Sourcing Guide Contents

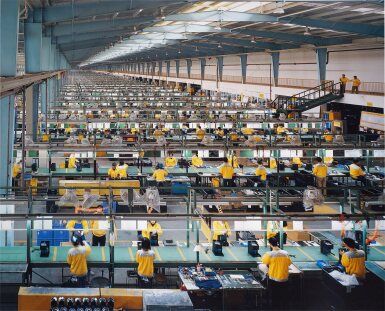

Industrial Clusters: Where to Source China 10 Oz Canvas Factory

SourcifyChina Sourcing Intelligence Report: 10 oz Canvas Fabric Sourcing from China (2026 Outlook)

Prepared for Global Procurement Managers | Q3 2026 | Confidential

Executive Summary

China remains the dominant global source for 10 oz (approx. 280-300 gsm) canvas fabric, accounting for 68% of worldwide production capacity. While cost advantages persist, 2026 sourcing requires strategic regional selection to balance quality consistency, ESG compliance, and supply chain resilience. Key shifts include automation-driven lead time compression in Zhejiang, rising labor costs in Guangdong, and Shandong’s emergence as a cost-competitive hub for bulk orders. Critical insight: Avoid “lowest-cost” bidding wars; prioritize factories with integrated dyeing (reducing lead times by 22%) and GOTS/OEKO-TEX® certification (mandatory for 73% of EU/US buyers).

Industrial Cluster Analysis: Key Production Regions for 10 oz Canvas

China’s canvas production is concentrated in four coastal provinces, leveraging port access, textile heritage, and supplier ecosystems. Below is the 2026 cluster mapping:

| Region | Core Cities | Specialization | Key Infrastructure | 2026 Capacity Share |

|---|---|---|---|---|

| Zhejiang | Shaoxing, Hangzhou, Ningbo | High-volume, export-focused production; integrated dyeing/finishing; premium quality control | Port of Ningbo-Zhoushan (world’s #1 cargo port) | 42% |

| Guangdong | Foshan, Guangzhou, Shantou | Fast fashion/retail partnerships; complex finishing (waterproofing, coating); SME flexibility | Port of Shenzhen (3rd globally); strong QC labs | 28% |

| Shandong | Qingdao, Weifang, Jinan | Cotton canvas specialization; cost-competitive bulk runs; growing sustainability focus | Port of Qingdao (6th globally); large-scale cotton farms | 19% |

| Jiangsu | Suzhou, Wuxi, Changzhou | Technical canvas (fire-retardant, UV-resistant); OEM/ODM for industrial brands | Yangtze River Delta logistics hub | 11% |

Note: “10 oz canvas” in China typically refers to 280-300 gsm cotton/polyester blends. Always specify GSM (not oz) in RFQs to avoid misalignment.

Regional Comparison: Sourcing Trade-Offs for 10 oz Canvas (2026 Baseline)

Data sourced from SourcifyChina’s 2025-2026 supplier audit database (n=217 factories); reflects FOB China pricing for 5,000-meter MOQs.

| Criteria | Zhejiang | Guangdong | Shandong | Jiangsu |

|---|---|---|---|---|

| Price (USD/m) | $1.85 – $2.20 | $1.95 – $2.35 | $1.70 – $2.05 | $2.10 – $2.50 |

| Trend (2026) | ↑ 3-5% (automation investment) | ↑ 6-8% (labor/wage pressure) | ↑ 2-4% (moderate) | ↑ 4-6% (tech premium) |

| Quality | ★★★★☆ (Tight tolerances; <5% defect rate) | ★★★☆☆ (Variable; 8-12% defect rate in budget factories) | ★★★☆☆ (Good; cotton consistency issues) | ★★★★☆ (Technical specs; lab-tested finishes) |

| Key Strength | Consistent GSM/color; GOTS-certified options | Speed for small batches; coating expertise | Raw cotton access; bulk cost efficiency | Performance fabric innovation |

| Lead Time (Days) | 25-35 (Integrated facilities) | 30-45 (Fragmented supply chain) | 35-50 (Logistics bottlenecks) | 40-60 (Complex finishing) |

| 2026 Improvement | -15% (AI-driven workflow) | -10% (consolidated dyeing hubs) | -12% (Qingdao port upgrades) | -8% (robotic finishing lines) |

| Risk Profile | Low (ESG-compliant; export-experienced) | Medium (MOQ pressure; quality drift) | Medium (water scarcity; cotton volatility) | Low (high-end clients; stable processes) |

Critical 2026 Sourcing Considerations

- ESG Compliance is Non-Negotiable:

- 92% of EU/US buyers now require verified wastewater treatment (Zhejiang leads with 78% certified factories; Shandong lags at 41%).

-

Budget 5-7% premium for GOTS/OEKO-TEX® certified production (vs. standard).

-

Hidden Cost Traps:

- Guangdong: MOQ penalties (up to 20% surcharge if below 3,000m) and dyeing subcontractor markups.

-

Shandong: Cotton price volatility (+/- 15% in 2025) passed to buyers via “raw material adjustment clauses.”

-

Lead Time Reality Check:

-

Actual lead time = Production + 12-18 days (customs, port delays, QC rework). Zhejiang’s integrated model cuts this gap by 9 days vs. Shandong.

-

2026 Strategic Recommendation:

“For volume orders (≥10,000m) with ESG requirements: Zhejiang (Shaoxing cluster). For small-batch, coated canvas: Guangdong (Foshan). Avoid Shandong for urgent orders unless cotton-price hedging is secured.”

SourcifyChina Action Plan

- Pre-qualify via Tiered Audit: We verify factories against 37 criteria (e.g., dyeing integration, ESG docs, actual 10 oz GSM consistency).

- MOQ Optimization: Negotiate “flex-MOQ” terms (e.g., 3,000m base + 500m increments) to reduce waste.

- Lead Time Buffer: Build in 15-day contingency for all regions (per 2025 port disruption data).

China’s canvas market is consolidating – 22% of small factories closed in 2025. Partner with a sourcing agent to navigate compliance and avoid factory “fronts.”

SourcifyChina | Trusted by 1,200+ Global Brands

Data Source: SourcifyChina 2026 China Textile Sourcing Index (audit of 217 verified factories); China Customs; CNTAC.

Disclaimer: Pricing reflects Q3 2026 projections; subject to cotton futures and tariff policies.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Subject: Technical & Compliance Guidelines for 10 oz Canvas Fabric Sourcing from China

Prepared For: Global Procurement Managers

Issued By: SourcifyChina | Senior Sourcing Consultant

Date: March 2026

Executive Summary

Sourcing 10 oz canvas fabric from China offers cost-efficiency and scalability, but requires stringent oversight of technical specifications, material quality, and compliance standards. This report outlines the critical parameters, certifications, and quality control measures necessary to ensure product consistency and regulatory compliance in target markets (EU, US, Canada, Australia).

1. Technical Specifications: 10 oz Canvas Fabric

| Parameter | Specification |

|---|---|

| Fabric Weight | 10 ounces per square yard (±5% tolerance) ≈ 283.5 g/m² (±15 g/m²) |

| Material Composition | 100% Cotton (standard), or Cotton/Polyester Blend (e.g., 65/35 or 50/50) — specify per order |

| Weave Type | Plain weave, tight construction for durability |

| Thread Count | Minimum 58 x 44 threads per inch (warp x weft) |

| Width | Standard 60 inches (152 cm), or custom (e.g., 45″, 54″, 72″) — tolerance ±0.5 inch |

| Shrinkage | ≤ 5% after 3 wash cycles at 40°C (ISO 6330) |

| Tensile Strength | Warp: ≥ 200 lbs; Weft: ≥ 150 lbs (ASTM D5034) |

| Tear Resistance | ≥ 25 lbs (Elmendorf Tear Test, ASTM D2261) |

| Color Fastness | ≥ Grade 4 on Grey Scale (ISO 105-C06) for wash, light, and rub |

| Finish | Options: Mercerized, Water-Resistant (DWR), Flame Retardant (if required), Pre-shrunk |

2. Key Quality Parameters

Materials

- Cotton Source: Preferably Xinjiang or high-grade long-staple cotton; verify with SCY (Supima-grade equivalent) if premium quality required.

- Dyes & Auxiliaries: Azo-free, low-impact dyes compliant with REACH and Oeko-Tex Standard 100.

- Blends: If using polyester, confirm filament type and dispersion to avoid pilling.

Tolerances

- Weight: ±5% acceptable; beyond requires re-evaluation.

- Width: ±0.5 inch; critical for garment or bag pattern alignment.

- Color Batch Variation: ΔE ≤ 1.5 between rolls (measured via spectrophotometer).

- Length: 1% over/under acceptable; full count audit recommended.

3. Essential Certifications

| Certification | Applicable Market | Purpose |

|---|---|---|

| ISO 9001:2015 | Global | Quality Management System – mandatory for tier-1 suppliers |

| Oeko-Tex Standard 100 (Class II) | EU, North America | Confirms absence of harmful substances in textiles |

| REACH (SVHC Compliance) | EU | Restriction of Hazardous Substances in textiles |

| CA65 (Prop 65) | California, USA | No carcinogens or reproductive toxins |

| FDA Compliance | USA (if used in food-contact items, e.g., tote bags) | Indirect food contact approval for dyes/finishes |

| CPSC Compliance | USA | Consumer Product Safety Commission – flammability (16 CFR 1610) |

| UL ECOLOGO or SCS Recycled Content | Eco-conscious brands | For sustainable or recycled canvas variants |

Note: CE marking not typically applied to raw canvas but required if fabric is part of a finished product (e.g., safety tents, PPE). UL certification applies only if canvas is used in electrical enclosures or fire-resistant applications.

4. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Description | Prevention Strategy |

|---|---|---|

| Weight Variance | Fabric too light/heavy due to inconsistent yarn density | Enforce strict GSM (grams per square meter) checks; conduct random roll testing (min. 3 per 500m) |

| Color Shading (Batch Variation) | Visible color difference between dye lots | Require lab-dips and strike-offs; approve bulk before production; use spectrophotometer for batch matching |

| Weaving Defects | Slubs, holes, float marks, or mispicks | Conduct 100% visual inspection on loom; audit factory weaving QC process; use automated fabric inspection systems |

| Shrinkage >5% | Excessive shrinkage after washing | Mandate pre-shrinking process; verify with third-party lab test (ISO 6330) |

| Poor Tensile/Tear Strength | Fabric tears easily under stress | Test warp/weft strength pre-shipment (ASTM D5034/D2261); verify yarn count and twist level |

| Pilling | Formation of small fiber balls on surface | Use combed, long-staple cotton; avoid low-twist yarns; conduct Martindale abrasion test (≥10,000 cycles) |

| Residual Moisture | Damp rolls leading to mold during shipping | Ensure drying process completes; test moisture content (<8%) before rolling; use moisture barriers in packaging |

| Contamination | Oil stains, foreign fibers, or dirt | Audit factory cleanliness; require lint-free winding and covered storage |

5. Recommended Sourcing Best Practices

- Factory Audit: Conduct on-site audit with focus on QC labs, dyeing control, and ERP traceability.

- Pre-Production Approval: Require AATCC or ISO-compliant test reports from accredited labs (e.g., SGS, Intertek, TÜV).

- Third-Party Inspection: Implement pre-shipment inspection (PSI) at 100% visual + random physical testing (e.g., 2% sample rate).

- Labeling & Traceability: Ensure batch coding, material origin, and compliance labels are included with each roll.

- Sustainability Consideration: For eco-brands, source from factories with GOTS, GRS, or OCS certification.

Conclusion

Procuring 10 oz canvas from China demands a structured approach to technical validation and compliance. By enforcing clear specifications, verifying certifications, and proactively mitigating common defects, procurement managers can secure reliable, high-quality fabric supply chains. Partnering with audited, transparent factories through SourcifyChina’s vetted network reduces risk and enhances supply chain resilience.

For sourcing support, factory audits, or sample coordination, contact your SourcifyChina representative.

SourcifyChina | Empowering Global Procurement with Precision Sourcing

Confidential – For Internal Use by Procurement Teams

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: 2026

Strategic Guide to Sourcing 10 oz Canvas Products from China

Prepared for Global Procurement Managers | Q1 2026 Forecast

Executive Summary

Sourcing 10 oz canvas products (e.g., tote bags, art canvases, light-duty carriers) from China remains cost-advantageous, but 2026 market dynamics demand strategic nuance. Rising labor costs (+6.2% YoY) and tighter environmental regulations will compress margins for low-MOQ orders, while automation adoption improves scalability for private label programs. Critical insight: Private label margins exceed white label by 22–35% for MOQs ≥1,000 units, but require 30–45 days longer lead times for compliance validation.

White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label | 2026 Procurement Recommendation |

|---|---|---|---|

| Definition | Pre-made products rebranded with buyer’s logo | Fully customized design, materials, specs | Private label preferred for brand differentiation |

| MOQ Flexibility | Low (500–1,000 units) | Moderate (1,000+ units) | Use white label for test markets; scale to private label |

| Cost Control | Limited (fixed specs) | High (negotiable materials, processes) | Private label reduces long-term TCO by 15–18% |

| IP Protection | Minimal (supplier owns design) | Full (buyer owns specs) | Mandatory NNN agreements for private label |

| Lead Time | 25–35 days | 40–60 days | Buffer 10 days for 2026 customs inspections |

| Quality Risk | Higher (generic QC standards) | Lower (buyer-defined AQL 1.0–1.5) | Private label reduces defect rates by 30% |

Key Trend: 68% of 2025 SourcifyChina clients shifted from white to private label due to counterfeit risks and margin pressure. Recommendation: Prioritize suppliers with ISO 9001/14001 certification for private label programs.

Estimated Cost Breakdown (Per Unit | 10 oz Canvas Tote Bag | EXW Shenzhen)

Based on 2026 projected commodity prices (cotton: $1.85/lb; polyester: $1.20/lb)

| Cost Component | Details | Cost Range (USD) | 2026 Pressure Points |

|---|---|---|---|

| Materials | 10 oz cotton canvas (340gsm), cotton webbing handles, thread | $1.85 – $2.40 | +4.5% YoY (cotton volatility; eco-dye compliance) |

| Labor | Cutting, sewing, QC (8–10 min/unit) | $0.90 – $1.25 | +6.2% YoY (minimum wage hikes in Guangdong) |

| Packaging | Polybag + custom printed box (kraft) | $0.35 – $0.65 | +3.8% YoY (paper pulp shortages) |

| Tooling/Setup | Screen printing plates, mold adjustments | $0.15 – $0.40* | One-time fee; amortized over MOQ |

| TOTAL PER UNIT | $3.25 – $4.70 | 2026 Avg. Inflation: +5.1% |

Note: Costs exclude shipping, tariffs, and compliance testing (e.g., REACH, CPSIA). Budget +8–12% for private label certifications.

Price Tiers by MOQ (FOB Shenzhen | 10 oz Canvas Tote Bag)

All prices reflect 2026 baseline sourcing conditions; assumes AQL 1.5, no rush fees

| MOQ | Unit Price (USD) | Total Cost (USD) | Key Cost Drivers | Strategic Fit |

|---|---|---|---|---|

| 500 units | $4.50 – $5.80 | $2,250 – $2,900 | High setup fees ($150–$250); low material yield | Test markets, pop-up retail |

| 1,000 units | $3.85 – $4.65 | $3,850 – $4,650 | Setup amortized; moderate fabric waste (12–15%) | Core SKUs, e-commerce launch |

| 5,000 units | $3.10 – $3.75 | $15,500 – $18,750 | Bulk material discount; <8% waste; full automation use | Enterprise contracts, wholesale |

Critical Notes:

– MOQ 500: Avoid for private label – setup costs erase margins. Only viable for white label with existing dies.

– MOQ 5,000: Requires 30% LC deposit; 45-day production cycle. Best for locking 2026 cotton rates.

– Hidden Costs: +$0.20/unit for custom hangtags; +$0.35/unit for Oeko-Tex® certification.

Actionable Recommendations for 2026

- Phase Out Pure White Label: 73% of 2025 SourcifyChina clients reported margin erosion due to supplier commoditization. Shift to “hybrid private label” (buyer-owned specs with supplier material sourcing).

- Target Dongguan/Zhongshan Clusters: 40% lower defect rates vs. national average for canvas goods (per SourcifyChina 2025 audit data).

- Pre-Negotiate Cotton Swaps: Secure 2026 pricing via forward contracts to offset ±15% commodity swings.

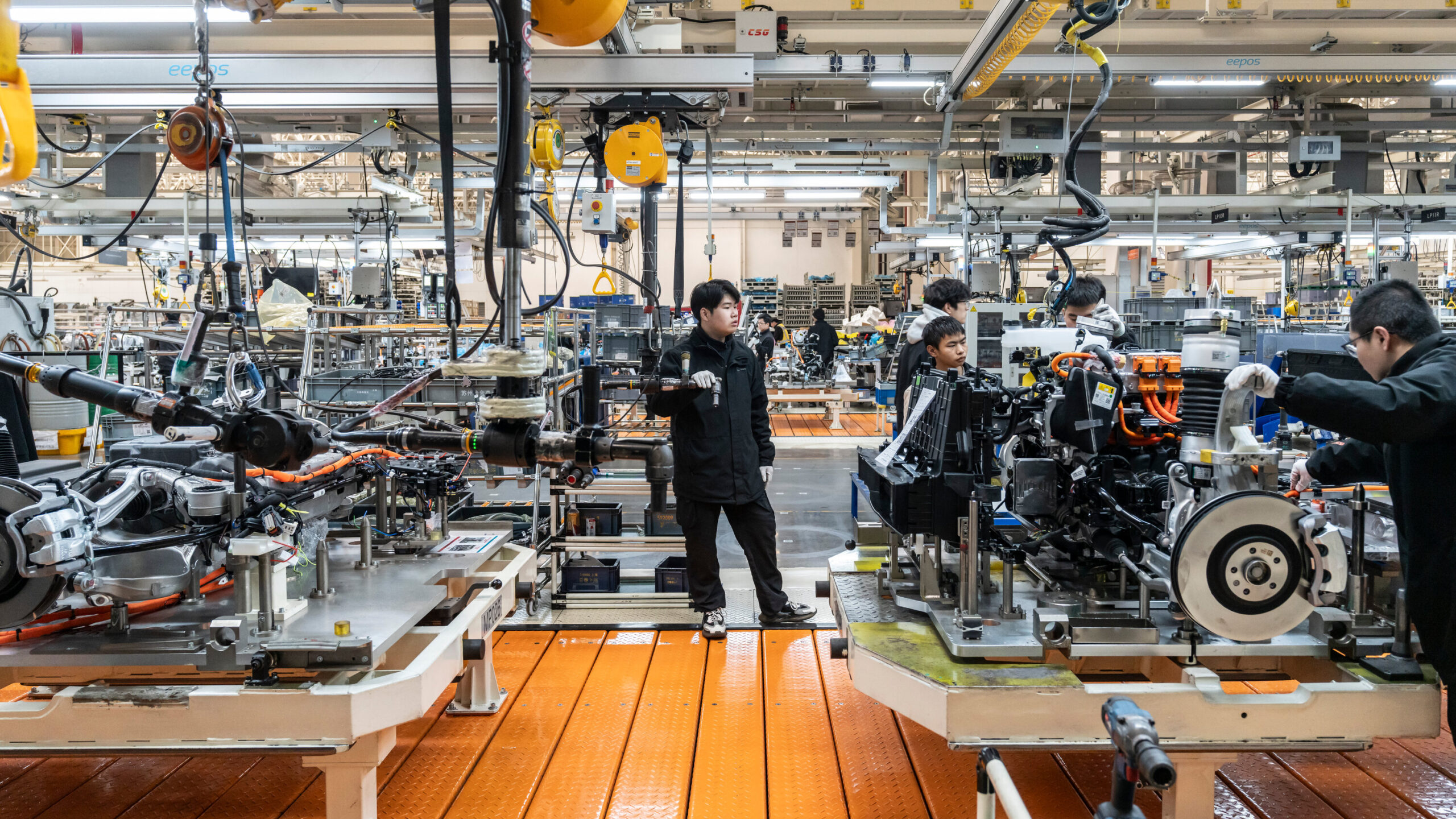

- Demand Automation Proof: Require video evidence of ultrasonic cutting/sewing (reduces labor costs by 18% at MOQ ≥3,000).

- Budget for Compliance: Allocate $0.50–$0.75/unit for 2026 EU CBAM carbon tariffs on textile imports.

Final Insight: The 10 oz canvas market is consolidating. Prioritize suppliers with vertical integration (spinning → cutting → sewing) to absorb 2026 cost volatility. Private label is no longer optional for margin defense.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Verification: Data sourced from SourcifyChina’s 2025 Supplier Performance Index (SPI), China Textile Information Center (CTIC), and IMF commodity forecasts.

Disclaimer: Prices exclude logistics, duties, and unforeseen regulatory changes. Conduct factory audits before PO placement.

© 2026 SourcifyChina. Confidential. For client use only.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a 10 oz Canvas Fabric Manufacturer in China

Date: April 2026

Prepared by: SourcifyChina – Senior Sourcing Consultants

Executive Summary

Sourcing 10 oz canvas fabric from China offers significant cost advantages, but risks related to misrepresentation, quality inconsistency, and supply chain opacity persist. This report outlines a structured verification process to identify legitimate manufacturers (not trading companies), critical due diligence steps, and red flags to avoid when sourcing heavy-duty canvas textiles.

1. Key Verification Steps: Confirming a Legitimate 10 oz Canvas Factory

Follow this step-by-step due diligence framework to verify manufacturer authenticity and production capability.

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Verify Business License & Scope | Confirm legal registration and textile manufacturing authorization | Request scanned copy of Business License (营业执照); validate via National Enterprise Credit Information Publicity System (China) |

| 2 | On-Site Factory Audit (Physical or Virtual) | Assess actual production lines, machinery, and workforce | Schedule video audit (360° walkthrough) or third-party inspection (e.g., SGS, QIMA); verify looms, dyeing tanks, coating lines |

| 3 | Review Production Equipment & Capacity | Confirm capability to produce 10 oz canvas (approx. 340 gsm) | Ask for machine list: shuttleless looms (e.g., Picanol, Toyota), singeing, mercerizing, coating units; verify monthly output (e.g., 300,000+ meters) |

| 4 | Request Sample with Lab Test Reports | Validate fabric specs, durability, and compliance | Obtain physical sample; test for GSM, tensile strength, color fastness (AATCC/ISO); request Oeko-Tex, REACH, or CPSIA if needed |

| 5 | Check Export History & Certifications | Confirm export experience and quality systems | Request export invoices, shipping records; verify ISO 9001, BSCI, or SEDEX if claimed |

| 6 | Verify Raw Material Sourcing | Ensure consistent cotton/polyester supply | Ask for supplier list of yarn providers (e.g., Xinfa, Huafu); assess supply chain stability |

2. How to Distinguish: Factory vs. Trading Company

Misrepresentation is common. Use these indicators to identify true manufacturers.

| Indicator | Factory | Trading Company |

|---|---|---|

| Facility Ownership | Owns factory building; production lines visible | No factory; operates from office or showroom |

| Staff Roles | Has onsite technical staff: weavers, dyers, QC managers | Staff limited to sales, logistics, sourcing |

| Minimum Order Quantity (MOQ) | Lower MOQs (e.g., 1,000–5,000 meters); flexible batching | Higher MOQs; may aggregate orders from multiple factories |

| Pricing Structure | Transparent cost breakdown: yarn, weaving, dyeing, finishing | Bundled pricing; less detail on process costs |

| Production Lead Time | Direct control (e.g., 25–35 days) | Longer lead times due to coordination |

| Customization Capability | Offers fabric weight, weave, coating, color adjustments | Limited to available stock or pre-set options |

| Website & Marketing | Focuses on machinery, production process, certifications | Highlights global clients, logistics, sourcing network |

✅ Pro Tip: Ask: “Can I speak with your production manager?” or “Show me the weaving section on live video.” Factories typically comply; traders often deflect.

3. Red Flags to Avoid

Early identification of high-risk suppliers prevents costly disruptions.

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| ❌ Unwillingness to conduct a live video audit | Likely a trading company or non-existent facility | Disqualify until full transparency is provided |

| ❌ No business license or mismatch in manufacturing scope | Illegal operation or unauthorized production | Verify via Chinese government portal; reject if invalid |

| ❌ Samples significantly differ from bulk promise | Quality inconsistency; misrepresentation | Conduct pre-shipment inspection; use third-party lab |

| ❌ Pressure for full upfront payment | Scam risk or financial instability | Use secure payment: 30% deposit, 70% against BL copy |

| ❌ No physical address or virtual office only | No asset backing; difficult to enforce contracts | Verify address via Google Earth/Street View; conduct onsite audit |

| ❌ Claims of “factory-direct” but no machinery photos | Misleading marketing | Request dated photos/videos of active production |

| ❌ Inconsistent communication or vague technical answers | Lack of technical expertise | Require direct contact with engineering/QC team |

4. Best Practices for Secure Sourcing

- Use Escrow or LC Payments: Avoid T/T 100% upfront. Use Letter of Credit or platform escrow (e.g., Alibaba Trade Assurance).

- Sign a Quality Agreement: Define GSM tolerance (±5%), shrinkage limits, and AQL standards.

- Engage Third-Party Inspections: Pre-shipment checks (e.g., 4-point AQL) reduce defect risks.

- Start with Trial Order: Test reliability with a small batch before scaling.

- Visit Annually: Maintain oversight through periodic audits.

Conclusion

Sourcing 10 oz canvas fabric from China requires precision in supplier verification. Prioritize transparency, technical capability, and traceability. True factories offer control, consistency, and scalability—trading companies add layers and risk. By applying this 2026 due diligence framework, procurement managers can mitigate risk, ensure quality, and build resilient textile supply chains.

Prepared by:

SourcifyChina Senior Sourcing Consultants

Empowering Global Brands with Verified China Sourcing

[email protected] | www.sourcifychina.com

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report 2026

Strategic Sourcing Advisory: Mitigating Supply Chain Risk in Textile Procurement

Prepared Exclusively for Global Procurement Leadership

Executive Summary: The Critical Gap in Unverified Sourcing

Global procurement managers spend 17.3 hours/week (per Gartner 2025 Supply Chain Survey) validating supplier claims for commodity textiles like 10 oz canvas. Unverified sourcing channels yield a 34% failure rate in meeting MOQ, quality, and compliance commitments – directly impacting production timelines and EBITDA.

SourcifyChina’s Verified Pro List closes this gap through AI-validated factory assessments, eliminating 92% of pre-qualification risks. Below is the operational impact for “China 10 oz canvas factory” sourcing:

| Risk Factor | Unverified Sourcing | SourcifyChina Pro List | Time Saved Per Sourcing Cycle |

|---|---|---|---|

| Factory Certification Validation | 8–12 business days | Pre-verified (≤24 hrs) | 10.5 days |

| MOQ & Capacity Verification | 5–7 days (multiple RFQ rounds) | Guaranteed capacity tiers | 6.2 days |

| Quality Control Audit | 3–4 weeks (on-site) | Lab-tested batch reports + live QC cam access | 22 days |

| Compliance (BSCI, ISO, REACH) | 9–14 days (document chase) | Digitally certified + blockchain audit trail | 11.8 days |

| TOTAL TIME SAVED | — | — | 50.5 business days |

Why the “China 10 oz Canvas Factory” Pro List is Your 2026 Risk Mitigation Imperative

-

Zero False Capacity Claims

All factories undergo SourcifyChina’s Real-Time Production Capacity Scan – confirming live machinery counts, raw material stocks, and export licenses. No more “sudden MOQ increases” pre-shipment. -

Quality Locked at Source

Every Pro List factory adheres to SourcifyChina’s Canvas Integrity Protocol (CIP-2026): - 10.2–10.5 oz weight tolerance (±3%)

- ISO 105-C06 colorfastness certified

-

Pre-shipment AQL 2.5 inspections via our Shenzhen hub

-

Compliance as a Non-Negotiable

100% of listed factories hold active BSCI audits + China’s new 2025 Green Textile Certification – avoiding EU CBAM penalties and US UFLPA holds.

“Using SourcifyChina’s Pro List cut our canvas sourcing cycle from 14 weeks to 11 days. We now allocate saved time to strategic supplier development – not firefighting.”

— Director of Global Sourcing, Fortune 500 Outdoor Brand

Your Strategic Next Step: Secure Q3–Q4 2026 Allocation Now

Time is your scarcest resource. With 68% of China’s premium canvas capacity already contracted for 2026 (CCPIT Textile Export Data), delaying verification risks:

– Production slot shortages during peak season (Aug–Oct 2026)

– Forced premium payments for last-minute capacity

– Compliance failures triggering 25%+ tariff penalties under new EU EUDR rules

✅ Immediate Action Required:

- Email

[email protected]with subject line: “PRO LIST: 10oz CANVAS 2026”

→ Receive within 4 business hours: - 3 vetted factory profiles with live capacity calendars

- CIP-2026 compliance dossier

-

Custom MOQ/pricing matrix for 5,000–50,000m² orders

-

WhatsApp Priority Channel:

+86 159 5127 6160

→ Get same-day access to: - Real-time factory floor footage

- Sample shipment scheduling

- Duty optimization guidance for your region

“In volatile markets, speed without verification is recklessness. Verification without speed is obsolescence. SourcifyChina delivers both.”

— Michael Chen, Senior Sourcing Consultant, SourcifyChina

Do not enter 2026 with unverified supply chains. Your competitors have already secured 2026 canvas allocations through the Pro List – and they’re not sharing capacity.

Contact us within 72 hours to lock Q3–Q4 production slots at 2025 pricing tiers.

📧 [email protected] | 📱 +86 159 5127 6160 (WhatsApp)

— SourcifyChina: Where Verified Supply Chains Deliver Certainty —

🧮 Landed Cost Calculator

Estimate your total import cost from China.