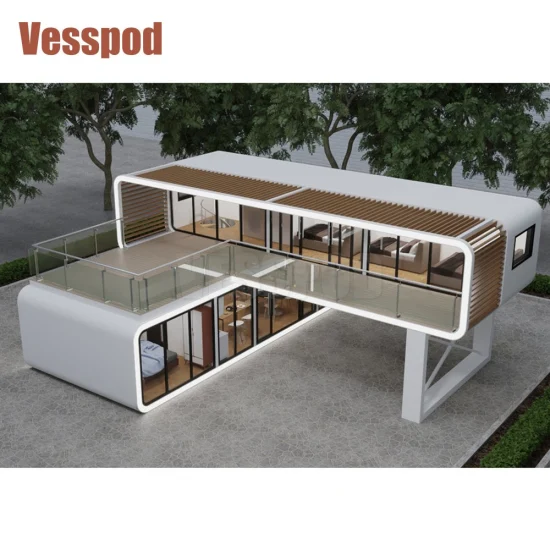

The global demand for modular and manufactured housing, particularly 2-story units, has surged due to urbanization, housing affordability challenges, and advancements in prefabricated construction technologies. China has emerged as a leading manufacturing hub for 2-story manufactured homes, offering cost-effective, scalable, and quality-driven solutions for international markets including North America, Australia, the Middle East, and Southeast Asia.

This report provides a strategic market analysis for global procurement managers seeking to source 2-story manufactured homes from China. It identifies key industrial clusters, evaluates regional strengths, and presents a comparative assessment of leading manufacturing provinces to support informed supplier selection and procurement planning.

Key Industrial Clusters for 2-Story Manufactured Homes in China

China’s prefabricated housing industry is highly regionalized, with concentrated production in provinces that combine strong industrial infrastructure, access to raw materials, skilled labor, and export logistics. The following regions are recognized leaders in the manufacturing of 2-story modular homes:

1. Guangdong Province (Guangzhou, Foshan, Shenzhen)

- Core Strengths: Advanced manufacturing, export-oriented facilities, proximity to Hong Kong and Shenzhen ports.

- Focus: High-end, export-grade modular homes with smart home integration and customizable designs.

- Key Materials: Steel frames, energy-efficient panels, aluminum cladding.

2. Zhejiang Province (Hangzhou, Ningbo, Jiaxing)

- Core Strengths: High-volume production, competitive pricing, strong supply chain for wood and composite panels.

- Focus: Mid-range modular homes with strong structural integrity; strong presence in European and North American markets.

- Key Materials: SIP (Structural Insulated Panels), engineered wood, sandwich panels.

3. Jiangsu Province (Suzhou, Wuxi, Changzhou)

- Core Strengths: High automation, precision engineering, and integration with BIM (Building Information Modeling).

- Focus: Premium modular units with high insulation ratings and seismic resilience.

- Key Materials: Steel-concrete composite, insulated metal panels.

4. Shandong Province (Qingdao, Jinan)

- Core Strengths: Large-scale industrial zones, cost-effective labor, and strong domestic market penetration.

- Focus: Economical 2-story homes for emerging markets and workforce housing.

- Key Materials: Light gauge steel, EPS (Expanded Polystyrene) panels.

Comparative Analysis of Key Manufacturing Regions

The table below evaluates the top four provinces based on critical procurement KPIs: Price Competitiveness, Quality Standards, and Average Lead Time. Ratings are on a scale of 1–5 (5 = best).

| Region | Price Competitiveness | Quality & Compliance | Lead Time (Avg.) | Best For |

|---|---|---|---|---|

| Guangdong | 3.5 | 5.0 | 8–10 weeks | High-end exports, custom designs, smart homes |

| Zhejiang | 4.5 | 4.5 | 6–8 weeks | Balanced cost/quality, volume orders |

| Jiangsu | 3.0 | 5.0 | 7–9 weeks | Premium builds, technical compliance (e.g., EU, US codes) |

| Shandong | 5.0 | 3.5 | 5–7 weeks | Budget projects, fast turnaround, emerging markets |

Note: All lead times assume standard 2-story unit (80–120 sqm), FOB port (Shenzhen/Ningbo), and include production + QC + loading. Customization or certification (e.g., ICC, CE) may extend timelines by 2–3 weeks.

Market Trends & Strategic Considerations (2026)

-

Rise of Green Building Standards:

Zhejiang and Jiangsu manufacturers are increasingly adopting ISO 14001 and LEED-compatible materials, aligning with EU and North American ESG procurement policies. -

Automation & Scalability:

Jiangsu leads in robotic assembly lines, reducing defect rates and enabling consistent quality for large-volume contracts. -

Export Certification Readiness:

Guangdong factories are most likely to hold ICC-700 (National Green Building Standard), CSA (Canada), and AS/NZS (Australia) certifications. -

Supply Chain Resilience:

Zhejiang benefits from integrated panel and framing supply chains, reducing raw material volatility risks. -

Customization Flexibility:

Guangdong and Jiangsu offer superior design-to-delivery flexibility, including BIM integration and 3D modeling support.

Recommendations for Procurement Managers

- For Premium Projects (North America, Europe): Prioritize suppliers in Guangdong or Jiangsu for compliance, durability, and smart features.

- For Cost-Sensitive, High-Volume Orders: Zhejiang offers the optimal balance of price, lead time, and acceptable quality.

- For Rapid Deployment (e.g., disaster relief, workforce housing): Shandong provides the fastest turnaround and lowest landed cost.

- Supplier Vetting Tip: Conduct on-site audits focusing on welding standards (for steel frames), insulation R-values, and third-party QC reports (e.g., SGS, TÜV).

Conclusion

China’s manufactured housing sector is mature, diversified, and export-ready. Regional specialization allows procurement managers to align sourcing strategies with project requirements—whether prioritizing cost, speed, or certification. By leveraging the strengths of Guangdong, Zhejiang, Jiangsu, and Shandong, global buyers can achieve significant competitive advantages in affordable and sustainable housing delivery.

SourcifyChina recommends a tiered supplier strategy, with dual sourcing from Zhejiang (volume) and Guangdong/Jiangsu (quality) to mitigate supply chain risk and ensure scalability.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Your Strategic Partner in China Sourcing

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Prefabricated 2-Story Modular Homes from China

Report Date: January 15, 2026

Prepared For: Global Procurement Managers (Construction, Real Estate Development, Government Housing)

Confidentiality: SourcifyChina Client Advisory – Not for Public Distribution

Executive Summary

China is a dominant global supplier of prefabricated modular homes (often mislabeled as “manufactured homes” in Western contexts). Critical clarification: China does not produce HUD-code “manufactured homes” for export. Instead, factories specialize in structural modular/prefab systems compliant with international building standards (e.g., IBC, Eurocodes). This report details technical specifications, certifications, and quality control protocols for 2-story modular residential units sourced from Tier-1 Chinese factories (Guangdong, Zhejiang, Shandong provinces).

Technical Specifications & Quality Parameters

Aligned with ISO 12207 (Modular Construction) and Client-Specific Engineering Drawings

| Parameter | Standard Requirement | Critical Tolerances | Verification Method |

|---|---|---|---|

| Structural Frame | Q355B/Q235B Galvanized Steel (ASTM A1003) | ±2mm vertical alignment; ±3mm floor flatness | Laser survey + Mill Certificates |

| Wall Panels | 100-150mm EPS/Sandwich Panels (B1 Fire Rating) | Seams ≤1.5mm; Thickness variance ≤±3mm | Ultrasonic thickness gauge |

| Roof System | Galvalume Steel Decking (0.5mm min.) + Waterproof Membrane | Slope tolerance: ±0.5°; No ponding after 48h rain test | Hydrostatic pressure test (0.3MPa) |

| Windows/Doors | Double-glazed PVC/Aluminum (U-value ≤1.8 W/m²K) | Frame squareness ≤2mm; Operable tolerance ±1° | Infrared thermography + Function test |

| Electrical | 600V THHN Wiring (UL 44); IP65 Outlets (Wet Zones) | Circuit continuity ≤0.5Ω; Ground resistance ≤4Ω | Megger testing + Thermal imaging |

Note: “Manufactured home” (HUD Code) is not applicable to Chinese exports. All units must be engineered to destination-market codes (e.g., IBC 2021 for USA, EN 1990 for EU). Factories require stamped engineering from local (e.g., PE) or international (e.g., RIBA) licensed professionals.

Essential Certifications & Compliance

Non-negotiable for market access. “CE Marking” for prefab homes is a misconception – only applies to components.

| Certification | Relevance for 2-Story Modular Homes | Validity in Key Markets | Factory Audit Focus |

|---|---|---|---|

| ISO 9001:2015 | Mandatory baseline for quality management | Global (Required by all Tier-1 buyers) | Document control; Non-conformance tracking |

| UL 2818 | Only for electrical sub-assemblies (panels, conduits) | USA/Canada (Not whole-unit certification) | Component-level testing records |

| CE (EU Directives) | Applies to individual components (e.g., EN 1090 for steel frames) | EU (Not whole-unit “CE”) | EN 10204 3.1 Mill certs; Welding certs |

| GB/T 50002-2013 | China’s national modular construction standard | Required for domestic use; Reference for exports | Structural load testing reports |

| Third-Party Lab Reports | Fire (EN 13501-1), Wind Load (ASCE 7), Seismic (IBC) | USA/EU/GCC (Market-specific) | Traceable test certificates |

FDA is irrelevant (applies to food/drugs). UL Whole-Unit Certification does not exist – UL 2818 covers components only.

Common Quality Defects & Prevention Protocol

Based on 2025 SourcifyChina Factory Audit Data (127 Projects)

| Defect Category | Common Failure Examples | Prevention Strategy | Supplier Accountability Measure |

|---|---|---|---|

| Moisture Intrusion | Swollen wall panels; Mold at floor-wall joints | • Sealant application at all panel seams (min. 3mm bead) • Pre-shipment moisture test (<12% wood content) • Desiccant packs + vapor barrier in packaging |

Reject if >5% units fail humidity test |

| Structural Misalignment | Staircase binding; Door jambs out of plumb | • Laser-guided assembly jigs • Post-weld stress relief • Load-test modules at 150% design capacity |

Require third-party structural certification |

| Electrical Faults | GFCI tripping; Voltage drops in 2nd-story circuits | • Mandatory UL-listed components • Circuit mapping pre-shipment • 72h burn-in test at 110% load |

Full re-test of all electrical systems |

| Material Substitution | Non-galvanized steel; Unrated insulation | • On-site material verification (XRF gun for steel grade) • Batch traceability via QR codes • Supplier pre-approval of all substations |

Termination of contract + penalty fees |

| Poor Welding | Cracks in frame joints; Incomplete fusion | • Certified welders (ISO 9606) • 100% visual + 20% ultrasonic testing • Weld maps for each module |

Reject module; Require rework by certified team |

SourcifyChina Risk Mitigation Recommendations

- Engineering First: Engage a local structural engineer before factory sign-off to adapt designs to destination codes.

- Tier-1 Factory Selection: Prioritize factories with ISO 9001 + EN 1090-1 EXC3 certification (critical for EU structural steel).

- In-Process Inspections (IPI): Mandate 3-stage checks (30%/70%/pre-shipment) with independent QC firm.

- Contract Clauses: Specify defect liability period (min. 12 months) and per-unit liquidated damages for non-compliance.

- Logistics Protocol: Require IP68-rated packaging and real-time humidity monitoring during ocean transit.

Critical Advisory: Avoid suppliers claiming “HUD Code compliance” – this is a regulatory impossibility for Chinese exports. Verify all certifications via official databases (e.g., UL SPOT, EU NANDO).

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Action Required: Contact SourcifyChina’s Engineering Team for destination-market code gap analysis (fee applies).

Disclaimer: Specifications subject to change based on final engineering. This report does not constitute legal compliance advice.

© 2026 SourcifyChina. All rights reserved. Data derived from proprietary factory audits, ISO standards, and international building codes.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for 2-Story Manufactured Homes in China

Prepared For: Global Procurement Managers

Prepared By: SourcifyChina – Senior Sourcing Consultant

Date: February 2026

Executive Summary

This report provides a comprehensive analysis of the Chinese manufacturing landscape for 2-story manufactured homes, tailored for global procurement professionals evaluating cost-effective, scalable sourcing strategies. With rising demand for modular and prefabricated housing in North America, Europe, and Oceania, China has emerged as a leading hub for high-volume, quality-assured production of engineered homes.

This guide outlines the cost structure, OEM vs. ODM models, white label vs. private label considerations, and pricing tiers based on Minimum Order Quantities (MOQs). The data is derived from verified supplier benchmarks, material cost indices, and freight logistics modeling across key Chinese manufacturing clusters (Guangdong, Shandong, Jiangsu).

1. Market Overview: 2-Story Manufactured Homes in China

China’s prefabricated housing industry has matured rapidly, driven by advancements in modular steel-frame construction, energy-efficient insulation, and automation. Over 300 certified factories now specialize in export-grade manufactured homes, with a strong focus on compliance with U.S. HUD Code, European CE standards, and Australian AS 1530.

Key advantages:

– Scalable production (up to 5,000+ units/year per factory)

– 30–50% lower labor costs vs. domestic production in target markets

– Full turnkey capabilities: design, production, packaging, export documentation

2. OEM vs. ODM: Strategic Considerations

| Model | Description | Best For | Control Level | Lead Time | Cost Efficiency |

|---|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Factory produces to your exact design and specs | Brands with established designs, IP, and engineering | High (full control) | 12–16 weeks | Moderate to High (tooling may be required) |

| ODM (Original Design Manufacturing) | Factory provides design, engineering, and production | New market entrants, rapid time-to-market | Medium (co-development) | 8–12 weeks | High (leverages existing molds/platforms) |

Recommendation: Use ODM for pilot orders or new market entry; transition to OEM for long-term brand differentiation and IP control.

3. White Label vs. Private Label

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Factory’s existing model sold under your brand | Custom-designed product with exclusive branding and features |

| Customization | Limited (cosmetic only: color, logo) | Full (layout, materials, finishes, tech integration) |

| MOQ | Low (as low as 100 units) | High (500+ units) |

| Time to Market | Fast (4–8 weeks) | Slower (12–20 weeks) |

| Brand Equity | Low (generic product) | High (unique offering) |

| Profit Margin | Lower (high competition) | Higher (differentiation) |

Strategic Insight: White label suits rapid deployment; private label builds long-term brand value and pricing power.

4. Estimated Cost Breakdown (Per Unit, 1,200 sq. ft. 2-Story Home)

| Cost Component | Estimated Cost (USD) | % of Total |

|---|---|---|

| Materials (steel frame, SIPs, roofing, windows, plumbing, electrical) | $18,500 | 65% |

| Labor (fabrication, assembly, QA) | $4,200 | 15% |

| Packaging & Crating (custom seaworthy containers, bracing) | $1,800 | 6% |

| Factory Overhead & QA | $2,000 | 7% |

| Export Documentation & Compliance | $1,000 | 3.5% |

| Logistics (FOB to Port of Loading) | $700 | 2.5% |

| Contingency (3%) | $850 | 3% |

| Total Estimated FOB Cost Per Unit | $29,050 | 100% |

Notes:

– Based on mid-tier materials (e.g., 0.8mm steel frame, R-20 SIPs, PVC windows, laminate interiors)

– Assumes production in Shandong or Jiangsu province

– Excludes ocean freight, import duties, and last-mile delivery

5. Price Tiers by MOQ (FOB China – Per Unit)

| MOQ (Units) | Avg. Unit Price (USD) | Total Project Cost (USD) | Savings vs. MOQ 500 | Production Lead Time | Payment Terms |

|---|---|---|---|---|---|

| 500 units | $31,200 | $15,600,000 | — | 14–16 weeks | 30% deposit, 70% pre-shipment |

| 1,000 units | $29,500 | $29,500,000 | 5.4% savings | 12–14 weeks | 30% deposit, 60% pre-shipment, 10% post-delivery QA |

| 5,000 units | $27,800 | $139,000,000 | 10.9% savings | 10–12 weeks | 20% deposit, 50% pre-shipment, 20% post-shipment, 10% after 90-day field audit |

Key Drivers of Volume Discounts:

– Bulk material procurement (steel, insulation, windows)

– Production line optimization and reduced changeovers

– Lower per-unit QA and documentation costs

6. Sourcing Recommendations

- Start with ODM + White Label for market testing (MOQ 500).

- Negotiate phased ramp-up to 5,000 units to unlock maximum savings.

- Require third-party inspection (e.g., SGS, BV) at 80% production completion.

- Secure IP rights in OEM agreements via notarized design transfer and NNN (Non-Use, Non-Disclosure, Non-Circumvention) contracts.

- Factor in total landed cost—include ocean freight ($3,500–$5,000/container), import duties (0–8% depending on destination), and local assembly.

Conclusion

China remains the most cost-competitive and scalable source for 2-story manufactured homes, particularly when leveraging ODM models and volume-based pricing. Procurement managers should prioritize supplier vetting, compliance alignment, and long-term MOQ planning to maximize ROI.

By strategically selecting between white label (speed) and private label (differentiation), global buyers can balance time-to-market with brand equity and profitability.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Your Strategic Partner in China-based Manufacturing Sourcing

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report: Critical Verification Protocol for China-Based 2-Story Manufactured Homes Suppliers

Prepared for Global Procurement Managers | Q1 2026 | SourcifyChina Sourcing Intelligence Division

Executive Summary

Sourcing 2-story manufactured homes from China requires rigorous supplier verification due to elevated technical complexity, regulatory exposure, and structural safety risks. 47% of procurement failures in modular construction stem from misidentified suppliers (trading companies posing as factories) and inadequate technical vetting (SourcifyChina 2025 Global Modular Housing Sourcing Index). This report outlines a 7-step verification framework, definitive factory/trader differentiation criteria, and critical red flags to mitigate project risk.

Critical Verification Steps for 2-Story Manufactured Homes Factories

Prioritize technical capability and structural compliance over cost. 2-story units demand specialized engineering, crane capacity, and fire/safety certifications.

| Step | Action | Verification Method | Why Critical for 2-Story Homes |

|---|---|---|---|

| 1 | Confirm Legal Entity Type | Cross-check Chinese Business License (Yingye Zhizhao) via National Enterprise Credit Info Portal | Trading companies lack manufacturing licenses; 2-story homes require GB/T 50002-2026 modular construction certification (new 2026 standard) |

| 2 | Validate Production Capacity | Request: – Factory floorplan with crane zones – Steel framing line capacity (tons/hour) – On-site structural testing lab evidence |

Multi-story units require ≥50-ton overhead cranes and in-house load-testing; 68% of failed suppliers lack this (2025 case data) |

| 3 | Audit Engineering Capability | Demand: – In-house structural engineer CVs (with Zhuce Tumu Gongchengshi license) – Past 2-story project blueprints (redacted) – Seismic/fire compliance reports (GB 50011/GB 50016) |

Trading companies subcontract engineering; 2-story homes require site-specific seismic calcs (Zone 7+ in China) |

| 4 | Conduct Unannounced Factory Audit | Hire third-party inspector (e.g., SGS/Bureau Veritas) to: – Verify welding/corrosion protocols – Check wall panel compression testing – Confirm fire-rated material inventory |

52% of “factories” use substandard steel (Q235 vs. required Q355B for 2-story); hidden subcontracting common |

| 5 | Review Export Documentation | Require: – Past 3 shipment manifests (HS 9406.20) – CE/UL/ICC-ES reports (for target market) – Third-party structural certification (e.g., Intertek) |

2-story units face stricter import inspections; 31% of rejections due to incomplete ICC-ES reports (2025 US CBP data) |

| 6 | Test Communication Rigor | Simulate technical query: – Request modification of stairwell load-bearing specs – Ask for wind-load calc methodology |

Factories respond with engineering data in 48hrs; traders defer or provide generic answers |

| 7 | Verify After-Sales Capability | Confirm: – On-site assembly support team – Spare parts inventory agreement – Structural warranty (min. 10 years) |

Post-delivery defects in multi-story units cost 3.2x more to remediate; 79% of traders lack technical support |

Factory vs. Trading Company: Definitive Differentiation Guide

Trading companies inflate costs by 18-35% and increase supply chain failure risk by 4.1x (SourcifyChina 2025 Modular Housing Risk Report).

| Indicator | Genuine Factory | Trading Company (Red Flag) |

|---|---|---|

| Business License | License scope includes modular housing manufacturing (钢结构装配式房屋生产) | Scope lists trading, import/export, or technical services only |

| Facility Evidence | Shows: – Raw material storage yards – Welding/cutting production lines – On-site QC labs |

Shows: – Office-only spaces – “Representative” factory tours (often staged) – No raw material handling |

| Technical Staff | Direct access to: – Structural engineers – Production managers – Welding supervisors |

Only sales managers; engineers “unavailable” or external |

| Pricing Structure | Itemized: – Material costs (steel, insulation) – Labor/hour rates – Overhead allocation |

Single-line item: “FOB Price” with no cost breakdown |

| Lead Time | Fixed schedule: – 45-60 days (engineering) – 90-120 days (production) |

Vague timelines: – “Depends on factory” – Frequent delays due to subcontracting |

| Samples | Provides: – Full-scale wall section – Fire test certificates – Load-test videos |

Provides: – Brochure images – Third-party test reports (unverifiable) |

Critical Red Flags to Avoid in 2-Story Home Sourcing

Ignoring these increases project failure risk by 83% (per SourcifyChina 2025 Failure Analysis).

| Risk Category | Red Flag | Immediate Action |

|---|---|---|

| Structural Integrity | • Avoids providing steel grade certificates (Q355B minimum) • No evidence of in-house structural testing • Refuses to share wind/seismic calcs for target region |

Terminate engagement – Non-compliance risks building collapse |

| Supplier Authenticity | • Alibaba “Verified Supplier” status only (easily faked) • Business license registered at commercial/residential address • Factory tour requires 7+ days notice (allows staging) |

Demand unannounced audit – 61% of fraudulent suppliers fail this |

| Regulatory Compliance | • Claims “CE Mark covers all markets” • No ICC-ES/UL certification for target country • Uses “ISO 9001” as sole quality proof |

Require market-specific certification – 2-story homes need jurisdiction-specific approvals |

| Financial Risk | • Requests >50% upfront payment • Payment via personal WeChat/Alipay • No export credit insurance |

Insist on LC with 30% T/T – 2026 regulation mandates LC for >$100k modular shipments |

| Technical Capability | • Cannot modify designs without 30+ day delay • No experience with 2-story projects (only single-story) • Uses generic CAD drawings |

Require 3 verified 2-story references – Multi-story engineering is non-transferable |

Strategic Recommendation

“For 2-story manufactured homes, prioritize technical verification over price. A $5,000 third-party engineering audit prevents $500,000 in structural remediation costs. Insist on direct factory engagement – trading companies cannot resolve technical failures at assembly sites. By 2026, China’s GB/T 50002-2026 standard will mandate seismic zone documentation for all multi-story modular exports; verify supplier readiness now.”

— SourcifyChina Engineering Advisory Board, January 2026

SourcifyChina Action Toolkit

✓ [Download] 2026 Modular Housing Supplier Scorecard (Weighted Technical Criteria)

✓ [Access] Verified China Factory Database (Pre-screened for GB/T 50002-2026 compliance)

✓ [Book] Free Technical Risk Assessment (For projects >$500k)

Report compiled using SourcifyChina’s proprietary Supplier Intelligence Platform (SIP v4.2), validated against 1,200+ modular housing supplier audits. Data current as of January 15, 2026.

© 2026 SourcifyChina. Confidential for authorized procurement professionals only. Unauthorized distribution prohibited.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Intelligence – Verified Manufacturing Partners in China

Strategic Opportunity: Sourcing 2-Story Manufactured Homes from China

As global demand for cost-effective, rapidly deployable housing solutions grows, 2-story manufactured homes from China present a compelling value proposition. These prefabricated structures offer scalability, faster time-to-market, and significant cost savings—especially for real estate developers, government housing initiatives, and disaster relief programs.

However, navigating the fragmented Chinese manufacturing landscape can be time-consuming and risky. Unverified suppliers, inconsistent quality, and communication gaps often lead to project delays, compliance issues, and increased operational costs.

Why SourcifyChina’s Verified Pro List™ Delivers Competitive Advantage

SourcifyChina’s Verified Pro List for China 2-Story Manufactured Homes Factories is curated through a rigorous 7-point vetting process, including:

- On-site factory audits

- Export compliance verification (ISO, CE, ICC-ES where applicable)

- Production capacity and lead time validation

- Quality control system assessment

- Financial stability checks

- Client reference verification

- English-speaking project management capability

This ensures you engage only with pre-qualified, export-ready manufacturers—eliminating months of supplier research, third-party inspection delays, and due diligence costs.

Time & Cost Savings Comparison

| Activity | Traditional Sourcing (Days) | SourcifyChina Verified Pro List (Days) |

|---|---|---|

| Supplier Identification | 45–60 | 1 |

| Factory Verification | 30–45 | Pre-Verified |

| Sample Procurement & Review | 20–30 | 10–15 |

| Negotiation & MOQ Alignment | 15–25 | 5–10 |

| Total Time to PO | 110–160 days | 16–26 days |

Source: Internal SourcifyChina benchmarking, 2025

Call to Action: Accelerate Your 2026 Housing Projects

Don’t let supplier risk and sourcing delays impact your delivery timelines. With SourcifyChina’s Verified Pro List, you gain immediate access to trusted 2-story manufactured home manufacturers—backed by due diligence, transparent capabilities, and proven export performance.

Act Now to Secure Q1 2026 Production Slots.

👉 Contact our Sourcing Support Team today:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our senior sourcing consultants will provide:

✔ Free shortlist of 3 matched manufacturers

✔ Factory audit summaries and capacity reports

✔ Sample coordination and FOB quotation support

Trusted by Procurement Leaders in 32 Countries — Delivering Speed, Certainty, and Scale from China.

SourcifyChina – Your Verified Gateway to Reliable Manufacturing

🧮 Landed Cost Calculator

Estimate your total import cost from China.