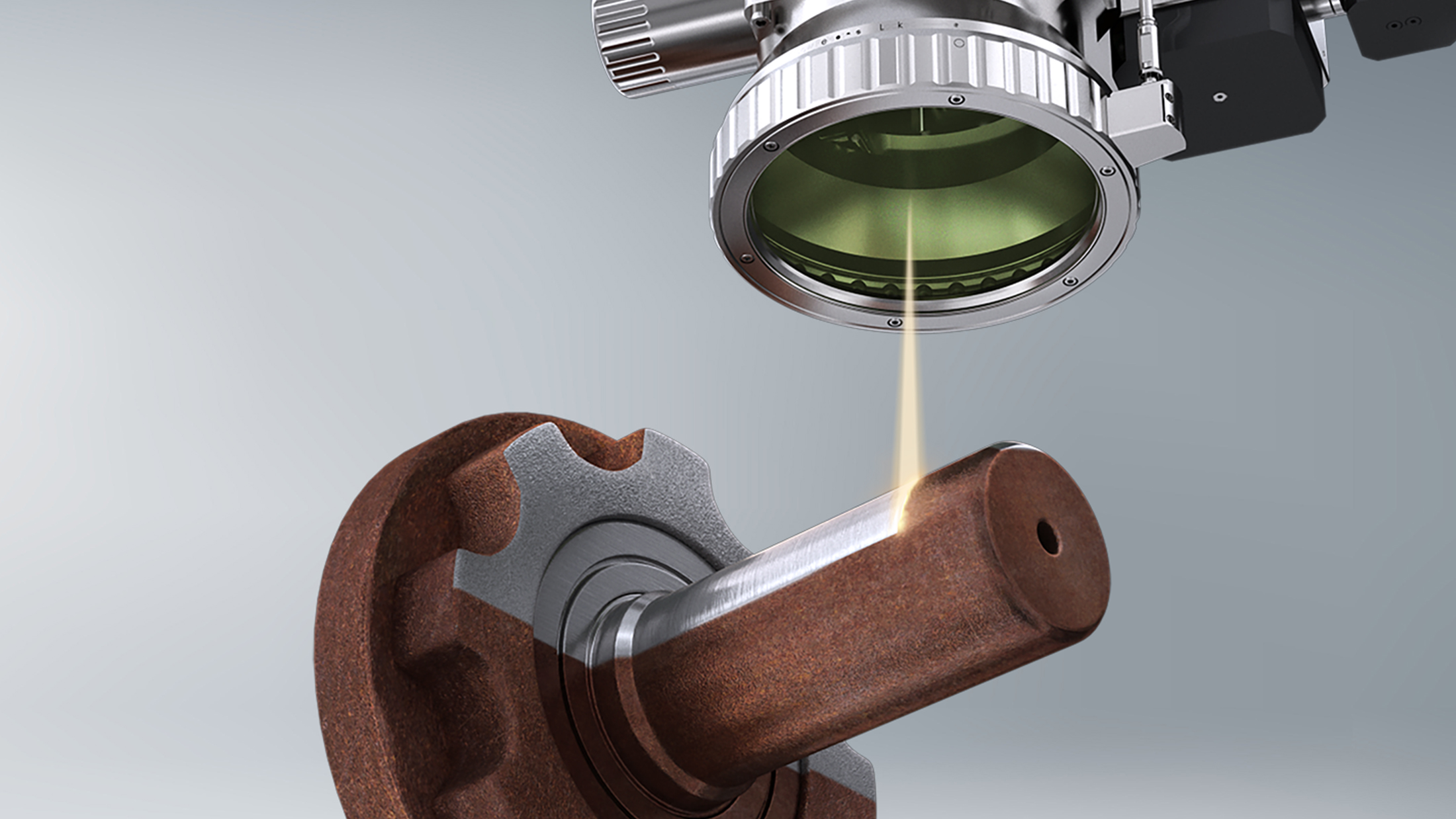

The global laser cleaning machine market is experiencing robust growth, driven by increasing demand for eco-friendly, precise, and efficient surface cleaning solutions across industries such as automotive, aerospace, manufacturing, and heritage conservation. According to a report by Mordor Intelligence, the market was valued at approximately USD 450 million in 2023 and is projected to grow at a CAGR of over 17% from 2024 to 2029. This expansion is fueled by the phasing out of traditional abrasive and chemical cleaning methods due to environmental regulations and the rising adoption of automation in industrial maintenance. Additionally, Grand View Research highlights that advancements in fiber laser technology and the decreasing cost of laser components are making these systems more accessible to small and medium enterprises. As a result, numerous manufacturers—particularly in China and other emerging economies—are entering the market with competitively priced, high-performance laser cleaning machines. Below, we examine the top 10 cost-effective laser cleaning machine manufacturers leveraging this growth trend to deliver value-driven solutions without compromising on quality or efficiency.

Top 10 Cheap Laser Cleaning Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Cleaning Machine

Website: pulsar-laser.com

Key Highlights: PULSAR Laser is a manufacturer of professional laser cleaning machines, developed and engineered for industrial maintenance, manufacturing, restoration and ……

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#3 Argento Lux

Website: argentolux.com

Key Highlights: Our company provides state-of-the-art Industrial Laser Equipment Sales and Mobile Laser Cleaning Services for a wide range of applications and industries….

#4 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#5 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#6 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#7 Laser Cleaning Machines

Website: wattsan.com

Key Highlights: Laser cleaning uses powerful laser beams to remove contaminants such as rust, paint, dirt or oxidation from a variety of surfaces….

#8 Laser cleaning

Website: p-laserusa.com

Key Highlights: Our laser machines are mainly used to remove the following contaminants: Rust – Paint – Coatings – Release Agents – Grease, Oils – Soot – Rubber- Organic ……

#9 Handheld Laser Cleaning Machines

Website: ipgphotonics.com

Key Highlights: Handheld and portable laser cleaning machines designed for manual applications including rust removal, paint stripping, restoration, and more….

#10 Laser Cleaning Machine

Website: baikeopto.com

Key Highlights: Backpack laser cleaning machine Pulse Laser Cleaning Machine Continuous Laser Cleaning Machine. 01|Backpack cleaner. BK-FLC50SC Max 50W Backpack Pulse Laser ……

Expert Sourcing Insights for Cheap Laser Cleaning Machine

H2: Market Trends for Cheap Laser Cleaning Machines in 2026

By 2026, the global market for cheap laser cleaning machines is expected to experience significant growth, driven by technological advancements, increased industrial automation, and a rising demand for eco-friendly surface treatment solutions. These cost-effective systems are becoming increasingly accessible to small and medium-sized enterprises (SMEs), shifting the competitive landscape of industrial cleaning. Below are the key market trends shaping the cheap laser cleaning machine sector in 2026:

1. Declining Costs Due to Technological Advancements and Mass Production

The average price of laser cleaning machines has steadily decreased, thanks to improvements in diode laser efficiency, modular design, and economies of scale. Chinese and Eastern European manufacturers have played a pivotal role in driving down costs, offering entry-level models under $5,000—making the technology viable for smaller workshops and niche applications such as mold restoration, heritage conservation, and automotive detailing.

2. Expansion into New Industrial and Niche Applications

Beyond traditional heavy industries like shipbuilding and aerospace, affordable laser cleaners are penetrating new markets in 2026, including food processing (equipment sanitation), electronics (delicate component cleaning), and art restoration. Portable, handheld models are particularly popular in these sectors due to their ease of use and minimal downtime.

3. Rising Demand for Eco-Friendly and Chemical-Free Cleaning

With tightening environmental regulations worldwide—especially in the EU and North America—industries are phasing out sandblasting and chemical solvents. Cheap laser cleaning machines offer a dry, non-abrasive, and waste-free alternative, aligning with corporate sustainability goals and reducing compliance costs.

4. Growth in Asia-Pacific and Emerging Markets

Asia-Pacific, particularly China, India, and Southeast Asia, is expected to dominate the low-cost laser cleaning market in 2026. Rapid industrialization, government support for green manufacturing, and a growing base of domestic manufacturers are fueling adoption. Local production reduces import costs and accelerates supply chain responsiveness.

5. Integration with Automation and Smart Manufacturing

Even budget laser cleaning systems in 2026 are increasingly equipped with IoT connectivity, basic AI-driven path planning, and compatibility with robotic arms. This trend enables integration into Industry 4.0 workflows, allowing SMEs to automate repetitive cleaning tasks and improve precision.

6. Competitive Pressure and Market Fragmentation

The low barrier to entry has led to a surge in vendors offering “cheap” laser cleaners, resulting in a fragmented market. While this benefits consumers through lower prices and wider choice, it also raises concerns about product quality, safety standards, and after-sales support. Third-party certifications and consumer review platforms are becoming critical decision-making tools.

7. Focus on User Safety and Training

As low-cost laser machines enter less regulated environments, safety awareness is growing. In 2026, many affordable models now include built-in safety interlocks, protective enclosures, and simplified user interfaces. Training modules and online support are increasingly bundled with purchases to ensure safe operation.

Conclusion

The cheap laser cleaning machine market in 2026 is characterized by democratization, innovation, and sustainability. As prices continue to fall and performance improves, these machines are transitioning from niche tools to mainstream industrial equipment. While competition intensifies, the long-term outlook remains positive, with strong growth projected across manufacturing, maintenance, and service sectors worldwide.

H2: Common Pitfalls When Sourcing Cheap Laser Cleaning Machines (Quality and Intellectual Property Risks)

Sourcing low-cost laser cleaning machines can be tempting for businesses aiming to reduce upfront costs. However, several critical pitfalls related to quality and intellectual property (IP) can undermine long-term value and operational efficiency. Being aware of these risks helps avoid costly mistakes.

1. Compromised Build Quality and Performance

Many cheap laser cleaning machines cut corners on components such as laser sources, cooling systems, and optical lenses. This often results in inconsistent cleaning performance, shorter service life, and higher maintenance costs. Low-quality lasers may lack the power stability or beam focus required for effective cleaning, reducing efficiency and increasing operational downtime.

2. Lack of Safety and Compliance Standards

Budget machines may not comply with international safety certifications (e.g., CE, FDA, or IEC standards). This poses safety risks to operators and can lead to legal liabilities or equipment seizure in regulated markets. Inadequate safety interlocks, poor beam shielding, and substandard electrical components are common issues.

3. Inadequate After-Sales Support and Warranty

Suppliers of cheap machines often provide limited or no technical support, spare parts, or warranty coverage. When issues arise, repairs can be slow and expensive, especially if the manufacturer is located overseas with long response times. This affects productivity and increases total cost of ownership.

4. Hidden Intellectual Property Infringement

Some low-cost manufacturers replicate designs, software, or components from reputable brands without authorization. Purchasing such machines may indirectly expose your business to IP infringement claims, especially in regions with strict IP enforcement (e.g., the EU or North America). Using counterfeit or cloned control systems can also introduce cybersecurity vulnerabilities.

5. Misleading Specifications and Overstated Capabilities

Cheap suppliers may exaggerate laser power, cleaning speed, or duty cycle in marketing materials. For example, a machine advertised as a “1000W laser” might actually deliver significantly less effective output due to poor thermal management or inefficient optics. Independent verification or third-party testing is often required to confirm performance claims.

6. Risk of Obsolete or Outdated Technology

To minimize costs, some manufacturers use outdated laser diodes or control systems. These may lack modern features like real-time monitoring, remote diagnostics, or integration with automation systems—limiting scalability and future-proofing.

7. Limited Software and Firmware Support

Proprietary software in low-cost machines is often poorly documented, incompatible with industry standards, or locked to prevent updates. This can prevent integration with existing production systems and hinder customization or troubleshooting.

Conclusion

While the initial price of a cheap laser cleaning machine may seem attractive, hidden costs related to performance, safety, support, and IP risks can outweigh the savings. Due diligence—such as verifying certifications, requesting performance tests, and investigating the supplier’s reputation—is essential to ensure reliability and legal compliance. Investing in a reputable supplier often provides better long-term value and reduces operational and legal exposure.

Logistics & Compliance Guide for Cheap Laser Cleaning Machine

Overview

This guide provides essential logistics and compliance information for the import, export, handling, and operation of low-cost laser cleaning machines. Adhering to these guidelines ensures safe transportation, regulatory compliance, and smooth customs clearance across international borders.

2.1 Shipping & Transportation

Packaging Requirements

– Use sturdy, shock-resistant packaging with ample foam or cushioning to protect sensitive optical and electronic components.

– Include moisture barriers (e.g., desiccant packs) to prevent condensation during transit, especially for ocean freight.

– Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture.”

Modes of Transport

– Air Freight: Recommended for urgent shipments; ensure compliance with IATA regulations for electronic and battery-operated equipment.

– Ocean Freight: Cost-effective for bulk orders; use sealed containers to minimize exposure to humidity and salt air.

– Ground Transport: Suitable for regional distribution; secure machines to prevent shifting during transit.

Battery Considerations

– If the machine includes an internal or external battery, classify under UN3481 (lithium-ion) or UN3091 (lithium metal) as applicable.

– Batteries must be shipped at ≤30% state of charge and protected from short circuits.

2.2 Import & Export Compliance

HS Code Classification

– Typical HS Code: 8515.31 – Laser-based equipment for industrial cleaning or surface treatment.

– Confirm local tariff codes with the destination country’s customs authority, as classifications may vary.

Export Controls

– Laser cleaning machines may be subject to export regulations due to laser power and potential dual-use applications.

– Check compliance with:

– U.S. Commerce Control List (CCL) – EAR99 or ECCN 6A003.b.4 (depending on power and pulse characteristics).

– Wassenaar Arrangement – Controls on high-power lasers.

– Obtain export licenses if required, especially for destinations under trade sanctions.

Documentation

– Commercial Invoice (with value, description, and harmonized code)

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (if claiming preferential tariffs)

– Export Declaration (e.g., AES filing for U.S. exports)

2.3 Regulatory & Safety Compliance

Laser Safety Standards

– Comply with IEC 60825-1: Safety of laser products – Equipment classification and requirements.

– Most laser cleaning machines fall under Class 4, requiring:

– Safety interlocks

– Key-controlled operation

– Emergency stop mechanisms

– Warning labels (e.g., “Laser Radiation Avoid Direct Exposure”)

CE Marking (EU)

– Required for sale in the European Economic Area.

– Ensure conformity with:

– Machinery Directive (2006/42/EC)

– Electromagnetic Compatibility (EMC) Directive (2014/30/EU)

– Low Voltage Directive (2014/35/EU)

– Technical File and EU Declaration of Conformity must be maintained.

FDA Registration (USA)

– All laser products must be registered with the FDA’s Center for Devices and Radiological Health (CDRH).

– Submit a Product Report and include a compliance label per 21 CFR 1040.10.

RoHS & REACH (EU)

– Confirm that machine components comply with:

– RoHS Directive – Restriction of hazardous substances (e.g., lead, cadmium).

– REACH Regulation – Registration, Evaluation, Authorization of Chemicals.

2.4 Customs Clearance & Duties

Duty Rates

– Vary by country; generally range from 0% to 10% for industrial laser equipment.

– Check preferential rates under free trade agreements (e.g., USMCA, ASEAN).

Customs Inspections

– Be prepared for inspection if laser power exceeds typical thresholds (e.g., >500W).

– Provide technical specifications (wavelength, output power, pulse duration) upon request.

Import Licenses

– Some countries (e.g., India, China, Russia) may require special permits for high-power laser devices.

– Partner with local agents to navigate licensing procedures.

2.5 End-Use Compliance & User Guidelines

Operator Training

– Provide safety manuals and training on:

– Proper PPE (laser safety goggles, protective clothing)

– Safe operating distances

– Fume extraction requirements

Environmental & Disposal Compliance

– Follow local regulations for disposal of electronic waste (e.g., WEEE Directive in EU).

– Do not landfill laser diodes or batteries; recycle through certified e-waste handlers.

Warranty & Service Logistics

– Include spare parts kits for critical components (e.g., nozzles, filters).

– Offer remote diagnostics and local service partner networks to reduce downtime.

Conclusion

Proper logistics planning and adherence to compliance standards are critical when distributing cheap laser cleaning machines. Ensure all regulatory, safety, and documentation requirements are met to avoid delays, fines, or safety incidents. Always verify country-specific rules and update compliance protocols as regulations evolve.

In conclusion, sourcing a cheap laser cleaning machine requires careful consideration of several key factors to ensure a balance between cost and quality. While lower-priced options can offer significant savings, it is essential to evaluate the machine’s specifications, build quality, safety features, and after-sales support. Buyers should compare suppliers—both local and international—taking into account warranty terms, customer reviews, and service availability. Platforms like Alibaba, Made-in-China, and direct manufacturer quotations often provide competitive pricing, especially from Chinese suppliers. However, hidden costs such as shipping, import duties, and lack of technical support must be factored in. Ultimately, the cheapest upfront price may not always translate to the best long-term value. A cost-effective choice combines affordability with reliability, suitable performance for your cleaning needs, and adequate support to ensure safe and efficient operation. Conducting thorough research and due diligence will lead to a successful and economical sourcing decision.