Introduction: Navigating the Global Market for Cheese Making Vats

The cheese making vat sits at the heart of every dairy operation—it’s where milk transforms into curd, where temperature precision determines product quality, and where operational efficiency directly impacts your bottom line. For B2B buyers in the USA and Europe, selecting the right vat isn’t simply a procurement decision; it’s a strategic investment that shapes production capacity for years to come.

The challenge is real. Today’s market offers everything from 50-gallon artisan vats to 3,000-gallon industrial systems, with prices ranging from $3,500 to over $31,000. Factor in the choice between new and used equipment, varying customization options, and regional compliance requirements, and the decision becomes complex fast.

What This Guide Covers

| Section | Key Topics |

|———|————|

| Equipment Types | Open-top vats, combo vats, specialty ricotta vats |

| Capacity Planning | Matching gallon capacity to production goals |

| Cost Analysis | New vs. used equipment ROI considerations |

| Supplier Evaluation | What to look for in equipment partners |

| Compliance | USA and EU regulatory requirements |

Who Should Read This

- Dairy plant managers expanding production capacity

- Artisan cheesemakers scaling from small-batch to commercial operations

- Procurement specialists evaluating capital equipment investments

- Operations directors optimizing existing cheese-making lines

Whether you’re sourcing your first commercial vat or replacing aging equipment, this guide delivers the specifications, market insights, and evaluation criteria you need to make a confident purchasing decision.

Article Navigation

- Top 10 Cheese Making Vat Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for cheese making vat

- Understanding cheese making vat Types and Variations

- Key Industrial Applications of cheese making vat

- 3 Common User Pain Points for ‘cheese making vat’ & Their Solutions

- Strategic Material Selection Guide for cheese making vat

- In-depth Look: Manufacturing Processes and Quality Assurance for cheese making vat

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘cheese making vat’

- Comprehensive Cost and Pricing Analysis for cheese making vat Sourcing

- Alternatives Analysis: Comparing cheese making vat With Other Solutions

- Essential Technical Properties and Trade Terminology for cheese making vat

- Navigating Market Dynamics and Sourcing Trends in the cheese making vat Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cheese making vat

- Strategic Sourcing Conclusion and Outlook for cheese making vat

- Important Disclaimer & Terms of Use

Top 10 Cheese Making Vat Manufacturers & Suppliers List

1. Cheese Vats Manufacturers and Suppliers in the USA and Canada

Domain: thomasnet.com

Registered: 1996 (29 years)

Introduction: D.R. Tech, Inc. · D.R. Tech, Inc. · Anco Equipment, LLC · Anco Equipment, LLC · Chem-Tainer Industries · Chem-Tainer Industries · Kusel Equipment · Kusel Equipment….

2. International Machinery Exchange: Dairy and Cheesemaking …

Domain: imexchange.com

Registered: 1997 (28 years)

Introduction: We offer cheese vats and finishing tables, curd mills, curd knives, curd pumps, cheese presses, cheese milk pasteurizers, mozzarella cookers and molders….

3. Cheese Making Vats – Pasta Filata – GEA

Domain: gea.com

Registered: 1995 (30 years)

Introduction: GEA offers a portfolio of flexible, reliable hydraulic setting vats for the production of a wide range of pasta filata cheeses….

4. Cheese Manufacturing Equipment – RELCO

Domain: relco.net

Registered: 2003 (22 years)

Introduction: RELCO is a specialized cheese equipment manufacturer with over 30 years of experience. RELCO’s cheese production equipment is in more than 500 cheese & dairy ……

5. Vats Categories – Kusel Equipment

Domain: kuselequipment.com

Registered: 2000 (25 years)

Introduction: Kusel’s legacy “Cook Rite” Enclosed Cheese Vats are a hallmark of reliable, large-scale cheese production, designed to provide consistency and quality with ……

6. Tetra Pak® Cheese Vat Yieldmaster 2

Domain: tetrapak.com

Registered: 1993 (32 years)

Introduction: Gives you the highest yield of any vat on the market · At 38,555 kg (or 85,000 lb) this is the largest cheese vat available · Durable, based on decades of ……

7. Cheesemaking Equipment – APT – Advanced Process Technologies

Domain: apt-inc.com

Registered: 2001 (24 years)

Introduction: Optimize your cheese production with APT’s advanced cheesemaking equipment, including cheese vats, finishing vats, draining belts, dosing systems, ……

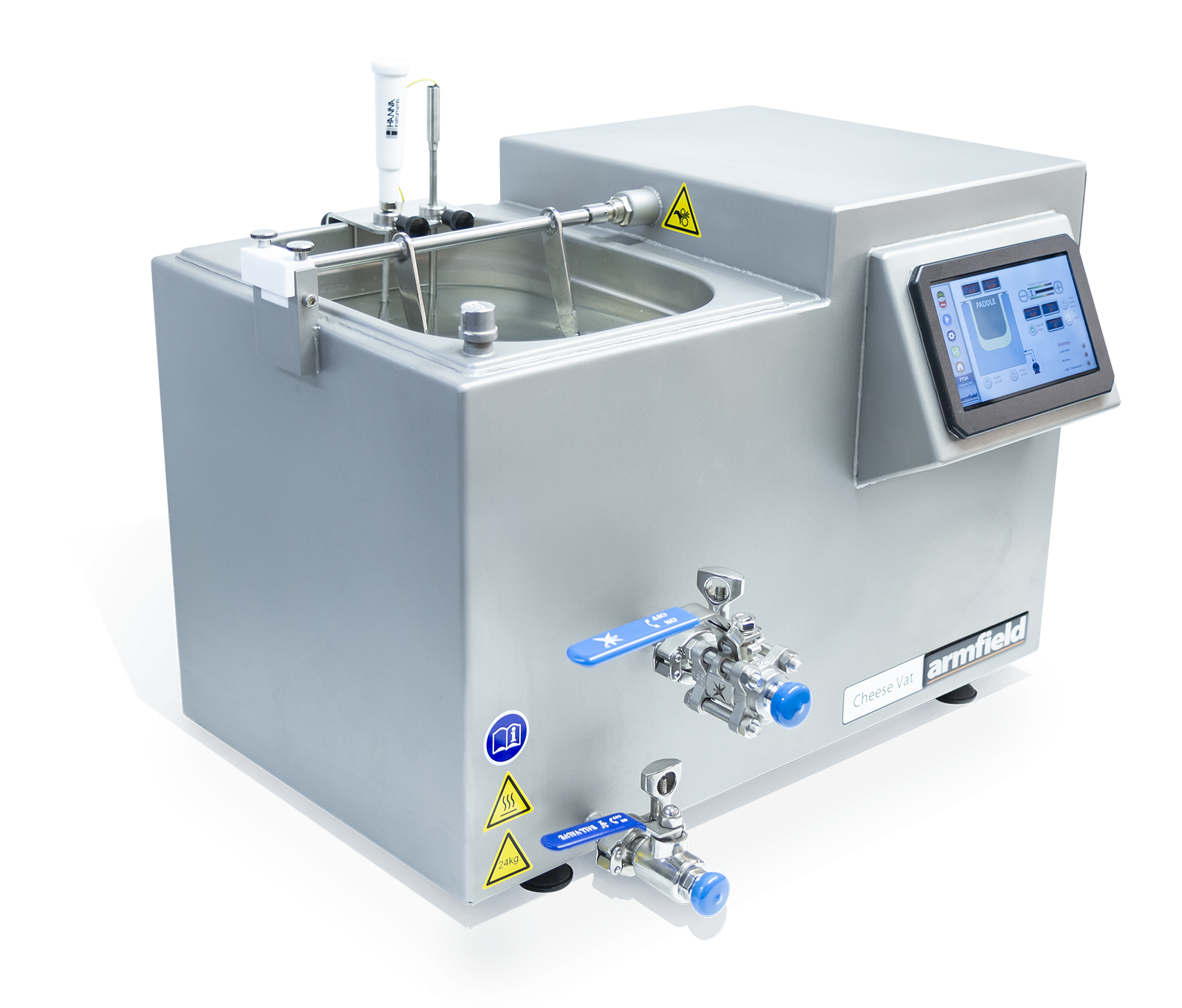

Illustrative Image (Source: Google Search)

8. Cheese Vats for sale – Anco Equipment

Domain: ancoequipment.com

Registered: 2012 (13 years)

Introduction: Anco Equipment provides a complete solution for all your cheese-making needs with our stainless steel cheese vats and other cheese-making equipment….

Understanding cheese making vat Types and Variations

Understanding Cheese Making Vat Types and Variations

Selecting the right cheese making vat directly impacts production efficiency, product quality, and operational costs. This section examines the primary vat types available to commercial cheese manufacturers, helping you match equipment specifications to your production requirements.

Illustrative Image (Source: Google Search)

Cheese Vat Types Comparison

| Type | Key Features | Primary Applications | Pros/Cons |

|---|---|---|---|

| Standard Open Cheese Vats | Open-top design, jacketed walls for temperature control, manual or semi-automated operation | General cheese production, artisan operations, small-to-medium facilities | ✓ Easy maintenance and cleaning ✓ Lower capital investment ✗ Labor-intensive ✗ Limited automation |

| Combo Vats | Multi-function capability, integrated pasteurization and cheese-making | Small-batch production, farmstead operations, specialty cheese makers | ✓ Space-efficient ✓ Reduced equipment footprint ✗ Higher per-unit cost ✗ Limited throughput |

| Ricotta/Specialty Vats | High-heat capability, specialized agitation systems, designed for whey-based products | Ricotta, mascarpone, and heat-coagulated cheese production | ✓ Optimized for specific cheese types ✓ Higher temperature tolerance ✗ Limited versatility ✗ Specialized maintenance |

| Enclosed/Automated Vats | Sealed design, CIP systems, programmable controls, automated curd handling | Large-scale industrial production, high-volume facilities | ✓ Consistent output ✓ Reduced labor costs ✗ Higher capital investment ✗ Complex maintenance |

| Double-O/Horizontal Vats | Dual-cylinder design, continuous processing capability, integrated drainage | High-volume cheddar and commodity cheese production | ✓ Maximum throughput ✓ Efficient curd handling ✗ Significant floor space required ✗ High acquisition cost |

Detailed Type Analysis

Standard Open Cheese Vats

Open cheese vats remain the industry workhorse for small-to-medium operations. Available in capacities ranging from 50 gallons to 3,000+ gallons, these vats feature:

- Jacketed construction for precise heating and cooling via steam or hot water circulation

- Stainless steel fabrication (typically 304 or 316 grade) for sanitary compliance

- Agitation systems with variable speed controls for curd development

- Integrated drainage with outlet valves for whey removal

Open-top configurations simplify visual monitoring, manual curd cutting, and equipment sanitation. Facilities processing under 10,000 pounds of milk daily typically find standard vats cost-effective.

Combo Vats

Combo vats integrate pasteurization and cheese-making functions into a single unit. These 200-400 gallon systems serve operations where:

- Floor space is limited

- Batch sizes remain consistent

- Capital equipment budgets require consolidation

While combo vats reduce equipment purchases, they create production bottlenecks—pasteurization and cheese-making cannot occur simultaneously in the same vessel.

Illustrative Image (Source: Google Search)

Ricotta and Specialty Vats

Purpose-built for heat-acid coagulation, ricotta vats handle the elevated temperatures (185°F+) required for whey protein recovery. Typical capacities reach 1,800 gallons or more. Key differentiators include:

- Enhanced thermal jackets for rapid heating

- Specialized agitator designs preventing protein scorching

- Optimized geometry for delicate curd formation

Facilities producing traditional Italian-style cheeses or maximizing whey utilization benefit from dedicated specialty vats.

Enclosed/Automated Vats

Industrial-scale operations leverage enclosed vats with integrated automation for:

- Clean-in-place (CIP) systems reducing sanitation labor

- Programmable logic controllers (PLCs) ensuring batch consistency

- Automated curd handling including cutting, stirring, and transfer

- Data logging for quality control and regulatory compliance

Capital costs run significantly higher, but labor savings and throughput gains justify investment at production volumes exceeding 50,000 pounds daily.

Illustrative Image (Source: Google Search)

Double-O and Horizontal Vats

The largest cheese manufacturers utilize double-O vats—twin horizontal cylinders enabling continuous curd processing. These systems:

- Process 10,000+ gallons per batch

- Integrate seamlessly with downstream equipment (curd mills, block formers)

- Minimize handling between production stages

Infrastructure requirements include reinforced flooring, dedicated utilities, and specialized technical support.

Selection Considerations

When evaluating vat types, assess these operational factors:

- Production volume — Match vat capacity to daily milk intake with room for growth

- Cheese varieties — Specialty products may require dedicated equipment

- Labor availability — Automation offsets workforce constraints

- Facility constraints — Measure available floor space, ceiling height, and utility access

- Budget parameters — Balance capital expenditure against operational efficiency gains

Used equipment offers cost advantages—functional 3,000-gallon vats trade between $15,000-$18,500, while new 300-gallon units start around $31,000. Evaluate refurbishment quality and remaining service life when considering pre-owned options.

Illustrative Image (Source: Google Search)

Key Industrial Applications of cheese making vat

Key Industrial Applications of Cheese Making Vats

Cheese making vats serve as the central processing vessel across diverse dairy operations, from artisan producers to large-scale industrial facilities. Below is a comprehensive breakdown of primary applications and their specific operational benefits.

| Industry Segment | Application | Typical Vat Capacity | Key Benefits |

|---|---|---|---|

| Artisan/Farmstead Creameries | Small-batch specialty cheese production | 50–200 gallons | Precise temperature control for traditional recipes; batch flexibility; lower capital investment |

| Mid-Scale Commercial Dairies | Regional cheese manufacturing | 300–800 gallons | Scalable production; consistent curd development; efficient labor utilization |

| Large Industrial Processors | High-volume commodity cheese | 1,400–3,000+ gallons | Maximum throughput; reduced per-unit processing costs; continuous operation capability |

| Ricotta & Whey Cheese Production | Acid-coagulated cheese varieties | 1,800+ gallons (specialized) | Purpose-built for high-heat processing; optimized whey protein recovery |

| Multi-Product Facilities | Combo vat operations | 200–400 gallons | Versatility for multiple cheese types; reduced equipment footprint |

Application-Specific Advantages

Post-Pasteurization Processing

– Serves as the primary vessel for milk coagulation immediately following pasteurization

– Maintains precise temperature zones critical for starter culture activation and rennet efficiency

Curd Development & Handling

– Open-top designs facilitate manual curd cutting, stirring, and visual monitoring

– Compatible with ancillary equipment including curd knives, whey screens, and milling machines

Operational Efficiency

– Simplified installation and maintenance protocols reduce downtime

– Fully customizable dimensions ensure integration with existing production lines

– Sanitary design supports compliance with FDA and EU dairy processing regulations

Illustrative Image (Source: Google Search)

Scalability Considerations

– Operations can select capacity based on production targets—ranging from 50-gallon artisan units to 3,000-gallon industrial systems

– Used equipment market provides cost-effective expansion options for growing operations

3 Common User Pain Points for ‘cheese making vat’ & Their Solutions

3 Common User Pain Points for Cheese Making Vats & Their Solutions

Pain Point 1: Capacity Mismatch with Production Demands

Scenario: A growing artisan cheese producer in Wisconsin invested in a 300-gallon vat three years ago. Now processing 2,000 gallons of milk daily, they face production bottlenecks and extended operating hours to meet demand.

Problem: Selecting the wrong vat capacity leads to either underutilization (wasted capital) or production constraints that limit business growth. With cheese vats ranging from 50 gallons to 3,000+ gallons, the initial investment decision has long-term operational consequences.

Solution:

– Conduct a thorough capacity analysis factoring in current production, 3-5 year growth projections, and seasonal demand fluctuations

– Consider modular setups with multiple mid-range vats (400-800 gallon) for flexibility

– Partner with suppliers offering both new and certified used equipment to scale cost-effectively as production grows

Illustrative Image (Source: Google Search)

Pain Point 2: Integration Challenges with Existing Dairy Operations

Scenario: A European cheese manufacturer purchases a new vat only to discover incompatibilities with their existing pasteurization system, drainage infrastructure, and facility layout.

Problem: Cheese vats must integrate seamlessly with upstream pasteurization equipment and downstream processing (curd handling, whey separation). Poor integration creates workflow inefficiencies, sanitation risks, and costly retrofitting.

Solution:

| Integration Factor | Key Consideration |

|——————-|——————-|

| Dimensions | Verify floor space, ceiling height, and doorway access |

| Connections | Match inlet/outlet specifications to existing piping |

| Accessories | Ensure compatibility with curd knives, whey screens, and milling equipment |

| Customization | Work with manufacturers offering fully customizable dimensions and features |

Pain Point 3: Maintenance Complexity and Downtime Costs

Scenario: A mid-sized cheese operation experiences unexpected vat failure during peak production season, resulting in product loss and delayed customer orders.

Illustrative Image (Source: Google Search)

Problem: Complex vat designs with difficult-to-access components increase cleaning time, complicate maintenance, and extend unplanned downtime—directly impacting product quality and profitability.

Solution:

– Prioritize open-top vat designs for simplified cleaning and inspection access

– Establish preventive maintenance schedules with documented protocols

– Maintain relationships with equipment suppliers offering replacement parts and technical support

– Consider certified used equipment from reputable dealers as backup capacity during maintenance periods

Strategic Material Selection Guide for cheese making vat

Strategic Material Selection Guide for Cheese Making Vats

Selecting the appropriate material for your cheese making vat is a critical decision that directly impacts product quality, operational efficiency, regulatory compliance, and long-term return on investment. This guide provides a comprehensive analysis of material options to inform your procurement strategy.

Primary Material Options

Stainless Steel (304 and 316 Grades)

Stainless steel dominates the commercial cheese making equipment market for compelling reasons:

Illustrative Image (Source: Google Search)

304 Stainless Steel

– Standard grade for most dairy applications

– Excellent corrosion resistance in typical dairy environments

– Cost-effective for operations using standard cleaning protocols

– Suitable for facilities processing primarily sweet-curd cheeses

316 Stainless Steel

– Contains molybdenum for enhanced corrosion resistance

– Required for high-salt environments (brined cheeses, ricotta production)

– Superior performance with aggressive CIP chemicals

– Recommended for coastal facilities or high-humidity environments

Surface Finish Considerations

The interior surface finish directly affects:

– Cleanability and sanitation compliance

– Bacterial adhesion potential

– Product release characteristics

– Maintenance requirements

| Finish Type | Ra Value (μm) | Best Application |

|---|---|---|

| 2B Mill Finish | 0.5-1.0 | Budget installations, non-contact surfaces |

| #4 Brushed | 0.4-0.8 | Standard dairy applications |

| Electropolished | 0.2-0.4 | Premium operations, specialty cheeses |

Regulatory Compliance Requirements

United States (FDA/3-A Sanitary Standards)

– 3-A Sanitary Standard 20-03 governs cheese vat construction

– Minimum 300-series stainless steel required for product contact surfaces

– Surface finish must not exceed 32 Ra microinch (0.8 μm)

Illustrative Image (Source: Google Search)

European Union (EC 1935/2004)

– Materials must not transfer components to food in dangerous quantities

– Declaration of Compliance required from manufacturers

– EHEDG certification recommended for export operations

Jacketing and Insulation Materials

The outer jacket and insulation system affects thermal efficiency and operating costs:

Jacket Construction

– Carbon steel (cost-effective, requires external coating)

– Stainless steel (premium durability, higher upfront cost)

– Dimple plate design maximizes heat transfer surface area

Insulation Options

– Polyurethane foam: High R-value, industry standard

– Mineral wool: Fire-resistant, suitable for high-temperature applications

– Closed-cell foam: Moisture-resistant, prevents thermal bridging

Illustrative Image (Source: Google Search)

Gasket and Seal Materials

Critical for preventing contamination and maintaining thermal efficiency:

| Material | Temperature Range | Chemical Resistance | Typical Lifespan |

|---|---|---|---|

| EPDM | -40°C to 120°C | Excellent (acids, alkalis) | 3-5 years |

| Silicone | -60°C to 200°C | Good (limited oils) | 2-4 years |

| Viton® | -20°C to 200°C | Excellent (oils, solvents) | 5-7 years |

| PTFE | -200°C to 260°C | Superior (all chemicals) | 7-10 years |

Material Selection by Cheese Type

Different cheese varieties impose specific material requirements:

Fresh Cheeses (Ricotta, Mozzarella)

– 316 stainless steel recommended due to high-acid environments

– Electropolished surfaces prevent protein adhesion

– High-temperature rated seals required

Aged Cheeses (Cheddar, Gouda)

– 304 stainless steel typically sufficient

– Standard #4 finish acceptable

– Focus on thermal jacket efficiency for precise temperature control

Illustrative Image (Source: Google Search)

Specialty/Artisan Cheeses

– Consider copper-clad interiors for traditional applications (where regulations permit)

– Premium surface finishes for delicate curd handling

Total Cost of Ownership Analysis

Material selection affects long-term operational costs:

Initial Investment Factors

– Raw material costs (316 SS costs 20-30% more than 304 SS)

– Fabrication complexity

– Surface finishing requirements

Ongoing Cost Considerations

– Cleaning chemical compatibility

– Maintenance frequency

– Expected service life

– Energy efficiency (thermal conductivity)

Illustrative Image (Source: Google Search)

Material Comparison Table

| Criteria | 304 Stainless Steel | 316 Stainless Steel | Copper-Clad | Carbon Steel (Jacket) |

|---|---|---|---|---|

| Initial Cost | Moderate | High | Very High | Low |

| Corrosion Resistance | Good | Excellent | Good (requires maintenance) | Poor (requires coating) |

| FDA/3-A Compliance | Yes | Yes | Limited applications | Non-contact only |

| EU Compliance | Yes | Yes | Restricted | Non-contact only |

| Salt/Acid Resistance | Moderate | Excellent | Good | Poor |

| Thermal Conductivity | 16 W/m·K | 16 W/m·K | 401 W/m·K | 50 W/m·K |

| Expected Lifespan | 20-30 years | 25-35 years | 15-25 years | 10-15 years |

| Maintenance Requirements | Low | Low | High | Moderate |

| Best Application | Standard operations | High-acid/salt environments | Artisan/traditional | Outer jackets only |

| Recyclability | High | High | High | Moderate |

Procurement Recommendations

- Specify material grade explicitly in purchase orders—avoid generic “stainless steel” designations

- Request mill certificates (MTR/MTC) for all product-contact materials

- Verify surface finish with documented Ra measurements

- Confirm gasket materials are compatible with your CIP protocols

- Consider future production needs—316 SS provides flexibility for product line expansion

Investing in appropriate materials at the outset minimizes replacement costs, ensures regulatory compliance across markets, and protects product quality throughout the equipment’s operational life.

In-depth Look: Manufacturing Processes and Quality Assurance for cheese making vat

In-depth Look: Manufacturing Processes and Quality Assurance for Cheese Making Vats

Understanding how cheese making vats are manufactured and quality-tested is essential for B2B buyers evaluating equipment suppliers. This section examines the production processes and quality standards that differentiate professional-grade vats from substandard alternatives.

Manufacturing Process Overview

Cheese vat manufacturing follows a precise sequence of operations designed to produce equipment that meets stringent food-safety and durability requirements.

Stage 1: Material Preparation

| Process Step | Description | Critical Factors |

|---|---|---|

| Material Selection | Sourcing food-grade stainless steel (typically 304 or 316L) | Corrosion resistance, weldability, FDA compliance |

| Sheet Cutting | Precision cutting via laser or plasma systems | Dimensional accuracy, edge quality |

| Surface Preparation | Grinding, deburring, and initial polishing | Elimination of contaminants, surface uniformity |

Raw material traceability documentation accompanies all steel from certified mills, ensuring compliance with food-contact regulations in both USA (FDA 21 CFR) and European (EC 1935/2004) markets.

Illustrative Image (Source: Google Search)

Stage 2: Forming and Shaping

The vat body undergoes multiple forming operations:

- Rolling/Bending: Flat sheets are formed into cylindrical or rectangular configurations using hydraulic press brakes and rolling machines

- Deep Drawing: End caps and curved sections are shaped through progressive die operations

- Jacket Formation: Double-wall construction for heating/cooling jackets requires precise dimensional control to ensure uniform heat distribution

Custom fabrication—common among specialty manufacturers like Ullmer’s Dairy Equipment—allows vats ranging from 50 gallons to 3,000+ gallons to meet specific operational requirements.

Stage 3: Welding and Assembly

Welding represents the most quality-critical manufacturing stage:

| Welding Method | Application | Quality Consideration |

|---|---|---|

| TIG (GTAW) | Interior seams, product-contact surfaces | Smooth, crevice-free welds; no porosity |

| MIG (GMAW) | Structural components, frames | Strength, penetration depth |

| Automated Orbital | Pipe connections, ports | Consistent, repeatable quality |

Assembly sequence:

1. Inner vessel welding and inspection

2. Jacket attachment and pressure testing

3. Agitator mounting system installation

4. Inlet/outlet port integration

5. Instrumentation and control component fitting

6. Insulation application (where applicable)

7. External cladding and finishing

Illustrative Image (Source: Google Search)

Stage 4: Surface Finishing

Interior surface finish directly impacts sanitation capability and product quality:

- Mechanical Polishing: Progressive grit sequences achieve target Ra values

- Electropolishing: Removes microscopic surface irregularities, enhances corrosion resistance

- Passivation: Chemical treatment restores chromium oxide layer post-welding

Industry-standard surface finishes:

– Product-contact surfaces: ≤0.8 µm Ra (32 µin) minimum; ≤0.4 µm Ra preferred

– Non-contact surfaces: ≤1.6 µm Ra acceptable

Quality Assurance Protocols

Reputable manufacturers implement multi-stage quality control aligned with international standards.

Applicable Quality Standards

| Standard | Scope | Relevance |

|---|---|---|

| ISO 9001:2015 | Quality management systems | Manufacturing process control |

| ISO 22000 | Food safety management | HACCP integration capability |

| 3-A Sanitary Standards | Dairy equipment design | USA market requirement |

| EHEDG Guidelines | Hygienic design | European market compliance |

| ASME Section VIII | Pressure vessel construction | Jacketed vat certification |

In-Process Quality Checks

Material verification:

– Mill test certificate review

– Positive Material Identification (PMI) testing

– Dimensional inspection of incoming stock

Illustrative Image (Source: Google Search)

Fabrication inspection:

– Weld visual inspection per AWS D18.1/D18.2

– Dye penetrant testing (PT) for surface-breaking defects

– Radiographic testing (RT) for critical welds on pressure-rated jackets

Dimensional verification:

– Capacity confirmation via volumetric measurement

– Geometric tolerance verification

– Agitator clearance checks

Final Quality Control

Before shipment, completed vats undergo comprehensive testing:

- Hydrostatic pressure testing: Jackets tested at 1.5× design pressure

- Leak testing: All welds, seals, and connections verified

- Surface finish measurement: Profilometer readings documented

- Functional testing: Agitators, valves, and instrumentation operated

- Cleanliness verification: Visual and swab testing for residual contamination

- Documentation package assembly: Material certs, weld maps, test reports, operating manuals

Quality Indicators for B2B Buyers

When evaluating suppliers, request evidence of:

- Certified welders: AWS or equivalent certifications for all welding personnel

- Documented procedures: Written work instructions for each manufacturing stage

- Traceability systems: Ability to trace any component back to raw material source

- Third-party certifications: 3-A authorization, EHEDG certification, or equivalent

- Inspection records: Willingness to provide test documentation with equipment

New vs. Used Equipment Considerations

The secondary market—represented by suppliers like Ullmer’s and Anco Equipment—offers cost advantages but requires additional quality scrutiny:

| Factor | New Equipment | Used/Refurbished |

|---|---|---|

| Documentation | Complete package | May be incomplete |

| Warranty | Full manufacturer coverage | Limited or none |

| Surface condition | Factory specification | Requires inspection |

| Compliance | Current standards | May need upgrades |

| Price range | $29,000–$35,000+ (300 gal) | $3,500–$23,500 (varies) |

For used equipment, insist on:

– Independent inspection reports

– Surface finish measurements

– Pressure test documentation

– Detailed photographic records

– Clear disclosure of any repairs or modifications

Supplier Qualification Checklist

Before committing to a purchase, verify:

- [ ] ISO 9001 certification (or equivalent QMS)

- [ ] 3-A authorization (USA) or EHEDG compliance (Europe)

- [ ] Documented manufacturing procedures

- [ ] Welder qualification records

- [ ] Material traceability capability

- [ ] In-house testing facilities

- [ ] Reference customers in similar applications

- [ ] Post-sale technical support availability

Understanding these manufacturing and quality assurance fundamentals positions buyers to make informed procurement decisions and establish productive long-term supplier relationships.

Illustrative Image (Source: Google Search)

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cheese making vat’

Practical Sourcing Guide: A Step-by-Step Checklist for Cheese Making Vats

Sourcing the right cheese making vat requires systematic evaluation of your operational needs, supplier capabilities, and long-term production goals. This checklist provides a structured approach to procurement decision-making.

Step 1: Define Your Production Requirements

Capacity Assessment

– [ ] Calculate daily/weekly milk processing volume

– [ ] Determine batch sizes required for your cheese varieties

– [ ] Account for future production scaling (recommend 20-30% headroom)

| Production Scale | Typical Vat Capacity |

|---|---|

| Artisan/Small | 50-200 gallons |

| Mid-size | 300-800 gallons |

| Industrial | 1,400-3,000+ gallons |

Cheese Type Considerations

– [ ] Standard cheese vat vs. specialty (e.g., ricotta vats with direct steam injection)

– [ ] Combo vats for multi-purpose operations

– [ ] Agitation requirements for your specific cheese varieties

Step 2: Establish Technical Specifications

- [ ] Interior dimensions compatible with facility layout

- [ ] Jacket configuration (single/double wall for heating/cooling)

- [ ] Material grade (304 vs. 316 stainless steel)

- [ ] Surface finish requirements (sanitary polish standards)

- [ ] Drainage positioning and valve specifications

- [ ] Agitator type and speed control requirements

Step 3: Evaluate New vs. Used Equipment

| Factor | New Equipment | Used Equipment |

|---|---|---|

| Price Range | $29,500-$31,000+ (200-300 gal) | $3,500-$23,500 (varies widely) |

| Warranty | Full manufacturer coverage | Limited or none |

| Customization | Fully configurable | As-is condition |

| Lead Time | Longer (manufacturing) | Immediate availability |

| Compliance | Current standards | May require updates |

Decision Criteria:

– [ ] Budget constraints assessed

– [ ] Timeline requirements defined

– [ ] Risk tolerance for used equipment evaluated

Illustrative Image (Source: Google Search)

Step 4: Supplier Qualification

Vendor Assessment Checklist

– [ ] Years in dairy equipment industry

– [ ] Manufacturing capabilities (custom fabrication vs. resale only)

– [ ] Geographic proximity for service/support

– [ ] Reference accounts in similar production scale

– [ ] Compliance certifications (3-A Sanitary Standards, FDA requirements)

Key Questions for Suppliers:

1. Do you offer installation support?

2. What maintenance and parts availability exists post-purchase?

3. Can you provide equipment inspection reports (for used vats)?

4. What customization options are available?

Step 5: Regulatory and Compliance Verification

- [ ] 3-A Sanitary Standards compliance confirmed

- [ ] FDA/USDA requirements for your jurisdiction

- [ ] EU CE marking (for European operations)

- [ ] Local health department specifications reviewed

- [ ] Documentation package includes compliance certificates

Step 6: Ancillary Equipment Requirements

Ensure sourcing includes necessary accessories:

– [ ] Vat strainers (approximately $2,850)

– [ ] Curd knives (horizontal and vertical)

– [ ] Whey screens

– [ ] Curd milling machines

– [ ] Temperature monitoring systems

– [ ] CIP (Clean-in-Place) compatibility components

Step 7: Total Cost of Ownership Analysis

Calculate beyond purchase price:

– [ ] Freight and delivery costs

– [ ] Installation and commissioning

– [ ] Utility connections (steam, water, electrical)

– [ ] Training requirements

– [ ] Spare parts inventory

– [ ] Maintenance contracts

– [ ] Energy consumption projections

Step 8: Pre-Purchase Inspection (Used Equipment)

- [ ] Physical inspection conducted or third-party inspection arranged

- [ ] Jacket integrity tested (pressure test)

- [ ] Agitator motor and gearbox condition verified

- [ ] Surface condition assessed (pitting, weld integrity)

- [ ] Valve and fitting condition documented

- [ ] Operating history obtained

Step 9: Finalize Purchase Terms

- [ ] Payment terms negotiated

- [ ] Delivery timeline confirmed

- [ ] Warranty terms documented

- [ ] Return/rejection conditions specified

- [ ] Installation support included (if applicable)

- [ ] Training provisions agreed

Quick Reference: Supplier Contact Preparation

Before contacting suppliers, have ready:

– Current and projected production volumes

– Facility dimensions and layout constraints

– Utility availability (steam pressure, electrical specifications)

– Timeline requirements

– Budget parameters

– Specific cheese types produced

Comprehensive Cost and Pricing Analysis for cheese making vat Sourcing

Comprehensive Cost and Pricing Analysis for Cheese Making Vat Sourcing

Understanding the full cost structure of cheese making vat procurement is essential for accurate budgeting and maximizing return on investment. This analysis breaks down pricing across equipment categories, identifies cost drivers, and provides actionable strategies to optimize your sourcing expenditure.

Current Market Pricing Overview

Based on current market data from leading suppliers, cheese vat pricing varies significantly based on capacity, condition, and configuration:

| Capacity Range | New Equipment | Used Equipment | Price Per Gallon (New) |

|---|---|---|---|

| 50 Gallons | $8,000–$12,000 | $4,500–$6,000 | $160–$240 |

| 150 Gallons | $18,000–$25,000 | $11,500–$15,000 | $120–$167 |

| 200 Gallons | $29,500+ | $15,000–$20,000 | $147+ |

| 300 Gallons | $31,000+ | $18,000–$23,000 | $103+ |

| 400–500 Gallons | $35,000–$50,000 | $11,500–$17,000 | $87–$125 |

| 800 Gallons | $55,000–$75,000 | $23,500–$35,000 | $69–$94 |

| 1,400–1,800 Gallons | $80,000–$120,000 | $4,000–$29,000 | $57–$86 |

| 3,000 Gallons | $150,000+ | $15,000–$18,500 | $50+ |

Key Insight: Per-gallon costs decrease substantially with larger capacity units, making scale a critical factor in cost optimization.

Detailed Cost Breakdown

1. Equipment Acquisition Costs (60–70% of Total Investment)

Base Unit Pricing Factors:

– Capacity: Primary cost determinant; larger vats offer better per-gallon economics

– Construction material: 304 vs. 316 stainless steel (316 adds 15–25% premium)

– Wall configuration: Single-wall, double-wall jacketed, or insulated designs

– Heating system: Steam, hot water, or electric heating elements

– Agitation mechanism: Manual, motorized paddle, or automated systems

Specialty Vat Premiums:

| Vat Type | Premium Over Standard |

|———-|———————-|

| Ricotta/specialty cheese vats | +20–35% |

| Combo vats (multi-function) | +25–40% |

| Enclosed/pressurized designs | +30–50% |

| Automated CIP-compatible | +15–25% |

New vs. Used Cost Comparison:

| Factor | New Equipment | Used Equipment |

|---|---|---|

| Initial cost | 100% (baseline) | 35–65% of new |

| Warranty coverage | 1–3 years standard | Limited or none |

| Customization | Fully customizable | As-is configuration |

| Lead time | 8–16 weeks | Immediate–4 weeks |

| Financing availability | Standard terms | Often cash/limited |

| Regulatory compliance | Current standards | May require updates |

2. Essential Accessories and Components (10–15% of Total Investment)

| Accessory | Price Range | Purpose |

|---|---|---|

| Vat strainer | $2,850–$4,500 | Curd/whey separation |

| Curd knives (set) | $800–$2,500 | Curd cutting |

| Vat whey screens | $1,200–$3,000 | Whey drainage |

| Curd milling machines | $5,000–$15,000 | Curd processing |

| Temperature controllers | $1,500–$4,000 | Process automation |

| Agitator motors/drives | $2,000–$8,000 | Mixing capability |

| Outlet valves | $500–$2,000 | Product discharge |

Budget Recommendation: Allocate 12–15% of base equipment cost for essential accessories.

3. Installation and Labor Costs (8–15% of Total Investment)

| Service | Cost Range | Variables |

|---|---|---|

| Freight/shipping (domestic) | $1,500–$8,000 | Distance, weight, rigging requirements |

| International shipping | $5,000–$25,000 | Origin, duties, documentation |

| Rigging and placement | $2,000–$6,000 | Equipment size, facility access |

| Utility connections | $3,000–$12,000 | Steam, water, electrical requirements |

| Plumbing modifications | $2,500–$10,000 | Drainage, supply lines |

| Electrical work | $1,500–$8,000 | Motor connections, controls |

| Commissioning/startup | $1,000–$5,000 | Training, calibration |

Regional Labor Rate Variations:

| Region | Skilled Labor Rate | Installation Timeline |

|---|---|---|

| Midwest USA | $75–$125/hour | Standard |

| Northeast USA | $95–$150/hour | +10–15% duration |

| Western Europe | €80–€140/hour | Standard |

| Eastern Europe | €40–€75/hour | +5–10% duration |

4. Logistics and Supply Chain Costs

Domestic Shipping (Continental USA):

– Standard freight: $2.50–$4.50 per mile for oversized equipment

– Expedited delivery: +40–60% premium

– Liftgate service: +$150–$400

– Inside delivery: +$300–$800

International Logistics:

| Route | Sea Freight (40ft container) | Air Freight (per kg) | Lead Time |

|---|---|---|---|

| USA to Europe | $3,500–$6,500 | $8–$15 | 4–6 weeks |

| Europe to USA | $4,000–$7,500 | $9–$16 | 4–6 weeks |

| Asia to USA/Europe | $2,500–$5,000 | $6–$12 | 5–8 weeks |

Additional Import Costs:

– Customs duties (USA): 0–4.4% for dairy equipment

– Customs duties (EU): 1.7–4.2% depending on classification

– Customs brokerage: $250–$750 per shipment

– Documentation/certificates: $200–$500

5. Ongoing Operational Costs (Annual)

| Cost Category | Annual Estimate | Notes |

|---|---|---|

| Preventive maintenance | 2–4% of equipment value | Parts, labor, inspections |

| Energy consumption | $3,000–$15,000 | Based on capacity and usage |

| Replacement parts | 1–2% of equipment value | Gaskets, seals, wear items |

| Cleaning supplies | $1,500–$5,000 | CIP chemicals, sanitizers |

| Calibration/certification | $500–$2,000 | Regulatory compliance |

Total Cost of Ownership Model

Example: 500-Gallon Cheese Vat (5-Year Analysis)

| Cost Component | New Equipment | Used Equipment |

|---|---|---|

| Base equipment | $42,000 | $14,000 |

| Accessories | $6,000 | $6,000 |

| Shipping | $3,500 | $3,500 |

| Installation | $8,000 | $10,000 |

| Year 1 Total | $59,500 | $33,500 |

| Annual operating (×5) | $35,000 | $42,000 |

| Major repairs (5-year) | $5,000 | $15,000 |

| 5-Year TCO | $99,500 | $90,500 |

| Annualized Cost | $19,900 | $18,100 |

Cost-Saving Strategies

Procurement Optimization

- Consider Refurbished Equipment

- Savings potential: 40–60% vs. new

- Look for dealer-reconditioned units with limited warranties

-

Verify compliance with current food safety standards

-

Right-Size Your Capacity

- Calculate actual production requirements with 20–30% growth buffer

- Oversized equipment increases capital and operating costs

-

Undersized equipment limits efficiency and throughput

-

Bundle Purchases

- Request package pricing for vat + accessories

- Typical bundle discount: 8–15%

-

Negotiate installation services inclusion

-

Timing Your Purchase

- Q4 often offers year-end inventory discounts

- Industry trade shows provide exclusive pricing

- Monitor dairy industry consolidation for used equipment availability

Supplier Negotiation Tactics

| Leverage Point | Potential Savings | Approach |

|---|---|---|

| Multi-unit orders | 10–20% | Commit to phased purchases |

| Payment terms | 3–5% | Offer faster payment for discount |

| Referral agreements | 2–5% | Provide testimonials/case studies |

| Long-term service contracts | 5–10% | Bundle maintenance agreements |

| Competitive bidding | 8–15% | Obtain 3+ qualified quotes |

Financing Considerations

| Option | Typical Terms | Best For |

|---|---|---|

| Equipment loan | 5–8% APR, 5–7 years | Ownership priority |

| Operating lease | 6–10% effective rate | Cash flow preservation |

| Capital lease | 5–9% effective rate | Tax advantages |

| Manufacturer financing | 0–6% promotional | New equipment purchases |

| SBA loans (USA) | 6–9% APR | Small operations |

Logistics Cost Reduction

- Consolidate Shipments

- Combine equipment orders to maximize container utilization

-

Coordinate with other buyers for shared freight

-

Flexible Delivery Windows

- Standard shipping vs. expedited saves 30–50%

-

Plan purchases 12–16 weeks ahead for new equipment

-

Regional Sourcing

- Reduce shipping distance where possible

-

Consider European suppliers for EU operations (avoid import duties)

-

Self-Arranged Freight

- Obtain independent freight quotes

- Supplier-arranged shipping often includes markup

Regional Pricing Variations

| Market | Price Index (USA = 100) | Key Factors |

|---|---|---|

| USA (Midwest) | 100 | Manufacturing hub, competitive market |

| USA (Coastal) | 105–115 | Higher logistics, labor costs |

| Western Europe | 110–130 | VAT, stricter regulations, labor costs |

| Eastern Europe | 85–100 | Lower labor, growing manufacturing base |

| UK (Post-Brexit) | 115–125 | Import duties, currency fluctuation |

Due Diligence Checklist for Cost Validation

Before finalizing any purchase, verify:

- [ ] All-inclusive pricing (no hidden fees)

- [ ] Warranty terms and coverage scope

- [ ] Spare parts availability and pricing

- [ ] Installation requirements and responsibilities

- [ ] Compliance certifications included

- [ ] Training and documentation provided

- [ ] Return/exchange policies

- [ ] References from similar-scale operations

Summary: Budget Planning Guidelines

| Operation Scale | Recommended Budget Range | Priority Focus |

|---|---|---|

| Artisan (<200 gal) | $15,000–$40,000 | Flexibility, quality |

| Small commercial (200–500 gal) | $40,000–$80,000 | Efficiency, scalability |

| Mid-size (500–1,500 gal) | $80,000–$150,000 | Automation, throughput |

| Industrial (1,500+ gal) | $150,000–$500,000+ | Integration, reliability |

Final Recommendation: Allocate 15–20% contingency beyond calculated costs to address unforeseen installation requirements, regulatory compliance updates, or accessory needs identified during commissioning.

Alternatives Analysis: Comparing cheese making vat With Other Solutions

Alternatives Analysis: Comparing Cheese Making Vats With Other Solutions

When evaluating cheese production equipment, understanding how traditional cheese making vats compare to alternative solutions helps inform capital investment decisions. This analysis examines the primary options available to commercial cheese producers in the USA and European markets.

Comparison Overview

| Factor | Traditional Cheese Vats | Enclosed Cheese Kettles | Continuous Cheese Processing Systems |

|---|---|---|---|

| Capacity Range | 50–3,000+ gallons | 100–1,500 gallons | 5,000+ gallons/hour throughput |

| Initial Investment | $4,000–$31,000+ | $25,000–$75,000 | $500,000–$2,000,000+ |

| Batch Flexibility | High | Moderate | Low |

| Cleaning/Maintenance | Easy (open-top design) | Moderate (enclosed systems) | Complex (automated CIP required) |

| Cheese Variety Capability | Excellent | Good | Limited to high-volume varieties |

| Space Requirements | Moderate | Moderate | Large footprint |

| Labor Intensity | Higher | Moderate | Minimal |

| Scalability | Add units as needed | Limited | Fixed capacity |

Alternative 1: Enclosed Cheese Kettles

Best For: Operations requiring enhanced contamination control or specific temperature precision.

Advantages:

– Superior temperature uniformity through jacketed heating systems

– Reduced contamination risk with sealed environment

– Better suited for soft cheese production

Limitations:

– Higher acquisition costs (typically 2–3x traditional vats)

– More complex maintenance requirements

– Reduced visibility during the cheese-making process

– Less flexibility for artisan techniques requiring manual curd handling

When to Choose Over Traditional Vats: Facilities producing soft or fresh cheeses in regulated environments where contamination control justifies premium pricing.

Alternative 2: Continuous Cheese Processing Systems

Best For: Large-scale industrial operations producing standardized cheese varieties at high volumes.

Advantages:

– Maximum throughput efficiency

– Consistent product quality through automation

– Reduced per-unit labor costs at scale

– Integrated whey separation and curd handling

Limitations:

– Capital investment exceeds $500,000 minimum

– Inflexible for small-batch or specialty production

– Requires dedicated technical staff for operation and maintenance

– Not economically viable below 10,000 gallons daily production

– Limited to commodity cheese varieties (cheddar, mozzarella)

When to Choose Over Traditional Vats: Industrial facilities processing 50,000+ gallons weekly with standardized product lines.

Key Decision Factors

Choose traditional cheese vats when:

– Production volumes range from artisan (50 gallons) to mid-scale (3,000 gallons per batch)

– Product diversity requires flexibility in batch sizes and techniques

– Budget constraints favor lower capital expenditure ($4,000–$31,000 range)

– Ease of cleaning and maintenance is prioritized

– Facility produces specialty, aged, or artisan cheese varieties

Consider alternatives when:

– Daily production exceeds 25,000 gallons consistently

– Product line is limited to 1–2 standardized cheese types

– Contamination control requirements exceed open-vat capabilities

– Labor costs significantly outweigh equipment investment

Market Availability

Traditional cheese vats offer the broadest procurement options, including:

– New equipment: $29,500–$31,000 for 200–300 gallon capacity

– Used equipment: $3,500–$23,500 depending on capacity and condition

– Specialty configurations: Ricotta vats, combo vats for dual-purpose operations

This pricing flexibility allows operations to scale incrementally, purchasing additional vats as production demands increase—an advantage unavailable with continuous processing systems requiring full-capacity commitment.

Essential Technical Properties and Trade Terminology for cheese making vat

Essential Technical Properties and Trade Terminology for Cheese Making Vats

Understanding the technical specifications and industry terminology is critical when sourcing cheese making vats for commercial operations. This section outlines the key properties buyers must evaluate and the trade terms commonly encountered in B2B transactions.

Key Technical Properties

Capacity Specifications

| Capacity Range | Typical Application | Approximate Price Range (USD) |

|---|---|---|

| 50–150 gallons | Artisan/small-batch operations | $4,500–$11,500 |

| 200–500 gallons | Mid-scale production | $11,500–$31,000 |

| 800–1,800 gallons | Industrial/specialty (e.g., ricotta) | $23,500–$29,000 |

| 3,000+ gallons | Large-scale commercial facilities | $15,000–$18,500 (used) |

Construction and Material Standards

- Shell Material: Food-grade stainless steel (typically 304 or 316L grade)

- Surface Finish: Sanitary polish for CIP (Clean-in-Place) compatibility

- Jacket Type: Double-walled for heating/cooling circulation

- Insulation: Thermal jacketing to maintain temperature consistency

Functional Components

- Agitation System: Variable-speed stirrers or paddle mechanisms

- Drainage Configuration: Bottom outlet valves, whey screens

- Temperature Control: Steam, hot water, or glycol jacket systems

- Open-Top Design: Facilitates cleaning, maintenance, and curd handling

Trade Terminology for B2B Procurement

| Term | Definition |

|---|---|

| MOQ (Minimum Order Quantity) | The lowest unit count a supplier will sell per transaction—typically 1 unit for vats |

| OEM (Original Equipment Manufacturer) | Supplier manufactures to buyer’s specifications under buyer’s brand |

| Combo Vat | Multi-function vat designed for pasteurization and cheese making in one unit |

| CIP (Clean-in-Place) | Automated cleaning system integrated into vat design |

| Lead Time | Production and delivery timeframe from order confirmation |

| FOB (Free on Board) | Shipping term indicating where ownership/risk transfers to buyer |

| Customization Options | Tailored dimensions, capacity, and feature configurations |

Procurement Considerations

- New vs. Used Equipment: Used vats offer significant cost savings (40–60% reduction) but require thorough inspection for wear, sanitation compliance, and jacket integrity.

- Regulatory Compliance: Verify 3-A Sanitary Standards certification (USA) or CE marking (Europe).

- Installation Requirements: Confirm utility connections (steam, water, drainage) and floor load capacity.

- Warranty Terms: Standard coverage ranges from 1–3 years on new equipment; used units typically sold “as-is.”

Navigating Market Dynamics and Sourcing Trends in the cheese making vat Sector

Navigating Market Dynamics and Sourcing Trends in the Cheese Making Vat Sector

Market Overview and Current Dynamics

The global cheese making vat market continues to evolve alongside the broader dairy processing equipment sector, driven by increasing artisanal cheese production, expanding specialty cheese demand, and modernization of existing dairy facilities. For B2B buyers in the USA and Europe, understanding current sourcing landscapes is critical for optimizing capital equipment investments.

Key Market Drivers

- Artisanal and craft cheese renaissance: Growing consumer preference for specialty and locally-produced cheeses has increased demand for small-to-medium capacity vats (50-500 gallons)

- Consolidation in large-scale production: Industrial dairy operations continue investing in high-capacity systems (1,400-3,000+ gallons) for efficiency gains

- Regulatory compliance requirements: Stricter food safety standards in both FDA (USA) and EU jurisdictions drive equipment upgrades

- Supply chain localization: Post-pandemic emphasis on domestic sourcing has strengthened North American and European manufacturing relationships

Sourcing Channels and Pricing Benchmarks

| Capacity Range | New Equipment Price (USD) | Used Equipment Price (USD) | Primary Applications |

|---|---|---|---|

| 50-150 Gallons | $11,500-$15,000 | $4,500-$8,000 | Artisanal, farmstead operations |

| 200-400 Gallons | $17,000-$31,000 | $11,500-$17,000 | Small commercial, specialty producers |

| 500-800 Gallons | $25,000-$40,000 | $11,500-$23,500 | Mid-scale commercial |

| 1,400-3,000 Gallons | $35,000-$60,000+ | $4,000-$18,500 | Industrial operations |

| Specialty (Ricotta) | $29,000+ | $20,000+ | Dedicated soft cheese production |

Note: Used equipment pricing varies significantly based on condition, age, and included accessories.

New vs. Used Equipment Considerations

New Equipment Advantages:

– Full manufacturer warranty coverage

– Complete customization (dimensions, features, capacity)

– Latest compliance with current regulatory standards

– Optimized energy efficiency

– Seamless integration with existing systems

Used Equipment Advantages:

– 40-70% cost reduction versus new

– Faster availability (no manufacturing lead time)

– Proven operational track record

– Lower depreciation impact

– Suitable for capacity testing before major investment

Established suppliers like Ullmer’s Dairy Equipment and Anco Equipment maintain both new and refurbished inventory, offering buyers flexibility across budget parameters.

Sustainability Trends Reshaping Procurement

Environmental considerations increasingly influence B2B purchasing decisions in the dairy equipment sector:

Energy Efficiency

– Modern vats feature improved insulation reducing heating/cooling energy requirements

– Variable-speed agitation systems minimize power consumption

– Heat recovery integration options for water jacket systems

Material Selection

– Stainless steel construction ensures 25-40+ year operational lifespan

– Recyclability at end-of-life aligns with circular economy objectives

– Reduced material waste through precision manufacturing

Water Conservation

– CIP (Clean-in-Place) compatible designs reduce water usage by 30-50%

– Closed-loop cooling systems minimize water consumption

– Efficient drainage designs accelerate cleaning cycles

Operational Sustainability

– Refurbished equipment extends product lifecycle, reducing manufacturing demand

– Local sourcing (USA/EU) reduces transportation emissions

– Modular designs enable component replacement versus full unit disposal

Historical Evolution of Cheese Vat Technology

Understanding the technological progression informs current procurement decisions:

Traditional Era (Pre-1950s)

– Copper and wooden vat construction

– Manual temperature control via direct fire or steam injection

– Labor-intensive operation requiring constant monitoring

Mechanization Period (1950s-1980s)

– Transition to stainless steel construction

– Introduction of jacketed heating/cooling systems

– Mechanical agitation replaced manual stirring

– Standardization of sanitary design principles

Automation Era (1990s-2010s)

– PLC-controlled temperature management

– Automated cutting and stirring programs

– CIP system integration

– Improved insulation and energy efficiency

Current Generation (2010s-Present)

– IoT connectivity for remote monitoring

– Predictive maintenance capabilities

– Full traceability integration

– Customizable automation levels

– Enhanced sustainability features

Regional Sourcing Considerations

North American Market

– Strong domestic manufacturing base (Wisconsin, California)

– Established dealer networks for new and used equipment

– Shorter lead times for standard configurations

– Service and parts availability advantages

European Market

– Heritage manufacturers with specialized expertise (Netherlands, Germany, Italy)

– Advanced automation integration options

– Strict CE marking and EU regulatory compliance

– Premium pricing offset by engineering sophistication

Strategic Procurement Recommendations

- Assess total cost of ownership beyond purchase price—include installation, training, maintenance, and energy costs

- Evaluate scalability requirements before committing to capacity

- Request customization options to optimize workflow integration

- Verify regulatory compliance documentation for your jurisdiction

- Consider hybrid approaches—used vats for initial capacity, new equipment for expansion

- Establish supplier relationships for ongoing parts and service support

The cheese making vat sector offers mature, reliable sourcing options for operations of all scales. Success depends on aligning equipment specifications with production goals while balancing capital constraints against long-term operational efficiency.

Frequently Asked Questions (FAQs) for B2B Buyers of cheese making vat

Frequently Asked Questions (FAQs) for B2B Buyers of Cheese Making Vats

1. What capacity options are available for commercial cheese vats?

Commercial cheese vats are available in a wide range of capacities to match different production scales:

| Production Scale | Typical Capacity Range |

|---|---|

| Small/Artisan | 50 – 200 gallons |

| Mid-Size | 300 – 800 gallons |

| Large Commercial | 1,400 – 3,000+ gallons |

| Specialty (Ricotta) | Up to 1,800 gallons |

Manufacturers offer customizable dimensions to ensure seamless integration with existing production lines.

2. What is the typical price range for cheese making vats?

Pricing varies significantly based on capacity, condition, and features:

- Small used vats (50 gallons): Starting around $4,500

- Mid-range new vats (200-300 gallons): $29,500 – $31,000

- Large used vats (3,000 gallons): $15,000 – $18,500

- Specialty ricotta vats (1,800 gallons): Approximately $29,000

Used equipment offers substantial cost savings while maintaining operational reliability.

3. Should we purchase new or used cheese vats?

Consider these factors when deciding:

New Equipment:

– Full manufacturer warranty

– Latest design features

– Custom specifications available

– Higher upfront investment

Used Equipment:

– 40-70% cost savings

– Immediate availability

– Proven performance history

– May require inspection/refurbishment

4. What features should we prioritize when selecting a cheese vat?

Key features for B2B buyers include:

- Open-top design for easy cleaning and maintenance

- Jacketed construction for precise temperature control

- Sanitary stainless steel (typically 304 or 316 grade)

- Agitation systems appropriate for your cheese type

- Drainage configuration compatible with your facility

- CIP (Clean-in-Place) compatibility for operational efficiency

5. What complementary equipment is required alongside cheese vats?

Essential accessories for a complete cheese-making operation:

- Vat strainers (approximately $2,850)

- Curd knives

- Curd milling machines

- Vat whey screens

- Agitators and stirring mechanisms

- Temperature monitoring systems

6. How do installation requirements differ between vat sizes?

Installation considerations scale with capacity:

| Factor | Small Vats | Large Vats |

|---|---|---|

| Floor space | Minimal | Significant footprint |

| Utility connections | Standard | Heavy-duty plumbing/electrical |

| Structural support | Standard flooring | May require reinforcement |

| Lead time | Often in-stock | Custom fabrication typical |

Reputable suppliers design vats for straightforward installation in existing facilities.

7. What regulatory standards must cheese vats meet in the USA and Europe?

USA Requirements:

– FDA 21 CFR Part 110 compliance

– 3-A Sanitary Standards certification

– State dairy board approvals

European Requirements:

– EU Regulation 852/2004 (food hygiene)

– CE marking where applicable

– EHEDG guidelines for hygienic design

Always verify equipment certifications before purchase to ensure regulatory compliance in your operating region.

8. What lead times should we expect for new versus used cheese vats?

Used Equipment:

– Typically available for immediate or near-immediate delivery

– Inspection and refurbishment may add 1-2 weeks

New/Custom Equipment:

– Standard configurations: 4-8 weeks

– Fully customized vats: 8-16 weeks depending on specifications

Plan procurement timelines accordingly, especially for facility expansions or new production lines.

Strategic Sourcing Conclusion and Outlook for cheese making vat

Strategic Sourcing Conclusion: Cheese Making Vats

Selecting the right cheese making vat represents a critical capital investment that directly impacts production efficiency, product quality, and long-term operational costs. The market offers substantial flexibility across capacity ranges—from 50-gallon artisan units to 3,000+ gallon industrial systems—with pricing spanning $3,500 to $31,000+ depending on specifications and condition.

Key Sourcing Considerations

| Factor | Strategic Impact |

|---|---|

| Capacity alignment | Prevents over/under-investment |

| New vs. used equipment | 40-60% cost savings on refurbished units |

| Customization options | Seamless integration with existing operations |

| Supplier support | Reduces downtime and maintenance costs |

Market Outlook

The cheese vat market continues evolving toward:

– Modular, customizable designs accommodating diverse production scales

– Enhanced sanitation features meeting stringent FDA and EU compliance standards

– Combo vat solutions offering multi-functionality for specialty cheese production

Recommended Next Steps

- Audit current and projected production volumes

- Evaluate total cost of ownership (new vs. refurbished)

- Request customization consultations from established suppliers

- Verify compliance certifications for target markets

Partnering with specialized dairy equipment suppliers ensures access to technical expertise, installation support, and ongoing maintenance—critical factors for maximizing equipment ROI and production uptime.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.