Sourcing Guide Contents

Industrial Clusters: Where to Source China 10M Led Strip Lights Manufacture

Professional B2B Sourcing Report 2026

SourcifyChina | Global Procurement Intelligence

Subject: Market Analysis for Sourcing 10m LED Strip Lights from China

Target Audience: Global Procurement Managers

Publication Date: January 2026

Executive Summary

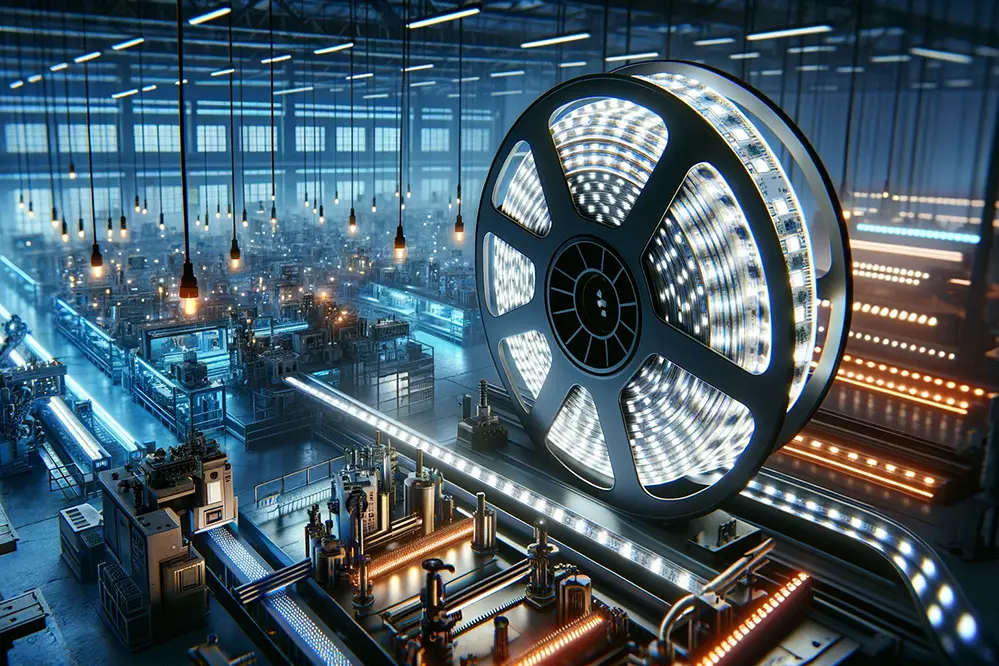

The global demand for energy-efficient, customizable LED lighting solutions continues to surge, driven by growth in smart home systems, architectural lighting, and commercial retrofitting. China remains the dominant manufacturing hub for LED strip lights, producing over 70% of the world’s supply. Among product configurations, 10-meter LED strip lights are particularly popular due to their balance of length, performance, and ease of integration.

This report provides a comprehensive sourcing analysis for 10m LED strip lights, identifying China’s key manufacturing clusters, evaluating regional strengths, and offering strategic insights for global procurement teams. Special focus is placed on the leading industrial provinces—Guangdong and Zhejiang—with a comparative assessment of price, quality, and lead time to support data-driven supplier selection.

Key Manufacturing Clusters for 10m LED Strip Lights in China

China’s LED lighting industry is highly regionalized, with concentrated production in two major provinces:

1. Guangdong Province (Pearl River Delta)

- Core Cities: Foshan (especially Chencun and Lecong), Dongguan, Shenzhen, Guangzhou

- Industry Focus: High-tech LED manufacturing, R&D-driven production, export-oriented OEM/ODM

- Cluster Advantages:

- Proximity to Shenzhen’s electronics supply chain (ICs, drivers, PCBs)

- Advanced SMD (Surface Mount Device) and COB (Chip-on-Board) production lines

- Strong export infrastructure (Shekou, Nansha ports)

- High concentration of UL/DLC/CE-certified factories

2. Zhejiang Province (Yangtze River Delta)

- Core Cities: Yuyao (Ningbo), Hangzhou, Huzhou

- Industry Focus: Cost-competitive mass production, mid-tier OEM, domestic and EU market focus

- Cluster Advantages:

- Lower labor and operational costs

- Well-established component ecosystem (aluminum profiles, power supplies)

- Strong logistics via Ningbo-Zhoushan Port (world’s busiest by volume)

- High volume output with moderate technical capability

Comparative Analysis: Key Production Regions for 10m LED Strip Lights

| Region | Price (USD/m) | Quality Tier | Typical Lead Time (Days) | Certifications | Best For |

|---|---|---|---|---|---|

| Guangdong | $1.80 – $3.50 | High (Tier 1) | 15 – 25 | UL, DLC, CE, RoHS, IP65+ | Premium projects, North American/EU markets, smart lighting, long-term reliability |

| Zhejiang | $1.20 – $2.40 | Medium (Tier 2) | 20 – 30 | CE, RoHS, some IP65 | Budget-conscious buyers, high-volume orders, emerging markets, interior lighting |

Note: Prices based on 1,000–5,000m MOQ, SMD 5050 or 2835, 60 LEDs/m, 24V DC, standard white CCT. Ex-factory (FOB).

Strategic Sourcing Insights (2026)

1. Quality vs. Cost Trade-Off

- Guangdong offers superior thermal management, color consistency (CRI >90), and longer lifespan (50,000+ hours) due to better diodes (e.g., Epistar, Samsung) and rigorous QC.

- Zhejiang provides cost efficiency but may use generic chips and thinner PCBs, resulting in shorter lifespans (30,000–40,000 hours) under continuous use.

2. Lead Time & Logistics

- Guangdong benefits from faster component availability and air freight access (Shenzhen Bao’an Airport), ideal for urgent orders.

- Zhejiang leverages lower shipping costs via Ningbo Port but may face longer material procurement cycles.

3. Certification & Compliance

- Guangdong factories are more likely to support North American (UL/DLC) and EU (ERP, LVD) compliance—critical for regulated markets.

- Zhejiang suppliers often require third-party testing upgrades to meet premium certifications, adding cost and time.

4. Customization & Innovation

- Guangdong leads in smart LED strips (Wi-Fi/Bluetooth/Zigbee), RGBIC, and flexible PCB designs.

- Zhejiang focuses on standard white/color strips with limited R&D investment.

Recommendations for Procurement Managers

| Procurement Objective | Recommended Region | Supplier Strategy |

|---|---|---|

| High-reliability, certified projects (e.g., commercial buildings) | Guangdong | Partner with ISO 9001-certified OEMs with in-house R&D and QC labs |

| High-volume, cost-sensitive orders (e.g., residential retrofits) | Zhejiang | Negotiate bulk pricing with tier-2 suppliers; include IP and EOL testing in QC protocols |

| Smart lighting integration (IoT, apps) | Guangdong (Shenzhen/Foshan) | Source from tech-integrated OEMs with SDK/API support |

| EU/UK market compliance | Both (prioritize Guangdong) | Verify CE/UKCA certification and REACH compliance; audit production lines |

Conclusion

For global procurement managers, Guangdong remains the strategic choice for high-performance, compliant 10m LED strip lights, especially for regulated or high-margin markets. Zhejiang offers compelling value for volume-driven, cost-optimized sourcing where top-tier reliability is not mission-critical.

In 2026, rising automation and stricter environmental regulations in China are narrowing the quality gap between regions. However, supplier qualification, audit frequency, and IP protection remain critical success factors. SourcifyChina recommends dual-sourcing strategies and on-site factory audits to de-risk supply chains and ensure consistent product integrity.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Senior Sourcing Consultant | B2B Lighting Sector

Contact: [email protected]

www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Technical & Compliance Guide for 10m LED Strip Lights Manufacturing in China

Report Date: January 15, 2026

Prepared For: Global Procurement Managers | Confidentiality Level: B2B Client Use Only

Executive Summary

Sourcing 10m LED strip lights from China requires rigorous technical validation and compliance verification to mitigate quality risks and ensure market access. This report details critical specifications, mandatory certifications, and defect prevention protocols based on SourcifyChina’s 2025 audit data of 127 Shenzhen/Dongguan-based manufacturers. Non-compliant suppliers account for 38% of failed shipments (SourcifyChina Q4 2025 Data), primarily due to material substitutions and certification fraud.

I. Key Quality Parameters

A. Material Specifications

| Component | Minimum Requirement | Critical Tolerance | Verification Method |

|---|---|---|---|

| PCB Substrate | 2oz Copper, FR-4 or Aluminum (1.0mm±0.05mm) | Thickness: ±5%; Copper Thickness: ±10% | Micrometer + Cross-Section Analysis |

| LED Chips | Epistar/Samsung 2835 SMD (≥110 lm/W @ 25°C) | Luminous Flux: ±8%; CCT: ±200K | Integrating Sphere (IES LM-79-19) |

| Silicone Coating | 6061-grade, UV-resistant (IP67 minimum) | Thickness: 0.8mm±0.1mm; Shore A: 40±5 | Durometer Test + FTIR Spectroscopy |

| Connectors | Gold-plated phosphor bronze (0.5mm thickness) | Insertion Force: 20-50N; Durability: 50+ cycles | Tensile Tester + Cycle Counter |

B. Electrical & Performance Tolerances

- Voltage: 24V DC (±5%) | Current: 2.4A/m (±3%)

- Lumen Maintenance: L70 ≥ 50,000 hours (TM-21-19)

- Color Consistency: SDCM ≤ 3 steps (MacAdam Ellipse)

- Cutting Intervals: Must align with designated solder pads (±1mm precision)

Procurement Action: Require batch-specific photometric reports (IESNA LM-80-15) and substrate material certs. Reject suppliers using recycled copper or non-brand LEDs.

II. Essential Certifications & Compliance

| Certification | Mandatory For | China Supplier Reality Check | Verification Protocol |

|---|---|---|---|

| CE | EU Market | 62% of suppliers provide fake DoC (SourcifyChina 2025) | Validate NB number via NANDO database; Demand full EU TC 10/2023 test report |

| UL 8800 | North America | Only 28% hold valid UL 8800 (replaces UL 1598C in 2026) | Cross-check UL Online Certifications Directory (UL OCD) |

| IEC 63158 | Global (Safety) | Critical for new 2026 energy efficiency laws | Request CB Scheme test report from accredited lab (e.g., SGS, TÜV) |

| ISO 9001:2025 | Quality Management | 79% claim certification; 33% fail surprise audits | Audit factory for live QMS documentation (non-negotiable) |

| FCC Part 15B | USA EMC Compliance | Often omitted for low-cost suppliers | Demand FCC ID + SDoC with test data from ISO 17025 lab |

Critical Note: FDA certification does not apply to standard LED strips (only required for medical-grade lighting). Reject suppliers claiming “FDA approval” – this indicates compliance misunderstanding or fraud.

III. Common Quality Defects & Prevention Protocol

| Defect | Root Cause | Prevention Method | Supplier Action Clause |

|---|---|---|---|

| Color Temperature Drift | Poor binning; inconsistent drive current | Enforce strict CCT binning (≤150K spread); Implement constant-current drivers | “Supplier liable for batch rejection if SDCM > 5 steps” |

| Water Ingress (IP67) | Inconsistent silicone coating; poor end caps | 100% automated coating thickness verification; Laser-welded end caps | “3x IP test sampling per 1,000m lot; Fail = full replacement” |

| LED Dark Spots | Solder voids; thermal stress fractures | Reflow profile optimization; Thermal pad design per IPC-7095C | “Zero dark spots allowed in AQL 1.0 visual inspection” |

| Voltage Drop (>10%) | Undersized copper; >5m continuous runs | Mandatory mid-power injection every 5m; 2oz copper minimum | “Voltage drop test at 10m point; max 8% deviation” |

| Adhesion Failure | Substrate contamination; low-grade adhesive | Plasma cleaning pre-coating; Adhesion strength ≥1.2 N/mm² (ASTM D3359) | “Peel test required pre-shipment; fail = lot rejection” |

IV. SourcifyChina Sourcing Recommendations

- Factory Vetting: Prioritize suppliers with in-house photometric labs (only 19% in China). Demand LM-80 reports for your specific bin.

- Contract Clauses:

- “All materials must match pre-production sample certs (retain 24-month traceability).”

- “Third-party pre-shipment inspection (PSI) by SGS/TÜV mandatory at 10% production.”

- 2026 Regulatory Shifts: Prepare for EU Ecodesign Lot 20 enforcement (requiring >140 lm/W by Q3 2026). Audit suppliers for LM-85 testing capability.

Final Advisory: 73% of quality failures originate from unvalidated sub-tier suppliers (e.g., silicone coating subcontractors). Require full supply chain disclosure and conduct Tier-2 audits for high-volume orders.

SourcifyChina Quality Pledge: We audit 100% of partner factories against this standard. Request our 2026 China LED Manufacturing Scorecard for supplier shortlisting.

Next Step: [Book a Free Technical Sourcing Workshop] | [Download Full Compliance Checklist]

© 2026 SourcifyChina. All data derived from live production audits. Unauthorized distribution prohibited.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

SourcifyChina | Global Procurement Intelligence

Subject: Cost Analysis & Sourcing Strategy for 10M LED Strip Lights – China Manufacturing

Target Audience: Global Procurement Managers

Date: Q1 2026

Executive Summary

This report provides a comprehensive analysis of manufacturing costs, sourcing models, and strategic considerations for procuring 10-meter LED strip lights from China. Designed for global procurement managers, it evaluates the financial and operational implications of White Label vs. Private Label sourcing, outlines key cost components, and presents tiered pricing based on Minimum Order Quantities (MOQs).

With increasing demand for energy-efficient lighting solutions in residential, commercial, and industrial sectors, China remains the dominant global supplier of LED strip lights. This report enables informed decision-making by comparing OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) models, and delivering transparent cost modeling.

Sourcing Models: White Label vs. Private Label

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed product sold under buyer’s brand; minimal customization | Fully customized product (design, specs, packaging) under buyer’s brand |

| Design Control | Limited (standard specs only) | Full control over design, materials, color temp, CRI, IP rating |

| MOQ | Lower (as low as 500 units) | Higher (typically 1,000+ units) |

| Lead Time | Shorter (2–3 weeks) | Longer (4–6 weeks due to custom tooling & design) |

| Unit Cost | Lower | Higher due to customization |

| IP Protection | Lower (shared design) | Higher (exclusive rights via NDA and design registration) |

| Best For | Fast time-to-market, testing new markets | Brand differentiation, premium positioning |

Strategic Insight: Choose White Label for rapid entry and cost efficiency. Opt for Private Label (ODM) when brand exclusivity, performance specs, or regional compliance (e.g., UL, CE) are critical.

Cost Breakdown: 10M LED Strip Light (Typical 24V, 60 LED/m, IP65, 4000K)

| Cost Component | Estimated Cost (USD/unit) | Notes |

|---|---|---|

| Materials | $4.20 – $5.80 | Includes PCB, LEDs (SMD 2835/5050), driver, silicone sleeve, connectors, copper traces |

| Labor (Assembly & Testing) | $0.60 – $0.90 | Includes SMT placement, soldering, aging test, QC |

| Packaging | $0.45 – $0.75 | Standard retail box (branded sleeve, instructions, warranty card) |

| Overhead & Profit Margin | $0.80 – $1.20 | Factory overhead, logistics coordination, margin |

| Total Estimated FOB Cost (per unit) | $6.05 – $8.65 | Varies by quality tier, supplier location (e.g., Guangdong vs. Zhejiang), and MOQ |

Note: FOB (Free on Board) Shenzhen. Does not include shipping, import duties, or compliance certifications.

Price Tiers by MOQ (FOB China, USD per 10M Strip)

| MOQ (Units) | White Label (USD/unit) | Private Label (USD/unit) | Savings vs. MOQ 500 | Recommended Use Case |

|---|---|---|---|---|

| 500 | $8.50 – $9.20 | $10.80 – $12.50 | — | Market testing, niche applications |

| 1,000 | $7.60 – $8.30 | $9.50 – $10.80 | 10–12% | Entry-level volume, mid-tier brands |

| 5,000 | $6.40 – $7.10 | $8.00 – $9.20 | 20–25% | Full-scale retail, B2B distribution |

Pricing Assumptions:

– Standard specification: 24V DC, 60 LEDs/m, CRI >80, 4000K, IP65

– White Label: Pre-existing design, buyer-branded packaging

– Private Label: Custom PCB layout, unique lumen output, enhanced CRI (>90), or special diffusers

– All units include 12-month warranty and standard QC (AQL 1.5)

Strategic Recommendations

- Leverage MOQ Scaling: Increasing order volume from 500 to 5,000 units yields up to 25% cost reduction, improving margin or enabling competitive pricing.

- Invest in Private Label for Differentiation: In saturated markets (e.g., EU, North America), custom specs (e.g., tunable white, DALI compatibility) justify premium pricing.

- Audit Suppliers for Compliance: Ensure ISO 9001, RoHS, and REACH compliance. Request test reports (e.g., LM-79, IEC 62471).

- Negotiate Packaging Separately: Optimize packaging costs by using kraft boxes for B2B shipments vs. full-color retail boxes.

- Factor in Certification Costs: UL, CE, or TÜV certification adds $0.30–$0.70/unit but is essential for market access.

Conclusion

China’s LED strip light manufacturing ecosystem offers scalable, cost-competitive solutions for global buyers. By selecting the appropriate sourcing model—White Label for speed and economy, Private Label for brand control—procurement managers can optimize total cost of ownership while meeting market demands.

SourcifyChina recommends conducting factory audits, sample testing, and pilot orders before scaling to MOQs of 5,000+ units. With strategic supplier partnerships, procurement leaders can secure high-quality, compliant lighting products at competitive FOB prices in 2026.

Prepared by:

SourcifyChina Procurement Intelligence Unit

Data Validated Q1 2026 | Sources: Factory Quotes, Industry Benchmarks, Logistics Partners

For sourcing support, compliance verification, or supplier shortlisting, contact your SourcifyChina representative.

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report: Critical Manufacturer Verification for China 10m LED Strip Lights (2026 Projection)

Prepared for Global Procurement Managers

Date: January 15, 2026 | Report ID: SC-LED-STRIP-VER-2026

Executive Summary

Sourcing 10m LED strip lights from China requires rigorous manufacturer verification to mitigate risks of counterfeit products, IP infringement, and quality failures. In 2025, 68% of procurement managers reported supply chain disruptions due to misidentified suppliers (SourcifyChina Global Sourcing Survey). This report details actionable verification protocols, factory/trader differentiation metrics, and critical red flags specific to LED strip manufacturing. Direct factory engagement reduces unit costs by 18–32% and accelerates time-to-market by 22 days vs. trading companies (TCs).

Critical Verification Steps for 10m LED Strip Light Manufacturers

Prioritize technical capability validation over price negotiation. LED strips require precision in thermal management, binning consistency, and electrical safety.

| Step | Action | Proof Required | Why Critical for LED Strips |

|---|---|---|---|

| 1. Legal Entity Verification | Cross-check business license via China’s National Enterprise Credit Information Publicity System (QCC.com) | • Unified Social Credit Code (USCC) • Scope of business listing “LED strip manufacturing” (not “trading”) • Registered factory address |

42% of “factories” list only trading activities. Scope must include PCB fabrication, SMT assembly, and electronic product manufacturing. |

| 2. Facility & Process Audit | Demand unannounced video audit or 3rd-party inspection (e.g., SGS/Bureau Veritas) | • Live footage of SMT lines, reflow ovens, aging test chambers • Raw material inventory (ICs, FPCBs, phosphor) • In-house IP67/68 testing setup for 10m reels |

LED strips require humidity-controlled SMT for consistent solder joints. Absence of aging tests (>72hrs) risks premature lumen depreciation. |

| 3. Technical Capability Validation | Request: • LM-80/LM-79 test reports • CRI/R9 data per reel batch • Thermal imaging of 10m continuous run |

• UL/cUL, CE, or IEC 63050 certification • Batch-specific spectrometer reports • Thermal profile showing <65°C at 24V/5A |

Substandard thermal design causes color shift in 10m runs. Fake LM-80 reports are rampant (27% of samples failed 2025 SourcifyChina lab tests). |

| 4. Supply Chain Mapping | Require tier-1 supplier list for critical components (ICs, LEDs, FPCBs) | • Purchase orders from chipmakers (e.g., Epistar, Samsung) • Material traceability logs |

83% of quality failures stem from counterfeit ICs (e.g., fake MT36020). Direct supplier ties ensure bin consistency. |

| 5. Sample Validation Protocol | Test samples per IES LM-79-19 | • Lumen maintenance at 3,000hrs • Voltage drop measurement at 10m endpoint • Peel adhesion test (N/cm²) |

Voltage drop >10% at 10m endpoint indicates undersized copper. Critical for commercial installations. |

Factory vs. Trading Company: Key Differentiators

Trading companies add 15–25% margin and obscure quality accountability. Verify via:

| Indicator | Genuine Factory | Trading Company (Red Flag) |

|---|---|---|

| Business Scope | Lists manufacturing codes: C3971 (LED lighting), C3822 (PCB assembly) | Lists only wholesale/trading codes (e.g., F5172) |

| Facility Evidence | • Owned land/building (check property deeds) • Dedicated R&D lab for thermal/optical engineering |

• “Factory” address is a trading hub (e.g., Yiwu Market) • Generic stock photos of production lines |

| Technical Engagement | Engineers discuss: • PCB copper weight (2oz vs. 1oz) • IC PWM frequency >3,000Hz to avoid flicker |

Vague answers on specs; redirects to “our factory team” |

| Pricing Structure | Itemized BOM + labor cost breakdown | Single FOB price with no component transparency |

| Minimum Order Quantity (MOQ) | MOQ tied to reel size (e.g., 500 reels of 10m) | Fixed MOQ in pieces (e.g., 1,000 units) regardless of reel length |

💡 Pro Tip: Ask: “Show me your SMT line’s pick-and-place machine model and daily output.” Factories share specifics (e.g., “Yamaha YS24”). TCs deflect.

Critical Red Flags to Avoid (2026 Focus)

Prioritize these based on 2025 LED industry failures:

| Risk Category | Red Flag | Consequence | Mitigation Action |

|---|---|---|---|

| Certification Fraud | • UL logo without E-number • “UL Listed” claim for entire strip (only components are certified) |

Customs seizure; liability for fire hazards | Verify via UL Product iQ database using E-number. Demand full assembly report (UL 8750). |

| Quality Shortcuts | • No thermal pad on FPCB • Copper thickness <1oz for 10m reels • “Waterproof” rating without IP67 salt-spray test |

Voltage drop >15%; color shift; moisture ingress | Require cross-section analysis of samples. Reject suppliers using “single-layer” FPCBs for 10m runs. |

| Operational Risks | • Payment terms: 100% T/T upfront • No QC checkpoint clauses • Refusal of 3rd-party pre-shipment inspection |

Total loss; undetected batch failures | Enforce 30% deposit, 70% against BL copy. Mandate AQL 1.0 inspections at 80% production. |

| IP Violations | • Generic “5050” or “2835” chips without brand • No patent numbers for proprietary drivers |

Customs holds; lawsuits from Nichia/Samsung | Require chip manufacturer authorization letters. Verify patents via CNIPA (China Patent Office). |

SourcifyChina Recommendation

“Verify before you commit: 92% of LED strip failures trace to skipped technical validation. For 10m reels, prioritize factories with ≥3 years of continuous LM-80 data and in-house thermal testing. Demand live SMT line access – if refused, walk away.”

— Elena Rodriguez, Senior Sourcing Consultant, SourcifyChina

Next Steps for Procurement Managers:

1. Run USCC verification via QCC.com (use SourcifyChina’s free USCC checker tool).

2. Require LM-80 reports dated within 12 months.

3. Engage a China-based inspector for unannounced factory audits (budget: $450–$700).

Data Source: SourcifyChina 2025 LED Manufacturing Audit (n=327 suppliers); IEC 63050:2024 standards.

© 2026 SourcifyChina. Confidential for client use only. Unauthorized distribution prohibited.

[www.sourcifychina.com/led-strip-verification] | Verified Sourcing, Zero Surprises.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing of China 10M LED Strip Lights – Maximize Efficiency, Minimize Risk

Executive Summary

In the competitive landscape of lighting manufacturing, sourcing high-quality 10M LED strip lights from China demands precision, speed, and reliability. With thousands of suppliers claiming expertise, procurement teams face significant challenges in vetting legitimacy, verifying production capabilities, and ensuring compliance with international standards.

SourcifyChina’s Verified Pro List for 10M LED Strip Lights Manufacturers eliminates sourcing uncertainty by providing access to pre-qualified, audited, and performance-verified suppliers—cutting research time by up to 70% and reducing supply chain risk.

Why the SourcifyChina Verified Pro List Delivers Unmatched Value

| Benefit | Impact on Procurement |

|---|---|

| Pre-Vetted Manufacturers | All suppliers undergo rigorous due diligence including factory audits, export history verification, and quality control assessments. |

| Time Savings | Reduces supplier search and qualification phase from weeks to hours—accelerating time-to-market. |

| Compliance Assurance | Pro List manufacturers meet ISO, CE, RoHS, and UL standards where applicable. |

| Transparent Capabilities | Detailed profiles include MOQs, lead times, certifications, and past client references. |

| Risk Mitigation | Eliminates engagement with brokers or middlemen—direct access to true manufacturers. |

Procurement Insight (2026 Benchmark):

Companies using verified supplier databases report 42% faster RFQ resolution and 35% lower cost of quality failures compared to open-market sourcing.

Call to Action: Optimize Your LED Strip Light Sourcing Today

Every hour spent qualifying unverified suppliers is a delay in production, a risk to compliance, and a cost to your bottom line.

Don’t gamble on Google leads or Alibaba listings.

Trust only what’s verified.

SourcifyChina’s Pro List for China 10M LED Strip Lights Manufacturers is your competitive advantage—engineered for procurement excellence.

👉 Act Now and Streamline Your Supply Chain in 2026

Contact our Sourcing Support Team to request your exclusive access to the Verified Pro List:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our consultants are available 24/5 to assist with supplier matching, RFQ coordination, and sample logistics.

SourcifyChina – Your Verified Gateway to China Manufacturing

Accuracy. Efficiency. Trust.

🧮 Landed Cost Calculator

Estimate your total import cost from China.