The global wood coatings market is experiencing steady expansion, driven by increasing demand for durable, aesthetically pleasing finishes in residential and commercial furniture, flooring, and cabinetry. According to Grand View Research, the global wood coatings market was valued at USD 12.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. A significant contributor to this trend is the rising consumer preference for natural wood aesthetics, with cherry wood—known for its rich, warm tones and fine grain—remaining a top choice in high-end interior applications. As demand for cherry wood-look finishes grows, especially in renovation and custom furniture markets, paint manufacturers have responded with advanced formulations that replicate the wood’s distinctive hue and depth. This has led to increased competition and innovation among coating producers, particularly in water-based and low-VOC technologies that meet evolving environmental standards. In this competitive landscape, seven manufacturers have emerged as leaders in developing and supplying high-fidelity cherry wood color paints, combining technical expertise, consistent quality, and market reach to meet the needs of professionals and consumers alike.

Top 7 Cherry Wood Color Paint Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 DEEP CHERRYWOOD ECC-42-3

Domain Est. 1996

#2 Sherwin

Domain Est. 1998

Website: sherwin-williams.com

Key Highlights: Discover the possibilities of Sherwin-Williams® paint with over 1700 paint colors. Get paint color tips, project ideas & product advice for DIY and Pros….

#3 Charming Cherry Paint Color DE5074

Domain Est. 1999

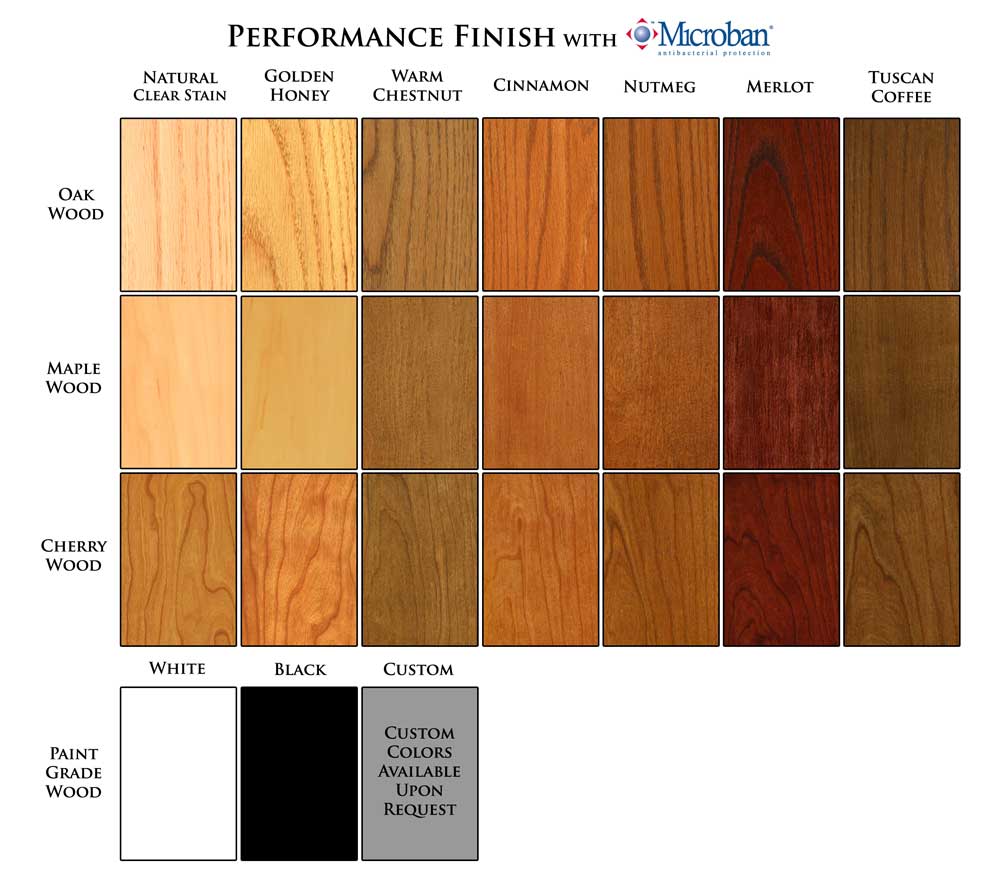

#4 Cherry Wood Stain Options

Domain Est. 2000

Website: amishoriginals.net

Key Highlights: Cherry wood stain options for our handcrafted Amish furniture. Explore our furniture products or visit us in Farmville, Virginia….

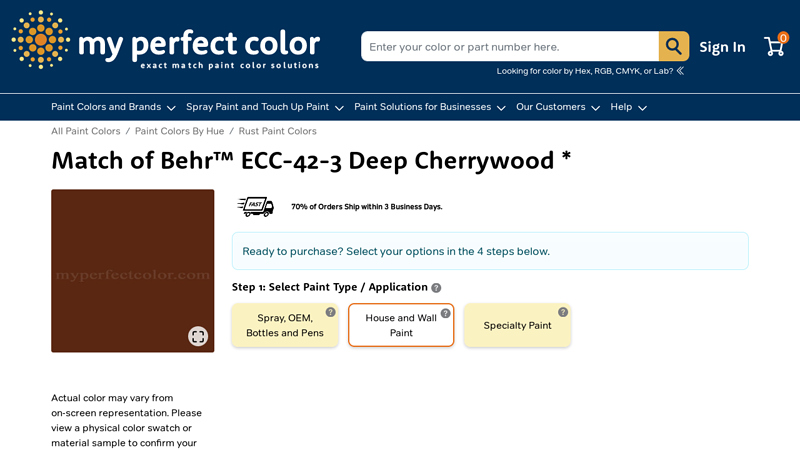

#5 Match of Behr™ ECC

Domain Est. 2004

#6 Cheery Cherry

Domain Est. 2004

Website: ppgpaints.com

Key Highlights: 90-day returnsCheery Cherry is a saturated, bright, coral pink with a raspberry undertone. It is a perfect paint color for a bedroom. Pair it with black accessories for ……

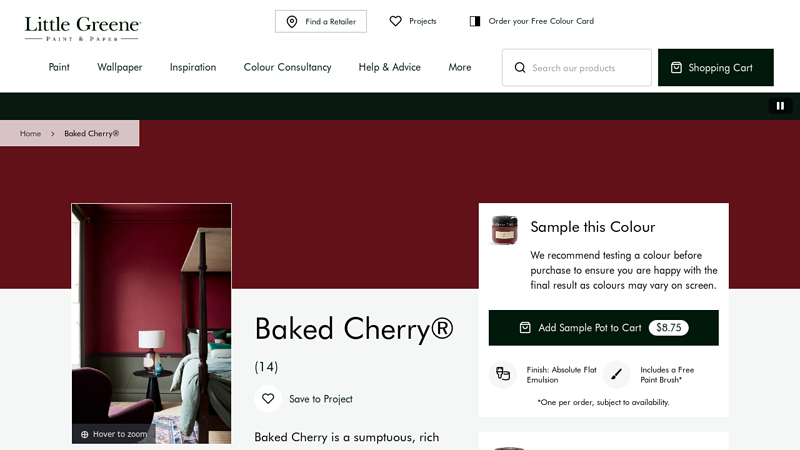

#7 Baked Cherry®

Domain Est. 2022

Website: littlegreene.us

Key Highlights: Baked Cherry paint by Little Greene—a rich cherry red paint for walls and interiors. Discover this classic crimson shade in our luxury red paint collection….

Expert Sourcing Insights for Cherry Wood Color Paint

H2: 2026 Market Trends for Cherry Wood Color Paint

As we approach 2026, the market for cherry wood color paint is experiencing notable shifts driven by evolving consumer preferences, sustainability demands, and innovations in paint technology. This H2 analysis explores key trends shaping the demand and application of cherry wood tone finishes in residential, commercial, and furniture markets.

1. Rising Popularity in Interior Design Aesthetics

Cherry wood color paint continues to gain traction due to its warm, rich tones that emulate the luxurious appearance of natural cherry wood. In 2026, interior design trends favoring biophilic elements and cozy, inviting spaces—such as the “warm minimalism” and “modern farmhouse” styles—are boosting demand. Consumers are increasingly opting for cherry wood hues in cabinetry, trim, and accent walls to add depth and elegance without the high cost of real wood.

2. Growth in Sustainable and Low-VOC Formulations

Environmental consciousness is a major driver in the paint industry. By 2026, manufacturers are prioritizing eco-friendly cherry wood color paints with low volatile organic compound (VOC) content and bio-based resins. Certifications like Greenguard Gold and Cradle to Cradle are becoming standard expectations. This shift aligns with stricter environmental regulations in North America and Europe, making sustainable cherry wood finishes a competitive advantage.

3. Expansion in DIY and Home Renovation Markets

The ongoing surge in home improvement projects—fueled by remote work lifestyles and rising property values—is propelling demand for accessible, high-quality finishes. Cherry wood color paint is increasingly available in user-friendly formats such as matte, satin, and wipe-on gel stains, catering to the do-it-yourself (DIY) consumer. Retailers report increased sales in precustomized cherry tones for kitchen cabinet makeovers and furniture refinishing.

4. Advancements in Paint Technology and Color Matching

In 2026, digital color matching and AI-driven paint formulation tools are enhancing the accuracy and consistency of cherry wood tones. Brands now offer augmented reality (AR) apps that allow customers to visualize cherry finishes in their actual spaces before purchasing. Additionally, durable, scratch-resistant coatings with UV protection are being integrated into cherry wood paint lines to improve longevity, especially in high-traffic areas.

5. Influence of Global Furniture and Cabinetry Trends

The furniture manufacturing sector is a significant end-user of cherry wood color finishes. As global demand for affordable, wood-look furniture rises—particularly in Asia-Pacific and Latin America—paint suppliers are developing cost-effective, high-performance cherry tone coatings for engineered wood products like MDF and plywood. This trend supports mass-market appeal while maintaining aesthetic quality.

Conclusion

By 2026, cherry wood color paint is positioned as a versatile and desirable finish across multiple sectors. Driven by design trends, sustainability, technological innovation, and robust DIY culture, the market is expected to see steady growth. Companies that invest in eco-conscious formulations, digital engagement tools, and consumer education will likely lead the segment in the coming years.

Common Pitfalls Sourcing Cherry Wood Color Paint (Quality, IP)

1. Inconsistent Color Matching Across Batches

A frequent issue when sourcing cherry wood color paint is batch-to-batch color variation. Lower-quality suppliers may lack precise color-matching technology or rigorous quality control, leading to noticeable differences in hue, saturation, or undertones. This inconsistency can compromise the aesthetic integrity of finished products, especially in large or multi-phase projects.

2. Poor Pigment Quality and Fading Over Time

Low-grade pigments or improper formulation can result in cherry wood paint that fades or shifts in color when exposed to UV light or environmental stressors. Inferior binders and resins may also contribute to chalking, peeling, or loss of luster, reducing the longevity and visual appeal of the coated surface.

3. Misrepresentation of “Cherry Wood” Shade

“Cherry wood” is not a standardized color, and suppliers may interpret it differently—ranging from warm reddish-brown to lighter amber tones. Without clear technical specifications or physical color samples, buyers risk receiving a shade that does not align with design expectations or brand standards.

4. Intellectual Property (IP) Risks with Custom Formulations

When developing a proprietary cherry wood color for branding or product differentiation, there’s a risk of IP infringement or misappropriation if proper safeguards aren’t in place. Suppliers may reuse custom formulations for other clients or fail to adhere to confidentiality agreements, potentially leading to unauthorized duplication or market confusion.

5. Lack of Documentation and Certification

Reputable sourcing requires transparency in material safety data sheets (MSDS), VOC content, compliance with environmental regulations (e.g., REACH, RoHS), and durability testing. Suppliers who omit or provide incomplete documentation may be cutting corners, increasing regulatory and reputational risks.

6. Overreliance on Digital Color Samples

Digital renderings or online swatches may not accurately represent how the paint appears under real-world lighting conditions. Without physical sample testing on the intended substrate, buyers may be disappointed with the final appearance, especially given cherry wood’s natural depth and grain interaction.

7. Inadequate Testing for Substrate Compatibility

Cherry wood color paint may perform differently depending on the underlying material (e.g., real wood, MDF, laminate). Without proper adhesion, flexibility, and finish testing, the paint may crack, blister, or delaminate, particularly in high-humidity or high-use environments.

8. Supply Chain Instability and Lead Time Delays

Relying on a single or unverified supplier can expose procurement to disruptions. Cherry wood color formulations—especially those using rare or region-specific pigments—may face raw material shortages, leading to delays or forced reformulations that alter the final appearance.

To mitigate these pitfalls, buyers should insist on physical samples, enforce strict quality agreements, verify IP protections in contracts, and conduct third-party testing when necessary.

Logistics & Compliance Guide for Cherry Wood Color Paint

Product Overview

Cherry Wood Color Paint is a decorative coating designed to simulate the appearance of natural cherry wood on various surfaces. This guide outlines the logistics handling, transportation, storage, and regulatory compliance requirements for safe and legal distribution and use.

Hazard Classification

Cherry Wood Color Paint is typically classified as a flammable liquid (UN 1263, Class 3) due to its solvent-based formulation. Always verify the specific Safety Data Sheet (SDS) provided by the manufacturer for accurate hazard classification. Water-based formulations may have different classifications, such as non-hazardous for transport under certain conditions.

Packaging Requirements

- Use UN-certified containers suitable for flammable liquids (e.g., metal or high-density polyethylene drums or pails with approved closures).

- Ensure packaging is tightly sealed to prevent leakage and vapor release.

- Inner liners or coatings may be required to prevent chemical interaction.

- Label all packages with proper shipping name, UN number, hazard class, and orientation arrows.

Labeling and Documentation

- Affix GHS-compliant labels including hazard pictograms, signal words, hazard statements, and precautionary statements.

- Include transport labels: Class 3 Flammable Liquid diamond label and, if applicable, Environmentally Hazardous Substance (dead fish/tree symbol).

- Provide a current Safety Data Sheet (SDS) compliant with local regulations (e.g., OSHA HazCom 2012 in the U.S., CLP in the EU).

- Prepare a Dangerous Goods Declaration for air or sea transport as required by IATA DGR or IMDG Code.

Storage Guidelines

- Store in a cool, dry, well-ventilated area away from direct sunlight and heat sources.

- Keep away from ignition sources—no smoking, open flames, or electrical equipment not rated for hazardous locations.

- Segregate from oxidizers, strong acids, and alkalis.

- Use grounded containers and bonding during transfer to prevent static discharge.

- Maximum storage temperature should not exceed 30°C (86°F).

Transportation Regulations

- Road: Comply with ADR (Europe), 49 CFR (U.S.), or equivalent national regulations for Class 3 flammable liquids.

- Air: Follow IATA Dangerous Goods Regulations—quantity limits, packaging specifications, and state variations apply.

- Sea: Adhere to IMDG Code requirements, including stowage and segregation rules.

- Domestic shipments may require placarding on vehicles for large quantities (e.g., 454 kg/1001 lbs or more in the U.S.).

Environmental and Regulatory Compliance

- Comply with VOC (Volatile Organic Compound) regulations such as U.S. EPA Method 24, EU Directive 2004/42/EC.

- Ensure product labeling meets TSCA (U.S.), REACH, and CLP regulations (EU), including substance identification and safe use instructions.

- Properly register and report chemicals as required by local authorities.

- Do not dispose of paint or waste in drains or environment. Follow local hazardous waste regulations for disposal.

Handling and Worker Safety

- Use in well-ventilated areas; local exhaust ventilation recommended for large-scale applications.

- Wear appropriate PPE: chemical-resistant gloves, safety goggles, and respiratory protection if vapor levels exceed exposure limits.

- Train personnel in fire safety, spill response, and first aid procedures.

- Maintain spill kits and fire extinguishers (Class B) in storage and handling areas.

Emergency Response

- In case of fire: Use dry chemical, CO₂, or foam extinguishers. Water may be ineffective.

- For spills: Contain with absorbent materials (e.g., sand, vermiculite), place in sealed containers, and dispose of as hazardous waste.

- For skin contact: Wash with soap and water. Remove contaminated clothing.

- For inhalation: Move to fresh air; seek medical attention if symptoms persist.

- Emergency contact: Include manufacturer’s emergency number on SDS and shipping documents.

Disposal and Recycling

- Dispose of empty containers and waste paint as hazardous waste in accordance with local, state, and federal regulations.

- Empty containers must be triple-rinsed or punctured to prevent reuse if allowed by law.

- Explore recycling programs for solvent recovery or container reconditioning where available.

Regulatory Documentation Archive

Maintain copies of:

– Safety Data Sheet (SDS) – Version and revision date

– Certificate of Analysis (if applicable)

– Transport declarations and shipping papers

– Regulatory compliance certifications (e.g., EPA, REACH)

– Training records for personnel

Ensure all documents are readily accessible and updated with product changes or regulatory updates.

In conclusion, sourcing cherry wood color paint requires careful consideration of both aesthetic and practical factors. Achieving an authentic cherry wood appearance involves selecting a paint or stain that accurately replicates the warm, rich reddish-brown tones and natural grain variation characteristic of real cherry wood. Whether using solid paint with wood-graining techniques or transparent stains over real wood, matching the finish—whether satin, semi-gloss, or matte—is crucial for a realistic result. Additionally, prioritizing high-quality, durable, and light-resistant products ensures long-lasting color fidelity and finish integrity. Exploring options from reputable paint manufacturers, consulting color-matching services, or even custom-mixing paints can help achieve the desired shade. Ultimately, successful sourcing hinges on balancing color accuracy, application method, durability, and project-specific requirements to deliver a beautiful and convincing cherry wood finish.