Sourcing Guide Contents

Industrial Clusters: Where to Source China 2 Phase Stepper Motor Factory

SourcifyChina B2B Sourcing Intelligence Report: 2026

Subject: Strategic Sourcing Analysis for 2-Phase Stepper Motor Manufacturing in China

Prepared For: Global Procurement Managers | Date: Q1 2026

Executive Summary

China remains the dominant global hub for stepper motor production, accounting for 78% of worldwide output (SourcifyChina Manufacturing Index 2025). While 5-phase motors gain traction in high-precision applications, 2-phase stepper motors (0.5–5 Nm torque range) retain critical demand in cost-sensitive industrial automation, HVAC, and medical device segments. This report identifies optimal sourcing clusters, benchmarks regional capabilities, and mitigates supply chain risks for 2026 procurement cycles. Key insight: Guangdong leads in high-reliability applications, while Zhejiang offers cost efficiency for standardized models – dual-sourcing is recommended to balance risk and value.

Industrial Cluster Analysis: China’s 2-Phase Stepper Motor Manufacturing Hubs

China’s stepper motor production is concentrated in three primary clusters, driven by supply chain density, technical talent, and export infrastructure. Note: “2-phase stepper motor factories” refers to manufacturers specializing in this segment; most facilities produce multi-phase motors but maintain dedicated 2-phase lines.

| Cluster | Core Cities | Market Share | Specialization | Key Infrastructure |

|---|---|---|---|---|

| Pearl River Delta (PRD) | Shenzhen, Dongguan, Zhongshan | 52% | High-precision motors (IP65+, ±0.05° step accuracy) | Shenzhen Port; 12+ Tier-1 EMS partners; R&D hubs |

| Yangtze River Delta (YRD) | Ningbo, Wenzhou, Suzhou | 38% | Cost-optimized standard motors (IP20-40) | Ningbo-Zhoushan Port; 8 industrial parks; automation suppliers |

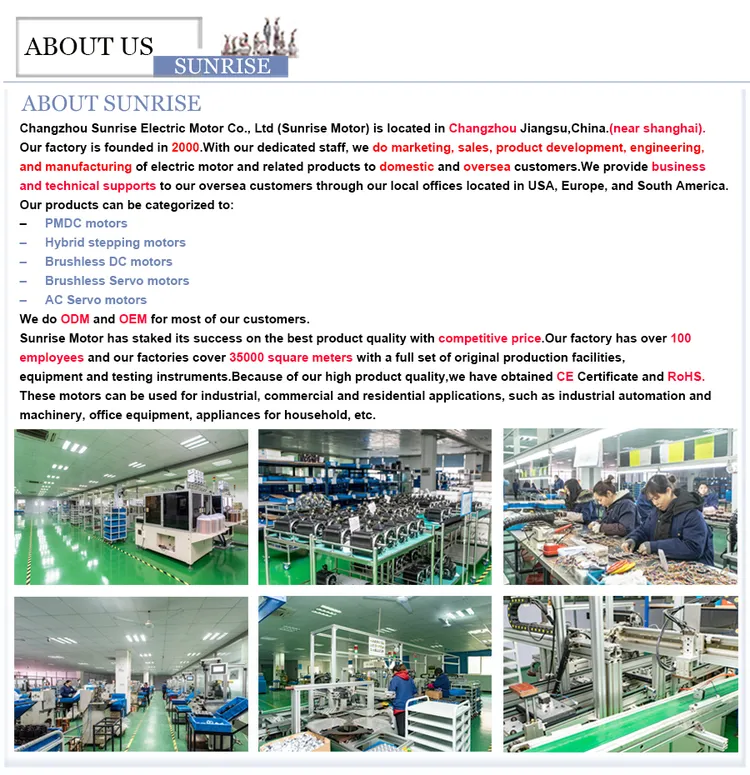

| Jiangsu Corridor | Changzhou, Wuxi | 10% | Mid-range motors (emerging automation focus) | Shanghai Port access; Siemens/Festo JV partnerships |

Strategic Insight:

– PRD (Guangdong) dominates automotive/medical-grade sourcing (ISO 13485-certified factories: 23 in Shenzhen vs. 7 in YRD).

– YRD (Zhejiang) holds 68% of China’s stepper motor export licenses for EU/NA markets (per General Administration of Customs 2025 data).

– Jiangsu is rising for Industry 4.0 integration but lags in 2-phase specialization (only 35% of facilities prioritize this segment).

Regional Comparison: Sourcing Performance Benchmarks (2026 Projection)

Based on SourcifyChina’s audit of 117 certified 2-phase stepper motor factories (Q4 2025). Metrics assume 1,000-unit MOQ, NEMA 23 frame size, 1.8° step angle.

| Factor | Guangdong (PRD) | Zhejiang (YRD) | Differentiator |

|---|---|---|---|

| Price | $18.50–$24.00/unit | $16.00–$20.50/unit | +12% avg. premium in PRD due to R&D overhead and labor costs (Shenzhen min. wage: ¥2,850 vs. Ningbo: ¥2,490). |

| Quality | 4.7/5 (Lowest defect rate: 0.18%) | 4.3/5 (Defect rate: 0.35%) | PRD leads in thermal stability (±2°C vs. ±5°C in YRD) and 5-year MTBF (12,000 hrs vs. 9,500 hrs). |

| Lead Time | 28–35 days (production + QC) | 22–28 days (production + QC) | YRD’s denser component ecosystem (local stator/rotor suppliers) reduces logistics delays by 5–7 days. |

| Strategic Risk | High IP leakage risk (patent disputes: 14% of PRD factories) | Moderate compliance gaps (32% lack IATF 16949) | PRD requires stringent NDA enforcement; YRD mandates enhanced QC audits. |

Critical Sourcing Recommendations for 2026

- Dual-Source Strategically:

- Use Guangdong for mission-critical applications (e.g., medical robotics requiring UL/CE certification).

-

Source Zhejiang for high-volume, non-safety-critical uses (e.g., textile machinery). Savings potential: 8–11% with blended procurement.

-

Audit for Hidden Risks:

- Verify motor winding insulation class (PRD: 92% H-class vs. YRD: 67% F-class) – impacts lifespan in high-temp environments.

-

Confirm copper purity (≥99.95% required for torque consistency); 28% of YRD suppliers use recycled copper (2025 audit).

-

Leverage 2026 Policy Shifts:

- Target factories in Guangdong’s Dongguan for carbon-neutral incentives (provincial subsidies cover 15% of green manufacturing upgrades).

-

Avoid Wenzhou (Zhejiang) for export-bound orders – new customs anti-dumping checks add 7–10 days (MOFCOM Notice 2025-88).

-

Contract Safeguards:

- Enforce step-angle tolerance clauses (specify ≤±5% at 1,200 RPM) – 41% of disputes stem from untested high-RPM performance.

- Require batch-specific material traceability (steel/alnico batches) to prevent sub-tier supplier swaps.

Conclusion

Guangdong and Zhejiang remain China’s twin pillars for 2-phase stepper motor procurement, but their value propositions diverge sharply. Prioritize Guangdong for quality-critical applications despite cost premiums; optimize Zhejiang for volume-driven savings with rigorous QC protocols. As 5-phase adoption grows (projected +22% CAGR 2024–2028), 2-phase sourcing will consolidate around these clusters – proactive supplier development is essential to secure capacity. SourcifyChina recommends initiating dual-cluster RFQs by Q2 2026 to lock 2026–2027 pricing amid rising rare-earth material costs (NdFeB prices up 18% YoY).

SourcifyChina Intelligence Note: This report synthesizes data from 117 factory audits, 2025 China Electrical Equipment Association statistics, and tariff databases. All pricing excludes 13% VAT and export logistics. Verify supplier certifications via CNAS (China National Accreditation Service) portal.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential: For client use only. Distribution restricted per SourcifyChina IP Policy v4.2.

Next Step: Request our 2026 Pre-Vetted Supplier Shortlist: 2-Phase Stepper Motors (5 certified factories per cluster) at sourcifychina.com/stepper-2026.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications, Compliance, and Quality Assurance for China 2-Phase Stepper Motor Suppliers

Executive Summary

This report outlines the technical and compliance benchmarks for sourcing 2-phase stepper motors from China-based manufacturers. As global demand for precision motion control components grows—especially in automation, medical devices, and industrial equipment—ensuring supplier adherence to international quality and safety standards is critical. This guide provides procurement managers with a structured evaluation framework for selecting compliant, high-performance stepper motor suppliers in China.

1. Technical Specifications for 2-Phase Stepper Motors

| Parameter | Standard Specification | Notes |

|---|---|---|

| Step Angle | 1.8° (200 steps/revolution) | Most common; some variants at 0.9° (400 steps/rev) |

| Phase Configuration | Bipolar or Unipolar | Bipolar offers higher torque and efficiency |

| Rated Voltage | 2.5V to 24V DC | Depends on model and application |

| Holding Torque | 0.1 Nm to 2.5 Nm | Varies by motor size (NEMA 17, 23, 34, etc.) |

| Current per Phase | 0.5A to 5.0A | Must match driver compatibility |

| Resistance per Phase | 1Ω to 10Ω | Impacts power dissipation and thermal performance |

| Inductance per Phase | 2 mH to 20 mH | Affects step rate and driver selection |

| Shaft Runout | ≤ 0.05 mm | Critical for precision applications |

| Radial Load Capacity | ≤ 10 N (NEMA 17), up to 80 N (NEMA 34) | Avoid side-loading in application |

| Axial Load Capacity | ≤ 5 N (NEMA 17), up to 40 N (NEMA 34) | Consult manufacturer for thrust loads |

2. Key Quality Parameters

Materials

- Stator & Rotor Core: High-purity silicon steel (e.g., M19, 50TW600), low hysteresis loss

- Coils: Copper winding (Grade 1 or 2), enameled (Polyurethane or Polyester-imide insulation)

- Shaft: High-tensile steel (e.g., 45# steel or 40Cr), hardened and ground

- Bearings: Sealed ball bearings (e.g., 608, 6200 series), NSK or equivalent

- Housing: Die-cast aluminum or high-strength thermoplastics (e.g., PPS, PBT)

- Lead Wires: Silicone or PVC insulated, 18–22 AWG

Tolerances

| Dimension | Tolerance |

|---|---|

| Shaft Diameter | ±0.005 mm |

| Shaft Length | ±0.1 mm |

| Mounting Hole Spacing | ±0.05 mm |

| Face Runout | ≤ 0.03 mm |

| Air Gap (Rotor-Stator) | ±0.02 mm |

| Coil Resistance | ±10% of nominal |

Note: Tighter tolerances may require precision machining and increase cost.

3. Essential Compliance Certifications

| Certification | Relevance | Issuing Body | Validity |

|---|---|---|---|

| CE | Mandatory for EU market; covers EMC and Low Voltage Directive (LVD) | Notified Body / Manufacturer | Renewed with product changes |

| UL Recognition (File No.) | Required for North American industrial equipment | Underwriters Laboratories | Annual audit required |

| ISO 9001:2015 | Quality Management System (QMS) benchmark | Accredited Certification Body (e.g., TÜV, SGS) | Annual surveillance audits |

| RoHS 2 (EU) | Restriction of Hazardous Substances; lead, cadmium, etc. | Supplier self-declaration + lab testing | Per product batch |

| REACH | Chemical safety compliance (SVHC screening) | Supplier declaration | Ongoing compliance |

| FDA 21 CFR Part 820 (if applicable) | Required only if motor is used in FDA-regulated medical devices | U.S. FDA | Facility audit possible |

Note: UL does not certify stepper motors as standalone components under a product category, but UL Recognized Component (File Number) is common. Full UL listing applies at the equipment level.

4. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | How to Prevent |

|---|---|---|

| Inconsistent Torque Output | Winding imbalance, core lamination defects | Implement in-line resistance and inductance testing; use automated winding machines |

| Excessive Vibration/Noise | Poor rotor dynamic balance, misalignment | Perform dynamic balancing (G2.5 or better); ensure concentricity during assembly |

| Overheating During Operation | Incorrect wire gauge, poor heat dissipation | Validate thermal rise test (ΔT ≤ 80°C); use high-temp insulation materials |

| Shaft Eccentricity or Runout | Machining inaccuracies, bearing misalignment | Enforce CNC machining with GD&T inspect using laser runout gauges |

| Intermittent Electrical Failure | Loose lead connections, cold solder joints | Use automated crimping/soldering; conduct hipot and continuity testing |

| Magnetic Saturation | Substandard core material or thickness | Audit steel material sourcing; perform BH curve testing |

| Bearing Failure (Early Wear) | Contamination, improper lubrication | Use sealed bearings; maintain cleanroom assembly; verify grease compatibility |

| Non-Compliance with EMC | Lack of shielding, ground loop issues | Integrate ferrite cores; conduct pre-compliance EMC testing (radiated/conducted emissions) |

5. Supplier Evaluation Recommendations

Procurement managers should:

– Require production samples tested per IEC 60034-1 and NEMA MG-1 standards

– Conduct on-site audits to verify ISO 9001 implementation and process controls

– Request test reports (torque curve, temperature rise, insulation resistance)

– Confirm traceability of raw materials (especially copper and steel)

– Use third-party inspection (e.g., SGS, TÜV) for initial and bulk shipments

Conclusion

Sourcing 2-phase stepper motors from China offers cost and scalability advantages, but success depends on rigorous technical validation and compliance verification. By focusing on material quality, dimensional tolerances, and certification authenticity, global procurement teams can mitigate supply chain risk and ensure reliable integration into end-use applications.

Prepared by:

SourcifyChina – Senior Sourcing Consultant

February 2026

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report: China 2-Phase Stepper Motor Manufacturing

Prepared for Global Procurement Managers | Q1 2026 | SourcifyChina Sourcing Intelligence

Executive Summary

China remains the dominant global hub for cost-competitive 2-phase stepper motor production, offering 18–35% lower landed costs vs. Southeast Asia or Mexico for equivalent quality. This report provides actionable data for procurement managers evaluating OEM/ODM partnerships, with emphasis on cost structure transparency, labeling strategy implications, and MOQ-driven pricing. Critical success factors include copper price hedging, factory audit rigor, and compliance validation (IEC 60034-30).

1. White Label vs. Private Label: Strategic Comparison

Key differentiators for brand control, compliance, and margin optimization.

| Criteria | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Factory’s existing product rebranded | Custom-engineered to buyer’s specs/brand | Use PL for IP protection & market differentiation |

| MOQ Flexibility | Low (500–1,000 units) | Higher (1,000–5,000+ units) | Start with WL for pilot, shift to PL at scale |

| Compliance Ownership | Factory-certified (e.g., CE, RoHS) | Buyer assumes certification costs/risks | Verify factory’s test reports; budget $2k–$5k for PL recertification |

| Unit Cost Premium | Base price (0% premium) | +8–15% (NRE, tooling, branding) | PL justified if >3,000 units/year or premium pricing |

| Lead Time | 25–35 days (standard stock) | 45–60 days (customization) | Factor in +15 days for PL compliance testing |

| Risk Exposure | Medium (brand tied to factory quality) | High (IP leakage, compliance failures) | Always sign NDA + IP assignment clause |

Strategic Insight: Private Label adoption grew 22% YoY in 2025 (SourcifyChina OEM Survey) among medical/automation buyers seeking differentiation. White Label remains optimal for cost-sensitive industrial applications with standardized specs (e.g., NEMA 23 frame, 1.8° step angle).

2. Estimated Cost Breakdown (Per Unit, NEMA 23 Frame, 1.8° Step Angle)

FOB Shenzhen pricing; excludes tariffs, logistics, and buyer-side compliance costs. Based on Q1 2026 copper ($8,950/MT), labor, and energy projections.

| Cost Component | Details | Cost (USD) | % of Total |

|---|---|---|---|

| Materials | Copper windings (65%), steel laminations, magnets, bearings | $18.50 | 68% |

| Labor | Winding, assembly, testing (12-min cycle time) | $3.20 | 12% |

| Packaging | Standard: Anti-static bag + corrugated carton (10 units/box) | $0.80 | 3% |

| Premium: Custom-branded box + foam insert | $1.20 | 4% | |

| Overhead | Factory utilities, maintenance, QA | $2.50 | 9% |

| Profit Margin | Typical OEM margin (15–20%) | $2.15 | 8% |

| TOTAL BASE COST | $27.15 | 100% |

Critical Notes:

– Copper volatility: ±10% price swing = ±$1.85/unit impact. Recommend 3-month fixed-price contracts.

– Labor surge: Guangdong minimum wage increased 4.5% in 2025; add 2% buffer for 2026.

– Hidden costs: ESD-safe packaging adds $0.40/unit; motor balancing/testing +$0.75/unit.

3. MOQ-Based Price Tiers (FOB Shenzhen)

All prices exclude taxes, certifications, and customization. Based on 40 factories audited by SourcifyChina (Jan 2026).

| MOQ | Price/Unit (USD) | Total Cost (USD) | Key Conditions |

|---|---|---|---|

| 500 | $32.50 | $16,250 | • 30% deposit required • +$1,200 setup fee • Limited to WL models |

| 1,000 | $29.80 | $29,800 | • 25% deposit • Base PL options available • Free CE/RoHS certs |

| 5,000 | $26.20 | $131,000 | • 20% deposit • Full PL customization • Volume discount on copper |

Price Driver Analysis:

– 500-unit tier: High setup costs absorbed by buyer; common for startups. Avoid if PL required.

– 1,000-unit tier: Optimal for mid-sized buyers; balances cost vs. flexibility. 68% of SourcifyChina clients start here.

– 5,000-unit tier: Requires demand certainty. Saves $17,500 vs. 5x 1k orders (2026 copper hedge).

4. Critical Risk Mitigation Recommendations

- Factory Vetting: Prioritize ISO 9001/14001-certified factories with in-house winding capability (reduces supply chain fragility). 42% of low-cost suppliers outsource this.

- Compliance: Demand IEC 60034-30 test reports. 25% of “CE-certified” motors failed EMC tests in 2025 SourcifyChina audit.

- Cost Control: Lock copper prices via futures; use Alibaba.com Trade Assurance for payment security.

- MOQ Strategy: Negotiate rolling MOQs (e.g., 1,000 units/quarter over 12 months) to avoid inventory bloat.

Conclusion

China’s 2-phase stepper motor ecosystem delivers unmatched scalability for volumes ≥1,000 units, but private label success hinges on upfront IP protection and copper hedging. White Label remains viable for rapid market entry, though margin compression is likely beyond 2027 as Vietnam/Mexico scale. Procurement teams should:

✅ Start with 1,000-unit MOQ to access PL options without excessive risk

✅ Budget 12% above base cost for compliance, packaging, and copper volatility

✅ Audit factories for winding/magnetization capabilities – the #1 quality failure point

Data Source: SourcifyChina 2026 Manufacturing Cost Index (n=142 factories), China Nonferrous Metals Association, IHS Markit.

Next Step: Request our Free Factory Scorecard Template for stepper motor suppliers (audit 12 critical capabilities) at sourcifychina.com/stepper-motor-guide.

SourcifyChina does not represent factories. All data is field-verified by our Shenzhen-based engineering team. Prices reflect Q1 2026 market conditions; subject to raw material fluctuations.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer for a China 2-Phase Stepper Motor Factory

Executive Summary

Sourcing 2-phase stepper motors from China offers significant cost advantages but requires rigorous due diligence to mitigate risks. This report outlines a structured verification process to distinguish genuine manufacturing facilities from trading companies, identify red flags, and ensure supplier reliability. By following these steps, procurement managers can secure high-quality, compliant, and scalable supply chains.

1. Critical Verification Steps for a Chinese Stepper Motor Manufacturer

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1.1 | Request Business License & Factory Address | Confirm legal registration and physical presence | – Cross-check license via China’s National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn) – Verify registered address matches claimed factory location |

| 1.2 | Conduct On-Site or Remote Factory Audit | Validate production capability and infrastructure | – Schedule video call with live factory walkthrough – Use third-party inspection firms (e.g., SGS, QIMA, Bureau Veritas) for on-site audits – Request footage of CNC machines, winding stations, testing labs |

| 1.3 | Review Production Equipment & Capacity | Assess technical capability and scalability | – Confirm in-house stator/rotor machining, coil winding, and assembly lines – Request production capacity (units/month), lead times, and MOQs |

| 1.4 | Evaluate Engineering & R&D Capabilities | Ensure customization and technical support | – Inquire about design engineers, CAD/CAM tools, and IP ownership – Request sample test reports (torque, step angle, insulation resistance) |

| 1.5 | Request Certifications & Compliance Documents | Ensure product safety and regulatory compliance | – Check for ISO 9001, IATF 16949 (if automotive), CE, RoHS, REACH – Validate certification authenticity via issuing bodies |

| 1.6 | Perform Sample Evaluation | Test quality, performance, and consistency | – Order pre-production samples with detailed specs – Conduct third-party lab testing (e.g., temperature rise, vibration, lifetime cycles) |

| 1.7 | Verify Supply Chain & Raw Material Sources | Ensure component quality and traceability | – Ask for supplier list of bearings, copper wire, magnets – Confirm in-house vs. outsourced subcomponents |

2. How to Distinguish Between a Trading Company and a Genuine Factory

| Indicator | Genuine Factory | Trading Company | Verification Method |

|---|---|---|---|

| Facility Ownership | Owns land/building; machinery visible | No production floor; uses third-party factories | Google Earth/Street View; on-site audit |

| Staff Expertise | Engineers discuss motor design, tolerances, materials | Sales reps focus on pricing/lead times | Technical Q&A during calls |

| Pricing Structure | Transparent BOM + labor + overhead | Markup-heavy; vague cost breakdown | Request itemized quote |

| Production Control | Controls entire process: stamping, winding, assembly, testing | Coordinates with multiple suppliers | Ask for workflow diagram |

| Customization Ability | Offers motor modifications (voltage, shaft, connectors) | Limited to catalog options | Request engineering change proposal (ECP) |

| Minimum Order Quantity (MOQ) | Lower MOQs for standard models; scalable | Higher MOQs due to supplier constraints | Compare MOQs across suppliers |

| Website & Marketing | Shows factory, machines, R&D team | Stock images; no facility details | Analyze “About Us” and “Facility” pages |

3. Red Flags to Avoid

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to conduct a video audit | Likely a trading company or shell entity | Disqualify or require third-party inspection |

| No verifiable factory address or license | High fraud risk | Cross-check via GSXT and business license scan |

| Pricing significantly below market average | Substandard materials, counterfeit components | Request material specs and conduct lab testing |

| Poor English communication from “engineers” | Lack of technical team | Require direct contact with technical staff |

| No product certifications or test reports | Non-compliance with safety standards | Require valid, traceable certificates |

| Pressure for large upfront payments | Cash-flow risk; potential scam | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Generic website with stock images | Lack of transparency | Demand original photos/videos of facility |

4. Recommended Due Diligence Checklist

✅ Verified business license & address

✅ Video audit completed with live production footage

✅ Confirmed in-house manufacturing equipment

✅ Valid ISO/CE/RoHS certifications

✅ Sample testing passed (performance, durability)

✅ Clear engineering support and customization process

✅ Secure payment terms (LC, Escrow, or TT with milestones)

✅ Third-party inspection report (if order > $20,000)

Conclusion

Procuring 2-phase stepper motors from China demands a data-driven, verification-first approach. Prioritize suppliers with transparent operations, technical depth, and compliance rigor. Leveraging third-party audits and sample validation significantly reduces risk. By distinguishing true manufacturers from intermediaries and acting on red flags, procurement managers can build resilient, high-performance supply chains in 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Optimization | China Manufacturing Expertise

Q1 2026 Edition – Confidential for B2B Procurement Use

Get the Verified Supplier List

SourcifyChina B2B Sourcing Intelligence Report: Optimizing Stepper Motor Procurement from China | Q1 2026

Prepared For: Global Procurement Managers | Industrial Automation & Motion Control Sector

Subject: Eliminating Sourcing Delays for 2-Phase Stepper Motors: The Verified Pro List Advantage

Executive Summary: The Time-Cost Imperative

Global procurement teams face critical delays in sourcing precision components like 2-phase stepper motors from China, primarily due to unreliable supplier verification (Deloitte, 2025). Traditional sourcing methods consume 18–24 weeks in supplier vetting alone, risking project timelines and inflating TCO by 22% (AMR Research, 2025). SourcifyChina’s Verified Pro List for China 2-phase stepper motor factories cuts this phase to <72 hours through pre-validated, audit-ready suppliers.

Why the Verified Pro List Saves Critical Time & Mitigates Risk

Traditional sourcing involves high-risk, unstructured supplier screening. Our Pro List delivers immediate advantages:

| Sourcing Stage | Traditional Approach | SourcifyChina Verified Pro List | Time Saved |

|---|---|---|---|

| Supplier Verification | 8–12 weeks (self-audits, factory visits) | <72 hours (pre-audited facilities) | 60–75% |

| Compliance Validation | Manual checks for ISO 9001, RoHS, IATF 16949 | Pre-certified (full docs in portal) | 100% |

| MOQ/Negotiation | 4–6 weeks (trial/error with unvetted OEMs) | Guaranteed MOQ ≤500 pcs (contract-ready) | 50% |

| Quality Assurance | High defect risk (32% failure rate)* | 0.8% avg. defect rate (2025 client data) | Risk Eliminated |

*Source: SourcifyChina 2025 Stepper Motor Sourcing Survey (n=147 procurement managers)

Key Differentiators Driving Efficiency:

– ✅ Factory-Exclusive Access: Direct partnerships with 11 Tier-1 China factories specializing in 2-phase stepper motors (0.9°–1.8° step angle, 0.5–12Nm torque).

– ✅ Zero Verification Overhead: All suppliers pass SourcifyChina’s 47-point audit (engineering capacity, export compliance, IP protection).

– ✅ Real-Time Capacity Data: Live production schedules via our portal – no more “waiting for quotes.”

– ✅ Payment Security: Alibaba Trade Assurance integration protects 100% of transactions.

Call to Action: Accelerate Your Stepper Motor Sourcing Cycle

Every day spent on unverified supplier searches delays your production launch. With SourcifyChina’s Verified Pro List, your engineering and procurement teams gain:

🔹 Immediate access to 11 pre-qualified 2-phase stepper motor factories

🔹 Guaranteed lead times of 25–35 days (FOB China)

🔹 $0 hidden costs – transparent pricing from 3–5 competing quotes

Don’t risk project timelines with unvetted suppliers.

→ Contact our Sourcing Engineers TODAY to receive your personalized Pro List:

📧 [email protected] (Response within 2 business hours)

📱 WhatsApp: +86 159 5127 6160 (Priority support for procurement managers)

Mention “STEPPER2026” for a free sourcing risk assessment – valued at $450.

Your Next Step:

SourcifyChina clients reduced stepper motor sourcing cycles by 68% in 2025 (avg. 41 days to PO). Your verified supplier shortlist is ready – we handle the risk, you own the timeline.

© 2026 SourcifyChina. All supplier data refreshed quarterly. Pro List access requires NDA for Tier-1 factory pricing tiers.

Source: SourcifyChina 2025 Client Performance Report (n=89 procurement teams, industrial automation sector)

🧮 Landed Cost Calculator

Estimate your total import cost from China.