The industrial hose clamp market, particularly chem clamps used in chemical processing, pharmaceutical, and high-purity fluid transfer applications, has seen steady expansion due to increasing demand for leak-proof, corrosion-resistant fastening solutions. According to Grand View Research, the global hose clamp market was valued at USD 5.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% through 2030. This growth is driven by rising industrial automation, stricter safety regulations, and expanding applications in sectors requiring high-performance sealing—such as semiconductor manufacturing and biopharmaceuticals. As demand for chemically resistant and sanitary clamps increases, especially in critical fluid handling systems, sourcing reliable manufacturers has become essential for ensuring compliance and system integrity. Based on market presence, product range, material innovation, and industry certifications, the following ten manufacturers have emerged as leaders in chem clamp production worldwide.

Top 10 Chem Clamp Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Clampco Products

Domain Est. 1999

Website: clampco.com

Key Highlights: We are a family owned, USA manufacturer of high-quality stainless-steel clamps including V-Band Couplings, T-Bolt Band Clamps, Strap Assemblies and more….

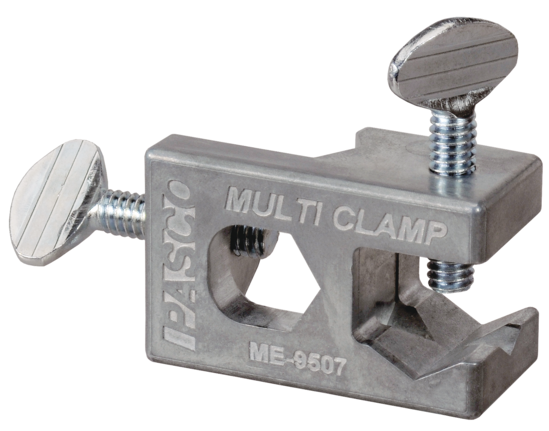

#2 PASCO scientific

Domain Est. 1994

Website: pasco.com

Key Highlights: We also carry just about all laboratory supplies, from rods, clamps, and Ohaus balances to mass and hanger sets and laboratory glassware. See our full offering ……

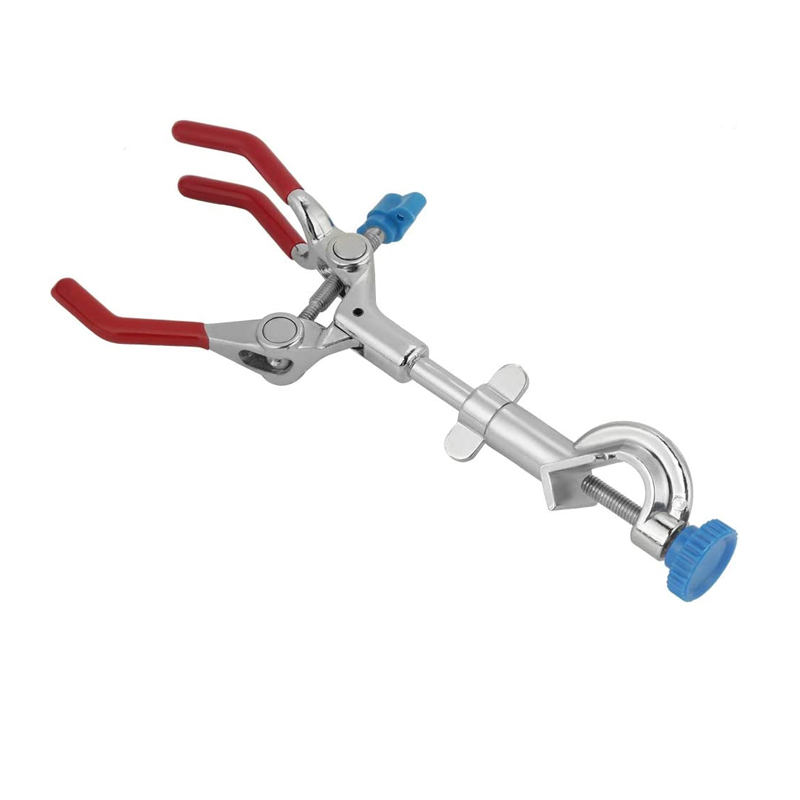

#3 Lab Clamps

Domain Est. 1995

Website: spectrumchemical.com

Key Highlights: Our wide selection of clamps include thermometer clamps, tubing pinch clamps, hose clamps, buret clamps, extension clamps, and more….

#4 Thomas Scientific

Domain Est. 1995 | Founded: 1900

Website: thomassci.com

Key Highlights: Thomas Scientific, a trusted lab supplier since 1900, provides the latest in equipment, supplies & chemicals to scientific research & educational ……

#5 LabJaws Clamps & Supports

Domain Est. 1996

Website: mec.ohaus.com

Key Highlights: Corrosion-resistant stainless steel clamps provide excellent chemical resistance, durability, and can be autoclaved. · Prevent accidents in the lab – versatile ……

#6 Clamps

Domain Est. 1998

Website: chemglass.com

Key Highlights: Clamps ; CG-9004. CHEMGLASS LAB CLAMPS, RUSTPROOF ; CG-9250. CLAMP HOLDERS ; CG-9257. CLAMP HOLDERS, ALL POSITION ; CG-9252. CLAMP HOLDERS, LARGE ; CG-9252-S-01….

#7 Test

Domain Est. 1998

Website: sigmaaldrich.com

Key Highlights: Find test-tube-clamp-chemistry and related products for scientific research at Merck….

#8 Laboratory Burette Clamp

Domain Est. 2003

Website: glasscolabs.com

Key Highlights: 2-day returnsBest Suppliers & Exporters of High Quality Laboratory Burette Clamp, Mild Steel, Black Powder Coated, Chrome Coated, Fisher Type….

#9 Laboratory Clamps: High

Domain Est. 2010

Website: hcl-clamping.com

Key Highlights: Scientific Research: Clamps secure laboratory tubing, experimental setups, & fluid control systems. They ensure leak-free connections in critical research….

#10 High Pressure Sanitary Tri Clamps

Domain Est. 2020

Website: gochemtek.com

Key Highlights: Made from heavy-duty 304 stainless steel, these clamps are designed to withstand elevated pressures while maintaining a tight seal on tri clamp fittings. Ideal ……

Expert Sourcing Insights for Chem Clamp

H2 2026 Market Trends for Chem Clamp

Based on current industry trajectories, technological advancements, and macroeconomic factors, the second half of 2026 (H2 2026) is expected to present a dynamic and evolving landscape for Chem Clamp, a leading manufacturer of sanitary clamps, fittings, and fluid handling components primarily serving the biopharma, food & beverage, and cosmetics industries. Key market trends shaping this period include:

1. Accelerated Adoption of Single-Use Systems (SUS) & Hybrid Solutions:

* Trend: The biopharma sector will continue its strong shift towards single-use technologies to enhance flexibility, reduce cross-contamination risks, and speed up facility changeovers. H2 2026 will see deeper integration of SUS not just in upstream (bioreactors) but also in downstream processing (filtration, chromatography, storage).

* Impact on Chem Clamp: Demand will surge for Chem Clamp’s single-use compatible clamp fittings (e.g., specific designs for silicone, TPE tubing) and components designed for rapid, sterile connections/disconnections. The company must emphasize validation support (extractables/leachables data) and interoperability with major SUS bag and tubing suppliers. Hybrid systems (combining reusable stainless steel piping with single-use bags/totes) will also drive demand for robust, reliable clamps at the interface points.

2. Intensified Focus on Supply Chain Resilience & Regionalization:

* Trend: Persistent global supply chain vulnerabilities and geopolitical tensions will push customers (especially in North America and Europe) to prioritize nearshoring and supplier diversification. Regulations like the US FDA’s emphasis on domestic API manufacturing will amplify this.

* Impact on Chem Clamp: Chem Clamp’s North American manufacturing base becomes a significant competitive advantage. Highlighting local production, shorter lead times, reduced logistics risks, and compliance with “Buy American” or similar initiatives will be crucial for winning major contracts. Expect increased scrutiny on supplier financial stability and contingency planning.

3. Heightened Demand for Digitalization & Smart Components:

* Trend: Industry 4.0 principles are penetrating process industries. Customers seek components that enable traceability, predictive maintenance, and process optimization.

* Impact on Chem Clamp: While traditional clamps are passive, there will be growing interest in “smart” solutions. This includes:

* Digital Product Passports (DPP): Embedding QR codes or RFID tags on clamps for full lifecycle traceability (material certs, manufacturing data, sterilization history, maintenance records).

* Sensors Integration: Potential for clamps with integrated strain, temperature, or pressure sensors (or designed to easily accommodate them) for real-time monitoring of connection integrity and process conditions.

* Digital Twins: Providing accurate 3D CAD models and material data seamlessly integrable into customers’ digital plant design and simulation software.

4. Sustainability as a Core Procurement Driver:

* Trend: ESG (Environmental, Social, Governance) criteria are becoming non-negotiable in procurement. Customers demand reduced environmental impact throughout a product’s lifecycle.

* Impact on Chem Clamp:

* Material Sourcing: Focus on recycled stainless steel (with full chain-of-custody) and sustainable packaging.

* Product Longevity & Reusability: Emphasizing the durability and long service life of reusable stainless steel clamps compared to single-use plastics (addressing the plastic waste concern of SUS).

* Energy Efficiency: Highlighting manufacturing processes with lower energy consumption.

* End-of-Life: Exploring take-back or recycling programs for worn-out fittings.

5. Tightening Regulatory Scrutiny & Standardization:

* Trend: Regulatory bodies (FDA, EMA, etc.) continue to demand higher levels of data integrity, process validation, and component qualification. Global harmonization efforts (e.g., around SUS) may progress.

* Impact on Chem Clamp: Comprehensive documentation (UDI, full material traceability, rigorous testing data – particulate, extractables, functional) becomes table stakes. Proactive engagement with standards bodies (ASME BPE, 3-A) and certification to relevant standards (e.g., 3-A, EHEDG) will be essential for market access. Expect increased demand for qualified supplier programs and audit support.

6. Expansion into Adjacent & Emerging Applications:

* Trend: Growth in cell & gene therapy (CGT), mRNA manufacturing, and precision fermentation creates demand for ultra-high-purity, small-scale, and highly flexible fluid handling solutions. The cosmetics and personal care industry is also adopting more biopharma-like standards.

* Impact on Chem Clamp: Opportunities exist in developing miniature or specialized clamp fittings for small-batch CGT processes and materials suitable for sensitive cosmetic formulations. Cross-pollination of biopharma-grade solutions into demanding F&B applications will continue.

Conclusion for H2 2026:

Chem Clamp enters H2 2026 positioned at the intersection of powerful, converging trends. Success will depend on its ability to: Leverage its manufacturing resilience to meet demand for localized supply, innovate rapidly in single-use compatibility and digitalization, embed sustainability into its core offering, and provide unparalleled regulatory support. Companies that proactively address these H2 2026 trends will not only defend their market share but capture significant growth in the expanding, high-purity fluid handling sector.

Common Pitfalls When Sourcing Chem Clamps (Quality, IP)

Sourcing Chem Clamps—critical components in biopharmaceutical and process piping systems—requires careful attention to quality and intellectual property (IP) concerns. Overlooking these aspects can lead to performance failures, regulatory non-compliance, or legal risks. Below are the most common pitfalls:

Quality-Related Pitfalls

1. Compromised Material Specifications

Many suppliers offer Chem Clamps made from substandard stainless steel (e.g., non-316L or non-ASTM compliant grades). Using inferior materials can result in corrosion, contamination, and shortened product lifespan, especially in aggressive chemical or sterile environments.

2. Inconsistent Dimensional Accuracy

Poorly manufactured clamps often exhibit out-of-tolerance dimensions, leading to leaks, improper sealing, or difficulty in assembly. This is especially critical in sanitary applications where consistent surface finishes and precise diametrical fit are required.

3. Substandard Surface Finishes

Chem Clamps must meet specific surface roughness requirements (e.g., Ra ≤ 0.8 µm) to prevent microbial adhesion and ensure cleanability. Suppliers may cut corners on electropolishing or passivation, increasing the risk of contamination in pharmaceutical systems.

4. Lack of Traceability and Certifications

Reputable manufacturers provide full material traceability (e.g., Mill Test Reports) and compliance with standards like ASME BPE, 3A, or FDA. Sourcing from suppliers without proper documentation undermines regulatory compliance and audit readiness.

5. Inadequate Quality Control Processes

Some vendors lack robust inspection protocols (e.g., pressure testing, dimensional checks, or visual inspection). This increases the likelihood of receiving defective or non-conforming parts, especially in high-purity applications.

Intellectual Property (IP)-Related Pitfalls

1. Counterfeit or Reverse-Engineered Products

Some suppliers offer clones of branded Chem Clamps (e.g., SMS, DIN, ISO standards with proprietary designs) that infringe on patented features. Using such components exposes end-users to legal liability and potential product recalls.

2. Unclear or Misrepresented Compliance

Suppliers may falsely claim compliance with industry standards or certifications. This misrepresentation not only breaches IP rights but can also void warranties and compromise system integrity.

3. Lack of Licensing Agreements

OEMs often license specific clamp designs. Sourcing from unauthorized manufacturers who lack proper licensing may result in IP infringement, leading to legal action or supply chain disruption.

4. Use of Proprietary Design Elements Without Permission

Even if a clamp meets dimensional standards, it may incorporate protected design features (e.g., unique groove profiles, locking mechanisms). Unauthorized replication can lead to patent or design rights violations.

Mitigation Strategies

- Verify Supplier Credentials: Choose vendors with proven track records, certifications (ISO 9001, ASME), and full traceability.

- Request Documentation: Insist on material test reports, compliance certificates, and design licenses where applicable.

- Conduct Supplier Audits: Perform on-site or third-party audits to assess quality systems and manufacturing practices.

- Engage Legal Review: For high-risk applications, consult IP counsel to ensure components do not infringe on patented designs.

- Stick to Authorized Distributors: Source directly from OEMs or their authorized partners to avoid counterfeit or IP-violating products.

By addressing these quality and IP pitfalls proactively, organizations can ensure reliable performance, regulatory compliance, and protection from legal exposure when sourcing Chem Clamps.

Logistics & Compliance Guide for Chem Clamp

Product Overview

Chem Clamp is a specialized chemical-resistant clamping device designed for secure fastening in industrial, laboratory, and hazardous environments. It is commonly used with tubing, hoses, and piping systems handling aggressive chemicals, high temperatures, or high-pressure applications. Ensuring proper logistics handling and regulatory compliance is essential for safe distribution and use.

Regulatory Classification

Chem Clamp may be subject to various international and regional regulations depending on its materials and intended use. It is typically classified under industrial hardware or laboratory equipment. No hazardous material classification applies to the clamp itself when unused; however, compliance is required for packaging, transport, and workplace safety standards such as OSHA, REACH, and RoHS.

Packaging Requirements

Use durable, moisture-resistant packaging to protect Chem Clamp units during transit. Each clamp should be sealed in polyethylene bags if sensitive to contamination. Bulk shipments must be palletized with edge protectors and stretch-wrapped. Include desiccant packs in humid environments to prevent corrosion, especially for metal variants.

Shipping & Transportation

Ship via ground or air freight depending on destination urgency. Ensure packages are labeled with correct UN number (if applicable), proper shipping name, and handling instructions. For international shipments, comply with IATA (air) or IMDG (sea) guidelines if transported with chemical systems. Maintain a minimum ambient temperature of 0–40°C during transit to preserve material integrity.

Storage Conditions

Store Chem Clamp in a dry, well-ventilated area away from direct sunlight and extreme temperatures. Ideal storage conditions are between 10–30°C with relative humidity under 60%. Keep away from strong oxidizers, acids, and solvents unless chemically compatible. Use original packaging until deployment to prevent dust accumulation or mechanical damage.

Import/Export Documentation

Prepare commercial invoice, packing list, and certificate of origin for cross-border shipments. If exported from the EU, ensure REACH compliance documentation is available. For shipments to the U.S., provide a compliance statement confirming adherence to RoHS and OSHA standards. Obtain export licenses only if required by destination country for industrial safety equipment.

Handling & Worker Safety

Operators must wear cut-resistant gloves and safety glasses when installing or removing Chem Clamp devices. Follow manufacturer torque specifications to avoid over-tightening. Conduct periodic inspections for wear, corrosion, or deformation—especially after exposure to chemicals. Dispose of damaged clamps according to local industrial waste regulations.

Environmental & Disposal Compliance

At end-of-life, Chem Clamp components should be segregated by material (e.g., stainless steel, plastic) and recycled where possible. Do not incinerate polymer parts without proper emission controls. Follow local regulations such as WEEE or EPA guidelines for disposal. No special hazardous waste designation is required for uncontaminated units.

Certification & Traceability

All Chem Clamp units must bear a batch/lot number and date of manufacture for traceability. Maintain records of material certifications (e.g., ASTM, ISO 9001) for a minimum of five years. Provide customers with a Declaration of Conformity upon request, confirming compliance with applicable EU and U.S. safety directives.

Emergency Response

In case of spillage or chemical exposure during use, refer to the Safety Data Sheet (SDS) of the transported medium—not the clamp. If a clamp fails under pressure, isolate the system immediately and follow facility emergency shutdown procedures. Report structural failures to the manufacturer for quality analysis.

Conclusion for Sourcing Chem Clamps

After a thorough evaluation of suppliers, product quality, cost, and lead times, sourcing chem clamps from the selected vendor presents a reliable and cost-effective solution for our operational needs. The chosen supplier demonstrates consistent quality compliance with industry standards (e.g., ASTM, ISO), offers competitive pricing, and provides dependable delivery timelines. Additionally, their capacity for scalability and responsiveness to technical inquiries ensures long-term partnership potential.

Moving forward, establishing a vendor qualification agreement and implementing periodic quality audits will help maintain product integrity and supply chain resilience. Overall, this sourcing strategy supports our commitment to safety, performance, and efficiency in fluid handling applications.