Introduction: Navigating the Global Market for Cheese Vats

The cheese manufacturing industry faces a critical equipment decision that directly impacts product quality, production efficiency, and long-term profitability: selecting the right cheese vat. Whether you’re scaling an artisan operation, upgrading aging infrastructure, or launching a new production facility, the cheese vat represents one of your most significant capital investments.

The Challenge

Today’s dairy processors must navigate a complex marketplace spanning:

- Capacity variations ranging from 50-gallon artisan units to 3,000+ gallon industrial systems

- Price points from $3,500 for used equipment to $31,000+ for new installations

- Configuration options including open vats, pasteurizing vats, ricotta-specific designs, and combo units

- Sourcing decisions between new, used, and refurbished equipment

Making the wrong choice results in production bottlenecks, compliance issues, excessive maintenance costs, or underutilized capacity—all directly affecting your bottom line.

What This Guide Covers

| Section | Focus |

|———|——-|

| Equipment Types | Open vats, pasteurizing vats, specialty configurations |

| Capacity Planning | Matching vat size to production requirements |

| New vs. Used | Cost-benefit analysis for each scenario |

| Supplier Evaluation | Key criteria for vendor selection |

| Compliance | FDA, USDA, and EU regulatory considerations |

This guide provides procurement teams, operations managers, and dairy business owners with the technical specifications, market intelligence, and evaluation frameworks needed to make informed purchasing decisions. We’ll cut through sales rhetoric to deliver actionable insights for both US and European markets.

Illustrative Image (Source: Google Search)

Article Navigation

- Top 10 Cheese Vat Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for cheese vat

- Understanding cheese vat Types and Variations

- Key Industrial Applications of cheese vat

- 3 Common User Pain Points for ‘cheese vat’ & Their Solutions

- Strategic Material Selection Guide for cheese vat

- In-depth Look: Manufacturing Processes and Quality Assurance for cheese vat

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘cheese vat’

- Comprehensive Cost and Pricing Analysis for cheese vat Sourcing

- Alternatives Analysis: Comparing cheese vat With Other Solutions

- Essential Technical Properties and Trade Terminology for cheese vat

- Navigating Market Dynamics and Sourcing Trends in the cheese vat Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cheese vat

- Strategic Sourcing Conclusion and Outlook for cheese vat

- Important Disclaimer & Terms of Use

Top 10 Cheese Vat Manufacturers & Suppliers List

1. Cheese Vats Manufacturers and Suppliers in the USA and Canada

Domain: thomasnet.com

Registered: 1996 (29 years)

Introduction: D.R. Tech, Inc. · D.R. Tech, Inc. · Anco Equipment, LLC · Anco Equipment, LLC · Chem-Tainer Industries · Chem-Tainer Industries · Kusel Equipment · Kusel Equipment….

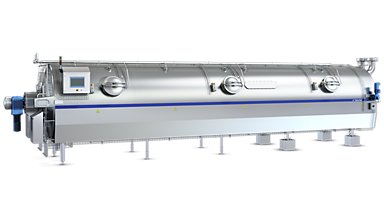

2. Tetra Pak® Cheese Vat Yieldmaster 2

Domain: tetrapak.com

Registered: 1993 (32 years)

Introduction: Gives you the highest yield of any vat on the market · At 38,555 kg (or 85,000 lb) this is the largest cheese vat available · Durable, based on decades of ……

3. Vats Categories – Kusel Equipment

Domain: kuselequipment.com

Registered: 2000 (25 years)

Introduction: Kusel’s legacy “Cook Rite” Enclosed Cheese Vats are a hallmark of reliable, large-scale cheese production, designed to provide consistency and quality with ……

4. Industrial Cheese Vats – RELCO

Domain: relco.net

Registered: 2003 (22 years)

Introduction: RELCO’s industrial cheese vats are designed for maximum yields, ease of use, and uniform curd size for the best quality cheese product….

Illustrative Image (Source: Google Search)

5. Top Cheese Vats for Dairy Production | Milkaya

Domain: milkaya.com

Registered: 2020 (5 years)

Introduction: Enhance your dairy processing efficiency with Milkaya’s high-quality cheese vats. Experience reliable performance with our durable equipment….

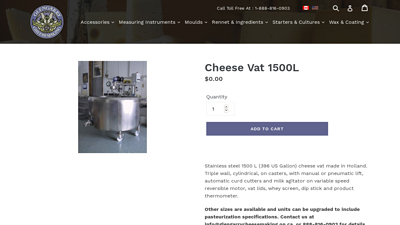

6. Cheese Vat 1500L – Glengarry Cheesemaking

Domain: glengarrycheesemaking.on.ca

Registered: 2000 (25 years)

Introduction: In stockStainless steel 1500 L (396 US Gallon) cheese vat made in Holland. Triple wall, cylindrical, on casters, with manual or pneumatic lift, automatic curd cutters ……

7. Cheese Vat Enclosed | New & Used Dairy Equipment

Domain: schiercompany.com

Registered: 1997 (28 years)

Introduction: 18,000 liter enclosed cheese vat, all stainless steel, horizontal, cylindrical processor, center mounted side sweep agitator; motor and gear box (5.5 HP, ……

8. Cheese Vats – Kalt Maschinenbau AG

Domain: kalt-ag.ch

Registered: N/A

Introduction: Individualized and tailor-made for traditional cheese dairies as well as for large industrial companies ; Large industrial company in Austria · Four times 31’500 ……

Illustrative Image (Source: Google Search)

Understanding cheese vat Types and Variations

Understanding Cheese Vat Types and Variations

Selecting the appropriate cheese vat directly impacts production efficiency, product quality, and operational costs. This section examines the primary cheese vat categories available to commercial dairy operations, helping you identify which configuration aligns with your production requirements.

Cheese Vat Classification Overview

| Type | Key Features | Primary Applications | Pros | Cons |

|---|---|---|---|---|

| Open Cheese Vat | Square design, large capacity (2,500+ lbs), no enclosed lid | High-volume production, raw milk cheese, separate pasteurization operations | Maximum accessibility, easy curd handling, scalable | Requires separate pasteurization, potential contamination exposure |

| Round Pasteurizing Cheese Vat | Circular design, removable lids, integrated swing agitator, 50-250 gallon capacity | Artisan production, small-batch cheese, R&D/product testing | All-in-one pasteurization and processing, full vat access, compact footprint | Limited capacity, not suited for large-scale operations |

| Combo Vat | Dual-function design, integrated heating/cooling, mid-range capacity (200-400 gallons) | Multi-purpose facilities, operations requiring flexibility | Versatile functionality, space-efficient, reduced equipment needs | Higher upfront cost, potential maintenance complexity |

| Ricotta Cheese Vat | High-capacity design (1,800+ gallons), specialized heating systems | Whey-based cheese production, ricotta manufacturing | Optimized for high-temperature processing, large batch capability | Single-purpose application, significant capital investment |

| Standard Production Vat | Variable capacity (50-3,000 gallons), jacketed construction, basic agitation | General cheese production across volume ranges | Wide capacity options, proven technology, available new/used | May require customization for specialty products |

Detailed Type Analysis

Open Cheese Vats

Open cheese vats represent the workhorse of high-volume cheese manufacturing. Their square configuration maximizes surface area for curd handling and facilitates efficient draining operations.

Specifications:

– Capacity: Typically 2,500 lbs product output and above

– Construction: Stainless steel with jacketed walls for temperature control

– Design: Open-top for unrestricted operator access

Optimal Use Cases:

– Facilities with dedicated pasteurization equipment

– Raw milk cheese production where separate heat treatment occurs

– Operations prioritizing batch flexibility and manual curd manipulation

Illustrative Image (Source: Google Search)

Investment Consideration: Commercial open vats offer competitive pricing with extensive design customization options.

Round Pasteurizing Cheese Vats

Designed specifically for artisan producers and small-scale operations, round pasteurizing vats integrate multiple processing steps into a single vessel.

Specifications:

– Capacity: 50-250 gallons

– Features: Removable lids, swing-arm agitator system

– Functionality: Combined pasteurization and cheese-making capability

Optimal Use Cases:

– Farmstead and artisan creameries

– New product development and testing

– Operations with space constraints

– Producers requiring HTST or batch pasteurization in-vat

Illustrative Image (Source: Google Search)

Operational Advantage: The swing agitator design provides complete vat access during all cheese-making phases without obstruction.

Combo Vats

Combo vats deliver multi-functional capability for operations requiring equipment versatility without duplicating assets.

Specifications:

– Capacity: 200-400 gallon range (typical)

– Features: Integrated heating, cooling, and agitation systems

– Market Pricing: $17,000-$29,500 (used to new)

Optimal Use Cases:

– Diversified dairy operations producing multiple product types

– Facilities transitioning between cheese varieties

– Mid-scale producers balancing capacity with flexibility

Illustrative Image (Source: Google Search)

Selection Note: Evaluate whether dual-functionality aligns with production schedules—dedicated equipment may prove more efficient for single-product operations.

Ricotta Cheese Vats

Purpose-built for whey-based cheese production, ricotta vats accommodate the specific thermal requirements and volumes associated with this product category.

Specifications:

– Capacity: 1,800 gallons (standard commercial sizing)

– Features: Enhanced heating systems for high-temperature processing

– Market Pricing: Approximately $29,000

Optimal Use Cases:

– Dedicated ricotta production lines

– Facilities utilizing whey streams from primary cheese operations

– High-volume Italian-style cheese manufacturers

Illustrative Image (Source: Google Search)

Efficiency Factor: Integrating ricotta production captures value from whey byproducts, improving overall facility economics.

Standard Production Vats

Standard vats span the broadest capacity range, serving operations from small artisan producers to industrial-scale manufacturers.

Specifications:

– Capacity Range: 50-3,000+ gallons

– Construction: Single or double-jacketed stainless steel

– Market Pricing: $3,500-$31,000 (capacity and condition dependent)

Capacity-Price Reference:

| Capacity | Condition | Approximate Price Range |

|———-|———–|————————|

| 50 gallon | Used | $4,500 |

| 150 gallon | Used | $11,500 |

| 300 gallon | New | $31,000 |

| 500 gallon | Used | $11,500 |

| 800 gallon | Used | $23,500 |

| 1,400 gallon | Used | $4,000-$4,500 |

| 3,000 gallon | Used | $15,000-$18,500 |

Illustrative Image (Source: Google Search)

Procurement Strategy: Used equipment offers significant cost reduction—pricing does not scale linearly with capacity, creating value opportunities at higher volumes.

Selection Criteria Summary

When evaluating cheese vat types, prioritize these factors:

- Production Volume: Match vat capacity to current and projected throughput

- Product Type: Specialty cheeses may require specific vat configurations

- Facility Integration: Consider existing pasteurization and downstream equipment

- Operational Flexibility: Weigh single-purpose efficiency against multi-product capability

- Capital Strategy: Balance new equipment warranties against used equipment value

Key Industrial Applications of cheese vat

Key Industrial Applications of Cheese Vats

Cheese vats serve as the foundational equipment across multiple sectors of the dairy industry, enabling precise control over the cheesemaking process from milk coagulation through curd formation. Below is a comprehensive breakdown of primary industrial applications and their specific operational benefits.

Industry Application Matrix

| Industry Sector | Vat Type | Typical Capacity | Primary Use Case |

|---|---|---|---|

| Artisan/Craft Creameries | Round Pasteurizing Vats | 50-250 gallons | Small-batch specialty cheeses, recipe development |

| Mid-Scale Dairy Processors | Open Cheese Vats | 300-800 gallons | Regional cheese production, private label manufacturing |

| Large Commercial Dairies | Commercial Open Vats | 1,400-3,000+ gallons | High-volume commodity cheese production |

| Specialty Cheese Producers | Ricotta Vats | 1,800 gallons | Whey-based and fresh cheese varieties |

| R&D/Quality Control Labs | Combo Vats | 200-400 gallons | Product testing, formulation trials |

Detailed Application Benefits

Artisan and Craft Cheese Production

– Round pasteurizing vats with swing agitators provide full access during the cheesemaking process

– Removable lids facilitate hands-on curd handling required for traditional techniques

– Smaller batch sizes (50-250 gallons) enable product differentiation and premium positioning

Illustrative Image (Source: Google Search)

Commercial Cheese Manufacturing

– Square open vat designs optimize production for batches yielding 2,500+ lbs of cheese product

– Configurations support both raw milk cheese production and operations where milk is pasteurized separately

– Scalable capacity options from 300 to 3,000+ gallons accommodate growth without process redesign

Specialty and Fresh Cheese Operations

– Dedicated ricotta vats handle the specific temperature and agitation requirements for whey-based cheeses

– Combo vats provide flexibility for facilities producing multiple cheese varieties

– Curd milling equipment integration supports cheddar production workflows including milling, salting, and hooping

Product Development and Testing

– Smaller capacity vats (50-200 gallons) reduce raw material costs during trial runs

– Identical process control to production-scale equipment ensures reliable scale-up

– Enables quality control sampling without disrupting main production lines

3 Common User Pain Points for ‘cheese vat’ & Their Solutions

3 Common User Pain Points for Cheese Vats & Their Solutions

Pain Point 1: Scaling Production Without Proportional Capital Investment

Scenario: A mid-sized artisan dairy is experiencing growing demand but faces budget constraints when considering equipment upgrades from their current 150-gallon vat to larger capacity units.

Illustrative Image (Source: Google Search)

Problem: New commercial cheese vats represent significant capital expenditure—ranging from $11,500 for 150-gallon units to $31,000+ for 300-gallon models. Scaling production often requires either multiple smaller vats or larger single units, both requiring substantial upfront investment.

Solution:

– Consider certified used cheese vats, which offer 40-60% cost savings (e.g., used 3,000-gallon vats available from $15,000-$18,500)

– Evaluate combo vats that serve dual purposes (pasteurizing and cheese-making)

– Partner with equipment suppliers offering financing or lease-to-own options

Pain Point 2: Matching Vat Design to Specific Cheese Production Requirements

Scenario: A specialty cheese producer needs equipment suitable for both raw milk cheese production and small-batch artisan varieties but is uncertain which vat configuration meets regulatory and operational requirements.

Problem: Different cheese types require specific vat designs—open square vats for large-scale production (2,500+ lbs), round pasteurizing vats for artisan batches, and specialized units like ricotta vats for specific products. Incorrect selection leads to inefficiency, compliance issues, or product quality problems.

Illustrative Image (Source: Google Search)

Solution:

| Production Type | Recommended Vat Style | Capacity Range |

|---|---|---|

| Raw milk cheese / Large batch | Open square vat | 500-3,000 gallons |

| Artisan / Small batch / R&D | Round pasteurizing vat | 50-250 gallons |

| Specialty (ricotta) | Dedicated ricotta vat | 1,800 gallons |

Pain Point 3: Ensuring Consistent Cleaning and Sanitation Compliance

Scenario: A dairy facility preparing for regulatory inspection needs to demonstrate proper sanitation protocols but struggles with vat designs that have difficult-to-reach areas.

Problem: Cheese vats with complex geometries, fixed agitators, or inaccessible corners create sanitation challenges, risking contamination and regulatory non-compliance across FDA (USA) and EU food safety standards.

Solution:

– Select vats with swing-away agitators providing full interior access during cleaning

– Prioritize all-stainless steel construction for easier sanitization

– Invest in removable lids and CIP (Clean-in-Place) compatible designs

– Add accessories like vat strainers to simplify curd handling and reduce contamination risks

Illustrative Image (Source: Google Search)

Strategic Material Selection Guide for cheese vat

Strategic Material Selection Guide for Cheese Vats

Selecting the appropriate materials for cheese vat construction directly impacts product quality, operational efficiency, regulatory compliance, and total cost of ownership. This guide provides a systematic framework for evaluating material options based on your specific production requirements.

Primary Construction Materials

Stainless Steel: The Industry Standard

Stainless steel dominates commercial cheese vat manufacturing for compelling reasons. The material’s inherent properties align precisely with dairy processing demands:

Grade 304 Stainless Steel

– Contains 18% chromium and 8% nickel

– Suitable for most standard cheese production environments

– Provides adequate corrosion resistance for milk and mild cleaning agents

– Lower initial cost compared to higher-grade alternatives

– Appropriate for operations with moderate cleaning chemical exposure

Grade 316/316L Stainless Steel

– Contains molybdenum for enhanced corrosion resistance

– Withstands aggressive sanitizers and high-chloride environments

– Required for coastal facilities or operations using chlorinated cleaners

– Essential for ricotta and other acid-heavy cheese production

– Higher upfront investment with extended service life

Illustrative Image (Source: Google Search)

Both Ullmer’s Dairy Equipment and Anco Equipment manufacture their commercial cheese vats using all stainless steel construction, reflecting industry-wide recognition of this material’s superiority for food-contact applications.

Surface Finish Considerations

The interior surface finish of your cheese vat affects both sanitation and cheese quality:

- 2B Mill Finish: Standard finish, acceptable for non-contact surfaces

- #4 Brushed Finish: Common for food-contact applications, adequate cleanability

- Electropolished Finish: Superior surface smoothness, optimal for CIP systems and stringent hygiene requirements

- Mirror Polish (#8): Maximum cleanability, highest cost, specified for premium installations

Surface roughness measured in Ra (roughness average) should not exceed 0.8 micrometers for food-contact surfaces per FDA and EU standards.

Jacketing and Insulation Materials

The thermal management system surrounding your cheese vat determines heating efficiency and temperature control precision.

Illustrative Image (Source: Google Search)

Jacket Construction

– Stainless steel outer jackets provide durability and corrosion resistance

– Dimple jacket designs maximize heat transfer surface area

– Half-pipe coil jackets offer targeted heating zones for larger vats

Insulation Options

– Polyurethane foam: High R-value, moisture-resistant, industry standard

– Mineral wool: Fire-resistant, suitable for high-temperature applications

– Closed-cell foam: Prevents moisture infiltration, maintains thermal efficiency

Proper insulation reduces energy consumption by 15-25% compared to uninsulated or poorly insulated alternatives.

Gasket and Seal Materials

Component seals represent critical failure points in cheese vat integrity:

Illustrative Image (Source: Google Search)

- EPDM (Ethylene Propylene Diene Monomer): Excellent resistance to hot water and steam, FDA-compliant grades available

- Silicone: Superior temperature range (-60°C to +230°C), ideal for pasteurizing vats

- PTFE (Teflon): Chemical-resistant, low friction, suitable for aggressive cleaning regimens

- Viton: Outstanding chemical resistance, higher cost, specified for demanding applications

Agitator and Hardware Components

Moving components within cheese vats require careful material selection to prevent contamination and ensure longevity:

Agitator Blades and Shafts

– 316L stainless steel standard for all milk-contact surfaces

– Polished welds eliminate bacterial harborage points

– Removable designs facilitate inspection and maintenance

Bearings and Seals

– Food-grade lubricants required for any bearing near product contact

– Magnetic coupling systems eliminate shaft seals entirely

– Ceramic bearing surfaces available for extended service intervals

Regulatory Compliance Requirements

Material selection must satisfy regulatory frameworks in your operating jurisdiction:

Illustrative Image (Source: Google Search)

United States (FDA)

– 21 CFR 177 governs indirect food additives

– 3-A Sanitary Standards specify acceptable materials and surface finishes

– State dairy regulations may impose additional requirements

European Union

– Regulation (EC) No 1935/2004 covers food contact materials

– EN 1672-2 specifies hygiene requirements for food machinery

– National regulations vary; verify local requirements

Documentation Requirements

– Material certificates (mill test reports) for traceability

– FDA letters of compliance for non-metallic components

– 3-A certification for complete equipment assemblies

Material Selection by Cheese Type

Different cheese varieties impose distinct material demands:

Illustrative Image (Source: Google Search)

Soft and Fresh Cheeses

– Prioritize surface smoothness for rapid cleaning

– 316L recommended due to higher moisture and acid exposure

– Electropolished surfaces reduce biofilm formation risk

Hard and Aged Cheeses

– Standard 304 stainless typically adequate

– Focus on thermal efficiency for extended cooking cycles

– Robust agitator construction for dense curd handling

Acid-Set Cheeses (Ricotta, Paneer)

– 316L stainless essential due to acid exposure

– PTFE gaskets resist degradation from citric or acetic acid

– Specialized vat designs available (e.g., Anco’s 1,800-gallon ricotta vats)

Cost-Benefit Analysis Framework

Evaluate material choices against your operational parameters:

Illustrative Image (Source: Google Search)

Initial Investment Factors

– Production volume requirements (50-gallon artisan vats to 3,000+ gallon commercial units)

– Cheese variety portfolio and associated material demands

– Regulatory environment stringency

– Available capital and financing terms

Lifecycle Cost Considerations

– Maintenance frequency and component replacement intervals

– Energy efficiency of thermal management systems

– Cleaning chemical compatibility and consumption rates

– Expected service life (properly maintained stainless vats exceed 20 years)

Risk Assessment

– Product contamination potential from material degradation

– Regulatory non-compliance consequences

– Production downtime costs from equipment failure

– Brand reputation implications

Procurement Specifications

When requesting quotes from equipment suppliers, specify the following material parameters:

Illustrative Image (Source: Google Search)

- Base metal grade with mill certification requirements

- Surface finish with Ra measurement specifications

- Weld quality standards (full penetration, ground smooth, passivated)

- Gasket and seal materials with FDA compliance documentation

- Insulation type and thickness with thermal performance guarantees

- Hardware grades for all fasteners and fittings

- Certification requirements (3-A, CE marking, etc.)

Material Comparison Table

| Material/Component | Grade 304 SS | Grade 316L SS | Electropolished 316L |

|---|---|---|---|

| Initial Cost | Baseline | +15-25% | +30-45% |

| Corrosion Resistance | Good | Excellent | Excellent |

| Acid Resistance | Moderate | High | High |

| Chloride Resistance | Low-Moderate | High | High |

| Surface Cleanability | Good | Good | Superior |

| Biofilm Resistance | Moderate | Moderate | High |

| Expected Lifespan | 15-20 years | 20-25 years | 25+ years |

| Best Application | Standard cheese production, inland facilities | Acid-set cheeses, coastal locations, aggressive CIP | Premium installations, high-hygiene requirements |

| Regulatory Compliance | FDA/3-A compliant | FDA/3-A compliant | FDA/3-A compliant, exceeds standards |

| Gasket Material | Temperature Range | Chemical Resistance | FDA Compliant | Relative Cost |

|---|---|---|---|---|

| EPDM | -40°C to +150°C | Good (not oil-resistant) | Yes | Low |

| Silicone | -60°C to +230°C | Moderate | Yes | Medium |

| PTFE | -200°C to +260°C | Excellent | Yes | High |

| Viton | -20°C to +200°C | Excellent | Yes | High |

| Insulation Type | R-Value per Inch | Moisture Resistance | Fire Rating | Application |

|---|---|---|---|---|

| Polyurethane Foam | 6.0-7.0 | Excellent | Varies | Standard vat insulation |

| Mineral Wool | 3.0-4.0 | Moderate | Excellent | High-temperature applications |

| Closed-Cell Foam | 4.0-5.0 | Excellent | Good | Humid environments |

Key Takeaways

Material selection for cheese vats requires balancing immediate budget constraints against long-term operational costs and risk factors. For most commercial operations in the USA and Europe, 316L stainless steel construction with appropriate gasket materials and quality insulation represents the optimal value proposition. Artisan producers processing under 250 gallons may find 304 stainless adequate for standard cheese varieties, while operations producing acid-set cheeses or operating in corrosive environments should specify 316L or higher-grade materials without exception.

Consult with equipment manufacturers such as Ullmer’s Dairy Equipment or Anco Equipment to discuss your specific production requirements and obtain detailed material specifications for your application.

In-depth Look: Manufacturing Processes and Quality Assurance for cheese vat

In-depth Look: Manufacturing Processes and Quality Assurance for Cheese Vats

Understanding how cheese vats are manufactured is essential for procurement decisions. The production quality directly impacts equipment longevity, sanitation compliance, and operational efficiency in your dairy facility.

Manufacturing Process Overview

Stage 1: Material Preparation

| Process Step | Details | Quality Considerations |

|---|---|---|

| Steel Selection | 304 or 316L stainless steel sheets | Mill certifications verified; 316L preferred for high-acid applications |

| Material Inspection | Thickness verification, surface defect scanning | Rejection of sheets with pitting, inclusions, or inconsistent gauge |

| Cutting | Laser or plasma cutting to specifications | Dimensional tolerance ±0.5mm for critical components |

| Surface Preparation | Degreasing, pickling, passivation | Ensures optimal weld adhesion and corrosion resistance |

Stage 2: Forming Operations

Commercial cheese vats—whether open square designs for high-volume production (2,500+ lbs capacity) or round pasteurizing vats for artisan operations (50-250 gallon)—require precision forming:

- Shell Rolling: Cylindrical or rectangular shell formation using hydraulic rollers

- Dish Forming: Bottom heads pressed or spun to specified profiles

- Jacket Fabrication: Double-wall construction for heating/cooling channels

- Port Preparation: CNC machining for inlet, outlet, and instrumentation connections

Stage 3: Assembly and Welding

Critical assembly procedures include:

- Tack Welding: Temporary positioning of components

- TIG/MIG Welding: Full penetration welds on product-contact surfaces; TIG preferred for sanitary seams

- Jacket Integration: Welding of outer jacket to inner vessel with proper expansion allowances

- Agitator Installation: Mounting of swing agitators (common in round vats) or fixed stirring systems

- Accessory Integration: Strainers, drain valves, temperature probes, and lid assemblies

Weld Quality Standards:

– No undercut, porosity, or incomplete fusion

– Interior welds ground and polished to ≤0.8 µm Ra surface finish

– Full radiographic or dye-penetrant inspection on pressure-bearing joints

Stage 4: Quality Control and Testing

| QC Checkpoint | Test Method | Acceptance Criteria |

|---|---|---|

| Dimensional Verification | CMM measurement, manual gauging | Per engineering drawings ±specified tolerances |

| Weld Integrity | Visual, dye penetrant, radiographic | Zero defects on sanitary surfaces |

| Hydrostatic Testing | Pressurized water test at 1.5x operating pressure | No leaks, deformation, or pressure drop |

| Surface Finish | Profilometer measurement | ≤0.8 µm Ra (product contact); ≤1.6 µm Ra (non-contact) |

| Jacket Leak Test | Air pressure test with soap solution | Zero bubble formation |

| Sanitary Compliance | Visual inspection of radii, crevices, dead legs | Meets 3-A Sanitary Standards |

Quality Standards and Certifications

ISO Certifications:

– ISO 9001:2015: Quality management system—ensures consistent manufacturing processes

– ISO 22000: Food safety management—critical for equipment entering food production environments

Industry-Specific Standards:

– 3-A Sanitary Standards: Mandatory for US dairy operations; governs design criteria for cleanability

– EHEDG Guidelines: European Hygienic Engineering & Design Group standards for EU compliance

– FDA 21 CFR Part 110: Current Good Manufacturing Practice requirements

– CE Marking: Required for equipment sold in European markets

Supplier Evaluation Checklist

When assessing cheese vat manufacturers, verify:

- [ ] Documented material traceability (heat numbers, mill certs)

- [ ] Certified welding procedures and welder qualifications

- [ ] In-house hydrostatic and leak testing capabilities

- [ ] Surface finish measurement and documentation

- [ ] 3-A authorization (US) or EHEDG certification (EU)

- [ ] ISO 9001 certification status

- [ ] Post-sale support and spare parts availability

Key Takeaways

- Manufacturing quality varies significantly between new equipment and refurbished/used units—request full inspection reports for pre-owned vats

- Jacket construction quality directly affects heating uniformity and energy efficiency

- Surface finish specifications are non-negotiable for sanitary compliance and CIP effectiveness

- Request factory acceptance testing (FAT) documentation before shipment

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cheese vat’

Practical Sourcing Guide: A Step-by-Step Checklist for Cheese Vats

Use this comprehensive checklist to streamline your cheese vat procurement process and avoid costly mistakes.

Phase 1: Pre-Sourcing Assessment

Define Production Requirements

- [ ] Calculate daily/weekly milk processing volume (gallons)

- [ ] Determine cheese types to produce (cheddar, ricotta, artisan varieties)

- [ ] Identify batch size requirements (50–3,000+ gallons)

- [ ] Assess whether pasteurization capability is needed in-vat or separate

Facility Evaluation

- [ ] Measure available floor space and ceiling height

- [ ] Verify utility connections (steam, water, electrical capacity)

- [ ] Confirm drainage and sanitation infrastructure

- [ ] Check doorway dimensions for equipment delivery

Phase 2: Equipment Specification

| Specification | Questions to Answer |

|---|---|

| Capacity | What gallon size matches your production scale? (50–3,000+ gal available) |

| Configuration | Open vat, enclosed, or combo vat design? |

| Shape | Round (artisan/small batch) or square (high-volume 2,500+ lbs)? |

| Features | Agitator type, lid style, heating/cooling jacket requirements? |

New vs. Used Decision Matrix

- [ ] Evaluate budget constraints (new: $29,000–$31,000 for 200–300 gal; used: $3,500–$23,500)

- [ ] Assess warranty requirements

- [ ] Consider lead times (new equipment typically longer)

- [ ] Factor in refurbishment costs for used equipment

Phase 3: Supplier Qualification

Vendor Research

- [ ] Identify specialized dairy equipment suppliers (Ullmer’s, Anco Equipment, regional distributors)

- [ ] Verify supplier credentials and industry reputation

- [ ] Request references from similar-scale operations

- [ ] Confirm after-sales support and parts availability

Compliance Verification

- [ ] Ensure equipment meets FDA 21 CFR Part 110 standards (USA)

- [ ] Verify EU Regulation 852/2004 compliance (Europe)

- [ ] Confirm 3-A Sanitary Standards certification

- [ ] Request material certifications (food-grade stainless steel)

Phase 4: Request for Quotation (RFQ)

Include in Your RFQ

- [ ] Detailed specifications and capacity requirements

- [ ] Delivery location and timeline requirements

- [ ] Installation and commissioning needs

- [ ] Training requirements for operators

- [ ] Warranty terms and service agreements

- [ ] Spare parts pricing and availability

Compare Quotes On

| Factor | Weight |

|---|---|

| Total cost (equipment + delivery + installation) | High |

| Lead time | Medium–High |

| Warranty coverage | Medium |

| Technical support availability | Medium |

| Spare parts accessibility | Medium |

Phase 5: Pre-Purchase Verification

For New Equipment

- [ ] Review engineering drawings and specifications

- [ ] Confirm customization options if needed

- [ ] Negotiate payment terms (typical: 30–50% deposit)

- [ ] Establish factory acceptance testing (FAT) protocol

For Used Equipment

- [ ] Request detailed photos and maintenance history

- [ ] Verify hours of operation and production history

- [ ] Arrange on-site inspection when possible

- [ ] Negotiate refurbishment scope if required

- [ ] Confirm all accessories included (strainers, agitators, lids)

Phase 6: Purchase and Delivery

- [ ] Finalize purchase agreement with clear terms

- [ ] Confirm delivery method and insurance coverage

- [ ] Schedule delivery to align with installation crew availability

- [ ] Prepare receiving area and unloading equipment

- [ ] Document condition upon arrival with photos

Phase 7: Post-Purchase Actions

- [ ] Complete installation per manufacturer specifications

- [ ] Conduct operational testing before production

- [ ] Train all operators on proper use and cleaning procedures

- [ ] Establish preventive maintenance schedule

- [ ] File warranty documentation and supplier contacts

Quick Reference: Price Benchmarks (USD)

| Capacity | New Price Range | Used Price Range |

|---|---|---|

| 50 gallon | $8,000–$12,000 | $4,500+ |

| 150–200 gallon | $11,500–$31,000 | $11,500+ |

| 300–500 gallon | $31,000+ | $11,500–$18,500 |

| 800–1,400 gallon | Contact supplier | $4,000–$23,500 |

| 1,800–3,000 gallon | Contact supplier | $15,000–$29,000 |

Prices reflect current market data; request updated quotes from suppliers.

Comprehensive Cost and Pricing Analysis for cheese vat Sourcing

Comprehensive Cost and Pricing Analysis for Cheese Vat Sourcing

Understanding the full cost structure of cheese vat procurement enables informed purchasing decisions and effective budget allocation. This analysis breaks down pricing factors, provides market benchmarks, and identifies cost optimization strategies for B2B buyers in the USA and Europe.

Current Market Pricing Overview

Based on current market data, cheese vat pricing varies significantly by capacity, condition, and configuration:

| Capacity Range | New Equipment | Used/Refurbished | Price Per Gallon (New) |

|---|---|---|---|

| 50 gallons | $8,000–$12,000 | $4,500–$6,000 | $160–$240 |

| 150 gallons | $18,000–$25,000 | $11,500–$15,000 | $120–$167 |

| 200 gallons | $25,000–$32,000 | $14,000–$20,000 | $125–$160 |

| 300 gallons | $31,000–$40,000 | $18,000–$25,000 | $103–$133 |

| 500 gallons | $38,000–$50,000 | $11,500–$25,000 | $76–$100 |

| 800 gallons | $55,000–$75,000 | $23,500–$35,000 | $69–$94 |

| 1,400 gallons | $80,000–$110,000 | $4,000–$18,000* | $57–$79 |

| 1,800 gallons | $95,000–$130,000 | $29,000–$45,000 | $53–$72 |

| 3,000 gallons | $140,000–$200,000 | $15,000–$35,000* | $47–$67 |

*Used equipment pricing varies significantly based on condition, age, and included components.

Key Observation: Per-gallon costs decrease substantially with larger capacities, making scale a critical factor in total cost of ownership calculations.

Cost Breakdown by Category

1. Materials and Manufacturing Costs (40–55% of Total Price)

Primary Material: Stainless Steel

– Grade 304 stainless steel: Standard for most applications

– Grade 316 stainless steel: 15–25% premium for enhanced corrosion resistance

– Current steel pricing fluctuations impact equipment costs by 8–15% annually

Component Cost Distribution:

| Component | Percentage of Material Cost |

|---|---|

| Vat shell and jacket | 35–45% |

| Agitation system | 15–20% |

| Control systems | 12–18% |

| Valves and fittings | 8–12% |

| Insulation | 5–8% |

| Surface finishing | 5–10% |

Vat Type Premium Considerations:

– Round pasteurizing vats: 10–15% premium over basic open vats (includes heating/cooling jacket, enhanced controls)

– Combo vats: 20–30% premium (dual functionality for pasteurization and cheese-making)

– Ricotta/specialty vats: 15–25% premium (higher heat ratings, specialized agitation)

2. Labor and Engineering Costs (20–30% of Total Price)

Manufacturing Labor:

– Welding and fabrication: 40–50% of labor costs

– Assembly and testing: 25–30%

– Quality control and certification: 15–20%

– Custom engineering: 10–15%

Regional Labor Cost Variations:

| Manufacturing Region | Relative Labor Cost | Quality Standard |

|---|---|---|

| USA (Wisconsin, Ohio) | Baseline | FDA/3-A compliant |

| Western Europe | +15–25% | EU CE marking |

| Eastern Europe | -20–30% | Variable |

| China/Asia | -40–50% | Requires verification |

Custom Engineering Premiums:

– Standard configurations: No additional cost

– Minor modifications: $2,000–$5,000

– Custom dimensions: $5,000–$15,000

– Fully bespoke designs: $15,000–$50,000+

3. Logistics and Delivery Costs (8–15% of Total Price)

Domestic Shipping (USA):

| Vat Size | Estimated Freight Cost | Transit Time |

|---|---|---|

| Under 200 gallons | $1,500–$3,500 | 5–10 days |

| 200–500 gallons | $3,500–$6,000 | 7–14 days |

| 500–1,500 gallons | $6,000–$12,000 | 10–21 days |

| Over 1,500 gallons | $12,000–$25,000+ | 14–30 days |

International Shipping Considerations:

– Ocean freight (container): $4,000–$15,000 depending on origin/destination

– Import duties: 0–6% (varies by country and trade agreements)

– Customs clearance: $500–$2,000

– Local delivery from port: $1,000–$5,000

European Logistics:

– Intra-EU shipping: Generally 20–30% lower than transatlantic

– UK post-Brexit: Additional customs costs of 5–10%

– Eastern European delivery: May require specialized carriers

4. Installation and Commissioning Costs (5–12% of Total Price)

| Service | Cost Range | Notes |

|---|---|---|

| Basic installation | $2,000–$8,000 | Positioning and connection |

| Full commissioning | $5,000–$15,000 | Includes testing and calibration |

| Utility connections | $3,000–$12,000 | Steam, water, electrical |

| Training | $1,500–$5,000 | Operator certification |

| Facility modifications | $5,000–$50,000+ | If required |

New vs. Used Equipment Analysis

Financial Comparison

| Factor | New Equipment | Used Equipment |

|---|---|---|

| Initial cost | 100% (baseline) | 30–65% of new |

| Warranty | 1–3 years standard | Limited or none |

| Expected lifespan | 20–30 years | 10–20 years remaining |

| Maintenance (Year 1–5) | Minimal | 15–30% higher |

| Financing availability | Standard terms | Limited options |

| Customization | Full flexibility | As-is typically |

| Lead time | 8–16 weeks | Immediate–4 weeks |

| Regulatory compliance | Current standards | May require updates |

Used Equipment Risk Assessment

Recommended Inspection Points:

1. Weld integrity and surface condition

2. Jacket pressure testing

3. Agitator motor and gearbox condition

4. Control system functionality

5. Compliance documentation

6. Previous product history (allergen considerations)

Hidden Costs with Used Equipment:

– Refurbishment: $5,000–$25,000

– Compliance upgrades: $3,000–$15,000

– Parts replacement: $2,000–$10,000

– Extended downtime risk: Variable

Total Cost of Ownership (TCO) Model

A 5-year TCO analysis provides more accurate procurement planning:

Example: 500-Gallon Cheese Vat

| Cost Category | New Equipment | Used Equipment |

|---|---|---|

| Purchase price | $45,000 | $18,000 |

| Shipping | $5,000 | $4,500 |

| Installation | $8,000 | $10,000 |

| Year 1–5 maintenance | $12,000 | $22,000 |

| Parts/repairs | $3,000 | $12,000 |

| Energy costs | $15,000 | $18,000 |

| Downtime costs | $2,000 | $8,000 |

| 5-Year TCO | $90,000 | $92,500 |

| Annual TCO | $18,000 | $18,500 |

Key Insight: While used equipment offers lower initial investment, TCO often equalizes within 5 years. New equipment may prove more economical for operations planning 10+ year equipment lifecycles.

Cost-Saving Strategies

Procurement Optimization

- Volume Purchasing

- Multi-unit orders: Negotiate 8–15% discounts

- Package deals (vat + accessories): 5–10% savings

-

Long-term supplier agreements: Preferred pricing tiers

-

Timing Strategies

- Off-season ordering (January–March): Better lead times, potential discounts

- End-of-quarter negotiations: Sales teams may offer flexibility

-

Trade show purchases: Promotional pricing often available

-

Specification Optimization

- Right-size capacity to actual needs (avoid over-specification)

- Standardize across facilities for parts commonality

- Evaluate necessity of premium features vs. standard configurations

Supplier Negotiation Tactics

| Negotiation Lever | Potential Savings | Approach |

|---|---|---|

| Payment terms | 2–5% | Offer faster payment for discount |

| Multi-year commitment | 5–10% | Service agreements bundled |

| Referral/testimonial | 3–7% | Marketing value exchange |

| Competitive bidding | 8–15% | Minimum 3 qualified quotes |

| Bundle accessories | 10–20% | Strainers, tools, spare parts |

Financing Considerations

Equipment Financing Options:

– Equipment loans: 5–9% APR, 5–7 year terms

– Operating leases: Preserve capital, potential tax advantages

– USDA programs (USA): Value-Added Producer Grants, dairy-specific financing

– EU funding: Regional development grants for food processing

Tax Optimization (Consult Qualified Advisor):

– Section 179 deduction (USA): Immediate expensing potential

– Bonus depreciation: Accelerated write-off schedules

– Investment tax credits: Regional incentives may apply

Logistics Cost Reduction

- Consolidate shipments with other equipment purchases

- Negotiate freight directly rather than accepting supplier-arranged shipping

- Consider regional suppliers to minimize distance

- Evaluate port proximity for international purchases

- Plan installation timing to avoid expedited shipping premiums

Regional Pricing Variations

USA Market

| Region | Relative Pricing | Key Suppliers |

|---|---|---|

| Wisconsin | Baseline | Multiple established manufacturers |

| Northeast | +5–10% | Higher logistics costs |

| West Coast | +8–15% | Limited local manufacturing |

| Southeast | +3–8% | Growing market presence |

European Market

| Region | Relative Pricing | Considerations |

|---|---|---|

| Netherlands/Germany | Baseline (EU) | Strong manufacturing base |

| Italy | +5–10% | Specialty/artisan focus |

| UK | +10–20% | Post-Brexit import costs |

| Eastern Europe | -10–20% | Growing manufacturing capability |

Budget Planning Template

Capital Budget Checklist:

- [ ] Base equipment cost

- [ ] Customization/options

- [ ] Freight and insurance

- [ ] Import duties (if applicable)

- [ ] Installation labor

- [ ] Utility modifications

- [ ] Commissioning and testing

- [ ] Operator training

- [ ] Spare parts inventory

- [ ] Contingency (10–15%)

Recommended Contingency Allocations:

– New equipment, domestic supplier: 10%

– Used equipment: 15–20%

– International procurement: 15–20%

– Custom specifications: 20%

Key Takeaways

- Per-gallon costs decrease significantly with larger capacity units—evaluate true production needs against economies of scale

- Used equipment offers 35–70% initial savings but requires thorough inspection and realistic maintenance budgeting

- Logistics costs represent 8–15% of total investment—factor early in supplier selection

- Total cost of ownership analysis over 5–10 years provides more accurate comparison than purchase price alone

- Negotiate comprehensively—bundle accessories, services, and payment terms for maximum value

- Regional sourcing can reduce both costs and lead times while simplifying compliance requirements

Alternatives Analysis: Comparing cheese vat With Other Solutions

Alternatives Analysis: Comparing Cheese Vats With Other Solutions

When evaluating cheese production equipment, dairy processors must consider multiple approaches to curd development and milk processing. This analysis examines traditional cheese vats against alternative solutions to help you determine the optimal fit for your operation.

Comparison Overview

| Factor | Traditional Open Cheese Vats | Enclosed Cheese-Making Systems | Multi-Purpose Processing Tanks |

|---|---|---|---|

| Capacity Range | 50–3,000+ gallons | 500–10,000+ gallons | 100–2,000 gallons |

| Price Range (New) | $11,500–$31,000+ | $75,000–$250,000+ | $20,000–$60,000 |

| Price Range (Used) | $3,500–$23,500 | $30,000–$100,000+ | $10,000–$35,000 |

| Best For | Artisan/specialty cheese, small-to-mid production | High-volume industrial operations | Diversified dairy facilities |

| Process Control | Manual to semi-automated | Fully automated | Moderate automation |

| Cheese Variety Flexibility | High | Moderate | Moderate |

| Footprint | Moderate | Large | Compact |

| Maintenance Complexity | Low | High | Moderate |

Alternative 1: Enclosed Cheese-Making Systems

Overview: Enclosed systems integrate pasteurization, curd formation, and cutting within a sealed environment, designed for continuous high-volume production.

Advantages:

– Higher throughput for industrial-scale operations

– Reduced contamination risk through sealed processing

– Automated temperature and timing controls

– Consistent product output batch-to-batch

Disadvantages:

– Capital investment 3–8x higher than open vats

– Limited flexibility for specialty or artisan varieties

– Complex maintenance requiring specialized technicians

– Longer lead times for parts and service

Best Fit: Large-scale commodity cheese producers processing 50,000+ lbs daily.

Alternative 2: Multi-Purpose Processing Tanks

Overview: Combo vats and multi-purpose tanks handle pasteurization, culturing, and initial curd development in a single vessel—such as the 200-gallon and 400-gallon combo vats available in the market ($17,000–$29,500).

Advantages:

– Consolidated equipment reduces floor space requirements

– Single-vessel workflow for small operations

– Lower total equipment investment for startups

– Suitable for diversified dairy product lines

Disadvantages:

– Compromised performance compared to purpose-built vats

– Smaller capacity limits scalability

– Batch scheduling constraints when producing multiple products

– May require additional equipment as production grows

Best Fit: Startup creameries, farm-based processors, or facilities producing multiple dairy products.

Why Traditional Cheese Vats Remain the Standard

Open cheese vats—available in configurations from 50 gallons ($4,500 used) to 3,000+ gallons ($15,000–$18,500 used)—continue to dominate artisan and mid-scale cheese production for several reasons:

-

Process Visibility: Direct access to curds enables real-time quality assessment and manual intervention during critical production stages.

-

Variety Flexibility: Square and round vat designs accommodate diverse cheese styles, from raw milk aged varieties to ricotta (specialized 1,800-gallon ricotta vats available at $29,000).

-

Scalable Investment: Operations can start with smaller units and expand incrementally without replacing core equipment.

-

Proven Reliability: Simpler mechanical systems mean lower maintenance costs and longer equipment lifecycles.

-

Resale Value: Active secondary market for used vats provides exit flexibility and acquisition opportunities.

Decision Framework

Choose traditional open cheese vats if:

– Production volume is under 25,000 lbs/day

– Product line includes specialty or artisan varieties

– Budget constraints require phased capital investment

– Operational flexibility is prioritized over automation

Consider enclosed systems if:

– Continuous high-volume production is required

– Product line focuses on 1–2 commodity cheese types

– Labor costs exceed equipment financing costs

– Regulatory requirements mandate enclosed processing

Evaluate multi-purpose tanks if:

– Floor space is severely limited

– Production includes non-cheese dairy products

– Startup capital is constrained

– Future scaling plans are undefined

Essential Technical Properties and Trade Terminology for cheese vat

Essential Technical Properties and Trade Terminology for Cheese Vats

Key Technical Specifications

Understanding cheese vat specifications is critical for procurement decisions. Below are the primary technical properties buyers must evaluate:

| Property | Description | Typical Range |

|---|---|---|

| Capacity | Volume measured in gallons or liters | 50–3,000+ gallons |

| Material | Construction grade, typically stainless steel | 304 or 316 SS |

| Jacket Type | Heating/cooling system configuration | Single, double, or dimple jacket |

| Agitation System | Stirring mechanism design | Swing agitator, horizontal, or vertical |

| Surface Finish | Interior polish grade affecting cleanability | 150–180 grit (sanitary standard) |

| Insulation | Thermal efficiency rating | Polyurethane or mineral wool |

| Drain Configuration | Outlet size and placement | 2″–4″ sanitary fittings |

Vat Categories by Application

- Open Cheese Vats: Square or rectangular design for cheddar, gouda, and similar varieties; ideal for 2,500+ lb production runs

- Round Pasteurizing Vats: 50–250 gallon capacity; suited for artisan producers and small-batch operations

- Ricotta Vats: Specialized design for high-heat processing (1,800+ gallon configurations available)

- Combo Vats: Multi-function units combining pasteurization and cheese-making capabilities

Standard Trade Terminology

| Term | Definition |

|---|---|

| MOQ | Minimum Order Quantity—typically 1 unit for custom fabrication |

| OEM | Original Equipment Manufacturer—custom branding/specification options |

| CIP | Clean-in-Place systems for automated sanitation |

| 3-A Sanitary Standards | U.S. certification for dairy equipment hygiene compliance |

| EHEDG | European Hygienic Engineering & Design Group certification |

| FOB | Freight on Board—shipping terms indicating cost responsibility transfer point |

| Lead Time | Manufacturing and delivery timeline (typically 8–16 weeks for new units) |

Pricing Benchmarks (USD)

- Used 50-gallon vat: ~$4,500

- New 150-gallon vat: ~$11,500

- New 300-gallon vat: ~$31,000

- Used 3,000-gallon vat: $15,000–$18,500

- Ricotta vats (1,800 gallon): ~$29,000

Procurement Considerations

- New vs. Used: Used equipment offers 40–60% cost savings; verify sanitary compliance and jacket integrity

- Customization: OEM options include agitator configuration, jacket design, and control panel integration

- Compliance: Confirm 3-A (USA) or EHEDG (Europe) certification for regulatory approval

- Accessories: Budget for curd mills, strainers ($2,850+), and CIP systems separately

Navigating Market Dynamics and Sourcing Trends in the cheese vat Sector

Navigating Market Dynamics and Sourcing Trends in the Cheese Vat Sector

Current Market Landscape

The cheese vat market serves a diverse spectrum of producers—from artisan dairy operations processing 50 gallons to industrial facilities handling 3,000+ gallons per batch. Understanding current sourcing dynamics is essential for making strategic equipment investments.

Market Segmentation by Capacity:

| Segment | Typical Capacity | Primary Buyers | Price Range (USD) |

|---|---|---|---|

| Artisan/Small Batch | 50-250 gallons | Craft cheesemakers, R&D facilities | $4,500-$12,000 |

| Mid-Scale Production | 300-800 gallons | Regional dairies, specialty producers | $11,500-$31,000 |

| Industrial Scale | 1,400-3,000+ gallons | Large-scale manufacturers | $15,000-$29,000+ |

Key Sourcing Trends

1. Used Equipment Market Growth

The secondary market for cheese vats has expanded significantly, driven by:

– Dairy consolidation creating surplus equipment

– Cost-conscious buyers seeking capital efficiency

– Proven durability of stainless steel construction

Used vats often sell at 30-60% below new equipment costs while maintaining operational viability.

2. Specialization in Vat Design

Manufacturers now offer application-specific configurations:

– Open vats for raw milk cheese production or pre-pasteurized milk processing

– Round pasteurizing vats with integrated heating for small-batch operations

– Combo vats combining multiple processing functions

– Ricotta-specific vats optimized for high-temperature whey processing

3. Regional Manufacturing Considerations

| Region | Strengths | Considerations |

|---|---|---|

| USA (Wisconsin corridor) | Proximity to dairy clusters, established service networks | Higher labor costs |

| Europe | Heritage engineering, PDO compliance expertise | Import logistics, currency fluctuation |

Sustainability Factors Shaping Procurement

Modern cheese vat selection increasingly incorporates sustainability criteria:

- Energy efficiency: Improved insulation and heat recovery systems reduce thermal losses

- Water conservation: Optimized CIP (clean-in-place) designs minimize water consumption

- Longevity: Stainless steel construction supports 20-30+ year operational lifespans

- Refurbishment potential: Quality used equipment extends material lifecycle

Historical Context

Cheese vat technology has evolved from traditional copper vessels to today’s precision-engineered stainless steel systems. Key developments include:

- Transition to food-grade stainless steel (mid-20th century)

- Integration of automated temperature control

- Development of enclosed pasteurizing vats for single-vessel processing

- Modular designs enabling flexible production scaling

Strategic Sourcing Recommendations

- Evaluate total cost of ownership—not just acquisition price—including installation, energy consumption, and maintenance

- Consider used equipment from established dealers with refurbishment capabilities

- Match vat design to production methodology—open vats for traditional processes, enclosed systems for integrated pasteurization

- Verify compliance with regional food safety standards (FDA, EU regulations)

- Assess supplier support infrastructure for parts availability and technical service

Frequently Asked Questions (FAQs) for B2B Buyers of cheese vat

Frequently Asked Questions (FAQs) for B2B Buyers of Cheese Vats

1. What sizes of cheese vats are available for commercial operations?

Commercial cheese vats range from 50 gallons to 3,000+ gallons, accommodating operations of all scales:

| Operation Size | Recommended Capacity |

|---|---|

| Artisan/Small Batch | 50-250 gallons |

| Mid-Size Creamery | 300-800 gallons |

| Large Commercial | 1,400-3,000+ gallons |

2. What is the difference between open cheese vats and pasteurizing cheese vats?

- Open Cheese Vats: Square or rectangular design for operations using pre-pasteurized or raw milk cheese production. Ideal for batches of 2,500 lbs or more.

- Pasteurizing Cheese Vats: Round design with removable lids and swing agitators, allowing in-vat pasteurization. Best suited for artisan producers and small batch operations (50-250 gallons).

3. Should I buy new or used cheese vat equipment?

| Factor | New Equipment | Used Equipment |

|---|---|---|

| Price Range | $29,000-$31,000+ | $3,500-$23,500 |

| Warranty | Full manufacturer warranty | Limited or none |

| Customization | Available | As-is condition |

| Lead Time | Longer | Immediate availability |

Used equipment offers significant cost savings for budget-conscious operations, while new vats provide customization options and full warranty coverage.

4. What materials are cheese vats constructed from?

Commercial cheese vats are manufactured from food-grade stainless steel (typically 304 or 316 grade), ensuring:

- Compliance with FDA and EU food safety regulations

- Corrosion resistance

- Easy sanitation

- Durability for continuous production cycles

5. What accessories and ancillary equipment should I consider?

Essential accessories for cheese vat operations include:

- Vat strainers (~$2,850)

- Curd milling machines (for cheddar production)

- Agitation systems

- Temperature control systems

- Drainage valves and fittings

6. What are the typical lead times for new cheese vat orders?

Lead times vary based on:

- Standard models: 8-16 weeks

- Custom configurations: 12-24 weeks

- Used/refurbished units: Immediate to 2 weeks

Contact suppliers early in your planning phase to account for manufacturing and shipping schedules.

7. What compliance standards must cheese vats meet for USA and European markets?

| Region | Key Standards |

|---|---|

| USA | FDA 21 CFR, 3-A Sanitary Standards, PMO requirements |

| Europe | EC 1935/2004, EN 1672-2, CE marking |

Ensure your supplier provides documentation confirming compliance with relevant regional standards.

8. What factors should I evaluate when selecting a cheese vat supplier?

Key evaluation criteria:

- Product range: New, used, and refurbished options

- Customization capabilities: Size, configuration, and feature modifications

- Technical support: Installation assistance and ongoing service

- Parts availability: Access to replacement components

- Industry experience: Track record with similar production requirements

- Geographic reach: Shipping and service coverage in your region

Strategic Sourcing Conclusion and Outlook for cheese vat

Strategic Sourcing Conclusion: Cheese Vat Investment

Selecting the right cheese vat represents a foundational decision that directly impacts production capacity, operational efficiency, and long-term profitability. The market offers diverse options across the investment spectrum:

| Capacity Range | New Equipment | Used Equipment |

|---|---|---|

| 50-200 Gallon | $29,500+ | $3,500-$11,500 |

| 300-800 Gallon | $31,000+ | $11,500-$23,500 |

| 1,400-3,000 Gallon | Custom quote | $4,000-$18,500 |

Key Takeaways for Procurement Teams

- Used equipment presents significant cost savings (40-70%) without compromising functionality for budget-conscious operations

- Specialized vats (ricotta, combo designs) command premium pricing but deliver process-specific advantages

- Supplier relationships with established fabricators ensure access to parts, service, and technical support

Market Outlook

Demand for artisan and specialty cheese continues driving investment in flexible, scalable vat solutions. Buyers should prioritize:

- Sanitary design compliance with FDA/EU regulations

- Energy-efficient heating systems

- Automation compatibility for future integration

Recommended Action: Conduct thorough capacity planning, request detailed specifications from multiple suppliers, and evaluate total cost of ownership—including installation, maintenance, and operational expenses—before finalizing procurement decisions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.