The global chiller market is experiencing robust expansion, driven by rising demand for efficient cooling solutions across commercial, industrial, and healthcare sectors. According to Grand View Research, the market size was valued at USD 32.4 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing urbanization, stringent energy efficiency regulations, and the proliferation of data centers requiring reliable thermal management. Mordor Intelligence further reinforces this trajectory, forecasting a CAGR of over 6% during the 2023–2028 period, with Asia-Pacific emerging as the fastest-growing regional market due to rapid industrialization and infrastructural development. As demand intensifies, innovation in HVAC technology and sustainability have become key differentiators among manufacturers. In this evolving landscape, the following nine chiller manufacturers stand out for their technological leadership, global reach, and consistent performance.

Top 9 Chiller Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cold Shot Chillers

Domain Est. 1999

Website: waterchillers.com

Key Highlights: Cold Shot Chillers manufactures water chillers designed to handle the demands of both industrial and commercial environments. Our units are built to withstand ……

#2 Industrial Chiller Manufacturer for Cooling Systems

Domain Est. 2004

Website: hyfra.com

Key Highlights: The HYFRA product range includes a wide selection of chillers for machines, lubricants, tools, lasers and a variety of other objects to be cooled….

#3 KKT Chillers USA

Domain Est. 2012

Website: kkt-chillersusa.com

Key Highlights: KKT Chillers is an industrial chiller manufacturer providing custom air & water chilled coolers for applications from medical to packaging….

#4 BROAD U.S.A. INC.

Website: broadusa.com

Key Highlights: BROAD is one of the world’s largest absorption chiller manufacturers with cooling tonnage ranges as small as 30 up to 3,300 ton. BROAD U.S.A. is a privately ……

#5 Water-Cooled Chillers

Domain Est. 1995

Website: york.com

Key Highlights: YORK® Water-cooled Chillers meet your building efficiency needs with the widest variety of water-cooled industrial and commercial chillers on the market….

#6 GEA ammonia chiller portfolio

Domain Est. 1995

Website: gea.com

Key Highlights: GEA offers an extensive product portfolio of ammonia chillers for virtually any application for industrial refrigeration and air conditioning….

#7 Chiller City

Domain Est. 1998

Website: chillercity.com

Key Highlights: Chiller City specializes in industrial recirculating chillers, medical chillers, refrigerant reclamation, and expert service and support….

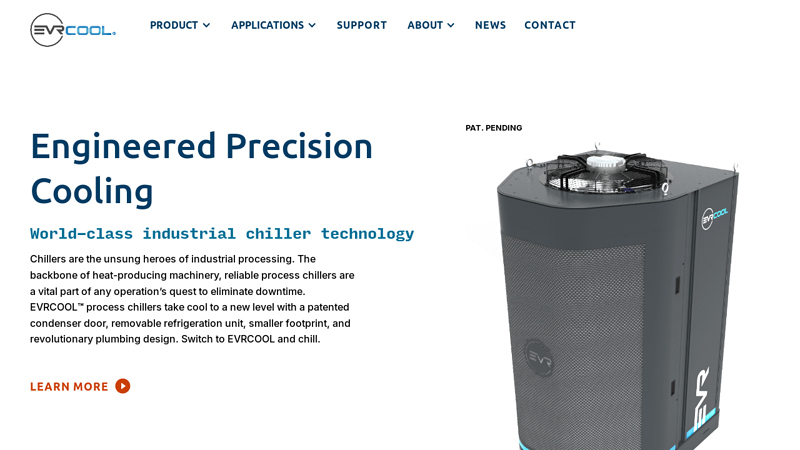

#8

Domain Est. 2023

Website: evrcool.com

Key Highlights: EVRCOOL process chillers take cool to a new level with a patented condenser door, removable refrigeration unit, smaller footprint, and revolutionary plumbing ……

#9 Chillers: Air-Cooled, Water-Cooled

Domain Est. 1995

Website: carrier.com

Key Highlights: Discover Carrier Commercial’s chillers and components for efficient, reliable cooling. Optimize your HVAC system with our innovative solutions today….

Expert Sourcing Insights for Chiller

H2: Projected 2026 Market Trends for Chillers

The global chiller market is poised for significant transformation by 2026, driven by technological innovation, regulatory shifts, and evolving end-user demands. As industries and commercial sectors prioritize energy efficiency and sustainability, key trends are emerging that will shape the chiller landscape in the coming years.

1. Growth in Energy-Efficient and Low-GWP Chillers

A major driver of the 2026 chiller market is the increasing adoption of chillers using low-global warming potential (GWP) refrigerants. Regulatory pressures—such as the Kigali Amendment to the Montreal Protocol and EU F-Gas regulations—are accelerating the phase-down of high-GWP refrigerants like HFCs. Manufacturers are responding with chillers utilizing natural refrigerants (e.g., ammonia, CO₂, hydrocarbons) and next-generation HFOs. These systems not only comply with regulations but also offer improved energy performance, appealing to sustainability-conscious buyers.

2. Rise of Smart and Connected Chillers

The integration of IoT (Internet of Things) and AI-driven analytics into chiller systems is transforming operations. By 2026, smart chillers equipped with predictive maintenance algorithms, remote monitoring, and cloud-based energy management platforms are expected to gain widespread adoption. These technologies enhance reliability, reduce downtime, and optimize energy consumption, particularly in data centers, hospitals, and large commercial buildings.

3. Expansion in Emerging Markets

Asia-Pacific, particularly India, Southeast Asia, and China, will continue to be a high-growth region for chillers due to rapid urbanization, industrial expansion, and rising demand for HVAC systems in new construction. Government initiatives promoting green buildings and energy efficiency are further stimulating chiller demand. Similarly, infrastructure development in the Middle East and Africa supports market growth, especially in cooling-intensive applications like district cooling and industrial processing.

4. Increased Demand in Data Centers and Telecom

With the proliferation of 5G networks and cloud computing, data centers are expanding globally—each requiring robust cooling solutions. By 2026, precision and liquid-cooled chillers will see strong demand to manage high-density server loads. Modular and scalable chiller systems are becoming preferred due to their flexibility and ease of integration in rapidly evolving digital infrastructures.

5. Shift Toward Modular and Rental Chillers

To meet temporary or peak cooling needs—especially in construction, events, and emergency industrial applications—the market for rental and modular chillers is expanding. This trend supports cost-efficiency and operational flexibility, allowing companies to avoid large capital expenditures while maintaining cooling capacity.

6. Focus on Sustainability and Lifecycle Cost Reduction

End users are increasingly evaluating chillers based on total cost of ownership (TCO), not just upfront price. This shift favors high-efficiency models with lower maintenance needs and longer lifespans. Manufacturers are responding with comprehensive service packages, energy audits, and lifecycle assessments to support long-term sustainability goals.

Conclusion

By 2026, the chiller market will be defined by innovation, regulatory compliance, and digital integration. Companies that prioritize energy efficiency, smart technologies, and sustainable design will lead the market, while demand in emerging economies and high-tech sectors will drive overall growth. Success in this evolving landscape will depend on agility, R&D investment, and alignment with global decarbonization objectives.

Common Pitfalls Sourcing Chillers (Quality, IP)

Sourcing chillers involves significant capital investment and long-term operational impact, making it crucial to avoid common pitfalls related to quality and intellectual property (IP). Overlooking these aspects can lead to performance issues, increased maintenance costs, legal risks, and supply chain vulnerabilities.

Poor Quality Control and Substandard Components

One of the most frequent pitfalls is selecting chiller suppliers based solely on price, leading to compromised build quality. Low-cost manufacturers may use inferior materials, such as subpar copper tubing, low-grade refrigerants, or inefficient compressors, which reduce reliability and lifespan. Inadequate quality assurance processes can result in units that fail prematurely or underperform in real-world conditions. Without proper factory acceptance testing (FAT) or third-party certifications (e.g., AHRI, ISO), buyers risk receiving equipment that does not meet promised efficiency or capacity ratings.

Lack of Transparency in Manufacturing and Sourcing

Many chiller suppliers outsource key components or entire assemblies without disclosing the original equipment manufacturers (OEMs). This lack of transparency makes it difficult to verify quality, trace defects, or ensure compliance with international standards. Hidden subcontracting can also obscure accountability, especially when troubleshooting performance issues or warranty claims. Buyers should insist on detailed documentation of component sources and manufacturing processes to mitigate this risk.

Intellectual Property (IP) Infringement Risks

Sourcing chillers—particularly from regions with weak IP enforcement—can expose buyers to legal and reputational risks. Some manufacturers reverse-engineer patented technologies (e.g., compressor designs, control algorithms, or heat exchanger configurations) without authorization. Purchasing such equipment may inadvertently involve the buyer in IP disputes, especially if the chiller is deployed globally. Additionally, counterfeit or cloned control systems can compromise operational safety and cybersecurity.

Inadequate Protection of Custom Designs and Specifications

When working with OEMs to develop custom chiller solutions, buyers often fail to secure proper IP agreements. Without clear contractual terms, the supplier may retain rights to design innovations, limiting the buyer’s ability to replicate, modify, or transfer the technology. This can hinder scalability and create vendor lock-in. Always ensure that IP ownership of custom engineering work is explicitly assigned to the buyer through legally binding agreements.

Insufficient After-Sales Support and Spare Parts Availability

Even high-quality chillers can become liabilities if the supplier lacks a robust service network or restricts access to genuine spare parts. Some manufacturers use proprietary components protected by IP, making it difficult or expensive to source replacements from third parties. This not only increases downtime but also gives the supplier excessive control over maintenance costs. Evaluate the supplier’s service infrastructure and parts logistics before finalizing procurement.

Overlooking Compliance with Regional Standards and Certifications

Chillers must meet specific regulatory and environmental standards (e.g., F-Gas regulations, DOE efficiency requirements, CE marking). Suppliers may provide units that appear compliant but lack valid certification or use non-compliant refrigerants. This can lead to installation delays, fines, or forced retrofits. Verify all certifications independently and confirm that the equipment meets the requirements of the target market.

Failure to Audit Supplier IP and Design Provenance

Due diligence should extend beyond technical specifications to include IP audits. Request documentation proving the legitimacy of design rights, software licenses, and component sourcing. Engage legal or technical experts to assess whether the chiller’s technology infringes on existing patents—especially if the price seems unusually low. Proactive vetting can prevent costly litigation and ensure long-term operational freedom.

By addressing these pitfalls early in the sourcing process—through thorough supplier evaluation, clear contracts, and independent verification—organizations can secure reliable, compliant, and legally sound chiller solutions.

Logistics & Compliance Guide for Chiller Equipment

Overview

Chillers are complex, heavy-duty mechanical systems used for temperature control in industrial, commercial, and HVAC applications. Their transportation, handling, and installation require careful planning to ensure safety, regulatory compliance, and equipment integrity. This guide outlines key logistics and compliance considerations.

Transportation Requirements

Equipment Packaging

- Chillers must be securely mounted on skids or frames suitable for lifting and transport.

- Protective covers should be used on electrical components, piping connections, and control panels.

- Outdoor or exposed units should have weather-resistant packaging to prevent corrosion during transit.

Mode of Transport

- Road: Use flatbed or lowboy trailers for oversized units. Confirm weight and dimension compliance with local road regulations (e.g., DOT in the U.S.).

- Sea: Secure units in shipping containers or on flat racks. Ensure compliance with IMDG Code for marine transport. Use moisture barriers and desiccants to prevent condensation.

- Air: Rare due to size and weight; only feasible for modular or compact chillers. Requires special freight handling and IATA compliance.

Weight and Dimension Compliance

- Verify chiller dimensions (L x W x H) and gross weight.

- Comply with regional transport regulations (e.g., AASHTO for U.S. highways, EU Directive 96/53/EC).

- Obtain necessary permits for oversize/overweight loads.

Handling and Installation

Lifting and Rigging

- Use manufacturer-specified lifting points only.

- Employ certified rigging equipment and trained personnel.

- Maintain chiller level during lifting to avoid internal damage.

Site Access

- Assess pathways, doorways, elevators, and structural load capacity.

- Plan disassembly/reassembly if modular transport is required.

- Use temporary supports or rails for indoor movement.

Environmental Conditions

- Avoid exposure to rain, snow, or extreme temperatures during installation.

- Protect refrigerant lines and electrical components from contamination.

Regulatory Compliance

International Standards

- Pressure Equipment Directive (PED 2014/68/EU): Applies to chillers with refrigerant circuits above threshold pressures in the EU.

- ASME BPVC: Required for pressure vessels in North America.

- ISO 5149: Safety requirements for refrigerating systems and heat pumps.

Environmental Regulations

- F-Gas Regulation (EU): Controls use and reporting of fluorinated greenhouse gases (e.g., HFCs). Requires leak checks and certified personnel.

- EPA Section 608 (U.S.): Mandates proper handling, recycling, and reporting of refrigerants. Certification required for technicians.

- Kigali Amendment: Phasedown of high-GWP refrigerants; influences chiller design and refrigerant selection.

Electrical and Safety Codes

- Comply with NFPA 70 (NEC) in the U.S. or IEC 60364 internationally for electrical installation.

- Adhere to OSHA or local workplace safety standards during handling and commissioning.

Documentation and Certification

Required Documentation

- Packing list and bill of lading

- Certificate of Conformity (CE, UL, CSA, etc.)

- Pressure vessel certification (ASME, PED)

- Refrigerant charge documentation

- Material Safety Data Sheets (MSDS) for refrigerants and oils

Customs and Import Compliance

- Provide HS code (e.g., 8415.82 for air conditioning machines with refrigerating units).

- Comply with country-specific import duties, energy efficiency standards (e.g., DOE in U.S.), and labeling requirements.

- Prepare for customs inspections; ensure all compliance marks are visible.

Post-Installation Compliance

Commissioning and Testing

- Perform leak tests per ISO 14903 or local standards.

- Verify refrigerant charge and electrical connections.

- Document performance tests and safety checks.

Maintenance and Recordkeeping

- Maintain logs of refrigerant handling, servicing, and leak repairs.

- Keep compliance records for audits (e.g., EPA, F-Gas reporting).

- Schedule regular inspections as required by local regulations.

Conclusion

Proper logistics planning and strict adherence to compliance standards are essential for the safe and legal transport, installation, and operation of chiller systems. Always consult manufacturer guidelines and engage certified professionals for handling, installation, and regulatory reporting.

Conclusion: Sourcing Chiller Manufacturers

In conclusion, sourcing chiller manufacturers requires a strategic and thorough approach to ensure reliability, performance, and long-term value. After evaluating key factors such as manufacturing capabilities, product quality, energy efficiency, certifications, after-sales support, and cost-effectiveness, it becomes evident that selecting the right supplier is critical to the success of HVAC or industrial cooling projects.

Prioritizing manufacturers with proven technical expertise, adherence to international standards (e.g., ISO, CE, AHRI), and a strong track record of innovation ensures that the chillers meet both current and future cooling demands. Additionally, engaging suppliers who offer customization options, comprehensive warranties, and responsive technical service enhances operational efficiency and minimizes downtime.

Geographical considerations, lead times, and supply chain resilience should also be weighed, especially when sourcing internationally. Building long-term partnerships with reputable manufacturers not only ensures consistent product quality but also fosters collaboration for continuous improvement and scalability.

Ultimately, a well-informed sourcing decision—based on due diligence, site visits (if possible), and reference checks—will lead to the acquisition of high-performance chillers that support sustainable operations and provide a strong return on investment.