The global laser cleaning machine market is experiencing robust growth, driven by increasing demand for eco-friendly, non-abrasive surface treatment solutions across industries such as automotive, aerospace, and precision manufacturing. According to Mordor Intelligence, the market was valued at USD 498.7 million in 2023 and is projected to reach USD 938.6 million by 2029, growing at a CAGR of 11.07% during the forecast period. This expansion reflects a rising preference for laser-based cleaning over traditional methods due to its precision, reduced environmental impact, and lower long-term operational costs. As adoption accelerates, cost efficiency has become a key differentiator for manufacturers and end-users alike. In response, a number of manufacturers have emerged as leaders in offering competitively priced, high-performance laser cleaning systems. Based on comprehensive pricing analysis, technical specifications, and customer feedback from verified sources, the following nine manufacturers stand out for delivering some of the most affordable laser cleaning machines without compromising core functionality or reliability.

Top 9 Cheapest Laser Cleaning Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Cleaning Machine Manufacturers

Website: fortunelaser.com

Key Highlights: Fortune Laser’s vision has always been to design and manufacture top quality industrial laser machines that will fit the customers’ needs, at an affordable ……

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#3 Laser cleaner machine prices

Website: pulsar-laser.com

Key Highlights: Laser cleaner machine prices and parameters, download our Catalogue….

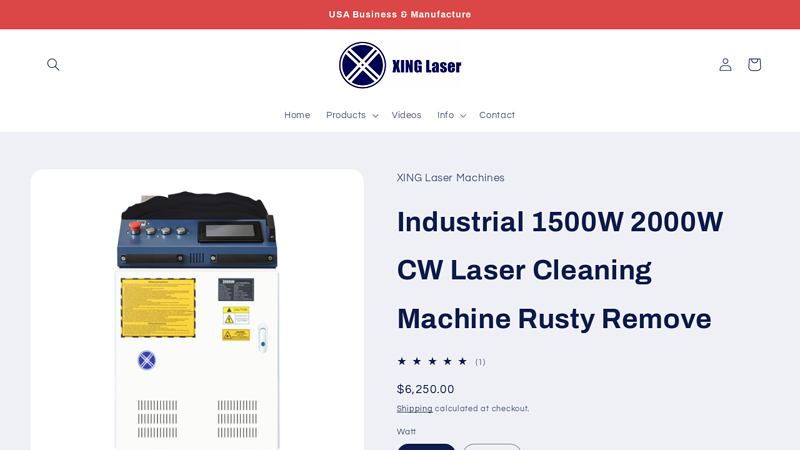

#4 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#5 Argento Lux

Website: argentolux.com

Key Highlights: Our company provides state-of-the-art Industrial Laser Equipment Sales and Mobile Laser Cleaning Services for a wide range of applications and industries….

#6 Laser Cleaning Machine

Website: baikeopto.com

Key Highlights: Backpack laser cleaning machine Pulse Laser Cleaning Machine Continuous Laser Cleaning Machine. 01|Backpack cleaner. BK-FLC50SC Max 50W Backpack Pulse Laser …Missing: cheapest m…

#7 Laser Cleaning Machine Manufacturer

Website: hantencnc.com

Key Highlights: At HantenCNC, our laser cleaning machines are available in a wide range, from $2,400 to $100,000. The cheapest option, an entry-level model, is portable and ……

#8 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#9 The Best Entry

Website: lasermaxwave.com

Key Highlights: The MaxWave laser cleaning machine is priced at $4,600–$5,500 per unit for small orders, making it very affordable for beginners. Most sellers provide a 2-year ……

Expert Sourcing Insights for Cheapest Laser Cleaning Machine

H2: 2026 Market Trends for the Cheapest Laser Cleaning Machines

As the global industrial sector increasingly adopts eco-friendly and precision-based technologies, laser cleaning machines are gaining traction across manufacturing, automotive, aerospace, and heritage conservation industries. By 2026, the market for the cheapest laser cleaning machines is expected to undergo significant transformation, driven by technological advancements, cost reductions, and expanding accessibility in emerging economies.

1. Price Decline Due to Mass Production and Component Innovation

One of the most prominent trends shaping the affordability of laser cleaning machines is the drop in core component costs—particularly fiber lasers and optical delivery systems. As fiber laser technology becomes more standardized and produced at scale, especially in China and Southeast Asia, manufacturers are able to offer entry-level models at competitive prices. By 2026, the cheapest laser cleaning machines are projected to fall below $2,000 for basic 100W–300W models, making them accessible to small and medium-sized enterprises (SMEs).

2. Rise of Chinese and Indian Manufacturers

China remains the dominant force in producing cost-effective laser cleaning solutions. Companies such as Wuhan Raycus, Han’s Laser, and JPT Opto-electronics are driving down prices through economies of scale and vertical integration. Indian manufacturers are also entering the low-cost segment, supported by government initiatives like “Make in India” and increasing domestic demand. This competition is expected to intensify in 2026, further lowering price points without compromising basic functionality.

3. Increased Demand in Developing Markets

Emerging markets in Southeast Asia, Africa, and Latin America are adopting laser cleaning for applications like rust removal, mold cleaning, and surface preparation in shipyards and workshops. The cheapest laser cleaning machines are particularly appealing due to their low operational costs compared to sandblasting or chemical methods. By 2026, these regions may account for over 40% of global demand for budget-friendly units.

4. Technological Improvements in Entry-Level Models

Even the cheapest laser cleaning machines are expected to see performance upgrades by 2026. Features such as improved beam quality, better cooling systems, and user-friendly interfaces are becoming standard even in sub-$3,000 units. Integration with handheld scanners and ergonomic designs enhances usability, broadening their appeal beyond industrial giants to independent contractors and repair shops.

5. Environmental and Regulatory Push

Growing global emphasis on sustainable manufacturing is accelerating the shift from abrasive and chemical cleaning methods to laser-based alternatives. Regulations limiting VOC emissions and waste disposal are particularly influential in Europe and North America. While high-end systems dominate regulated environments, the cheapest laser cleaning machines are finding niches in small-scale compliance applications, especially in auto repair and restoration.

6. E-Commerce and Direct-to-Consumer Sales Growth

Online platforms like Alibaba, Amazon, and specialized B2B marketplaces are streamlining access to low-cost laser cleaning machines. By 2026, direct sales from manufacturers to end-users are expected to account for a growing share of the market, eliminating middlemen and reducing prices. Enhanced product transparency, customer reviews, and financing options are further boosting adoption.

Conclusion

The 2026 market for the cheapest laser cleaning machines will be defined by affordability, wider accessibility, and incremental technological improvements. While these budget models may lack the power and precision of premium systems, they are becoming viable tools for a broad range of cleaning tasks. As production scales and competition increases, the entry barrier to laser cleaning technology will continue to fall, democratizing access across industries and geographies.

Common Pitfalls When Sourcing the Cheapest Laser Cleaning Machine: Quality and IP Concerns

When sourcing the cheapest laser cleaning machine, buyers often overlook critical factors that can lead to long-term operational, financial, and legal challenges. While cost is an important consideration, prioritizing price over quality and intellectual property (IP) integrity can result in subpar performance, safety risks, and legal exposure. Below are the most common pitfalls to avoid.

Poor Build Quality and Component Sourcing

Low-cost laser cleaning machines often use inferior materials and substandard components to cut manufacturing costs. This includes low-grade optics, underpowered or unstable laser sources, and inadequate cooling systems. These issues lead to frequent breakdowns, inconsistent cleaning performance, and shortened machine lifespan. Buyers may spend more on maintenance and downtime than they saved initially.

Lack of Safety Features and Certifications

Budget machines may not comply with international safety standards such as CE, FDA, or IEC 60825 for laser safety. Skipping these certifications increases the risk of operator injury and non-compliance with workplace regulations. Without proper safety interlocks, enclosures, or warning systems, users expose themselves to hazardous laser radiation and potential legal liability.

Inadequate After-Sales Support and Service

Cheaper machines are often sold by suppliers with limited or no local technical support. When issues arise, users face long wait times for repairs, unavailability of spare parts, or language barriers. This lack of support can halt production and reduce return on investment, especially in industrial environments requiring high uptime.

Misleading Power Ratings and Performance Claims

Some low-cost manufacturers inflate laser power ratings or cleaning speed claims to appear competitive. Actual performance may fall significantly below advertised specs due to inefficient beam delivery or thermal throttling. Without third-party testing or performance validation, buyers risk investing in equipment that fails to meet their cleaning requirements.

Intellectual Property (IP) Infringement Risks

Sourcing extremely cheap machines, especially from unverified suppliers, increases the risk of purchasing equipment that infringes on patented technologies. Copying designs, firmware, or proprietary laser control systems can expose buyers to legal action, particularly in markets with strong IP enforcement like the EU or North America. Using counterfeit or cloned technology may also void insurance coverage or compliance certifications.

Limited Software Capabilities and No Firmware Updates

Low-cost models often come with basic or outdated software lacking advanced features like scan path programming, real-time monitoring, or integration with automation systems. Additionally, many cheap machines do not receive firmware updates, leaving them vulnerable to bugs, security flaws, or compatibility issues with new production systems.

Hidden Costs of Ownership

While the upfront cost may be low, hidden expenses such as high energy consumption, frequent part replacements, operator training for unreliable systems, and reduced productivity due to machine instability can drastically increase the total cost of ownership over time.

Conclusion

Sourcing the cheapest laser cleaning machine can lead to significant trade-offs in quality, safety, reliability, and legal compliance. Buyers should prioritize verified manufacturers with transparent specifications, proper certifications, and strong IP practices—even if it means a higher initial investment. A thorough due diligence process helps avoid costly pitfalls and ensures long-term operational success.

Logistics & Compliance Guide for the Cheapest Laser Cleaning Machine

Purchasing the cheapest laser cleaning machine often involves sourcing internationally, especially from manufacturers in Asia. While cost savings are attractive, navigating logistics and compliance is critical to ensure a smooth delivery, legal operation, and safety. This guide outlines key considerations.

Understanding the Product and Its Risks

Before shipping begins, confirm the exact specifications of the laser cleaning machine. The “cheapest” models may use lower-power Class 3B or Class 4 lasers, which pose significant safety hazards including eye and skin damage, fire risk, and fumes from vaporized contaminants. Knowing the laser class (per IEC 60825-1) is essential for compliance with international shipping and import regulations.

International Shipping Considerations

Shipping laser equipment internationally requires careful planning. Air freight is faster but more expensive and subject to stricter hazardous material rules. Sea freight is economical for heavy machinery but takes weeks. Ensure the supplier packages the machine securely with shock-absorbing materials to prevent damage during transit. Request insurance coverage for the full value of the machine, as low-cost units may lack robust build quality and are more prone to damage.

Import Regulations and Customs Clearance

Each country has specific import regulations for laser devices. In the U.S., the FDA’s Center for Devices and Radiological Health (CDRH) regulates lasers under 21 CFR 1040.10 and 1040.11. Importers must file an FDA listing and ensure the product meets performance standards, including proper labeling, safety interlocks, and emission indicators. In the EU, compliance with the CE marking is mandatory, requiring conformity with the Machinery Directive (2006/42/EC) and the Laser Product Safety standard (EN 60825-1). Documentation such as a commercial invoice, packing list, bill of lading, and certificate of conformity must be accurate to avoid customs delays or seizure.

Electrical and Safety Certification

Verify that the machine meets electrical safety standards for your region (e.g., UL in North America, CE in Europe, CCC in China). Cheap models may lack proper certification or use non-standard voltage (e.g., 220V 50Hz vs. 110V 60Hz), requiring a transformer. Operating an uncertified device may void insurance and expose users to liability in case of accidents.

End-Use Compliance and Workplace Safety

Even after successful import, ensure the machine complies with local occupational health and safety regulations. In the U.S., OSHA requires employers to implement laser safety programs for Class 3B and 4 lasers, including training, controlled access, protective eyewear, and warning signs. In the EU, the Provision and Use of Work Equipment Regulations (PUWER) and the Control of Artificial Optical Radiation at Work Regulations apply. Conduct a site risk assessment and provide appropriate personal protective equipment (PPE).

After-Sales Support and Warranty Limitations

Low-cost machines may come with limited or no warranty, and spare parts or technical support could be difficult to obtain internationally. Confirm service availability and response times before purchasing. Consider the total cost of ownership, including potential downtime and repair expenses, which may offset initial savings.

Final Recommendations

While the cheapest laser cleaning machine offers upfront savings, prioritize compliance, safety, and reliability. Verify certifications, plan for import requirements, and ensure the machine meets workplace safety standards. Choosing a slightly more expensive but compliant and well-supported model may be more cost-effective in the long run.

Conclusion: Sourcing the Cheapest Laser Cleaning Machine

After evaluating various suppliers, models, and market options, sourcing the cheapest laser cleaning machine requires a careful balance between initial cost and long-term value. While several manufacturers—particularly in China—offer competitively priced machines, the lowest upfront price does not always translate to the best overall investment. Key factors such as build quality, laser power, after-sales support, warranty, and safety certifications must be considered to avoid hidden costs related to maintenance, downtime, or inadequate performance.

To secure the most cost-effective solution:

- Compare total cost of ownership, not just purchase price.

- Verify technical specifications to ensure the machine meets your application requirements.

- Prioritize suppliers with proven reliability, customer support, and service networks.

- Request product demonstrations or trial units, where possible.

- Explore bulk discounts, financing options, or refurbished models for further savings.

In conclusion, while budget-friendly laser cleaning machines are available—especially from direct manufacturers in Asia—the cheapest option should not compromise on safety, durability, or effectiveness. A well-researched purchase ensures both affordability and operational efficiency in the long run.