The global plywood market is experiencing steady expansion, driven by rising demand in construction, furniture, and interior design sectors. According to Grand View Research, the global plywood market was valued at USD 38.9 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.1% from 2023 to 2030. A notable segment within this growth is hardwood plywood, particularly cherry plywood, which is prized for its rich color, fine grain, and workability. With increasing preference for aesthetically pleasing and durable materials in cabinetry, millwork, and high-end furniture, demand for premium 3/4-inch cherry plywood has surged. This has spurred innovation and competition among manufacturers striving to balance quality, sustainability, and consistency. Based on production capacity, product performance, industry reputation, and availability, the following seven manufacturers have emerged as leaders in supplying top-tier 3/4-inch cherry plywood to domestic and international markets.

Top 7 Cherry Plywood 3/4 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Cherry Plywood 3/4 Manufacturer, Supplier and Factory

Domain Est. 2023

Website: tlplywood.com

Key Highlights: Buy high-quality Cherry Plywood from China manufacturer. We are a leading supplier and factory offering reliable products at competitive prices….

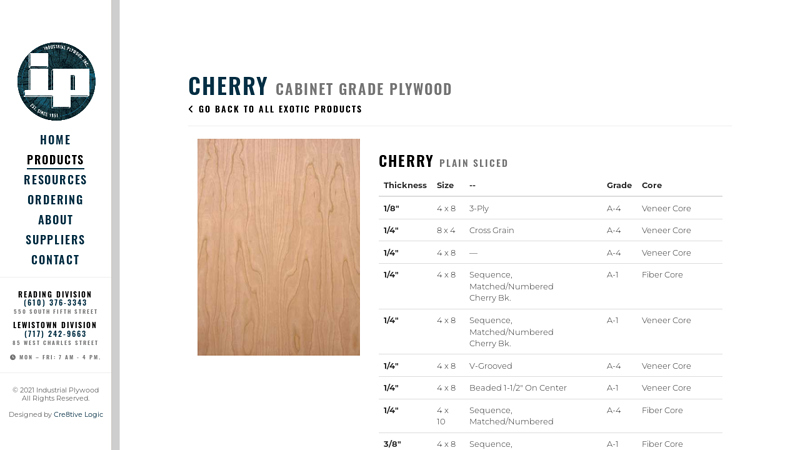

#2 Cherry

Domain Est. 2000

Website: industrialplywood.com

Key Highlights: Industrial Plywood. Home · Products · Resources · Ordering · About · Suppliers … 3/4″, 4 x 8, Sequence, Matched/Numbered Cherry Bk. A-1, Fiber Core. 3/4″, 4 x 8 ……

#3 3/4″ (18mm) Cherry Pre

Domain Est. 1997

#4 Hardwood Plywood Supplier

Domain Est. 1999

Website: plywoodcompany.com

Key Highlights: 30-day returnsFind the Perfect Cherry Hardwood Plywood only at Plywoodcompany.com · Tree Origin: Cherry plywood is made mostly from the black cherry tree (Prunus serotina), ……

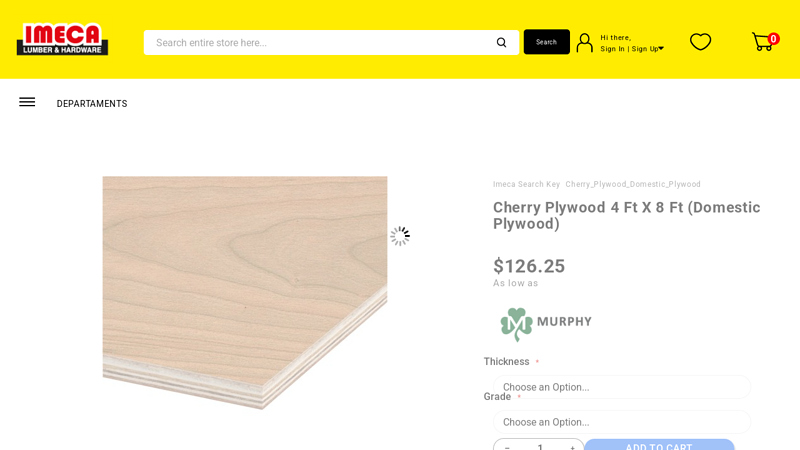

#5 Cherry Plywood 4 ft x 8 ft (Domestic Plywood)

Domain Est. 2002

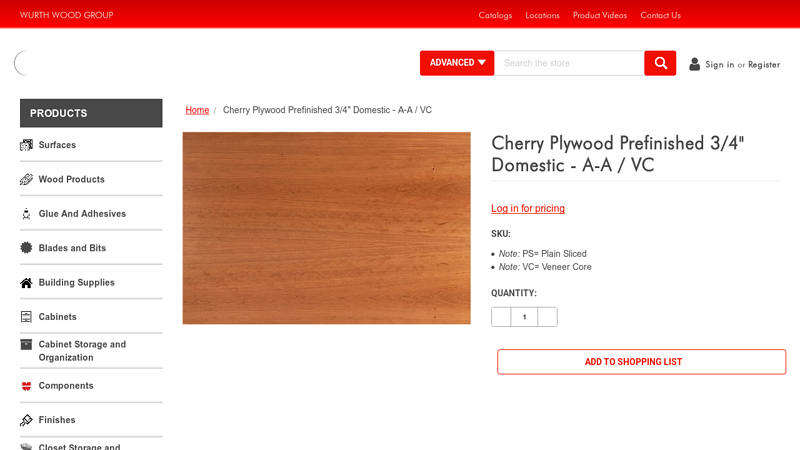

#6 Cherry Plywood Prefinished 3/4″ Domestic

Domain Est. 2006

Website: wurthwoodgroup.com

Key Highlights: Cherry Plywood Prefinished 3/4″ Domestic – A-A / VC · Note: PS= Plain Sliced · Note: VC= Veneer Core….

#7 Best Cherry Plywood 3 4 Supplier, Manufacturer

Domain Est. 2019

Website: lituo-plywood.com

Key Highlights: Looking for high-quality cherry plywood 3/4? Linyi Lituo Imp & Exp Co., Ltd. offers a wide selection of premium cherry plywood at competitive prices….

Expert Sourcing Insights for Cherry Plywood 3/4

H2: Projected Market Trends for 3/4″ Cherry Plywood in 2026

As we approach 2026, the market for 3/4″ cherry plywood—a premium hardwood panel favored in high-end cabinetry, furniture, and interior millwork—is expected to be shaped by a confluence of economic, environmental, and consumer-driven factors. While precise forecasting requires real-time data beyond current availability, analysis of current trajectories points to several key trends likely to influence supply, demand, pricing, and sourcing strategies.

1. Sustained Premium Pricing with Moderate Increases

Cherry plywood will continue to command a high price point due to its status as a luxury material. In 2026, prices are expected to rise moderately—likely in the 3–5% annual range—driven by persistent supply constraints, increasing labor and processing costs, and inflationary pressures in logistics. However, sharp spikes akin to the 2020–2022 pandemic-era volatility are unlikely barring unforeseen disruptions.

2. Supply Chain Stabilization with Ongoing Constraints

The industry is expected to see improved supply chain reliability compared to recent years, particularly in transportation and manufacturing throughput. However, fundamental constraints in raw cherry log availability will persist. Slow tree maturation (cherry trees require 50+ years for optimal harvest), competition from solid lumber markets, and limited domestic U.S. hardwood plantation expansion will keep log supplies tight. This scarcity will continue to bottleneck plywood production, especially for high-grade, veneer-matched panels.

3. Heightened Focus on Sustainability and Certification

Consumer and B2B demand for sustainable sourcing will intensify in 2026. Builders, architects, and designers will increasingly require Forest Stewardship Council (FSC) or Sustainable Forestry Initiative (SFI) certification for cherry plywood. Manufacturers investing in traceable supply chains and eco-friendly adhesives (e.g., phenol-formaldehyde-free or low-VOC options) will gain competitive advantage. Transparency in forest management practices will become a market differentiator.

4. Growth in Custom and Value-Added Offerings

To offset raw material scarcity and margin pressures, producers and distributors will likely expand value-added services. Expect increased availability of pre-sanded, pre-finished, or pre-cut cherry plywood tailored for cabinetmakers and custom installers. CNC-ready panels and digital matching for book-matched grain patterns will cater to high-end residential and boutique commercial projects, where precision and aesthetics are paramount.

5. Regional Sourcing and Localization Trends

Due to transportation costs and carbon footprint concerns, there will be a growing preference for regionally sourced cherry, particularly from the Appalachian region (Pennsylvania, West Virginia, Ohio). Mills closer to end markets may leverage “local” branding as a premium feature. Import reliance remains limited—cherry plywood is rarely imported in volume due to U.S. dominance in black cherry (Prunus serotina) production—making the market largely domestic.

6. Impact of Housing and Remodeling Markets

The performance of the 3/4″ cherry plywood market in 2026 will closely follow trends in high-end new construction and kitchen/bath remodeling. If mortgage rates stabilize and luxury homebuilding remains resilient, demand for cherry—a symbol of timeless craftsmanship—will hold firm. However, a broader economic downturn could shift consumer preferences toward more affordable alternatives like birch, maple, or engineered wood with cherry veneers.

7. Technological Integration in Production and Sales

Digital platforms will play a larger role in product selection and procurement. Augmented reality (AR) tools allowing designers to visualize cherry finishes in real spaces, along with online inventory systems offering real-time grade and availability tracking, will become standard. Mills investing in automation to optimize veneer yield from limited logs will improve efficiency and reduce waste.

Conclusion

By 2026, the 3/4″ cherry plywood market will remain a niche but vital segment of the hardwood panel industry, characterized by premium value, supply limitations, and evolving consumer expectations. Success will depend on sustainable sourcing, product differentiation, and responsiveness to high-end design trends. While not a mass-market commodity, cherry plywood will retain its appeal among discerning builders and homeowners seeking enduring beauty and quality—making it a resilient, albeit specialized, component of the building materials landscape.

Common Pitfalls Sourcing Cherry Plywood 3/4 (Quality, IP)

Sourcing high-quality 3/4-inch cherry plywood with an acceptable amount of pinholes (IP) can be challenging. Avoid these common pitfalls to ensure you get a product that meets your project’s aesthetic and structural requirements.

Misunderstanding “Quality” Grades

Different suppliers use varying grading standards (e.g., BB/BB, C/D, A1, A2). Assuming all “A-grade” cherry plywood is equal can lead to disappointment. Some grades may allow visible repairs, patches, or color variations. Always request grade-specific samples and clarify grading criteria with your supplier.

Overlooking Pinhole Tolerance

Pinholes (IP) are small insect or resin bore marks common in cherry. Failing to specify acceptable pinhole density and size upfront often results in material that requires excessive filling or sanding. Define your pinhole tolerance clearly—some premium suppliers offer “pin knot free” or “select” grades with minimal IP.

Ignoring Core Construction

The core (e.g., veneer, MDF, or particleboard) significantly impacts stability and workability. A poorly constructed core can lead to warping or uneven surfaces. Ensure the core is void-free and appropriate for your application—especially for cabinetry or furniture where flatness is critical.

Skipping Sample Review

Never order without a physical sample. Online photos or descriptions can misrepresent color, grain pattern, and pinhole distribution. Review full sheets if possible to assess consistency across the batch.

Choosing Unreliable Suppliers

Not all suppliers specialize in hardwood plywood. Generic lumberyards may carry cherry plywood with inconsistent quality or limited grading options. Work with reputable hardwood dealers or suppliers known for architectural-grade materials to ensure better consistency and accountability.

Underestimating Lead Times and Availability

High-quality, low-pin cherry plywood may not be stocked locally and could require longer lead times. Last-minute sourcing often forces compromises on quality. Plan ahead and confirm availability before committing to a design.

Neglecting Sanding and Finish Considerations

Even high-grade cherry plywood may require light sanding, and pinholes may still need filling. Assuming the material will be ready-to-finish out of the box can delay your project. Budget time and materials for proper surface prep.

By addressing these pitfalls early, you can source 3/4-inch cherry plywood that meets both your aesthetic expectations and performance needs.

Logistics & Compliance Guide for Cherry Plywood 3/4″

Product Overview

Cherry Plywood 3/4″ is a high-quality hardwood plywood commonly used in cabinetry, furniture, millwork, and interior design applications. It features a smooth, warm-toned cherry veneer face with cross-banded plies for enhanced stability. The 3/4″ (19mm) thickness provides structural integrity and is compatible with standard joinery and finishing techniques.

Packaging & Handling

- Packing Method: Sheets are typically bundled with protective corner boards, shrink-wrapped, and placed on sturdy wood or composite pallets.

- Stacking: Do not exceed recommended stacking height (usually 6–8 feet) to prevent warping or damage.

- Handling: Use mechanical equipment (e.g., forklifts or pallet jacks) to move full pallets. Avoid dragging or dropping sheets.

- Edge Protection: Maintain corner guards during transit to prevent chipping.

Transportation Requirements

- Mode of Transport: Suitable for truck, rail, or containerized ocean freight.

- Container Loading: Maximize space using standard 4′ x 8′ sheets. Secure loads with straps and dunnage to prevent shifting.

- Moisture Protection: Use moisture barriers or vapor retarders when shipping in humid climates or marine environments.

- Temperature Control: Avoid prolonged exposure to extreme heat or cold to prevent veneer delamination or core damage.

Storage Conditions

- Environment: Store indoors in a dry, well-ventilated area with controlled humidity (35–55% RH) and temperature (60–80°F).

- Elevation: Keep pallets off the floor using skids or pallets to prevent moisture absorption.

- Covering: Protect from dust and direct sunlight; do not wrap tightly in plastic to avoid condensation buildup.

Regulatory & Compliance Standards

- Formaldehyde Emissions: Complies with CARB Phase 2 (California Air Resources Board) and EPA TSCA Title VI for composite wood products.

- Sourcing & Sustainability: Ensure FSC® (Forest Stewardship Council) or PEFC™ certification if required. Verify chain-of-custody documentation.

- Import/Export:

- HTS Code: 4412.31.0510 (Plywood of non-coniferous wood, face veneer of tropical wood or certain non-tropical species).

- Lacey Act Compliance: Provide proof of legal harvest and chain of custody for U.S. imports.

- ISPM 15: Wooden packaging (pallets) must be heat-treated and stamped for international shipments.

Quality Inspection & Acceptance

- Visual Inspection: Check for voids, delamination, core gaps, and surface defects per ANSI/HPVA HP-1 standards.

- Dimensional Accuracy: Verify thickness (0.720″–0.750″), flatness, and squareness.

- Documentation: Confirm mill certificate, grade stamp, compliance labels, and test reports are included.

Hazard & Safety Information

- Dust Hazard: Sanding generates fine wood dust—use PPE (respirator, goggles) and dust collection per OSHA 1910.1000.

- Handling Safety: Wear gloves to avoid splinters; use proper lifting techniques to prevent injury.

- Flammability: Store away from open flames and high-heat sources; typical combustibility of wood products applies.

Disposal & Recycling

- Waste Management: Follow local regulations for disposal. Can often be recycled as biomass or repurposed.

- Hazardous Waste: Not classified as hazardous under EPA RCRA when uncontaminated.

Key Certifications to Request

- CARB Phase 2 or TSCA Title VI Compliance Certificate

- FSC®/PEFC™ Chain-of-Custody (if applicable)

- Mill Test Report (MTR) or Quality Certificate

- ISPM 15 Mark on Pallets (for export)

Adhering to this guide ensures safe, compliant, and efficient handling of Cherry Plywood 3/4″ across the supply chain.

In conclusion, sourcing 3/4-inch cherry plywood requires careful consideration of quality, grade, supplier reliability, and intended application. High-quality cherry plywood, known for its rich color, fine grain, and workability, is ideal for cabinetry, furniture, and fine woodworking projects. To ensure the best results, prioritize suppliers that offer FSC-certified or sustainably sourced materials, specify soft maple or birch cross-bands for stability, and provide consistent veneer matching options. Comparing prices from local lumberyards, specialty woodworking suppliers, and online vendors can help balance cost and convenience. Ultimately, selecting the right cherry plywood involves balancing aesthetic preferences, structural requirements, and budget—ensuring a durable, attractive finish for your project.