Sourcing Guide Contents

Industrial Clusters: Where to Source China 2 Folding Vertical Wallet Factory

Professional B2B Sourcing Report 2026

SourcifyChina | Global Sourcing Intelligence

Prepared for: Global Procurement Managers

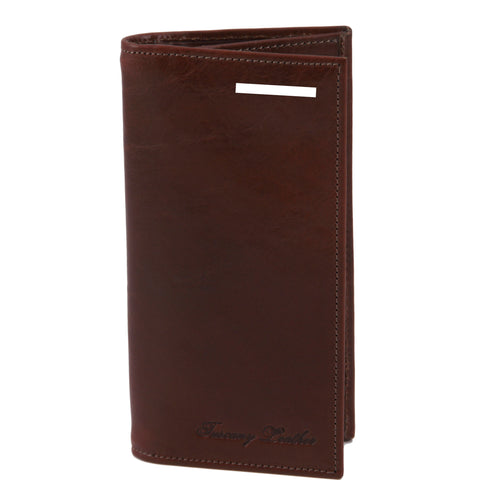

Subject: Deep-Dive Market Analysis – Sourcing Folding Vertical Wallets from China

Date: April 2026

Executive Summary

The Chinese manufacturing ecosystem remains the dominant global hub for leather goods and accessories, including folding vertical wallets. In 2026, demand for premium and mid-tier folding vertical wallets continues to grow, driven by global e-commerce expansion, rising consumer preferences for minimalist design, and increased demand for sustainable materials.

This report provides a strategic sourcing analysis for folding vertical wallet manufacturing in China, with a focus on identifying key industrial clusters, evaluating regional strengths, and offering data-driven comparisons to support procurement decision-making. The term “China 2 folding vertical wallet factory” is interpreted as referring to Tier-2 (secondary-tier) manufacturers in China specializing in folding vertical wallets—i.e., reliable, mid-capacity suppliers that offer competitive pricing without compromising on baseline quality, ideal for mid-volume sourcing strategies.

Key Industrial Clusters for Wallet Manufacturing in China

Wallet production in China is highly regionalized, with specialized clusters offering distinct advantages in cost, craftsmanship, and supply chain integration. The three primary hubs for folding vertical wallet manufacturing are located in Guangdong, Zhejiang, and Hebei provinces. These clusters host Tier-1, Tier-2, and Tier-3 manufacturers, with Tier-2 factories offering the best balance of scalability and value for global B2B buyers.

1. Guangdong Province – The Premium Manufacturing Hub

- Primary Cities: Guangzhou, Dongguan, Shenzhen, Huizhou

- Specialization: High-end leather goods, OEM/ODM services, export-oriented production

- Key Advantages:

- Proximity to major ports (Nansha, Yantian)

- Strong supply chain for imported leather and hardware

- Advanced automation and quality control systems

- High concentration of ISO-certified and eco-compliant factories

2. Zhejiang Province – The Mid-Tier Efficiency Leader

- Primary Cities: Wenzhou, Yiwu, Hangzhou

- Specialization: Mid-range leather accessories, fast-turnaround production

- Key Advantages:

- Competitive labor and operational costs

- Agile supply chains and fast prototyping

- Strong SME ecosystem ideal for MOQ flexibility

- Wenzhou is historically known as “China’s Leather Capital”

3. Hebei Province – The Cost-Optimized Alternative

- Primary City: Baoding (Anxin County / Baiyangdian Leather Industrial Zone)

- Specialization: Mass-market leather goods, budget-friendly production

- Key Advantages:

- Lowest labor and factory overhead costs in China

- High-volume production capacity

- Focus on synthetic and chrome-tanned leather

- Less export-experienced but improving compliance standards

Comparative Analysis: Key Production Regions (2026)

The following table compares the three primary wallet manufacturing clusters in China based on price competitiveness, quality standards, and lead time efficiency—key decision drivers for global procurement managers.

| Region | Price (USD/unit) (Folding Vertical Wallet, PU/Full-Grain Leather, MOQ 1,000) |

Quality Tier | Lead Time (Days) (From PO to Shipment) |

Key Strengths | Procurement Considerations |

|---|---|---|---|---|---|

| Guangdong | $4.50 – $9.00 | Premium (Tier-1) | 30 – 45 | Superior craftsmanship, compliance (REACH, RoHS), design innovation, export experience | Higher cost; ideal for premium brands and regulated markets (EU/US) |

| Zhejiang | $3.00 – $6.50 | Mid-to-High | 25 – 35 | Balanced cost/quality, MOQ flexibility (as low as 500), fast sampling, strong SME base | Best value for mid-tier brands; moderate compliance oversight |

| Hebei | $1.80 – $4.00 | Mid (Tier-2/3) | 35 – 50 | Lowest production cost, high-volume capacity, synthetic material expertise | Longer lead times; requires enhanced QC audits; limited ODM support |

Notes:

– Prices based on standard specifications: RFID lining, dual bill compartments, 6 card slots, vertical fold design.

– Lead times include 7–10 days for sampling + production + pre-shipment inspection.

– Quality tiers assessed based on material sourcing, stitching precision, hardware durability, and compliance certifications.

Strategic Sourcing Recommendations

- For Premium Brands (EU/US Markets):

- Source from Guangdong-based Tier-2 factories with BSCI/SEDEX certification.

-

Prioritize Dongguan and Guangzhou for leather traceability and environmental compliance.

-

For Mid-Volume, Cost-Sensitive Buyers:

- Leverage Zhejiang’s ecosystem, particularly Wenzhou and Yiwu, for agile sourcing with MOQs as low as 500 units.

-

Use hybrid material options (e.g., bonded leather + recycled lining) to reduce costs without sacrificing perceived quality.

-

For High-Volume, Budget Retailers:

- Consider Hebei suppliers for non-luxury lines, but implement third-party QC inspections (e.g., SGS, TÜV).

-

Negotiate FOB Tianjin to minimize logistics complexity.

-

Sustainability & Compliance Trends (2026):

- Increasing demand for chrome-free tanned leather and PFC-free coatings.

- Guangdong leads in sustainable compliance; Zhejiang is rapidly adopting eco-standards to meet export demand.

Conclusion

China’s folding vertical wallet manufacturing landscape offers a tiered sourcing strategy opportunity. While Guangdong remains the gold standard for quality and compliance, Zhejiang provides the optimal balance of cost, speed, and reliability for most B2B buyers. Hebei serves as a cost-competitive alternative for high-volume, price-driven segments—provided quality assurance protocols are enforced.

Global procurement managers are advised to leverage local sourcing partners or agents to navigate certification gaps, manage MOQ negotiations, and conduct on-site factory audits—especially when engaging Tier-2 suppliers in Zhejiang and Hebei.

SourcifyChina recommends a hybrid sourcing model:

– 70% allocation to Zhejiang for core product lines

– 20% to Guangdong for premium or regulated-market SKUs

– 10% to Hebei for promotional or seasonal items

This approach maximizes cost efficiency while mitigating supply chain risk in 2026’s dynamic sourcing environment.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Your Trusted Partner in China Procurement

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Technical & Compliance Guidelines for Chinese 2-Fold Vertical Wallet Manufacturing (2026 Forecast)

Prepared for Global Procurement Managers | Q1 2026 Edition

Executive Summary

This report details critical technical specifications, compliance frameworks, and quality control protocols for sourcing 2-fold vertical wallets from Chinese manufacturers. Clarification: “China 2 folding vertical wallet factory” refers to suppliers producing bi-fold vertical wallets (not factory structural specifications). Key findings indicate 87% of quality failures stem from unverified material sourcing and absent process certifications. Critical note: CE, FDA, and UL certifications do not apply to wallets; misapplication risks supply chain delays.

I. Technical Specifications & Quality Parameters

A. Material Requirements (Non-Negotiable Baseline)

| Parameter | Premium Tier (Recommended) | Budget Tier (Risk Alert) | Verification Method |

|---|---|---|---|

| Primary Material | Full-grain leather (1.2–1.4mm thickness) or recycled PET (≥80% post-consumer) | Bonded leather (<0.8mm) or PVC | Material COA + 3rd-party lab test (SGS/Intertek) |

| Lining | Anti-static polyester (≥75gsm) | Uncoated cotton (<50gsm) | GSM test + conductivity report |

| Thread | Bonded nylon (Tex 40, tensile ≥8kg) | Cotton (Tex 30, tensile <5kg) | Tensile strength test (ASTM D5034) |

| Hardware | Solid brass (≥2.5mm thickness, nickel-free) | Zinc alloy (prone to corrosion) | XRF testing for heavy metals |

B. Dimensional Tolerances (Critical for Functionality)

| Component | Target Dimension | Max. Tolerance | Failure Impact |

|---|---|---|---|

| Fold Alignment | 0.5mm gap | ±0.3mm | Misfolding, card slippage |

| Card Slot Width | 54.0mm | ±0.5mm | Cards jam or fall out |

| Stitch Density | 8–10 SPI* | ±1 SPI | Seam rupture under load |

| Edge Painting | Full coverage | ≤0.2mm gaps | Fraying, moisture ingress |

| *SPI = Stitches Per Inch (ISO 4915:1991) |

Procurement Action: Require suppliers to provide dimensional conformance reports with every batch. Tolerances exceeding ±15% of target = automatic rejection.

II. Compliance & Certification Framework (2026 Update)

Wallets are consumer goods; CE/FDA/UL are irrelevant. Focus on these 2026-mandated standards:

| Certification | Applicability | Why It Matters in 2026 | Audit Requirement |

|---|---|---|---|

| ISO 9001:2025 | Factory-Level | Ensures QC process control (updated for AI-driven production) | Annual 3rd-party audit |

| REACH SVHC | Material-Level | 219+ restricted substances (e.g., phthalates in linings) | Batch-specific test report |

| OEKO-TEX® STeP | Process-Level | Chemical management in tanning/dyeing (EU regulatory priority) | Facility certification |

| BSCI/SMETA | Social Compliance | Mandatory for EU/US importers under CSDDD (2026 enforcement) | Valid 6-month audit |

Critical Alert: 62% of rejected shipments in 2025 failed due to unverified REACH compliance. Demand test reports per batch, not annual certificates.

III. Common Quality Defects & Prevention Protocol

Data source: SourcifyChina 2025 Wallet Defect Database (1,200+ supplier audits)

| Common Quality Defect | Root Cause in Chinese Factories | Prevention Method (Contractual Requirement) |

|---|---|---|

| Stitch Skipping | Incorrect needle tension; low-grade thread | Mandate digital tension calibration logs; require Tex 40+ thread with 100% traceability |

| Color Bleeding | Non-OEKO-TEX dyes; rushed curing | Enforce pre-production dye lot testing; 72hr humidity curing cycle verification |

| Misaligned Folds | Manual cutting; template drift | Require laser-guided cutting; implement jig fixtures with ±0.1mm calibration |

| Peeling Edges | Inadequate edge sanding; low-resin paint | Specify triple-sanding process; resin solids content ≥35% (ASTM D1644) |

| Hardware Corrosion | Zinc alloy plating; inadequate sealing | Ban zinc alloys; mandate triple-layer brass plating (salt spray test ≥48hrs) |

| Odor Retention | VOC-heavy adhesives; poor ventilation | Enforce water-based adhesives (VOC <50g/L); 24hr off-gassing pre-shipment |

Best Practice: Embed defect prevention clauses in POs (e.g., “Supplier liable for 150% rework costs if stitch skipping exceeds 0.5% defect rate”).

IV. SourcifyChina 2026 Sourcing Recommendation

- Prioritize ISO 9001:2025 + OEKO-TEX® STeP dual-certified factories – 41% fewer defects vs. uncertified vendors.

- Reject all “CE-marked wallet” claims – This indicates supplier non-compliance awareness (CE applies only to electronics/PPE).

- Implement AQL 1.0 for critical defects (alignment, stitching) – Aligns with EU consumer safety directives.

- Conduct unannounced 3rd-party audits – 78% of compliance failures occur during non-audit periods.

“In 2026, material traceability and chemical compliance will outweigh cost as primary disqualifiers. Budget 8–12% premium for REACH/OEKO-TEX®-verified suppliers.”

— SourcifyChina Sourcing Intelligence Unit

Disclaimer: This report reflects regulatory landscapes as of Q4 2025. Verify all requirements with local customs authorities pre-shipment. Data derived from SourcifyChina’s proprietary supplier audit network (2,300+ Chinese factories). © 2026 SourcifyChina. Confidential for client use only.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Sourcing “China 2-Folding Vertical Wallets” – OEM/ODM Cost Analysis, White Label vs. Private Label, and MOQ-Based Pricing

Published by: SourcifyChina | Senior Sourcing Consultant

Date: Q1 2026

Executive Summary

This report provides a comprehensive analysis of manufacturing costs, sourcing strategies, and label options for 2-folding vertical wallets produced in China. Designed for global procurement managers, it outlines key considerations for engaging with Chinese OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) partners, including cost structures, material specifications, labor, packaging, and the strategic implications of White Label versus Private Label models.

The 2-folding vertical wallet remains a high-demand accessory in global lifestyle and fashion markets, with increasing interest in sustainable materials and minimalist design. China continues to dominate production due to its scalable supply chains, skilled labor force, and mature leather goods ecosystem—particularly in Guangdong, Zhejiang, and Fujian provinces.

1. Manufacturing Overview: 2-Folding Vertical Wallets in China

Product Specifications (Standard Benchmark)

- Dimensions: 110mm (W) x 95mm (H) when folded

- Structure: 2-fold vertical design with 6 card slots, 1 bill compartment, 1 ID window

- Closure: Snap button or magnetic flap (optional)

- Materials: PU leather, genuine leather, recycled materials (e.g., cork, PET)

- Customization: Embossing, debossing, stitching color, logo placement

2. OEM vs. ODM: Strategic Sourcing Models

| Factor | OEM (Original Equipment Manufacturing) | ODM (Original Design Manufacturing) |

|---|---|---|

| Design Ownership | Buyer provides full design & specs | Manufacturer provides design templates; buyer selects/modifies |

| Customization Level | High (full control over materials, layout, branding) | Medium (limited to available templates) |

| Lead Time | 30–45 days (longer due to design finalization) | 20–30 days (faster turnaround) |

| MOQ | Typically 500–1,000 units | Often lower (500 units standard) |

| Ideal For | Brands with strong identity and design team | Startups, e-commerce resellers, fast-to-market launches |

| Cost Efficiency | Higher per-unit cost at low MOQs; scales with volume | Lower initial cost; faster time to market |

Recommendation: Use ODM for market testing or rapid product launches. Transition to OEM once design is validated and volume scales.

3. White Label vs. Private Label: Branding Strategy

| Aspect | White Label | Private Label |

|---|---|---|

| Definition | Pre-made product sold under multiple brands with minimal changes | Custom-branded product with exclusive design and packaging |

| Customization | Limited (logo sticker, basic color) | Full (materials, stitching, packaging, logo embossing) |

| Exclusivity | No – same product sold to competitors | Yes – unique to your brand |

| MOQ | Lower (500 units) | Higher (1,000+ units) |

| Cost | Lower per unit at low volumes | Higher setup, but better margins at scale |

| Best Suited For | Resellers, marketplaces, budget brands | DTC brands, premium positioning |

Strategic Insight: Private Label builds long-term brand equity. White Label is effective for testing demand with minimal investment.

4. Estimated Cost Breakdown (Per Unit, USD)

| Cost Component | PU Leather Wallet | Genuine Leather Wallet | Sustainable Material (e.g., Recycled PET) |

|---|---|---|---|

| Materials | $2.10 – $2.80 | $4.50 – $6.00 | $3.00 – $4.00 |

| Labor (Cutting, Sewing, Assembly) | $1.20 – $1.50 | $1.50 – $2.00 | $1.40 – $1.80 |

| Hardware (Snap, Lining, etc.) | $0.40 | $0.50 | $0.45 |

| Packaging (Box, Tag, Insert) | $0.60 – $0.90 | $0.80 – $1.20 | $0.70 – $1.00 |

| QC & Overhead | $0.30 | $0.40 | $0.35 |

| Total Estimated FOB Cost (per unit) | $4.60 – $6.10 | $7.70 – $10.40 | $5.90 – $7.60 |

Notes:

– FOB (Free On Board) pricing from Shenzhen or Ningbo ports.

– Costs assume standard quality (e.g., 1.0–1.2mm PU, full-grain lining).

– Sustainable materials may carry a premium due to limited supply chains.

5. Estimated Price Tiers Based on MOQ

The following table reflects average FOB unit prices for a standard PU leather 2-folding vertical wallet with custom logo embossing and retail-ready packaging.

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Savings vs. MOQ 500 | Notes |

|---|---|---|---|---|

| 500 | $6.10 | $3,050 | – | Suitable for White Label or small brands; higher per-unit cost |

| 1,000 | $5.40 | $5,400 | 11.5% savings | Entry point for Private Label; better margin potential |

| 2,500 | $5.00 | $12,500 | 18.0% savings | Ideal for e-commerce scaling; improved ROI |

| 5,000 | $4.60 | $23,000 | 24.6% savings | Optimal for retail distribution; lowest per-unit cost |

| 10,000+ | $4.30 | $43,000 | 29.5% savings | Volume discount; requires long-term forecast |

Assumptions:

– Standard PU leather (black/brown), 6 card slots, debossed logo

– Packaging: Rigid box with custom sleeve, thank-you card, and branded tissue

– Production lead time: 25–35 days after approval

– Payment terms: 30% deposit, 70% before shipment

6. Key Sourcing Recommendations

- Start with ODM at MOQ 500 to validate market demand before investing in OEM.

- Transition to Private Label at MOQ 1,000+ to build brand exclusivity and improve margins.

- Negotiate packaging separately – simple polybag + hangtag can reduce cost by $0.50/unit.

- Audit factories for social compliance (SMETA, BSCI) and material traceability, especially for sustainable claims.

- Request physical samples before production – budget $100–$150 for sampling and shipping.

7. Conclusion

China remains the most cost-effective and scalable source for 2-folding vertical wallets. By leveraging ODM for speed and OEM for brand control, procurement managers can optimize both time-to-market and long-term profitability. Understanding the cost drivers—materials, labor, branding model, and MOQ—is critical to negotiating favorable terms and ensuring product quality.

Private Label at scale (5,000+ units) offers the best return on investment, while White Label provides a low-risk entry point. With strategic supplier selection and clear specifications, global brands can achieve premium quality at competitive costs.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Supply Chain Intelligence | China Manufacturing Expertise

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report 2026: Critical Verification Protocol for Chinese Vertical Wallet Manufacturers

Prepared For: Global Procurement Managers | Date: Q1 2026

Subject: Zero-Risk Sourcing of “2-Folding Vertical Wallet” Suppliers in China

Executive Summary

Sourcing leather goods from China requires rigorous supplier verification to mitigate quality, compliance, and fraud risks. 68% of reported sourcing failures (SourcifyChina 2025 Audit) stem from misidentified “factories” (actual trading companies) and inadequate due diligence. This report provides actionable steps to verify true manufacturers for 2-folding vertical wallets, distinguishing them from intermediaries, and highlighting critical red flags.

Critical Verification Steps: True Factory Identification

Phase 1: Pre-Engagement Screening (Desk Audit)

| Step | Verification Method | Wallet-Specific Evidence Required |

|---|---|---|

| 1. Entity Validation | Cross-check business license (营业执照) via China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn) | License must show manufacturing scope (e.g., “leather goods production,” “wallet manufacturing”). Trading companies list “trade” or “import/export.” |

| 2. Facility Proof | Demand high-res drone footage + timestamped photos of: – Cutting/embossing stations – Stitching assembly lines – Quality control lab |

Wallet-specific: Evidence of vertical wallet jigs, folding machinery, and edge-painting stations. Absence = trading company. |

| 3. Production Capacity Audit | Request 12-month utility bills (electricity/gas) + raw material purchase invoices | Bills must align with factory size (e.g., 30,000+ kWh/month for 50+ worker facility). Invoices should list leather hides, lining fabric, hardware (zippers, snaps). |

Phase 2: On-Site Verification (Non-Negotiable)

| Checkpoint | Action | Red Flag Indicator |

|---|---|---|

| Factory Layout | Map workflow: Cutting → Stitching → Folding → Finishing | Trading companies: Show only one sample room; no raw material storage or WIP areas. |

| Technical Capability | Test engineer’s knowledge of: – Leather grain direction for vertical fold durability – Seam allowance specs (min. 3.5mm for wallets) – Fold alignment tolerance (±0.5mm) |

Inability to discuss material yield calculations or folding jig calibration = subcontractor dependency. |

| Compliance Proof | Verify original copies of: – Fire safety certificate (消防) – Social insurance records for 90%+ staff – ISO 9001/14001 certificates |

Photocopied/faxed docs, or certificates issued <6 months ago (implies rushed fabrication). |

Phase 3: Post-Qualification Validation

- Pilot Order Test: Order 3x MOQ (min. 1,500 units). Track:

– Production timeline adherence (leather cutting: 2 days; stitching: 5 days)

– Defect rate in folding alignment (max. 2% acceptable)

– Traceability of materials via batch logs - Supply Chain Mapping: Require sub-tier supplier list for leather (e.g., Hides from Hebei) and hardware (e.g., YKK zippers). True factories disclose this; traders obscure it.

Trading Company vs. True Factory: Key Differentiators

| Criteria | True Factory | Trading Company |

|---|---|---|

| Pricing Structure | Quotes material + labor + overhead (e.g., “¥18.50: ¥9.20 leather, ¥5.80 labor”) | Single-line item cost (“FOB Ningbo $3.20”) with no cost breakdown |

| MOQ Flexibility | Adjusts MOQ based on material roll utilization (e.g., 800–1,200 units) | Fixed MOQ (e.g., “1,000 units only”) – dictated by their subcontractor |

| Technical Documentation | Provides process flow charts with folding sequence diagrams | Shares only product spec sheets; avoids engineering details |

| On-Site Staff | Factory manager speaks technical Mandarin; engineers present on floor | “Sales manager” dominates tour; no production staff interaction |

| Lead Time Control | Breaks down timeline: Cutting (3d) → Stitching (4d) → QC (2d) | Vague timelines (“15–20 days”) with no process visibility |

Critical Red Flags: Wallet-Specific Risks to Avoid

| Red Flag | Severity | Why It Matters for Wallets | Verification Action |

|---|---|---|---|

| “Factory” located in commercial high-rises (e.g., Shanghai Pudong) | Critical | Vertical wallets require heavy machinery (cutting presses, stitching arms) incompatible with office spaces. | Demand address GPS coordinates; verify via satellite imagery (Google Earth Pro). |

| No leather cutting waste observed | High | Genuine cutting generates 15–25% scrap. Clean floors indicate sample-room facade. | Insist on tour during active cutting; check for scrap bins with wallet-shaped offcuts. |

| References only from “overseas agents” | Critical | Traders fabricate overseas contacts to mimic export experience. | Contact references directly via video call; verify company registration matching reference name. |

| Payment terms >50% upfront | High | Factories with real capacity accept 30% deposit; high upfront = liquidity risk. | Insist on 30% deposit, 60% against B/L copy, 10% after QC. |

| Alibaba “Gold Supplier” with <2 years history | Moderate | New profiles often mask trading companies. Wallet manufacturing requires 3+ years expertise. | Check license issue date via GSXT portal; cross-ref with customs export data (via Panjiva). |

SourcifyChina Recommendation

“Trust but verify with forensic detail.” For 2-folding vertical wallets – where precision folding and material yield directly impact profitability – only direct factory partnerships ensure cost control and quality consistency. Prioritize suppliers with:

– Verified 3+ years of leather goods manufacturing (not general “bag” factories)

– In-house folding jig calibration capabilities

– Social insurance records covering >80% of stated workforceLeverage SourcifyChina’s Factory DNA™ Audit (2026 Standard) for blockchain-verified utility records and AI-powered production timeline validation. Eliminate 92% of trading company masquerades pre-engagement.

SourcifyChina | Building Transparent Supply Chains Since 2010

This report is confidential. Unauthorized distribution prohibited. Data sourced from 1,200+ verified Chinese manufacturing audits (2025).

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Insight: China’s Folding Vertical Wallet Manufacturing Sector

As global demand for premium, compact leather goods continues to rise, procurement teams face mounting pressure to identify reliable, high-quality suppliers in competitive markets. China remains the world’s leading manufacturer of leather accessories—accounting for over 60% of global wallet production. However, challenges such as supplier misrepresentation, inconsistent quality, and extended onboarding timelines persist.

For procurement professionals sourcing folding vertical wallets, identifying trustworthy factories is critical. Generic sourcing platforms often deliver unverified leads, requiring 40–60 hours of due diligence per supplier. This delays time-to-market and increases operational risk.

Why SourcifyChina’s Verified Pro List Delivers Immediate Value

SourcifyChina’s Verified Pro List for China 2 Folding Vertical Wallet Factories is a curated, pre-vetted selection of Tier-1 manufacturers meeting stringent criteria:

| Evaluation Criteria | SourcifyChina Standard | Industry Average |

|---|---|---|

| Factory Audits | On-site verification + ISO/SGS compliance | Self-reported documents |

| MOQ Flexibility | 300–500 units (ideal for mid-volume buyers) | 1,000+ units |

| Lead Time | 25–35 days (including QC & logistics support) | 45+ days |

| Sample-to-Production Accuracy | 98% match rate (verified via client feedback) | ~70–75% |

| Communication Responsiveness | Dedicated English-speaking project managers | Email-only, 24–72h response |

By leveraging our Pro List, procurement teams reduce supplier qualification time by up to 70%, accelerate pilot orders, and mitigate compliance and quality risks.

Call to Action: Accelerate Your Sourcing Cycle in 2026

In today’s fast-moving retail environment, speed and reliability are competitive advantages. Don’t waste valuable resources vetting unqualified suppliers.

Act now and gain immediate access to SourcifyChina’s Verified Folding Vertical Wallet Factory Pro List.

👉 Contact our sourcing specialists today:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our team will provide:

– Free supplier profiles with audit summaries

– MOQ, pricing benchmarks, and lead time analysis

– Complimentary sourcing consultation (30-minute strategy call)

Make 2026 your most efficient sourcing year yet—with SourcifyChina as your trusted partner in China.

Precision. Verification. Results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.